Академический Документы

Профессиональный Документы

Культура Документы

Articol ENG

Загружено:

Alina AlexandraАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Articol ENG

Загружено:

Alina AlexandraАвторское право:

Доступные форматы

A clinical evaluation of fixed partial denture impressions

Nachum Samet, DMD,a Michal Shohat, DMD,b Alon Livny, DMD,c and Ervin I. Weiss, DMDd

Harvard School of Dental Medicine, Boston, Mass; Hadassah–Hebrew University School of Dental

Medicine, Jerusalem, Israel

Statement of problem. Providing the dental laboratory with an accurate replication of the hard and soft

tissue of a patient is important. Therefore, it is essential to examine whether clinicians critically evaluate

impressions routinely before sending them to the laboratory.

Purpose. This study evaluated the quality of impressions sent to commercial laboratories for the fabrication

of fixed partial dentures (FPD) by describing the frequency of clinically detectable errors and by analyzing

correlations between the various factors involved.

Material and methods. A total of 193 FPD impressions were evaluated, immediately after arrival at 11 dental

laboratories, by 3 calibrated examiners. The impression technique and material used, tray type, and number of

prepared units were recorded for each impression. Data relating to errors and faults, including defects in material

polymerization, retention to tray, tissue contact by tray, crucial areas beyond tray borders, heavy-bodied material

exposure through the wash material (for double-step impressions), inadequate union of materials, retraction

cords embedded in impressions, and air bubbles, voids, or tears along the margin were also documented. The

data were analyzed with the Pearson chi-square test (a=.05).

Results. Of the impressions, 89.1% had 1 or more observable errors. Significant correlations were found

between material type and voids or tears at the finish line (Rv = 0.17, P,.025) and between material type and

polymerization problems (Rv = 0.223, P,.004).

Conclusions. Within the limitations of this study, impressions made with polyethers had the most detectable

errors, followed by condensation-type silicones. The high frequency of detectable errors found in impressions

sent for FPD fabrication is of concern. (J Prosthet Dent 2015;94:112-7.)

CLINICAL IMPLICATIONS

Based on the results of this study, more critical evaluation of impressions for fixed prosthodontics

on the part of the dentist is recommended.

T ransfer of an accurate replication of the patient’s

hard and soft tissue to the dental laboratory is impor-

sion materials of 2 viscosities are applied at the same

time), or (4) the double-step technique (in which the

tant.1 Most dentists have experienced the results of mak- impression is made in 2 steps, using material of different

ing a poor impression. The ability to identify and analyze viscosity in each step).

inaccurate impressions and to understand how to avoid Since impressions replicate both the teeth and the

them is key to successful restoration. There are various gingiva, success is based on understanding the anatomy

techniques for making fixed partial denture (FPD) im- of the periodontal tissues, creating an accurate and deci-

pressions.2-7 These include the following: (1) the single pherable preparation (especially at the finish line), using

copper band technique, (2) the monophase technique the correct impression material and appropriate tech-

(in which an impression material of only 1 viscosity is niques.1,3,8 However, none of these alone will ensure

used), (3) the single-step technique (in which impres- an accurate impression. Many studies on impression

accuracy have been published.9-14 The majority were

in vitro studies in which it was assumed that the evalu-

a

Instructor, Director of Predoctoral Prosthodontics Department of

ated impressions were acceptable, meaning no visible

Restorative Dentistry and Biomaterial Science, Harvard School of errors were observed. Only a few studies reported on

Dental Medicine. the quality of the impressions made in vivo.15,16

b

Resident, Department of Prosthodontics, Hadassah–Hebrew Therefore, it is important to examine whether clinicians

University School of Dental Medicine. critically evaluate impressions routinely before sending

c

Resident, Department of Community Dentistry, Hadassah–Hebrew

University School of Dental Medicine.

them to the laboratory. The aim of this study was

d

Asssociate Professor, Head, Department of Prosthodontics, to evaluate the quality of impressions sent to commercial

Hadassah–Hebrew University School of Dental Medicine. laboratories for fabrication of FPDs, to describe the

112 THE JOURNAL OF PROSTHETIC DENTISTRY VOLUME 94 NUMBER 2

SAMET ET AL THE JOURNAL OF PROSTHETIC DENTISTRY

Fig. 1. Frequency distribution by number of errors; 172 impressions had 1 or more detectable errors.

frequency of clinically detectable impression errors, Table I. Occurrence of various detectable errors

and to determine possible correlations between various

Criteria Percent occurrence*

factors.

