Академический Документы

Профессиональный Документы

Культура Документы

Drill Pipe Troubleshooting Guidelines

Загружено:

km17900 оценок0% нашли этот документ полезным (0 голосов)

33 просмотров1 страницаGuidelines

Оригинальное название

Dlscrib.com Drill Pipe Troubleshooting Guidelines

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документGuidelines

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

33 просмотров1 страницаDrill Pipe Troubleshooting Guidelines

Загружено:

km1790Guidelines

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

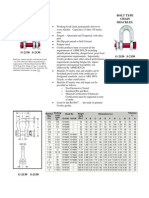

Drill Pipe Tips

These common defects, their usual effects, probable causes and possible corrections, are listed in this chart to help Tuboscope customers recognize their drill

pipe problems in time to do something about them.

PROBLEM: PROBLEM: PROBLEM: PROBLEM: PROBLEM:

Tube Body Surface Notching NECKING BENT PIPE GALLED SHOULDERS BELLED BOXES

PROBLEM:

SLIP AREA MASH (Usually located near either or (Most often found in the slip area

USUAL EFFECT:

WASHOUT (Located in slip area) both upsets) and center third of pipe body) Distorted connection, loss of

USUAL EFFECT:

(Usually occurs near pin end USUAL EFFECT: USUAL EFFECT: USUAL EFFECT: Loss of shoulder seal, excessive shoulder seal, will not mate

upset taper or in area from lower Surface impression, stress Reduced pipe O.D. / I.D., body Accelerated O.D. wear in pipe shoulder to shoulder standoff, properly with another connection,

part of slip area to box and upset concentrator wall thinning body and tool joints, vibration, false make-up torque, unstable split body

taper) high stress level, advanced connection (wobble) PROBABLE CAUSE:

PROBABLE CAUSE: PROBABLE CAUSE:

USUAL EFFECT:

fatigue Improper make up torque,

Defective slip component, Stuck pipe, over-pull (stretch), PROBABLE CAUSE:

Hole in pipe, drop in mud improper slip handling, excessive excessive hook load PROBABLE CAUSE: Insufficient lubrication on additional down-hole make up,

pressure, string separation, lost connection make-up or breakout, Bending in slips, setting tool joint shoulders, insufficient make-up thin tool joints, improper thread

time POSSIBLE CORRECTION: lubricants

bending pipe in slips too high above slips, improper torque, shoulder fins, high spots

Avoid sticking pipe, avoid over-

PROBABLE CAUSE:

tong/line geometry, no back up on shoulder POSSIBLE CORRECTION:

POSSIBLE CORRECTION:

pull, consult API RP 7G for load

Surface notching, cyclic stressing, tong on makeup or breakout, poor Maintain tool joint O.D., consult

Improve slip/bowl maintenance, limits per pipe class POSSIBLE CORRECTION:

fatigue cracking transportation handling, dropping API RP 7G charts or tool joint

use care while setting sips. Apply rotary tool joint compound

PROBLEM:

pipe on racks, critical rotary manufacturer recommendations,

POSSIBLE CORRECTION: Consult API RP 7G for maximum to shoulders when doping

EXPANSION speeds, picking up pipe with for proper make up torque per

Minimize surface notching, height setting of tool joints above connection, remove shoulder fins

(Usually located above the pin winch line in center, improper drill tool joint class, minimize

reduce stress level, and avoid slips by beveling shoulder, remove

and below the box which had collar weight additional down-hole make up,

critical rotary speed. Move high spots by refacing, consult

been backed off) API-RP 7G or the tool joint use only recommended rotary tool

bottom-hole pipe up hole on trips, PROBLEM: POSSIBLE CORRECTION:

Surface Notching Consult API RP 7G for maximum manufacturers charts for proper joint compound, use stabbing

taper transition zone, use shock USUAL EFFECT:

guide, recut box

subs TONG CUTS Expanded O.D. /I.D. split pipe or height setting of tool joints above make-up torques per tool joint

(Usually located near pin and box tool joint slips, use both tongs, placed 90° class, use stabbing guide PROBLEM:

PROBLEM: end upsets) apart, consult API RP

RP 7G or the STRETCHED PINS

TWIST OFF PROBABLE CAUSE: tool joint manufacturers PROBLEM:

USUAL EFFECT: Stuck pipe, internal explosion for PIN BREAK USUAL EFFECT:

