Академический Документы

Профессиональный Документы

Культура Документы

Understanding Underground Electric Transmission Cables

Загружено:

fffАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Understanding Underground Electric Transmission Cables

Загружено:

fffАвторское право:

Доступные форматы

Understanding underground electric transmission cables https://electrical-engineering-portal.com/understanding-underground-elec...

Electrical Cable Design Build Electrical Design

By | | | Share!

Home / Technical Articles / Understanding Underground Electric Transmission Cables

Get access to premium

electrical guides, technical

articles and much more!

MORE INFORMATION

Underground cables have different technical

requirements than overhead lines and have different

environmental impacts. Due to their different physical,

environmental, and construction needs, underground

transmission generally costs more and may be more

complicated to construct than overhead lines.

1 of 11 02/01/2019, 5:35 p.m.

Understanding underground electric transmission cables https://electrical-engineering-portal.com/understanding-underground-elec...

distribution

The design and construction of underground

transmission lines differ from overhead lines because

of two significant technical challenges that need to be

overcome. These are:

1. Providing sufficient insulation so that

cables can be within inches of grounded

material.

2. Dissipating the heat produced during

the operation of the electrical cables.

The first underground transmission line

was a 132 kV line constructed in 1927.

The cable was fluid-filled and paper

insulated. The fluid was necessary to

dissipate the heat.

There are two main types of underground transmission

lines currently in use. One type is constructed in a

pipe with fluid or gas pumped or circulated through

and around the cable in order to manage heat and

insulate the cables. The other type is a solid dielectric

cable which requires no fluids or gas and is a more

recent technological advancement.

2 of 11 02/01/2019, 5:35 p.m.

Understanding underground electric transmission cables https://electrical-engineering-portal.com/understanding-underground-elec...

The common types of underground cable

construction include:

1. High-pressure, fluid-filled pipe (HPFF)

2. High-pressure, gas-filled pipe (HPGF)

3. Self-contained fluid-filled (SCFF)

4. Solid cable, cross-linked polyethylene (XLPE)

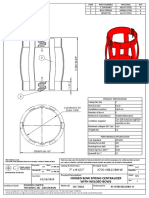

A high-pressure, fluid-filled (HPFF) pipe-type of

underground transmission line, consists of a steel pipe

that contains three high-voltage conductors. Each

conductor is made of copper or aluminum; insulated

with high-quality, oil-impregnated kraft paper

insulation; and covered with metal shielding (usually

lead) and skid wires (for protection during

construction).

Inside steel pipes, three conductors are surrounded by

a dielectric oil which is maintained at 200 pounds per

square inch (psi). This fluid acts as an insulator and

does not conduct electricity. The pressurized dielectric

fluid prevents electrical discharges in the conductors’

insulation. An electrical discharge can cause the line

to fail. The fluid also transfers heat away from the

conductors. The fluid is usually static and removes

heat by conduction. In some situations the fluid is

pumped through the pipe and cooled through the use

of a heat exchanger. Cables with pumped fluids

require aboveground pumping stations, usually located

within substations.

The pumping stations monitor the pressure and

temperature of the fluid. There is a radiator-type

3 of 11 02/01/2019, 5:35 p.m.

Understanding underground electric transmission cables https://electrical-engineering-portal.com/understanding-underground-elec...

any degradation or trouble with the cable materials.

The outer steel pipe protects the conductors from

mechanical damage, water infiltration, and minimizes

the potential for oil leaks. The pipe is protected from

the chemical and electrical environment of the soil by

means of a coating and cathodic protection.

Problems associated with HPFF pipe-type

underground transmission lines include maintenance

issues and possible contamination of surrounding soils

and groundwater due to leaking oil.

The high-pressure, gas-filled (HPGF) pipe-type of

underground transmission line is a variation of the

HPFF pipe-type, described above. Instead of a

dielectric oil, pressurized nitrogen gas is used to

insulate the conductors. Nitrogen gas is less effective

than dielectric fluids at suppressing electrical

discharges and cooling.

4 of 11 02/01/2019, 5:35 p.m.

Understanding underground electric transmission cables https://electrical-engineering-portal.com/understanding-underground-elec...

filled pipes.

Thicker insulation and a warmer pipe reduce the

amount of current the line can safely and efficiently

carry. In case of a leak or break in the cable system,

the nitrogen gas is easier to deal with than the

dielectric oil in the surrounding environment.

