Академический Документы

Профессиональный Документы

Культура Документы

7568-2144 Typical Manhole Details

Загружено:

Khabbab Hussain K-hАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

7568-2144 Typical Manhole Details

Загружено:

Khabbab Hussain K-hАвторское право:

Доступные форматы

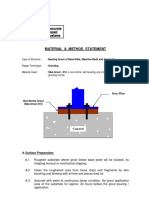

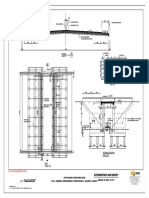

Ductile iron access cover to

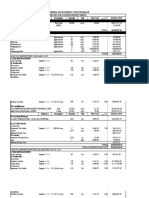

EN124 (size and loading TYPE OF DEPTH FROM DN LARGEST PIPE IN MINIMUM INTERNAL MINIMUM ACCESS SIZE REMARKS

Mortar haunching ACCESS SOFFIT TO MANHOLE / MEANS DIMENSIONS

class as detailed in table

to M.H. cover and frame COVER LEVEL (m) OF DESCENT INTO RECTANGULAR CIRCULAR

SHAFT

MANHOLE C 1.0 - 1.5 _ 750 x 750 C Generally in accordance with safe work in

confined spaces - Health and safety commission

750 x 600 E

2-3 Courses of Class B

engineering brick.. 750 x 600 E

Ductile iron access cover to

EN124 (size and loading 1200 x 675 C Larger opening size is required for manholes at

class as detailed in table shallower depths to permit standing / crouching

1200 x 675 C

1200 x 675 C Cover loading class C250 in fields and D400 in

Lifting eyes in roads / road margins

The larger of 1800 or 1200 x 675 C

concrete rings to be

(DN + 450)

pointed

Designation 1 mortar

2-3 Courses of Class B Precast concrete chamber MANHOLE B 1.5 - 3.0 _ 750 x 600 E Where a ladder is provided, a larger size may be

haunching to M.H. cover

engineering brick.. sections and cover slab to needed

and frame 750 x 600 E

Not less than 900mm

be bedded with mortar, proprietary bitumen or

In-situ concrete to be resin mastic sealant 750 x 600 E

Weirwall 300min above GEN3 (designed to

crown of incoming pipe BRE Special Digest 1 750 x 600 E Cover loading class C250 in fields and D400 in

1200mm x 675mm Concrete in 200mm min. C20 Concrete surround roads / road margins

opening in cover Agressive Ground) (300mm Max.)

slab The larger of 1800 or

(DN + 450)

High level overflow High strength concrete The bottom precast manhole

Precast concrete

Encased in concrete 600mm topping ring to be built into base

ring I. These sizes apply to straight-through pipes; larger sizes may be required for turning chambers or chambers with several side

below ground level to be brought up to a dense concrete min. 75mm

smooth face neatly shaped branches or where specific maintenance requirements are necessary, e.g. disconnecting traps.

and Concrete benching slope

Geotextile Inlet

finished to all branch to be 1 in 10 II. Minimum height of chamber in shafted manhole 2m from benching to underside of reducing slab.

Membrane

connections Water Bar

(20mm minimum thickness) Grace Servicised III.

Servitite AT200 or a safe system of work.

similar approved

300 min Min 300mm below IV. C denotes central.

lowest pipe invert Construction joint Distance between top of pipe

and underside of precast

manhole ring to be 50mm V. E denotes eccentric.

C28 concrete Dowel bars

Inverts to be formed C20 Concrete base

using channel pipes

A393 mesh (min. 50mm cover) 300mm to barrel of pipe

min. dia. > 1500mm 1500 Min.

80mm C20 blinding

A393 mesh (min. 50mm cover)

min. dia. > 1500mm 100mm C20 blinding

Refer to table

NOTES:

1. FIGURED DIMENSIONS ONLY TO BE TAKEN

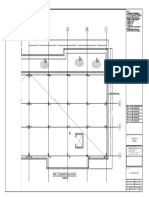

TYPICAL PRECAST MANHOLE DETAIL - TYPICAL PRECAST MANHOLE DETAIL - 2.