(Usually occurs near pin end recommendations for proper

Multiple surface notches, stress back off (Cup type failure) Distorted connection, will not

upset taper or in area from lower make-up torque per tool joint

concentrators mate properly with another

part of slip area to box end upset POSSIBLE CORRECTION:

class, minimize breakout torques, USUAL EFFECT: connection, possible pin break

taper) PROBABLE CAUSE: Avoid sticking pipe, minimize minimize down-hole torques, use String separation, fishing job, lost

Tongs placed on pipe, worn tool explosive force. Be sure explosive properly spaced stripping time PROBABLE CAUSE:

USUAL EFFECT:

joints, improper tong jaws, poor is placed in tool joint area, between pipe layers to minimize Improper make-up torques,

String separation, fishing job, lost PROBABLE CAUSE: additional down-hole make-up,

handling carefully inspect pipe before re- bending in storage or transit,

time Improper trip make-up torque, improper thread lubricant

use avoid tough rough handling when

POSSIBLE CORRECTION: additional downhole make-up,

PROBABLE CAUSE: moving pipe, use slings to winch POSSIBLE CORRECTION:

Place tongs only on tool joint, improper type of lubricant

Surface notching, cyclic stressing, PROBLEM: pipe, avoid critical rotary speeds, Consult API RP 7G or tool joint

maintain tool joint diameter, use producing excessive tension vs.

fatigue cracking COLLAPSE avoid dropping string manufacturer recommendations

only correct long jaws, use sharp make-up/torque

(Usually begins near tube center, for proper make-up torques per

POSSIBLE CORRECTION: tong dies

often travels toward both ends) POSSIBLE CORRECTION: tool joint class, minimize

Minimize surface notching,

reduce stress level, avoid critical PROBLEM: USUAL EFFECT:

Tool Joint Consult API RP 7G charts or the additional downhole make-up,

rotary speed. Move bottom-hole CHAIN CUTS Flattens tube, circulation block, tool joint manufacturer use only recommend compound,

PROBLEM:

pipe up taper transition zone, use (Usually found in an area over string separation recommendations for proper use stabbing guide, recut pin

WASHOUT

shock subs and just above pin end upset) make-up torque per tool joint

PROBABLE CAUSE: USUAL EFFECT: class, minimize additional PROBLEM:

USUAL EFFECT: Excessive O.D. pressures, drill GALLED THREADS

PROBLEM: Erosion of shoulder (face) seal downhole make-up, use

Circumferential grooves (notch) at stem test, O.D. wear, I.D. erosion

FATIGUE CRACKING and threads, mud pressure loss, recommended rotary tool joint USUAL EFFECT:

pin end upset area, stress

(Predominately found near pin POSSIBLE CORRECTION:

string separation, lost time compound Damages mating threads, false

concentrators, cold worked metal

end upset taper and in an area Consult API RP 7G or drill pipe torque, improper make-up,

PROBABLE CAUSE: PROBLEM:

from box end upset taper to lower PROBABLE CAUSE: manufacturers collapse charts per connection wobble, leaking

Leaking shoulder (face) seals, PIN BREAK

part of slip area) Excessive spinning; chain slip pipe class, minimize O.D. wear, shoulder seal, washout, pin

damaged shoulder (face) seals, (Flat fracture type failure)

keep pipe straight, and prevent insufficient make up torque, break, drop string, lost time

USUAL EFFECT: POSSIBLE CORRECTION:

Washout, twist off, string Power change tension, consider I.D. erosion with plastic coating galled threads producing USUAL EFFECT: PROBABLE CAUSE:

separation, lost time, pipe loss use of power pipe spinner excessive shoulder standoff, String separation; fishing job, lost Thread damage, handling without

PROBLEM: time

shoulder fins rolled between thread protectors, cross

PROBABLE CAUSE:

PROBLEM:

O.D. WEAR

seals, high spots on shoulder- PROBABLE CAUSE:

threading, worn threads, improper

Cyclic stressing, surface notches Surface Notching (Usually appears in center third of

(false make-up torque), excessive Pin wobble due to insufficient lubrication, dirty connection,

(corrosion, cuts, etc), hydrogen RUBBER CUT EXTERNAL RING pipe body)

shoulder removal by refacing, make-up, shoulder fins, false defective kelly saver sub

embrittlement CORROSION USUAL EFFECT: stretched pin threads, dirty torque, fatigue cracking at thread POSSIBLE CORRECTION:

POSSIBLE CORRECTION:

(Usually found in an area Body wall thinning, reduced threads and shoulders, mis- root, galled threads Handle pipe only with thread

Dampen stress, avoid critical approximately 2’ above pin end tensile capacity, reduced cross stabbing connection, improper

tool joint) protector, use care in stabbing

rotary speeds, minimize surface section, reduced collapse jacking of stands in stand back POSSIBLE CORRECTION:

Consult API-RP 7G charts or the and make-up, use stabbing guide,

notching, move bottom-hole pipe USUAL EFFECT:

resistance area recut worn threads, use only

up hole on trips, use shock subs, tool joint manufacturer

Circumferential groove, stress PROBABLE CAUSE: POSSIBLE CORRECTION: recommended rotary tool joint

and prevent H2S in flow. Use recommendations for proper

concentrator Abrasive formations, bent pipe, Consult API RP 7G charts for compound, clean connections

lowest strength pipe where make-up torque per tool joint

deviated hole, high rotary speeds proper make up torque per tool class, repair shoulder fins, use before use, repair or replace kelly

possible. Minimize rate of change PROBABLE CAUSE:

Corrosion / erosion at ends of drill joint class, or tool joint stabbing guide, repair galled saver sub

in hole deviation POSSIBLE CORRECTION:

pipe/ casing protectors– poor mud manufacturer recommendations, threads

Straighten pipe, minimize ole PROBLEM:

PROBLEM: drain/ cleaning at protector end remove shoulder damage by SHOULDER FINS

deviation/rate of change, and

Surface Notching refacing. If possible, recut PROBLEM:

POSSIBLE CORRECTION:

avoid critical rotary speeds USUAL EFFECT:

CORROSION PITTING connection; remove shoulder fins PIN BREAK

Periodically move or remove by beveling shoulder; consult API- (Flat fracture type failure when Prevents shoulder make-up, false

(General in location) PROBLEM:

protector, clean pipe at ends and RP 7G, or tool joint manufacturers torque and make-up are known to torque, leaking shoulder seal,

ID. EROSION

USUAL EFFECT: under protector recommendations for maximum be satisfactory) wash-out, connection wobble, pin

(General location but often

Bodywall loss, localized surface shoulder removal by refacing; break, drop string, lost time

PROBLEM:

appears near upset areas) USUAL EFFECT:

notch, stress concentration keep thread protectors installed PROBABLE CAUSE:

Surface Notching USUAL EFFECT:

String separation; fishing job, lost

PROBABLE CAUSE:

while picking up, laying down, Mating tool joint with different

HAMMER MARKS Body-wall thinning, reduced time

Water, oxygen, CO2, salt, H2S, handling, transporting, or storing O.D.’s, handling damage

(Usually found on tube in areas cross-section, reduced tensile

stress pipe; clean threads and shoulder PROBABLE CAUSE:

near the pin and box end tool capacity, reduced collapse POSSIBLE CORRECTION:

before make-up; use care when H2S, hydrogen embrittlement,

POSSIBLE CORRECTION:

joints) resistance Maintain tool joint O.D‘s if

tripping pipe; use use only pipe pe excessive pin tension

Maintain mud PH above 9.5, use possible, remove fins by refacing

USUAL EFFECT:

PROBABLE CAUSE:

jack tool with wide

wide area contact.

plastic coatings, inhibitors, POSSIBLE CORRECTION: and beveling, use stabbing guide,

Localized surface notch, cold High velocity abrasion, sharp

oxygen scavenger, clean pipe I.D. PROBLEM:

Control H2S in flow, reduce stress handle pipe only with thread

worked metal sand (solids), drilling, fluid

& O.D., dampen stress, monitor DRY OR MUDDY CONNECTION level if possible, remove string protectors

PROBABLE CAUSE:

turbulence, general corrosion from service for period of time,

with corrosion test rings

Tapping pipe to check fluid level USUAL EFFECT: inspect tool joint threads PROBLEM:

POSSIBLE CORRECTION:

PROBLEM: on trip out Leaking shoulder (face) seals PROBLEM: HEAT CHECKING

Plastic coating, minimize drilling

Surface Notching fluid abrasives, inhibitors, PROBABLE CAUSE:

WEAR USUAL EFFECT:

POSSIBLE CORRECTION:

SLIP CUTS minimize exposure to treating Insufficient make-up torque, (Thin shoulders) Time joint body cracking,

