Академический Документы

Профессиональный Документы

Культура Документы

Fluorseals Ptfe Unfilled: Advertise With Matweb!

Загружено:

Priyadarshini KrishnaswamyОригинальное название

Авторское право

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Fluorseals Ptfe Unfilled: Advertise With Matweb!

Загружено:

Priyadarshini KrishnaswamyАвторское право:

Advertise with MatWeb!

Data sheets for over 130,000 metals, plastics, ceramics, and composites.

HOME • SEARCH • TOOLS • SUPPLIERS • FOLDERS • ABOUT US • FAQ • LOG IN

Searches: Advanced | Category | Property | Metals | Trade Name | Manufacturer | Recently Viewed Materials

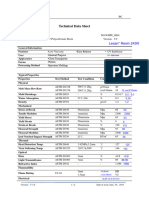

Fluorseals PTFE Unfilled

Categories: Polymer; Thermoplastic; Fluoropolymer; Polytetrafluoroethylene (PTFE); Polytetrafluoroethylene (PTFE),

Molded

Material

Notes: Information provided by TEKU GmbH Fluorkunststoffe, a distributor of Fluorseals materials.

Vendors: Click here to view all available suppliers for this material.

Please click here if you are a supplier and would like information on how to add your listing to this material.

Printer friendly version Download as PDF Download to Excel (requires Excel and Windows)

Export data to your CAD/FEA program Add to Folder: My Folder 0/0

Physical Metric English Comments

Properties

Density 2.15 - 2.18 g/cc 0.0777 - 0.0788 lb/in³ DIN 53479

Deformation 14 % 14 % 14 MPa, 100 h, 23°C; ASTM D621-59

Mechanical Metric English Comments

Properties

Hardness, Shore D 55 - 59 55 - 59 DIN 53505

Ball Indentation 27.0 - 32.0 MPa 3920 - 4640 psi DIN 53456

Hardness

Tensile Strength at 20.0 - 40.0 MPa 2900 - 5800 psi ASTM 1457-69 T

Break

Elongation at Break 250 - 500 % 250 - 500 % ASTM 1457-69 T

Tensile Modulus 0.750 GPa 109 ksi DIN 53457

Flexural Strength 14.0 MPa 2030 psi 3.5% Flexural Stress; DIN 53452

Compressive 10.0 MPa 1450 psi 1% Yield Point; DIN 53454

Strength

18.0 MPa 2610 psi 10% Yield Point; DIN 53454

Izod Impact, 16.0 kJ/m² 7.61 ft-lb/in² DIN EN ISO 197 397

Notched (ISO)

Izod Impact, NB NB DIN EN ISO 197 397

Unnotched (ISO)