The self-contained, fluid-filled (SCFF) pipe-type of

underground transmission is often used for underwater

transmission construction. The conductors are hollow

and filled with an insulating fluid that is pressurized to

25 to 50 psi. In addition, the three cables are

independent of each other. They are not placed

together in a pipe.

Each cable consists of a fluid-filled conductor insulated

with high-quality kraft paper and protected by a lead-

5 of 11 02/01/2019, 5:35 p.m.

Understanding underground electric transmission cables https://electrical-engineering-portal.com/understanding-underground-elec...

The fluid reduces the chance of electrical discharge

and line failure. The sheath helps pressurize the

conductor’s fluid and the plastic jacket keeps the water

out. This type of construction reduces the risk of a

total failure, but the construction costs are much

higher than the single pipe used to construct the

HPFF or HPGF systems.

The cross-linked polyethylene (XLPE) underground

transmission line is often called solid dielectric cable.

The solid dielectric material replaces the pressurized

liquid or gas of the pipe-type cables. XLPE cable has

become the national standard for underground electric

transmission lines less than 200 kV.

There is less maintenance with the solid cable, but

impending insulation failures are much more difficult to

monitor and detect. The diameter of the XLPE cables

increase with voltage. Each transmission line requires

three separate cables, similar to the three conductors

6 of 11 02/01/2019, 5:35 p.m.

Understanding underground electric transmission cables https://electrical-engineering-portal.com/understanding-underground-elec...

ducts or buried side-by-side. Each cable consists of a

copper or aluminum conductor and a semi-conducting

shield at its core.

A cross-linked polyethylene

insulation surrounds the core.

The outer covering of the cable

consists of a metallic sheath and

a plastic jacket.

For 345 kV XLPE construction, two sets of three

cables (six cables) are necessary for a number of

reasons, primarily so that the capacity of the

underground system matches the capacity of the

overhead line. This design aids in limiting the scope of

any cable failure and shortens restoration time in an

emergency situation.

Most underground transmission requires increased

down time for the repair of operating problems or

maintenance issues compared to overhead lines. The

double sets of cables allows for the rerouting of the

power through the backup cable set, reducing the

down time but increases the construction footprint of

the line.

SPONSORED SEARCHES

7 of 11 02/01/2019, 5:35 p.m.

Understanding underground electric transmission cables https://electrical-engineering-portal.com/understanding-underground-elec...

Microgrid Control Lightning protection in GPS is Doomed (No The fundamentals of

Systems a nutshell (design, Joke) protection relay co-

bonding, earthing... ordination and...

Ad SEL electrical-engineering-portal.com Ad XY electrical-engineering-portal.com

Buy live event tickets. Construction & Transformer practice The basic

electrical design of book for electrical understanding of an

400/220/132 KV... engineers earthing protection...

Ad StubHub electrical-engineering-portal.com electrical-engineering-portal.com electrical-engineering-portal.com

Premium membership gives you an access to

specialized technical articles and extra premium

content (electrical guides and software).

GET PREMIUM NOW

Bipul Raman (@BipulRaman)

8 of 11 02/01/2019, 5:35 p.m.

Understanding underground electric transmission cables https://electrical-engineering-portal.com/understanding-underground-elec...

Blogger. Read more at :

https://web.bipul.in

For 3.3kV my existing cable was

single core 240sq.mm PILC it was

Govindaraju failed. no spare cable available. May I

K

A

replace with 3 core 185sq.mm PVC

APPR

R 11 66 ,, 22 00 11 88

cable ?

(reply)

Best

(reply)

Bapi Dey

S

SEEP

P 11

11 ,, 22 00 11 44

9 of 11 02/01/2019, 5:35 p.m.

Understanding underground electric transmission cables https://electrical-engineering-portal.com/understanding-underground-elec...

I am doing a exhibit in my community

about the movement of energy for

Miles kids in my classroom. Is there a way

Huston

A

to obtain a sample sectional piece of

AUG

UG 00 88 ,, 22 00 11 44

one of these large XLPE HV cables

for display?

thanks!

miles

(reply)

I have cu/xlpe/pvc 12/20kV mv

cables. According to your article, I

Lightninglord77can use this as my underground rmu

O

OCCT

T 00 44 ,, 22 00 11 33

supply even its not armored cable or

swa. Please confirm as I will proceed

with this in my time constraint project.

Many thanks

(reply)

Tell us what you're thinking... we care about your

opinion!