Voids or tears at finish line 50.7 (98)

MATERIAL AND METHODS Putty exposure through wash 44.0 (85)

(in double-step technique)

A total of 193 FPD impressions from 11 commercial Air bubbles at finish line 40.4 (78)

dental laboratories were examined between May and Pressure of tray on soft tissue 38.3 (74)

July 2002. Forty-one dentists submitted the impres- Inadequate retention of material to tray 33.7 (65)

sions with a request for FPD fabrication. Impressions Flow problems 23.8 (46)

without specific requests for FPDs, or those made with Retraction cord attached to impression 6.2 (12)

materials with which the examiners were not familiar, Of 193 impressions for FPD evaluated by 3 examiners, 172 (89.1%) had 1 or

were excluded from the study. more detectable errors.

*Percentages relate to 193 impressions. Total number in parentheses.

All impressions were evaluated immediately after

reaching the laboratory. The impressions were num-

terial exposure through the wash material for double-

bered prior to evaluation so that the identities of the

step impressions, inadequate union of the materials,

dentists were unknown to the examiners, preventing

retraction cords embedded in the impressions, and air

bias. Other than numbering them, the impressions

bubbles, voids, or tears along the finish line.

were not manipulated by the laboratory staff prior to

The collected data were examined for the frequency

examination. The impressions were evaluated by 1 of 3

of occurrence of each observation, and the correlations

calibrated examiners. Interoperator calibration was

between observations were computed using Cramer V

achieved by having the examiners inspect 10 impressions

correlation statistics. Statistical software (SPSS version

to determine common standards before analyzing the

10.1; SPSS Inc, Chicago, Ill) was used for statistical anal-

specimens. Statistical analysis of the calibration was not

ysis. The Pearson chi-square test was used to determine

performed, since the evaluation results according to

significance (a=.05).

the criteria mentioned below were identical for all

3 examiners for all 10 impressions.

For each impression, the jaw, technique, tray type,

RESULTS

material, and number of prepared units were recorded.

Data referring to errors and visible defects were also Of the 193 impressions examined, 99 (51.3%) were

documented, including defects in material flow, inad- maxillary impressions and 94 (48.7%) were mandibular

equate retention to the tray, tissue contact by the tray, impressions. Of the impressions, 49 (25.4%) contained

crucial areas outside the tray border, heavy-bodied ma- 4 or more FPD abutments; 69 (35.8%) contained 2 or

AUGUST 2015 113

THE JOURNAL OF PROSTHETIC DENTISTRY SAMET ET AL

Fig. 3. Distribution of voids or tears at finish line area by type

Fig. 2. Distribution of impression materials by impression of impression material. Significant correlation was found

technique. Significant correlation was found between im- between presence of voids or tears at finish line area and

pression material and impression technique (P,.0001). impression material used (P,.025).

Fig. 5. Representative example of air bubbles at finish line.

Of 193 impressions, 77 (40%) had air bubbles at margin line.

Fig. 4. Representative impression demonstrating voids and

tears at finish line.

3 abutments, and 75 (38.8%) included a single unit. The (52.3%) of the impressions. The distribution of impres-

monophase technique was used in 11 (5.7%) of the im- sion materials was 38 (19.7%) polyether; 51 (26.4%)

pressions, the double-step technique in 81 (42%) of condensation-type silicone; and 104 (53.9%) addition-

the impressions, and the single-step technique in 101 type silicones. Custom trays were used for 1 (0.5%), rigid

114 VOLUME 94 NUMBER 2

SAMET ET AL THE JOURNAL OF PROSTHETIC DENTISTRY

Fig. 6. Distribution of flow problems by impression material. Fig. 7. Flow problems in impression sent for FPD fabrication.