FROM THIS DRAWING.

ALL DRAWINGS TO BE CHECKED BY THE

TYPE D TYPE B 3.

CONTRACTOR ON SITE.

ENGINEER/EMPLOYERS REPRESENTATIVE, AS

Depth from ground level to soffit of pipe 1 - 1.5m Maximum depth from cover level to soffit of pipe 3.0m Ductile iron access cover to

Ductile iron access

APPROPRIATE, TO BE INFORMED BY THE

EN124 (size and loading CONTRACTOR OF ANY DISCREPANCIES

class as detailed in table cover to EN124

BEFORE ANY WORK COMMENCES.

(size and loading

4. THE CONTRACTOR SHALL UNDERTAKE A

class as detailed in

THOROUGH CHECK FOR THE ACTUAL

Designation 1 mortar table

2-3 Courses of Class B LOCATION OF ALL SERVICES/UTILITIES,

haunching to M.H. cover

engineering brick.. ABOVE AND BELOW GROUND, BEFORE ANY

and frame

WORK COMMENCES.

Designation 1 mortar

2-3 Courses of Class B 5. ALL LEVELS SHOWN RELATE TO ORDNANCE

haunching to M.H. cover

Rocker Pipe engineering brick.. SURVEY DATUM AT MALIN HEAD.

and frame

Joint to be as close as

possible to face of manhole 1200mm x 675mm

Rocker Pipe Cover Slab

to permit satisfactory joint opening in cover 1200mm x 675mm

Weirwall 300min above bedded on PC chamber

and subsequent movement. slab opening in cover

crown of incoming pipe section with mortar,

resin mastic sealant slab

Joint to be as close as Precast concrete

possible to face of manhole ring Bottom precast concrete

to permit satisfactory joint A Dec. '15 PLANNING ISSUE MN DC

High level overflow ring to be built into base

Encased in concrete and subsequent movement. 500 min. concrete min. 75mm.

Geotextile Inlet High strength concrete topping Rev Date Description By Chkd.

Membrane to be brought up to a dense

smooth face neatly shaped and 200mm C20 Concrete

Pipe joint with channel surround

Precast concrete 500 finished to all branch connections

to be located min. 100mm (300mm Max.)

ring 1.2m minimum min (min. thickness 20mm)

inside face of manhole Concrete benching slope Client:

diameter Min 300mm below

300 min to be 1 in 10 to 1 in 30

lowest pipe invert

Distance between top

Minimum width of benching C28 concrete of pipe and underside of

Pipe joint with channel C20 concrete precast manhole ring to be 50mm.

to be located min. 100mm to be 500mm.

inside face of chamber. A393 mesh (min. 50mm Inverts to be formed

cover)min. dia. > 1500mm 1500 Min. using Channel pipes 300mm to barrel of pipe

80mm C20 blinding Project:

Manholes with outgoing

pipes greater than 600mm A393 mesh (min. 50mm cover)

min. dia. > 1500mm 1200 Min. WEST DUBLIN

dia. should be fitted with 80mm C20 blinding

guard rails and toe hold / steps.

220 / 110 kV SUBSTATION

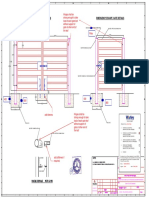

Minimum width TYPICAL PRECAST MANHOLE DETAIL - TYPICAL PRECAST MANHOLE DETAIL - & ASSOCIATED WORKS

of benching

to be 225mm. TYPE E TYPE C Title:

Depth from ground level to soffit of pipe 1.0 - 1.45m

Depth from ground level to soffit of pipe 1 - 1.5m

PLAN ON MANHOLE TYPE D PLAN ON MANHOLE TYPE B TYPICAL

MANHOLE DETAILS

Rocker Pipe

Joint to be as close as

600 x 600 ductile iron cover and frame to en124 possible to face of manhole

215 loading class 125, bedded on minimum of 10mm to permit satisfactory joint

designation 1 mortar and subsequent movement. Scale @ A1: 1:25

215

Prepared by: Checked: Date:

200

200

M. Nolan D. Conneran October 2015

750

Internal plaster Project Director: D. Grehan

900

900

Blockwork Drawing Status: Planning

900 Precast concrete ring

1.2m minimum diameter

200

Patrick J. Tobin & Co. Ltd.

TOBIN Consulting Engineers, AECOM,

Pipe joint with channel Block 10-4, Blanchardstown Kingswood Drive,

PLAN SECTION to be located min. 100mm Corporate Park, Dublin 15, City West Business Campus,

inside face of chamber. Ireland. Dublin 24,

Note:

tel: +353-(0)1-8030406 Ireland.

Duct chamber consisting of grade 25:20 base and roof slab

fax:+353-(0)1-8030409 T +353 (0) 1 403 9300

200mm thick, 215mm thick blockwork walls and heavy duty

e-mail: dublin@tobin.ie

ductile iron cover as specified.

www.tobin.ie

TYPICAL DUCT CHAMBER DETAIL Revision:

PLAN ON MANHOLE TYPE E Drawing No.: 7568-2144 A

Вам также может понравиться

- Typical Manhole DetailsДокумент1 страницаTypical Manhole DetailsRamadan Rashad100% (1)

- TYPICAL DETAIL DRAWING - SYABAS PC SLab PDFДокумент20 страницTYPICAL DETAIL DRAWING - SYABAS PC SLab PDFBMZОценок пока нет

- BOQ For Construction of Boundary Wall in QTR No. III-31 in Colony Sector at MANIT PDFДокумент2 страницыBOQ For Construction of Boundary Wall in QTR No. III-31 in Colony Sector at MANIT PDFVeena NageshОценок пока нет

- JJ Cruz + Associates S-02: Standard HooksДокумент1 страницаJJ Cruz + Associates S-02: Standard HooksCarlo GarciaОценок пока нет

- Clubhouse Structural NotesДокумент17 страницClubhouse Structural NotesCarlo Doragos100% (1)

- Material & Method Statement: Concrete Repair SystemsДокумент3 страницыMaterial & Method Statement: Concrete Repair SystemsJuris DixonОценок пока нет

- PMC UG WATER TANK & STP Revised-Model - R0 - Approved As Noted - 2022.01.17Документ1 страницаPMC UG WATER TANK & STP Revised-Model - R0 - Approved As Noted - 2022.01.17Ranjan Kumar JenaОценок пока нет

- Investment Cost 1st ConstructionДокумент3 страницыInvestment Cost 1st ConstructionSasheen Dela Cruz100% (1)

- Sheet Size and Sewage Rising Main DetailsДокумент1 страницаSheet Size and Sewage Rising Main DetailsmohdnazirОценок пока нет

- Item Rate Boq: Validate Print HelpДокумент8 страницItem Rate Boq: Validate Print HelpDanish BhatОценок пока нет

- Clotan Steel - Purlin Span LengthsДокумент3 страницыClotan Steel - Purlin Span LengthsColin SillmanОценок пока нет

- BoqДокумент24 страницыBoqsrinivasmantry88Оценок пока нет

- Method Statement For Providing Pipe Sleeve Opening On R.C. BeamДокумент1 страницаMethod Statement For Providing Pipe Sleeve Opening On R.C. Beamhiyumiwks100% (1)

- Mogadishu Hotel-Raft Foundation Layout - 1bДокумент1 страницаMogadishu Hotel-Raft Foundation Layout - 1bdanokrayОценок пока нет

- Reinforced Concrete Boundary Wall DetailДокумент1 страницаReinforced Concrete Boundary Wall DetailGelbert SilotОценок пока нет