Coefficient of 0.23 - 0.27 0.23 - 0.27 v = 1 m/s

Friction, Dynamic

0.25 - 0.28 0.25 - 0.28 v = 1.9 m/s

Abrasion 4.0 4.0 mm of depth after 5 hrs load duration; Partner

Material ST 50

Torsional Stiffness 160 MPa 23200 psi DIN 53447

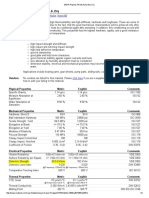

Electrical Metric English Comments

Properties

Volume Resistivity 1.00e+18 ohm-cm 1.00e+18 ohm-cm DIN 53482

Surface Resistance 1.00e+17 ohm 1.00e+17 ohm DIN 53482

Dielectric Constant 2.1 2.1 DIN 53483

@Frequency 50.0 - 100 Hz @Frequency 50.0 - 100 Hz

Dielectric Strength 50.0 - 80.0 kV/mm 1270 - 2030 kV/in VDE 0303 Part 2

@Thickness 0.200 mm @Thickness 0.00787 in

Dissipation Factor 0.000030 0.000030 DIN 53483

@Frequency 1000 Hz @Frequency 1000 Hz

0.000050 0.000050 DIN 53483

@Frequency 50 Hz @Frequency 50 Hz

0.000070 0.000070 DIN 53483

@Frequency 1e+6 Hz @Frequency 1e+6 Hz

<= 0.00010 <= 0.00010 DIN 53483

@Frequency 1000 - 100000 Hz, @Frequency 1000 - 100000 Hz,

Temperature -50.0 - 200 °C Temperature -58.0 - 392 °F

Comparative >= 600 V >= 600 V VDE 0303 Part 1/9.64

Tracking Index

Thermal Metric English Comments

Properties

CTE, linear 160 µm/m-°C 88.9 µin/in-°F DIN 52328

@Temperature 20.0 - 100 °C @Temperature 68.0 - 212 °F

195 µm/m-°C 108 µin/in-°F DIN 52328

@Temperature 20.0 - 200 °C @Temperature 68.0 - 392 °F

250 µm/m-°C 139 µin/in-°F DIN 52328

@Temperature 20.0 - 300 °C @Temperature 68.0 - 572 °F

Specific Heat 0.960 J/g-°C 0.229 BTU/lb-°F adiabatic calorimeter

Capacity @Temperature 0.000 °C @Temperature 32.0 °F

1.03 J/g-°C 0.246 BTU/lb-°F adiabatic calorimeter

@Temperature 50.0 °C @Temperature 122 °F

Thermal >= 0.500 W/m-K >= 3.47 BTU-in/hr-ft²-°F DIN 52612

Conductivity

Melting Point 320 - 340 °C 608 - 644 °F Melting Range; DTA

Maximum Service 260 °C 500 °F Long Term

Temperature, Air

300 °C 572 °F Short Term

Vicat Softening 110 °C 230 °F in air; DIN 53460

Point

Minimum Service -200 °C -328 °F

Temperature, Air

Descriptive Properties

Bending cycles to

>10^6

failure

Heat of Combustion 4600 kJ/kg

Incandescence

Level 1

resistance

Volume change

between r.t. and 27 to 28%

melting range

Volume Change in

5 to 8%

the melting interval

Some of the values displayed above may have been converted from their original units and/or rounded in order to display the information in a consistent format.

Users requiring more precise data for scientific or engineering calculations can click on the property value to see the original value as well as raw conversions to

equivalent units. We advise that you only use the original value or one of its raw conversions in your calculations to minimize rounding error. We also ask that you

refer to MatWeb's terms of use regarding this information. Click here to view all the property values for this datasheet as they were originally entered into MatWeb.

Users viewing this material also viewed the following:

DuPont Performance Polymers Vespel® SP-211 Polyimide, 15% Graphite, 10% Teflon® Filled, Machined

Asahi Glass Fluon® PTFE

DuPont Performance Polymers Vespel® SF-0940 Polyimide Foam, High Density

Ensinger TECASINT 1611 Polyimide, 30% PTFE Filled (PI)

Вам также может понравиться

- Fluorseals PTFE 15% Glass FilledДокумент1 страницаFluorseals PTFE 15% Glass FilledPriyadarshini Krishnaswamy0% (1)

- MaterialData - 56973 2Документ2 страницыMaterialData - 56973 2red_beastОценок пока нет

- Polikim EFALON® T-100 Virgin PTFEДокумент2 страницыPolikim EFALON® T-100 Virgin PTFEPriyadarshini KrishnaswamyОценок пока нет

- T Work9000Документ2 страницыT Work9000Maike SongОценок пока нет

- MAWP Calculation SpreadsheetДокумент9 страницMAWP Calculation SpreadsheetLawrence Osuvwe OfuokuОценок пока нет

- PVC Foam - PropertiesДокумент1 страницаPVC Foam - PropertiesBảo Nghi TrươngОценок пока нет

- TP Wanhua Clarnate A1227 Vs Lexan 243RДокумент2 страницыTP Wanhua Clarnate A1227 Vs Lexan 243RMitja GorseОценок пока нет

- Eriks - Composites Epratex Phenol PDFДокумент1 страницаEriks - Composites Epratex Phenol PDFravindra erabattiОценок пока нет

- Rilsan Fine Powders Physical PropertiesДокумент2 страницыRilsan Fine Powders Physical Propertiesธนาชัย เต็งจิรธนาภาОценок пока нет

- 316 Stainless Steel, Anneal...Документ3 страницы316 Stainless Steel, Anneal...Moisés Vázquez ToledoОценок пока нет

- PLUMBING PIPING MATERIALS (uPVC)Документ10 страницPLUMBING PIPING MATERIALS (uPVC)Imran AzizОценок пока нет

- 1661ff33-51be - ZA - LF2103 Film - EN-ZAДокумент2 страницы1661ff33-51be - ZA - LF2103 Film - EN-ZApepeОценок пока нет