Use brass tipped hammer, tap

(Located in slip area) acids damaged shoulders (face) washout, string separation lost

pipe lightly USUAL EFFECT:

Reduces torque capacity, belled time

USUAL EFFECT: POSSIBLE CORRECTION:

Transverse surface notch, stress PROBLEM:

Consult API-RP 7G or tool joint boxes, reduced shoulder seat PROBABLE CAUSE:

SLIP AREA CRUSHING Far East Inspection Locations- area

concentrator manufacturer recommendations Rapid heating due to friction

(Located in slip area) between tool joint and formation,

PROBABLE CAUSE: Indonesia Inspection: for proper make-up torque per PROBABLE CAUSE:

USUAL EFFECT: tool joint class, or, remove Crooked pipe, high rotary speeds, casing, whip stock, etc. high

Pipe turning in slips, defective +62 (0)21 780 6265

Slip area O.D/ I.D. reduction, shoulder damage by refacing. If rotary speeds, rapid cooling

slips/bowl, improper slip handling abrasive formations

longitudinal splits in slip area, Papua New Guinea Inspection: possible, recut connection; POSSIBLE CORRECTION:

POSSIBLE CORRECTION: POSSIBLE CORRECTION:

body wall thinning +62 (0)21 780 6265 remove shoulder fins by beveling Reduce rotary speeds through

Use back-up tong for makeup and shoulder; consult API RP 7G, or Straighten pipe, reduce rotary

tight areas; minimize tool- joint-to-

breakout, do not spin pipe with PROBABLE CAUSE:

tool joint manufacturer for speeds where possible, apply

Abrupt setting of slips, defective Singapore Inspection: formation contact

rotary, improve slip/bowl maximum shoulder removal by hard facing to box and pin end

slip/ bowl maintenance, improper +65 6861 2688 tool joints where possible

maintenance, use care while refacing; keep thread protectors PROBLEM:

setting slips. slips size SHOULDER DAMAGE

Malaysia (Labuan) Inspection: installed while picking up, laying

POSSIBLE CORRECTION: +60 8 741 3020 down, handing, transporting, or USUAL EFFECT:

Stop pipe movement before storing pipe; clean threads and Leaking shoulder seal, washout.

setting slips, check slip-to-pipe fit, Malaysia (Kemaman) shoulder before make-up; use String separation, lost time

improve maintenance, and use Inspection: care when tripping pipe;

PROBABLE CAUSE:

only correct slip size +60 9 863 1885 use stabbing guide Miss-stabbing connection,

handling damage,, improper pipe

China (Shekou) Inspection: jacking

+86 755 2669 1915

POSSIBLE CORRECTION:

Use care when tripping pipe,

© Copyright NOV Tuboscope 2011

Вам также может понравиться

- Performance Sheet Tubing: Pipe Body: Tubular AssemblyДокумент1 страницаPerformance Sheet Tubing: Pipe Body: Tubular Assemblykm1790Оценок пока нет

- IDM Log 1585699074609Документ68 страницIDM Log 1585699074609km1790Оценок пока нет

- Packard International Products - Drop-In Check ValvesДокумент2 страницыPackard International Products - Drop-In Check Valveskm1790Оценок пока нет

- 3.500 HWDP With NC38 (3.5IF) (4.750 X 2.250 TJ) ConventionalДокумент1 страница3.500 HWDP With NC38 (3.5IF) (4.750 X 2.250 TJ) Conventionalkm1790Оценок пока нет

- HWDP 3.5 03Документ2 страницыHWDP 3.5 03km1790Оценок пока нет

- HWDP 2.875 01Документ2 страницыHWDP 2.875 01km1790Оценок пока нет

- Heavy Weight Drill Pipe (HWDP)Документ2 страницыHeavy Weight Drill Pipe (HWDP)km1790Оценок пока нет

- Inches - Fraction Decimal EquivalentsДокумент7 страницInches - Fraction Decimal Equivalentskm1790Оценок пока нет

- Conversion Chart - From Inches To MMДокумент12 страницConversion Chart - From Inches To MMkm1790Оценок пока нет

- A Inch Decimal MillimeterConversionChartДокумент1 страницаA Inch Decimal MillimeterConversionChartkm1790Оценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1091)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- 12.1 ANSYS NcodeДокумент4 страницы12.1 ANSYS Ncodespudweb_techОценок пока нет

- AAPA IG2 Cold Mixed Granular Materials Guide Guide ReducedДокумент52 страницыAAPA IG2 Cold Mixed Granular Materials Guide Guide Reducedwiwit annisaОценок пока нет