- Bsi Eof DWG Cs 150 (0) - Lighting Pole 10m HeightДокумент1 страницаBsi Eof DWG Cs 150 (0) - Lighting Pole 10m HeightdharuОценок пока нет

- Mild Steel BendДокумент5 страницMild Steel BenddialoggbiОценок пока нет

- Spec-High MastДокумент18 страницSpec-High MastHarmandeep AhluwaliaОценок пока нет

- Roadway Kerb DetailsДокумент74 страницыRoadway Kerb DetailsFenner Electromechanical100% (1)

- CC-B2-STR-2102: Approved Approved As Noted Not Required Not Approved Consultant Review CommentsДокумент1 страницаCC-B2-STR-2102: Approved Approved As Noted Not Required Not Approved Consultant Review CommentsirfanquadriОценок пока нет

- Muthiga Apartments Structural Plans 5 Floors-Model5Документ1 страницаMuthiga Apartments Structural Plans 5 Floors-Model5Daniel OkereОценок пока нет

- Concrete Column and Footing Reinforcement DetailsДокумент1 страницаConcrete Column and Footing Reinforcement DetailsAmr HalabyОценок пока нет

- Specification of Works PDFДокумент365 страницSpecification of Works PDFJacqueline TanОценок пока нет

- Stair Handrail Shop DrawingДокумент1 страницаStair Handrail Shop DrawingdantevariasОценок пока нет

- B.o.Q of Baste Shelga BridgeДокумент12 страницB.o.Q of Baste Shelga BridgeAhmed BakrОценок пока нет

- Raft Foundation Bottom B2 Reinforcement Detail PlanДокумент1 страницаRaft Foundation Bottom B2 Reinforcement Detail PlanFatih KoçakОценок пока нет

- 4a Bulk Water Meter Installation in Chamber Drawing - PEWSTDAMI004Документ1 страница4a Bulk Water Meter Installation in Chamber Drawing - PEWSTDAMI004Abey Vettoor100% (2)

- Repair and painting works of Swastik Alps CHSДокумент25 страницRepair and painting works of Swastik Alps CHSSandeep MauryaОценок пока нет

- 33-2018 - Vol-4 & Vol-10 Boq - Add-5Документ31 страница33-2018 - Vol-4 & Vol-10 Boq - Add-5Usman ArifОценок пока нет

- Warehouse DrawingsДокумент6 страницWarehouse DrawingsnokoОценок пока нет

- Air Valve Chamber Details Type (1) For 16 BarsДокумент1 страницаAir Valve Chamber Details Type (1) For 16 BarsHesham Elbana100% (1)

- Workshop Floor Plans and ElevationsДокумент2 страницыWorkshop Floor Plans and ElevationsLouis KiwaОценок пока нет

- Bathroom FittingsДокумент4 страницыBathroom Fittingsdox4printОценок пока нет

- Water Supply & Sanitry DOMBOQДокумент31 страницаWater Supply & Sanitry DOMBOQajay_430Оценок пока нет

- QP10-Q-617 Rev0 Typical Steel StructuresДокумент1 страницаQP10-Q-617 Rev0 Typical Steel StructuresnawajhaОценок пока нет

- Landfill Liners: Types and Importance for Waste IsolationДокумент16 страницLandfill Liners: Types and Importance for Waste IsolationLataBamalОценок пока нет

- Contoh BetonДокумент29 страницContoh Betonnaffian2Оценок пока нет

- H003 76-10526-Detail DesignДокумент1 страницаH003 76-10526-Detail DesignMazen IsmailОценок пока нет

- Di Pipe DrawingsДокумент6 страницDi Pipe DrawingsZatul Akmal ZamilОценок пока нет

- Bridge DrawingДокумент1 страницаBridge DrawingsorowareОценок пока нет

- MS 322 HDPE SDR 11 Nascon Bel Air ClusterДокумент87 страницMS 322 HDPE SDR 11 Nascon Bel Air Clustersasi kОценок пока нет