Significant correlation was found between flow problems and Such problems were significantly correlated with impression

impression material used (P,.004). material used.

plastic trays for 23 (11.9%), metal trays for 63 (32.7%), type silicones, and 14.4% of the addition-type silicones

and soft plastic trays for 106 (54.9%) of the impressions. (Fig. 6). An example of a flow problem is shown

Of the 193 impressions, 172 (89.1%) had 1 or more in Figure 7. No other significant correlations were

detectable errors. Thirty-eight (19.7%) impressions had found.

1 error, 46 (23.8%) had 2 errors, 36 (18.7%) had 3

errors, 33 (17.1%) had 4 errors, 16 (8.3%) had 5 errors,

DISCUSSION

and 3 (1.6%) had 6 different detectable errors. A de-

scription of these errors and their frequencies appear Dentists face numerous clinical challenges, and eval-

in Table I. The frequency distribution according to uating self-performance for quality assurance can be de-

number of errors is shown in Figure 1. manding. In this study, impressions were examined

A significant correlation was found between impres- according to the following criteria: the use of appropri-

sion material and impression technique (Rv = 0.319, ate trays, sufficient retention of the impression material

P,.0001). Of the addition-type silicone impressions, to the tray, complete polymerization of the materials

51% were made using a single-step technique, 48% us- with proper adherence to each other, and the absence

ing a double-step technique, and 1% using a monophase of bubbles, voids, or tears along the finish line.

technique. Of the condensation-type silicone impres- This study showed that 89.1% of the impressions had

sions, 62.7% were made using a single-step technique 1 or more detectable errors. These findings are in agree-

and 37.3%, using a double-step technique. Of the poly- ment with Winstanley et al15 and Carrotte et al,16 al-

ether impressions, 26.3% were made as monophase im- though the criteria used for evaluation were not the

pressions, 42% were made using a single-step technique, same. Winstanley and Carrotte assessed retention of

and 31.7% were made using a double-step technique the impression to the tray, the accuracy of the impres-

(Fig. 2). A significant correlation was found between sion at the finish line, and the presence of other

the type of material used and voids or tears at the mar- defects that could affect occlusal relationships. Based

gin line (Rv = 0.17, P,.025), as 76.3% of the polyether on these criteria, the impressions were categorized into

impressions, 68.6% of the condensation-type silicones, 4 groups, ranging from satisfactory to unsatisfactory

and 53.8% of the addition-type silicones demonstrated prosthetic results. According to the present study find-

this error (Fig. 3). Examples of voids and tears and air ings, 50.7% of all the impressions had voids or tears in

bubbles at the finish line area are shown in Figures 4 the finish line area, 40.4% had air bubbles at the margin

and 5, respectively. Significant correlation was also line, and 26.9% had both.

found between the type of material used and problems These errors may be due to difficulties in obtaining an

indicating a lack of flow of the material. (Rv = 0.223, intimate contact between the impression material and

P,.004) Flow problems were observed in 42.1% of the tooth in an area in which biological fluids and air

the polyether impressions, 30% of the condensation- are present, faulty manipulation of the impression

AUGUST 2015 115

THE JOURNAL OF PROSTHETIC DENTISTRY SAMET ET AL

material while placing it around the prepared tooth, or lack of attention resulted in these impressions being

premature removal of the impressions from the mouth. sent to the laboratory.