- SABIC Innovative Plastics Lexan® 940 PC: Polymer, Thermoplastic, Polycarbonate (PC)Документ3 страницыSABIC Innovative Plastics Lexan® 940 PC: Polymer, Thermoplastic, Polycarbonate (PC)MRC RailОценок пока нет

- Arsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!Документ2 страницыArsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!David LluguinОценок пока нет

- PTFE Bronze Wear - enДокумент1 страницаPTFE Bronze Wear - enAli AlashryОценок пока нет

- Ultra-Soft Thermal Conductive PadДокумент2 страницыUltra-Soft Thermal Conductive PadArunkumar PBОценок пока нет

- Hojas TécnicasДокумент2 страницыHojas TécnicasalejandrocharlescollОценок пока нет

- Bucha Flangeada Oilite FFM 30x38x20Документ2 страницыBucha Flangeada Oilite FFM 30x38x20GooyОценок пока нет

- Virgin Ptfe: (Polytetrafluoroethylene)Документ1 страницаVirgin Ptfe: (Polytetrafluoroethylene)visvisvisvisОценок пока нет

- Robust Pressure Transmitters T.3: 1.4404 / AISI 316LДокумент4 страницыRobust Pressure Transmitters T.3: 1.4404 / AISI 316LRodica PuscauОценок пока нет

- Ds DMH 600 Ptfe VirginДокумент1 страницаDs DMH 600 Ptfe VirginMuhammad Ejaz QureshiОценок пока нет

- SABIC Innovative Plastics Cycoloy C6200 PCABSДокумент3 страницыSABIC Innovative Plastics Cycoloy C6200 PCABSLex WangОценок пока нет

- Technical Data Sheet - Steel Cord FR GradeДокумент2 страницыTechnical Data Sheet - Steel Cord FR Gradeamol1321Оценок пока нет

- Mitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedДокумент2 страницыMitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedJuan Orlando Loaiza MurilloОценок пока нет

- Fisa Tehnica Bond PVDFДокумент1 страницаFisa Tehnica Bond PVDFionut ionutОценок пока нет

- PHE SelectionsДокумент67 страницPHE SelectionsSelva Kumar Selva KumarОценок пока нет

- 0001 - POLYFOAM Super (Gen) 09-30.11.2020Документ1 страница0001 - POLYFOAM Super (Gen) 09-30.11.2020Meeran MohamedОценок пока нет

- ChainДокумент2 страницыChainmyusuf_engineerОценок пока нет

- 304 Stainless SteelДокумент3 страницы304 Stainless Steelnum fistismОценок пока нет

- POM Diet: Polyacetale, Copolymer, Standard Colour: WhiteДокумент1 страницаPOM Diet: Polyacetale, Copolymer, Standard Colour: WhitemorchedtounsiОценок пока нет

- Nylacast Moly Cast Nylon 6, MoS2 FilledДокумент3 страницыNylacast Moly Cast Nylon 6, MoS2 Filledprasad.jppmОценок пока нет

- Desmodur TTX1xxMOCA 83 To 95 Shore AДокумент2 страницыDesmodur TTX1xxMOCA 83 To 95 Shore AFrench CorvetteОценок пока нет

- FT - Ventiladores - 3550 - 734 - Nova VersãoДокумент9 страницFT - Ventiladores - 3550 - 734 - Nova VersãoCésarBaptistaОценок пока нет

- PRESOTATO S4320 TecsisДокумент2 страницыPRESOTATO S4320 TecsisRolando Jara YoungОценок пока нет

- Bidirectional Orifice Without Bevel - Thickness: 0.25 To 0.5 Mm. Unidirectional Orifice With Bevel 0.5 To 1.25 MMДокумент2 страницыBidirectional Orifice Without Bevel - Thickness: 0.25 To 0.5 Mm. Unidirectional Orifice With Bevel 0.5 To 1.25 MMMarcel BaliñoОценок пока нет

- Somos PerFORM SS-PDS Letter PDFДокумент2 страницыSomos PerFORM SS-PDS Letter PDFAdriano AraujoОценок пока нет

- Tds PBT 1130Документ2 страницыTds PBT 1130Huyền VũОценок пока нет

- Aluminum 7175 T736Документ3 страницыAluminum 7175 T736TylerLALA100% (1)