- Hilti Hit Hy 170Документ37 страницHilti Hit Hy 170Adhil RamsurupОценок пока нет

- Gewan Island Qatar concrete BOQДокумент7 страницGewan Island Qatar concrete BOQabid hamzaОценок пока нет

- Section Section Section: FC Sefc, LLCДокумент1 страницаSection Section Section: FC Sefc, LLCeliu100Оценок пока нет

- Main Gate & Emergency Gate DrawingДокумент2 страницыMain Gate & Emergency Gate DrawingAkil Vahora100% (1)

- Boundary Wall DrawingДокумент1 страницаBoundary Wall DrawingBig Boy ToyzОценок пока нет

- DOE Description & Picture List Price 2020 PDFДокумент127 страницDOE Description & Picture List Price 2020 PDFNizam AmirОценок пока нет

- Saudi Cast Product Catalogue 2017 (Covers & Drains)Документ251 страницаSaudi Cast Product Catalogue 2017 (Covers & Drains)syed mustafa ali100% (4)

- PilesДокумент17 страницPilesntah84Оценок пока нет

- Sewerage Drawings PDFДокумент125 страницSewerage Drawings PDFvenustasia100% (1)

- Calg CDДокумент92 страницыCalg CDMilutinMMОценок пока нет

- Standard DetailsДокумент14 страницStandard DetailsGayan IndunilОценок пока нет

- Footpath Sections All PDFДокумент1 страницаFootpath Sections All PDFANKESH SHRIVASTAVAОценок пока нет

- WSS - 078 Valve Chamber Type A and Type B and Connection To Supply Mains - Air Valves - DetailsДокумент1 страницаWSS - 078 Valve Chamber Type A and Type B and Connection To Supply Mains - Air Valves - DetailssatyamОценок пока нет

- Technical Data Sheet For HIT-HY 170 Injectable Mortar For Anchor in Concrete Technical Information ASSET DOC 4398553Документ31 страницаTechnical Data Sheet For HIT-HY 170 Injectable Mortar For Anchor in Concrete Technical Information ASSET DOC 4398553ing urban100% (2)

- PEB StructuresДокумент36 страницPEB StructuresDass DassОценок пока нет

- Keenagoda BOQ FinalДокумент30 страницKeenagoda BOQ FinalChamin Subhawickrama50% (2)

- Cost For Each Pile CapДокумент4 страницыCost For Each Pile CapGeetashree PaulОценок пока нет

- Picket fence Repainting project scope and bill of quantitiesДокумент5 страницPicket fence Repainting project scope and bill of quantitiesAndrew ArahaОценок пока нет

- ADC Part 10Документ1 страницаADC Part 10Maung PDDОценок пока нет

- Gas Turbine Flow MeterДокумент33 страницыGas Turbine Flow MeterKhabbab Hussain K-hОценок пока нет

- Rotary LightДокумент1 страницаRotary LightKhabbab Hussain K-hОценок пока нет

- 489-100-A SERIES: Features Variations Available Ul ListingsДокумент5 страниц489-100-A SERIES: Features Variations Available Ul ListingsKhabbab Hussain K-hОценок пока нет

- Reliability & Style: ArealДокумент2 страницыReliability & Style: ArealKhabbab Hussain K-hОценок пока нет

- Hydro Testing ProcedureДокумент12 страницHydro Testing ProcedureGaapchuОценок пока нет

- Albany BlankДокумент1 страницаAlbany BlankKhabbab Hussain K-hОценок пока нет

- 580DC05E93116Документ8 страниц580DC05E93116Khabbab Hussain K-hОценок пока нет

- A 48 - A 48M - 03 Qtq4l0e0oe0 - PDFДокумент6 страницA 48 - A 48M - 03 Qtq4l0e0oe0 - PDFfekihassanОценок пока нет