The fact that impressions are often removed from the These findings are based on criteria for producing sat-

mouth when the dentist ‘‘feels’’ that the material has isfactory impressions. The high incidence of imperfect

polymerized, disregarding the polymerization time impressions is disturbing. The possible underlying

recommended by the manufacturer, may explain pre- causes include low awareness of the need for critical

mature removal. self-evaluation, clinical or financial pressure, and lack

Significant correlations were found only between mate- of knowledge or ethics.

rial type and voids and tears at the finish line, and between This study is based on the review of impressions made

material type and flow problems, which suggests that that by 41 dentists and sent to 11 commercial dental labora-

polyethers, followed by condensation-type silicones, are tories. The laboratories included in this study were not

the most improperly used materials. This may be explained randomly selected but were chosen according to geo-

by partial compliance with the manufacturer’s instruc- graphic availability and access by the examiners.

tions, such as uneven hand mixing. The use of electro- Dentists’ identities were not recorded due to ethical is-

mechanical mixers may minimize this problem. Another sues, although this information could be valuable. A lim-

explanation for this finding might be the use of stock itation of the study is the lack of magnification

trays rather than custom trays for polyether impressions. equipment used during examination. Magnification

Insertion of a large amount of monophase material into might have made the proportions of faulty impressions

a stock tray could result in layering patterns and trapped even higher.

air. It is difficult to account for the discrepancy between This study examined only the outcome of impression

the prevalence of monophase impressions (5.7%) and making, but further studies are needed to evaluate the

the use of custom trays (0.5%). The results of this study quality of the dies and the outcome of the definitive res-

indicate that the most commonly used materials were ad- toration. It is possible that the technician will, upon re-

dition-type silicones (49.8%) followed by condensation- viewing the final cast and detecting possible problems,

type silicones (24.4%). The least commonly used materials send it back to the dentist for further instructions.

were polyethers (18.2%). Although addition-type sili- Therefore, it is impossible to determine, according to

cones are more expensive than condensation-type sili- this study, the proportion of faulty impressions that ac-

cones, they allow for a longer time between making tually became definitive restorations and whether these

the impression and pouring it.8 Also, cartridge dispensers restorations would be deemed acceptable.

for addition-type silicones avoid the need for hand

mixing. The limited use of polyethers by dentists could

be attributed to their high cost and strong taste,8 or CONCLUSIONS

to the fact that dentists are less familiar with this type of Within the limitations of this study, impressions

material. made with polyethers followed by condensation-type

Another finding emerging from the present study is silicones have the most detectable errors. The high

that single-step impressions are the most frequently frequency of detectable errors found in impressions

used. This method is faster and probably adopted by sent for FPD fabrication is a concern. A more critical

experienced dentists to decrease procedure time, but it evaluation of impressions on the part of the dentist

does not allow for the error compensation inherent in is recommended.

the double-step technique. A significant correlation be-

tween technique type and defects at the finish line was

not found. The relative accuracy of these 2 impression REFERENCES

techniques has been previously discussed6,7 and is 1. Chiche GJ, Harrison JD, Caudill R. Impression considerations in the

beyond the scope of the present article. maxillary anterior region. Compendium 1994;15:318-22.

The most widely used impression trays were soft plas- 2. Chee WW, Donovan TE. Polyvinyl siloxane impression materials: a

review of properties and techniques. J Prosthet Dent 1992;68:728-32.

tic stock trays (54.9%), as found in previous studies.15,16 3. Millar B. How to make a good impression (crown and bridge). Br Dent J

The use of a soft plastic stock tray cannot be considered a 2001;191:402-5.

‘‘visible defect,’’ although there is possibility for inac- 4. Messing JJ. Copper band technique. Br Dent J 1965;119:246-8.