- Be Me Tell U Rgical 0708Документ26 страницBe Me Tell U Rgical 0708sasi4uallОценок пока нет

- Inspection, Planning of Offshore JacketДокумент3 страницыInspection, Planning of Offshore JacketsaulolmОценок пока нет

- Logstar PDFДокумент184 страницыLogstar PDFZdravko IvancicОценок пока нет

- (A. Hobbacher) Fatigue Design of Welded JointsДокумент130 страниц(A. Hobbacher) Fatigue Design of Welded JointsandypcОценок пока нет

- A Review On NSM-CFRP Technique Using in Shear Strengthening of RC Deep BeamsДокумент18 страницA Review On NSM-CFRP Technique Using in Shear Strengthening of RC Deep Beamsbassem kooliОценок пока нет

- Release NotesДокумент10 страницRelease NotestaddeoОценок пока нет

- 2.3 Safety and Environmental IssuesДокумент4 страницы2.3 Safety and Environmental IssuesHuy VõОценок пока нет

- Oil and Gas BrochureДокумент11 страницOil and Gas BrochureMitra HelmetОценок пока нет

- Module 1 & 2 - CMTДокумент13 страницModule 1 & 2 - CMTMyka Mhey BatallonesОценок пока нет

- Notches and Their EffectsДокумент18 страницNotches and Their EffectssathvikОценок пока нет

- Issue #16 Calculating Rope Stretch 2016Документ6 страницIssue #16 Calculating Rope Stretch 2016Carlos Bruno MatosОценок пока нет

- Metal Fatigue SpreadsheetsДокумент56 страницMetal Fatigue SpreadsheetsrallabandiОценок пока нет

- PVP2020-21106 INCEFA-PLUS ProjectДокумент8 страницPVP2020-21106 INCEFA-PLUS Projectnahla0helmyОценок пока нет

- Review On Uncertainties in Fatigue Loads and Fatigue Life o - 2022 - Ocean Enginhighlighted2Документ15 страницReview On Uncertainties in Fatigue Loads and Fatigue Life o - 2022 - Ocean Enginhighlighted2mohamad shahrakОценок пока нет

- API RP 1102 Pipeline Crossing Calculations: Input DataДокумент2 страницыAPI RP 1102 Pipeline Crossing Calculations: Input Datapatrick6364Оценок пока нет

- TurboTalk Vol11Документ12 страницTurboTalk Vol11Prastowo PriyatmokoОценок пока нет

- Managed Intelligent Integrity For Flexible Pipe: New PipelinesДокумент30 страницManaged Intelligent Integrity For Flexible Pipe: New PipelinesHafiz RahmanОценок пока нет

- Volume - IiДокумент125 страницVolume - IiastorОценок пока нет

- EAD-330008-05-0601-Anchor ChannelДокумент116 страницEAD-330008-05-0601-Anchor ChannelLe site de thierry thierryОценок пока нет

- CT Job DesignДокумент7 страницCT Job DesignAKOMOLAFE ABAYOMIОценок пока нет

- Efthymiadis PHD Thesis FinalДокумент280 страницEfthymiadis PHD Thesis FinalAR HassanОценок пока нет

- Crosby ShacklesДокумент6 страницCrosby Shacklessabah8800Оценок пока нет

- International Journal of Fatigue: Qunshan Ye, Shaopeng Wu, Ning LiДокумент5 страницInternational Journal of Fatigue: Qunshan Ye, Shaopeng Wu, Ning LiRicardo Tapia VillotaОценок пока нет

- Performance Evaluation of Waterproofing Membrane SДокумент19 страницPerformance Evaluation of Waterproofing Membrane STrần Văn QuốcОценок пока нет

- Welded Joint Concerns For Shock, Vibration & Fatigue: by Tom IrvineДокумент26 страницWelded Joint Concerns For Shock, Vibration & Fatigue: by Tom IrvineJitendra ItankarОценок пока нет

- 15 StressConcentrationsДокумент32 страницы15 StressConcentrationsalberthawkingОценок пока нет

- Airport Pavement Design WorkshopДокумент543 страницыAirport Pavement Design Workshopfaissu100% (2)

- Designers' Guide To EN 1992-2 Concrete Bridges (2007)Документ381 страницаDesigners' Guide To EN 1992-2 Concrete Bridges (2007)Ialomiteanu Dan100% (7)