- CraneFS Pipe Fittings Brochure 0416Документ23 страницыCraneFS Pipe Fittings Brochure 0416Nguyễn Hoàng DũngОценок пока нет

- Epdm Gasket: FeaturesДокумент4 страницыEpdm Gasket: FeaturesKhabbab Hussain K-hОценок пока нет

- Brochure AttractДокумент2 страницыBrochure AttractKhabbab Hussain K-hОценок пока нет

- Water and Energy Saving: Ideal Design & PriceДокумент2 страницыWater and Energy Saving: Ideal Design & PriceKhabbab Hussain K-hОценок пока нет

- Topographic Plan-Model PDFДокумент1 страницаTopographic Plan-Model PDFKhabbab Hussain K-hОценок пока нет

- ABRO 3450 Foil/Skrim/Kraft (FSK) Sealing Tape: Product InformationДокумент1 страницаABRO 3450 Foil/Skrim/Kraft (FSK) Sealing Tape: Product InformationKhabbab Hussain K-hОценок пока нет

- DetailДокумент1 страницаDetailKhabbab Hussain K-hОценок пока нет

- HH CatalogueДокумент20 страницHH CatalogueKhabbab Hussain K-hОценок пока нет

- 2290 Aluminum Foil Tape PDFДокумент1 страница2290 Aluminum Foil Tape PDFKhabbab Hussain K-hОценок пока нет

- 11⁄2” & 21⁄2” Synthetic Hose Nozzles Models A, B, CДокумент1 страница11⁄2” & 21⁄2” Synthetic Hose Nozzles Models A, B, CKhabbab Hussain K-hОценок пока нет

- Cy Astm - GüncelДокумент1 страницаCy Astm - GüncelKhabbab Hussain K-hОценок пока нет

- Brochure Accessories PDFДокумент14 страницBrochure Accessories PDFKhabbab Hussain K-hОценок пока нет

- Report 160mm PDFДокумент1 страницаReport 160mm PDFKhabbab Hussain K-hОценок пока нет

- Brochure AccessoriesДокумент2 страницыBrochure AccessoriesKhabbab Hussain K-hОценок пока нет

- (17!12!10) Mechanical Site Inspection Report-1Документ16 страниц(17!12!10) Mechanical Site Inspection Report-1Khabbab Hussain K-hОценок пока нет

- Os&y Valve Detail-1Документ1 страницаOs&y Valve Detail-1Khabbab Hussain K-hОценок пока нет

- ABRO 3450 Foil/Skrim/Kraft (FSK) Sealing Tape: Product InformationДокумент1 страницаABRO 3450 Foil/Skrim/Kraft (FSK) Sealing Tape: Product InformationKhabbab Hussain K-hОценок пока нет

- 2290 Aluminum Foil TapeДокумент1 страница2290 Aluminum Foil TapeKhabbab Hussain K-hОценок пока нет

- Heat Tracing Cable PDFДокумент1 страницаHeat Tracing Cable PDFKhabbab Hussain K-hОценок пока нет

- Gate ValveДокумент1 страницаGate ValveKhabbab Hussain K-hОценок пока нет

- Dear Sir,: Total Price Ex-Our Stores in JD Including Customs & Sales Tax 3,120.00Документ1 страницаDear Sir,: Total Price Ex-Our Stores in JD Including Customs & Sales Tax 3,120.00Khabbab Hussain K-hОценок пока нет

- 6325 Edge Node: Compact Multi-Service Provisioning PlatformДокумент3 страницы6325 Edge Node: Compact Multi-Service Provisioning PlatformEhsan RohaniОценок пока нет

- Wk. 2 Bauhaus - Concepts & Styles - TheArtStoryДокумент3 страницыWk. 2 Bauhaus - Concepts & Styles - TheArtStoryGarrison GerardОценок пока нет

- What Is Meant by Data Communication and ExplainДокумент14 страницWhat Is Meant by Data Communication and ExplainFernando TanginОценок пока нет