5. Gelbard S, Aoskar Y, Zalkind M, Stern N. Effect of impression materials

curacies due to the flexible nature of these trays.14,15 and techniques on the marginal fit of metal castings. J Prosthet Dent

The widespread use of such trays may be related to their 1994;71:1-6.

low price and/or to the clinician’s lack of knowledge re- 6. Thongthammachat S, Moore BK, Barco MT 2nd, Hovijitra S, Brown DT,

Andres CJ. Dimensional accuracy of dental casts: influence of tray

garding their shortcomings. Regardless of tray type, 33% material, impression material, and time. J Prosthodont 2002;11:98-108.

of all impressions showed inadequate retention to the 7. Idris B, Houston F, Claffey N. Comparison of the dimensional accuracy of

tray, an error that can be readily avoided by using the one- and two-step techniques with the use of putty/wash addition silicone

impression materials. J Prosthet Dent 1995;74:535-41.

proper removal technique or appropriate adhesive. It is 8. Anusavice KJ, Phillips RW. Phillip’s science of dental materials. 11th ed.

difficult to determine whether lack of knowledge or St. Louis: Elsevier; 2003. p. 205-55.

116 VOLUME 94 NUMBER 2

SAMET ET AL THE JOURNAL OF PROSTHETIC DENTISTRY

9. Laufer BZ, Baharav H, Ganor Y, Cardash HS. The effect of marginal 16. Carrotte PV, Winstanley RB, Green JR. A study of the quality of

thickness on the distortion of different impression materials. J Prosthet impressions for anterior crowns received at a commercial laboratory.

Dent 1996;76:466-71. Br Dent J 1993;174:235-40.

10. Marcinak CF, Draughn RA. Linear dimensional changes in addition curing

silicone impression materials. J Prosthet Dent 1982;47:411-3. Reprint requests to:

11. Hung SH, Purk JH, Tira DE, Eick JD. Accuracy of one-step versus two-step DR MICHAL SHOHAT

putty wash addition silicone impression technique. J Prosthet Dent 1992; HEBREW UNIVERSITY SCHOOL OF DENTAL MEDICINE

67:583-9. DEPARTMENT OF PROSTHODONTICS

12. Lee IK, DeLong R, Pintado MR, Malik R. Evaluation of factors affecting the PO BOX 12272

accuracy of impressions using quantitative surface analysis. Oper Dent JERUSALEM, ISRAEL 91120

1995;20:246-52. FAX: 972-2-6429683

13. Gordon GE, Johnson GH, Drennon DG. The effect of tray selection on the E-MAIL: izhar123@netvision.net.il

accuracy of elastomeric impression materials. J Prosthet Dent 1990;63:

12-5. 0022-3913/$30.00

14. Carrotte PV, Johnson A, Winstanley RB. The influence of the impression Copyright 2015 by The Editorial Council of The Journal of Prosthetic

tray on the accuracy of impressions for crown and bridge work–an inves- Dentistry.

tigation and review. Br Dent J 1998;185:580-5.

15. Winstanley RB, Carrotte PV, Johnson A. The quality of impressions for

crowns and bridges received at commercial dental laboratories. Br Dent

J 1997;183:209-13. doi:10.1016/j.prosdent.2015.05.002

AUGUST 2015 117

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Complete Healing of A Large Periapical Lesion Following Conservative Root Canal Treatment in Association With Photodynamic TherapyДокумент9 страницComplete Healing of A Large Periapical Lesion Following Conservative Root Canal Treatment in Association With Photodynamic TherapyAlina AlexandraОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Jdhodt 09 00356 PDFДокумент4 страницыJdhodt 09 00356 PDFAlina AlexandraОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Liste 29 IASI DДокумент8 страницListe 29 IASI DHarnagea LiviuОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Parameters That Influence The Properties of Fiber Reinforced Composites. ReviewДокумент7 страницParameters That Influence The Properties of Fiber Reinforced Composites. ReviewAlina Alexandra100% (1)

- Evaluation of The Periodontal Bacteria Prevalence in Teenage SmokersДокумент8 страницEvaluation of The Periodontal Bacteria Prevalence in Teenage SmokersAlina AlexandraОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

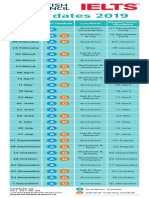

- Calendar Ielts 2019Документ1 страницаCalendar Ielts 2019ioana zorilaОценок пока нет