YOU R R EAL

YO UR EAL N AME *

EMAIL ADD R ESS

AD DR ESS *

10 of 11 02/01/2019, 5:35 p.m.

Understanding underground electric transmission cables https://electrical-engineering-portal.com/understanding-underground-elec...

SUBMIT COMMENT

© 2019 EEP - Electrical Engineering Portal. All Rights Reserved | Privacy Policy | Terms of Service

The content is copyrighted to EEP and may not be reproduced on other websites.

11 of 11 02/01/2019, 5:35 p.m.

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Cost Estimation Manual For Low Rise Buildings: Bureau of ConstructionДокумент3 страницыCost Estimation Manual For Low Rise Buildings: Bureau of Constructionjhomel garcia100% (1)

- LumberДокумент40 страницLumberjosh dionisio100% (1)

- European HE, IPE, IPN UPN Steel SectionsДокумент5 страницEuropean HE, IPE, IPN UPN Steel SectionsAristotle MedinaОценок пока нет

- Nammcesa 000011 PDFДокумент680 страницNammcesa 000011 PDFBasel Osama RaafatОценок пока нет

- Garrett ManualДокумент1 страницаGarrett ManualdromakiОценок пока нет

- Vertical TransportationДокумент48 страницVertical TransportationTutIk Kusuma WardaniОценок пока нет

- BS 1377part4 90 PDFДокумент49 страницBS 1377part4 90 PDFkranthi13100% (1)

- CURTIS 250 Through 350hp Parts BreakdownДокумент38 страницCURTIS 250 Through 350hp Parts BreakdownrobertОценок пока нет

- ASTM C494, PDF PDFДокумент9 страницASTM C494, PDF PDFMuhammad Zaini Gani100% (10)

- Safety Procedures in ConstructionДокумент21 страницаSafety Procedures in ConstructionMalith De Silva100% (1)

- Astm A572Документ4 страницыAstm A572udaykiranorange100% (2)

- M.tech Curriculum 0Документ49 страницM.tech Curriculum 0Yash DhabaliaОценок пока нет

- Cmat 11Документ4 страницыCmat 11Emmanuel Cafirma RiveraОценок пока нет

- BS 3M 60-1998 (ISO 7169-1998) ScanДокумент21 страницаBS 3M 60-1998 (ISO 7169-1998) ScandokuОценок пока нет

- HMR MDF Board: Inspiration For Living TrendsДокумент2 страницыHMR MDF Board: Inspiration For Living Trendsfazli khaironОценок пока нет

- Alcomet FurseweldOverviewДокумент7 страницAlcomet FurseweldOverviewHemo A AlsharifОценок пока нет

- Ps 0700 0812obh WДокумент1 страницаPs 0700 0812obh WLoreleiОценок пока нет

- Butterfly ValveДокумент4 страницыButterfly ValveFlowBiz Exports Pvt. Ltd.Оценок пока нет

- 4687 - Carrier 30 GF 120Документ36 страниц4687 - Carrier 30 GF 120ชัยณรงค์ เทียนบุตรОценок пока нет

- Abrasion Value of AggregateДокумент4 страницыAbrasion Value of AggregateUsama ChatthaОценок пока нет

- DR KP-JayaДокумент73 страницыDR KP-JayaVinay Sain0% (1)

- TAOM Fact Sheet 9 Geothermal PipelinesДокумент1 страницаTAOM Fact Sheet 9 Geothermal PipelinesTalang AkarОценок пока нет

- Aral Catalouge June 2017 0Документ242 страницыAral Catalouge June 2017 0beboo KhamisОценок пока нет

- Advanced MechanicsДокумент9 страницAdvanced MechanicsIvan MonoОценок пока нет

- Defining Titles and Career Paths in BIMДокумент7 страницDefining Titles and Career Paths in BIMjon_kasilagОценок пока нет

- Stanley CatalogueДокумент33 страницыStanley Cataloguetechb neoОценок пока нет

- Booklet Tier I I PhaseДокумент48 страницBooklet Tier I I PhaseAkhlaq HussainОценок пока нет

- Ejercicio AnexoДокумент20 страницEjercicio AnexoAndres Camilo Hernandez RuizОценок пока нет

- Sensus WP Dynamic Cold Water Meter (DN40-300)Документ4 страницыSensus WP Dynamic Cold Water Meter (DN40-300)Roderikus Rendy MОценок пока нет

- GF Flange PPДокумент8 страницGF Flange PPRosi Nuraeni YusfiОценок пока нет