- Example - Bearing ReplacementДокумент44 страницыExample - Bearing Replacementyoungc71Оценок пока нет

- Wireless M Bus Quick Start GuideДокумент71 страницаWireless M Bus Quick Start GuideprasanthvvОценок пока нет

- TT37 - Tomb of Harwa in Theban NecropolisДокумент9 страницTT37 - Tomb of Harwa in Theban NecropolisAhmed Tolba100% (1)

- Trox-Drum Jet DiffusersДокумент6 страницTrox-Drum Jet Diffusersshoukat14Оценок пока нет

- Keylogger in CДокумент3 страницыKeylogger in CPrashant UniyalОценок пока нет

- Research and Application of Ajax TechnologyДокумент18 страницResearch and Application of Ajax TechnologySachin Ganesh ShettigarОценок пока нет

- Https Solengreenfieldcity - Weebly.com Model-HousesДокумент65 страницHttps Solengreenfieldcity - Weebly.com Model-HousesLuis S Alvarez JrОценок пока нет

- Instructions For Online Bid SubmissionДокумент3 страницыInstructions For Online Bid Submissionkartik spectomsОценок пока нет

- Daily site report progressДокумент9 страницDaily site report progressVikrant KoulОценок пока нет

- AP6522 Spec SheetДокумент3 страницыAP6522 Spec SheetAdvantec SrlОценок пока нет

- Steps For Construction of Earth RoadsДокумент2 страницыSteps For Construction of Earth RoadsRohit Rangnekar83% (6)

- Districts Alphabetical EastGodavariДокумент23 страницыDistricts Alphabetical EastGodavarirameshraju_nitwОценок пока нет

- Exam JN0-633Документ83 страницыExam JN0-633Haffiz AnugragiriОценок пока нет

- Door Schedule Door TypesДокумент1 страницаDoor Schedule Door TypesPau LlenaОценок пока нет

- Aca Univ 2 Mark and 16 MarkДокумент20 страницAca Univ 2 Mark and 16 MarkmenakadevieceОценок пока нет

- Planting in A Post-Wild World: IndexДокумент11 страницPlanting in A Post-Wild World: IndexTimber Press0% (1)

- NGINX High Performance - Sample ChapterДокумент26 страницNGINX High Performance - Sample ChapterPackt PublishingОценок пока нет

- Common Problems (Complete)Документ26 страницCommon Problems (Complete)junreymorales100% (1)

- Wika LMB Eng Ik CCB Hvac 01Документ22 страницыWika LMB Eng Ik CCB Hvac 01riyadigeng19gmailcomОценок пока нет

- Sterner Infranor Capella-5d Series Brochure 2010Документ8 страницSterner Infranor Capella-5d Series Brochure 2010Alan MastersОценок пока нет

- SAP HANA Security Introduction: Key Concepts & FeaturesДокумент34 страницыSAP HANA Security Introduction: Key Concepts & FeaturesSachin Deo100% (1)

- Aci Structural Journal Mar.-Apr. 2015 v. 112 No. 02Документ146 страницAci Structural Journal Mar.-Apr. 2015 v. 112 No. 02Professor Dr. Nabeel Al-Bayati-Consultant Engineer100% (5)

- Sanghvi Estella BycullaДокумент6 страницSanghvi Estella BycullaMandar KadamОценок пока нет

- Broch Waterproofing Plan 508Документ20 страницBroch Waterproofing Plan 508Bashir SolimanОценок пока нет

- Boris Groys - Self Design and Public SpaceДокумент6 страницBoris Groys - Self Design and Public SpaceMartaОценок пока нет

- DDAL07-12 - in Search of Secrets 1.0 - L14Документ19 страницDDAL07-12 - in Search of Secrets 1.0 - L14CarolynОценок пока нет

- Vulnerability ManagementДокумент87 страницVulnerability ManagementMike Ac100% (3)