- Clinical Study: Relationship Between Cariogenic Bacteria and PH of Dental Plaque at Margin of Fixed ProsthesesДокумент5 страницClinical Study: Relationship Between Cariogenic Bacteria and PH of Dental Plaque at Margin of Fixed ProsthesesAlina AlexandraОценок пока нет

- Telescopic Partial Dentures-Concealed Technology: Tushar Vitthalrao Bhagat, Ashwini Nareshchandra WalkeДокумент5 страницTelescopic Partial Dentures-Concealed Technology: Tushar Vitthalrao Bhagat, Ashwini Nareshchandra WalkeAlina AlexandraОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Marginal and Internal Fit of Zirconia Based Fixed Dental Prostheses Fabricated With Different ConceptsДокумент7 страницMarginal and Internal Fit of Zirconia Based Fixed Dental Prostheses Fabricated With Different ConceptsAlina AlexandraОценок пока нет

- The Oral Rehabilitation Using Metal-Ceramic Bridges. Case PresentationДокумент4 страницыThe Oral Rehabilitation Using Metal-Ceramic Bridges. Case PresentationAlina AlexandraОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Strategic Use of Telescopic Retainers and Semi-Rigid Precision Attachments in A Geriatric Patient: A Case ReportДокумент6 страницStrategic Use of Telescopic Retainers and Semi-Rigid Precision Attachments in A Geriatric Patient: A Case ReportAlina AlexandraОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Clinical Evaluation of Failures in Removable Partial DenturesДокумент6 страницClinical Evaluation of Failures in Removable Partial DenturesAlina AlexandraОценок пока нет

- Telescopic Partial Dentures-Concealed Technology: Tushar Vitthalrao Bhagat, Ashwini Nareshchandra WalkeДокумент5 страницTelescopic Partial Dentures-Concealed Technology: Tushar Vitthalrao Bhagat, Ashwini Nareshchandra WalkeAlina AlexandraОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Strategic Use of Telescopic Retainers and Semi-Rigid Precision Attachments in A Geriatric Patient: A Case ReportДокумент6 страницStrategic Use of Telescopic Retainers and Semi-Rigid Precision Attachments in A Geriatric Patient: A Case ReportAlina AlexandraОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Strategic Use of Telescopic Retainers and Semi-Rigid Precision Attachments in A Geriatric Patient: A Case ReportДокумент6 страницStrategic Use of Telescopic Retainers and Semi-Rigid Precision Attachments in A Geriatric Patient: A Case ReportAlina AlexandraОценок пока нет

- Priyanka Arien Dr.Документ5 страницPriyanka Arien Dr.barcimОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Custom Occlusal Template As An Insertion Guide For Precision Removable Partial DenturesДокумент2 страницыCustom Occlusal Template As An Insertion Guide For Precision Removable Partial DenturesAlina AlexandraОценок пока нет

- Erg in DentДокумент5 страницErg in DentAqilah MahabirОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- A Comparative EvaluationДокумент4 страницыA Comparative EvaluationAlina AlexandraОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- ArchMedHealthSci31138-6898434 190944 PDFДокумент7 страницArchMedHealthSci31138-6898434 190944 PDFAlina AlexandraОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- 1 s2.0 S2212017313007147 MainДокумент8 страниц1 s2.0 S2212017313007147 MainAlina AlexandraОценок пока нет

- 1 s2.0 S2212017313007147 MainДокумент8 страниц1 s2.0 S2212017313007147 MainAlina AlexandraОценок пока нет

- Anunt Concurs Medic Cu Activitate IntegrataДокумент5 страницAnunt Concurs Medic Cu Activitate IntegrataAlina AlexandraОценок пока нет

- 19 Kommuri Sahithi ReddyДокумент14 страниц19 Kommuri Sahithi ReddyAlina AlexandraОценок пока нет

- Guidance On Occupational Hazards in DentistryДокумент20 страницGuidance On Occupational Hazards in DentistryAlina AlexandraОценок пока нет