- Ptfe Data SheetДокумент1 страницаPtfe Data SheetEko PrastyoОценок пока нет

- PTFE 25% Carbon FilledДокумент1 страницаPTFE 25% Carbon FilledIan Putra Adita WibisanaОценок пока нет

- Wanhua PC Injection Moulding 20 Mfi Clarnate A1227Документ2 страницыWanhua PC Injection Moulding 20 Mfi Clarnate A1227lucasОценок пока нет

- Covestro Bayblend® FR3000 PC - ABS BlendДокумент2 страницыCovestro Bayblend® FR3000 PC - ABS Blendavinashchauhan2695Оценок пока нет

- Technical Data SheetДокумент2 страницыTechnical Data SheetLeductoan LeОценок пока нет

- Pre Applied Loosely Laid PVC Membrane RevДокумент1 страницаPre Applied Loosely Laid PVC Membrane Revmukesh patelОценок пока нет

- Datasheet Cast Acrylic Sheet enДокумент1 страницаDatasheet Cast Acrylic Sheet entrippОценок пока нет

- Tecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)Документ1 страницаTecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)David Matthew Kurniawan BEngОценок пока нет

- Scanned DocumentsДокумент1 страницаScanned DocumentsCivil structureОценок пока нет

- Grade: St900 DM311: Polypropylene CompoundДокумент1 страницаGrade: St900 DM311: Polypropylene Compoundhugo santiago chavez godoyОценок пока нет

- TDS Co-3-X 27 03 2018 (003) - 1687274055Документ2 страницыTDS Co-3-X 27 03 2018 (003) - 1687274055KSXОценок пока нет

- Free SpanДокумент1 страницаFree Spanatma82419Оценок пока нет

- Aluminum 1060-Data-SheetДокумент2 страницыAluminum 1060-Data-SheetMaruda8382Оценок пока нет

- Tds A1105 en 2017pdfpdfДокумент2 страницыTds A1105 en 2017pdfpdfagungОценок пока нет

- Desmodur TD6xx Based SystemsДокумент2 страницыDesmodur TD6xx Based SystemsKris SzongОценок пока нет

- Lanxess Durethan B 30 S 000000 Astm enДокумент2 страницыLanxess Durethan B 30 S 000000 Astm enJoan GnanaoliОценок пока нет

- Dow Ldpe 0 75 Mfi Non Slip 310eДокумент3 страницыDow Ldpe 0 75 Mfi Non Slip 310eaman.chaudhary3663Оценок пока нет

- PA 6.6 Nylon 6.6Документ2 страницыPA 6.6 Nylon 6.6Naeem KhanОценок пока нет

- Stainless Steel 1.4404 316lДокумент3 страницыStainless Steel 1.4404 316lDilipSinghОценок пока нет

- Stainless Steel 1.4404 316lДокумент3 страницыStainless Steel 1.4404 316lDilipSinghОценок пока нет

- Module 8Документ12 страницModule 8Vallapureddy VenkateshОценок пока нет

- General Properties: Viton® A - 66% Fluorine Chemical Resistance - GOODДокумент2 страницыGeneral Properties: Viton® A - 66% Fluorine Chemical Resistance - GOODpradeep315Оценок пока нет

- Module 3Документ54 страницыModule 3charusat09Оценок пока нет

- Clausius InequalityДокумент53 страницыClausius InequalityNandhanОценок пока нет

- Second Law of ThermodynamicsДокумент40 страницSecond Law of ThermodynamicscaptainhassОценок пока нет

- Viton O Ring TDSДокумент2 страницыViton O Ring TDSPriyadarshini KrishnaswamyОценок пока нет

- HSN/HNBR O-RingsДокумент2 страницыHSN/HNBR O-RingsPriyadarshini KrishnaswamyОценок пока нет

- Work and HeatДокумент12 страницWork and HeatAmit Singh DehuryОценок пока нет

- Pure SubstanceДокумент42 страницыPure SubstanceNitin KumarОценок пока нет

- Nptel - Iitm.ac - in Courses Webcourse-Contents IISc-BANG Basic Thermodynamics PDF Module 1Документ32 страницыNptel - Iitm.ac - in Courses Webcourse-Contents IISc-BANG Basic Thermodynamics PDF Module 1lakumas15Оценок пока нет

- RAC Lecture 4Документ14 страницRAC Lecture 4api-3734466Оценок пока нет

- Beams On Elastic FoundationДокумент6 страницBeams On Elastic FoundationTRI MULYANTOОценок пока нет