- Digital Smile Design-Instrumentul Ideal de Comunicare Între Membrii Echipei Medicale Şi Pacienţi Pentru Restaurarea Cu Succes A Zonei EsteticeДокумент6 страницDigital Smile Design-Instrumentul Ideal de Comunicare Între Membrii Echipei Medicale Şi Pacienţi Pentru Restaurarea Cu Succes A Zonei EsteticeAlina AlexandraОценок пока нет

- Writing-Practice Test 1 IELTS General Training Model Answers PDFДокумент2 страницыWriting-Practice Test 1 IELTS General Training Model Answers PDFMNAOUARОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Sindromul de Canal Carpian La Medicul DentistДокумент6 страницSindromul de Canal Carpian La Medicul DentistOana Andreea UrsicăОценок пока нет

- Diagnosticul Diferenţial Al Adenopatiei Metastatice CervicaleДокумент5 страницDiagnosticul Diferenţial Al Adenopatiei Metastatice CervicaleAlina AlexandraОценок пока нет

- Guidance On Occupational Hazards in DentistryДокумент20 страницGuidance On Occupational Hazards in DentistryAlina AlexandraОценок пока нет

- Lecture 1 Introduction To Industrial HygieneДокумент40 страницLecture 1 Introduction To Industrial Hygienesiti zubaidahОценок пока нет

- Fluoride Menace in OrissaДокумент83 страницыFluoride Menace in OrissaProfessor PrabhatОценок пока нет

- Blood TypingДокумент11 страницBlood Typingprakash gusainОценок пока нет

- Gallstone, Choledocholithiasis, Ascending CholangistisДокумент12 страницGallstone, Choledocholithiasis, Ascending CholangistisNurulasyikin MAA100% (1)

- RSPCA Shuts Down Another Animal SanctuaryДокумент10 страницRSPCA Shuts Down Another Animal SanctuaryGlynne SutcliffeОценок пока нет

- LNG Hazards and SafetyДокумент60 страницLNG Hazards and SafetyFernando GrandaОценок пока нет

- Hand in Hand For A Healthier World: Logiq V5 ExpertДокумент4 страницыHand in Hand For A Healthier World: Logiq V5 ExpertPablo RamirezОценок пока нет

- Im9 2002 PDFДокумент89 страницIm9 2002 PDFV1QT0RОценок пока нет

- ApproachPerformance 01 PDFДокумент6 страницApproachPerformance 01 PDFAdam MazurekОценок пока нет

- AssignmentДокумент2 страницыAssignmentReserva, ArchelleОценок пока нет

- EQ-5D-5L User GuideДокумент28 страницEQ-5D-5L User GuideCristi100% (1)

- MRCP 2 PACES Exam Cases From 2011Документ6 страницMRCP 2 PACES Exam Cases From 2011Kolitha KapuduwageОценок пока нет

- Child Health Services-1Документ44 страницыChild Health Services-1francisОценок пока нет

- Playlist AssignmentДокумент7 страницPlaylist AssignmentTimothy Matthew JohnstoneОценок пока нет

- 2022 Arihant Political Science MCQs Term-1 Sample PapersДокумент192 страницы2022 Arihant Political Science MCQs Term-1 Sample PapersImran Arshad100% (4)

- Laminar AirflowДокумент15 страницLaminar AirflowKamran AshrafОценок пока нет

- Annual Leave Policy of University of YorkДокумент15 страницAnnual Leave Policy of University of YorkJohn Son100% (1)

- Sacrococcygeal TeratomaДокумент21 страницаSacrococcygeal TeratomaEm VelascoОценок пока нет

- No. Kode Dan Nama Kode Diagnosa ICD 10 Nama PenyakitДокумент11 страницNo. Kode Dan Nama Kode Diagnosa ICD 10 Nama PenyakitViki AY15Оценок пока нет

- Analysis of GRIHA Certified BuildingsДокумент26 страницAnalysis of GRIHA Certified BuildingsAnshul Sharma100% (7)

- Bulk Stimulants Lubricants Other Laxatives GI StimДокумент5 страницBulk Stimulants Lubricants Other Laxatives GI Stimrosita d. ramosОценок пока нет

- HUL275 Environment Development and Society Assignment 2 Victims and SurvivorsДокумент3 страницыHUL275 Environment Development and Society Assignment 2 Victims and SurvivorsSachin BatwaniОценок пока нет

- Ch5 PDFДокумент35 страницCh5 PDFsandeepОценок пока нет

- Herald Spelling BeeIntermediateДокумент10 страницHerald Spelling BeeIntermediateTheng RogerОценок пока нет

- Major Neurological Syndromes PDFДокумент260 страницMajor Neurological Syndromes PDFVirlan Vasile Catalin100% (1)

- Identifikasi Dan Prevalensi Nematoda Saluran Pencernaan Kuda Lokal (Equus Caballus) Di Kecamatan Moyo Hilir SumbawaДокумент7 страницIdentifikasi Dan Prevalensi Nematoda Saluran Pencernaan Kuda Lokal (Equus Caballus) Di Kecamatan Moyo Hilir SumbawaBeebli PuchaОценок пока нет

- Quality Manual: Pt. Ani Mitra Jaya Frozen ChepalopodДокумент1 страницаQuality Manual: Pt. Ani Mitra Jaya Frozen ChepalopodMia AgustinОценок пока нет

- StoryДокумент6 страницStoryGerard NicholasОценок пока нет

- Brazilian Sanitary Guide For Cruise ShipsДокумент82 страницыBrazilian Sanitary Guide For Cruise ShipsStanislav KozhuharovОценок пока нет

- Hazop PDFДокумент18 страницHazop PDFLuiz Rubens Souza Cantelli0% (1)

- Summary: The Laws of Human Nature: by Robert Greene: Key Takeaways, Summary & AnalysisОт EverandSummary: The Laws of Human Nature: by Robert Greene: Key Takeaways, Summary & AnalysisРейтинг: 4.5 из 5 звезд4.5/5 (30)

- The 16 Undeniable Laws of Communication: Apply Them and Make the Most of Your MessageОт EverandThe 16 Undeniable Laws of Communication: Apply Them and Make the Most of Your MessageРейтинг: 5 из 5 звезд5/5 (73)

- Weapons of Mass Instruction: A Schoolteacher's Journey Through the Dark World of Compulsory SchoolingОт EverandWeapons of Mass Instruction: A Schoolteacher's Journey Through the Dark World of Compulsory SchoolingРейтинг: 4.5 из 5 звезд4.5/5 (149)

- How to Talk to Anyone: Learn the Secrets of Good Communication and the Little Tricks for Big Success in RelationshipОт EverandHow to Talk to Anyone: Learn the Secrets of Good Communication and the Little Tricks for Big Success in RelationshipРейтинг: 4.5 из 5 звезд4.5/5 (1135)

- Summary: The 5AM Club: Own Your Morning. Elevate Your Life. by Robin Sharma: Key Takeaways, Summary & AnalysisОт EverandSummary: The 5AM Club: Own Your Morning. Elevate Your Life. by Robin Sharma: Key Takeaways, Summary & AnalysisРейтинг: 4.5 из 5 звезд4.5/5 (22)

- Dumbing Us Down: The Hidden Curriculum of Compulsory SchoolingОт EverandDumbing Us Down: The Hidden Curriculum of Compulsory SchoolingРейтинг: 4.5 из 5 звезд4.5/5 (496)

- Summary: Trading in the Zone: Trading in the Zone: Master the Market with Confidence, Discipline, and a Winning Attitude by Mark Douglas: Key Takeaways, Summary & AnalysisОт EverandSummary: Trading in the Zone: Trading in the Zone: Master the Market with Confidence, Discipline, and a Winning Attitude by Mark Douglas: Key Takeaways, Summary & AnalysisРейтинг: 5 из 5 звезд5/5 (15)