- Module 5Документ17 страницModule 5captainhassОценок пока нет

- Material Report: Compound Data SheetДокумент2 страницыMaterial Report: Compound Data SheetPriyadarshini KrishnaswamyОценок пока нет

- Astm D139 PDFДокумент4 страницыAstm D139 PDFPriyadarshini KrishnaswamyОценок пока нет

- Apple Rubber Chart - Hot Topics PDFДокумент2 страницыApple Rubber Chart - Hot Topics PDFPriyadarshini KrishnaswamyОценок пока нет

- PARKER - Oring HandBookДокумент96 страницPARKER - Oring HandBookLuis AparcanaОценок пока нет

- Viton O Ring TDSДокумент2 страницыViton O Ring TDSPriyadarshini KrishnaswamyОценок пока нет

- Apple Rubber Chart - Hot Topics PDFДокумент2 страницыApple Rubber Chart - Hot Topics PDFPriyadarshini KrishnaswamyОценок пока нет

- Astm D4462-90Документ2 страницыAstm D4462-90Priyadarshini KrishnaswamyОценок пока нет

- ASTMДокумент6 страницASTMHTCОценок пока нет

- Astm D4462-90Документ2 страницыAstm D4462-90Priyadarshini KrishnaswamyОценок пока нет

- Astm D139 PDFДокумент4 страницыAstm D139 PDFPriyadarshini KrishnaswamyОценок пока нет

- D 471 - 06 PDFДокумент13 страницD 471 - 06 PDFLC Chong100% (1)

- Astm D4462-90Документ2 страницыAstm D4462-90Priyadarshini KrishnaswamyОценок пока нет

- Astm D395 PDFДокумент6 страницAstm D395 PDFümit özkan100% (1)

- Astm D572 PDFДокумент4 страницыAstm D572 PDFPriyadarshini KrishnaswamyОценок пока нет

- Experiment-3 Study of Critical Heat Flux (Boiling Heat Transfer)Документ7 страницExperiment-3 Study of Critical Heat Flux (Boiling Heat Transfer)Mukul ChandraОценок пока нет

- An Introduction To The Electronic Structure of Atoms and MoleculesДокумент169 страницAn Introduction To The Electronic Structure of Atoms and MoleculesCá Rô Châu MỹОценок пока нет

- Control of Epoxy Creep Using Graphene: Full PapersДокумент7 страницControl of Epoxy Creep Using Graphene: Full PapersPaulo SantosОценок пока нет

- API 570 - Mockup OP - Paper 2 + MДокумент13 страницAPI 570 - Mockup OP - Paper 2 + MShanawas Abdul Razak80% (5)

- LITERATUREДокумент27 страницLITERATUREArun VОценок пока нет

- Filler Metal P92Документ33 страницыFiller Metal P92Elisa del RealОценок пока нет

- NTC 2008 Ex002 PDFДокумент5 страницNTC 2008 Ex002 PDFputra wiraОценок пока нет

- Engineering Science - Static Engineering SystemsДокумент8 страницEngineering Science - Static Engineering SystemsSteven GoddardОценок пока нет

- Finite Element Procedure To Simulate Sandwich Structure With An Auxetic Core Under Impact Loading Using ABAQUS/ExplicitДокумент11 страницFinite Element Procedure To Simulate Sandwich Structure With An Auxetic Core Under Impact Loading Using ABAQUS/ExplicitInternational Journal of Advances in Applied Sciences (IJAAS)Оценок пока нет

- Parison of Dia para FerroДокумент4 страницыParison of Dia para FerroMUNAZIRR FATHIMA FОценок пока нет

- Nature of Reservoir Fluids Phase Behaviour of Reservoir FluidsДокумент83 страницыNature of Reservoir Fluids Phase Behaviour of Reservoir FluidsAnonymous qaI31HОценок пока нет

- Problem Set No. 1Документ2 страницыProblem Set No. 1russelpagaoОценок пока нет

- Kinetic Theory of An Ideal GASДокумент45 страницKinetic Theory of An Ideal GASTâm NguyễnОценок пока нет

- Aluminium Plate SuppliersДокумент15 страницAluminium Plate Supplierssanghvi overseas incОценок пока нет

- Steel-Conceret Composite Girder Bridge 2016Документ83 страницыSteel-Conceret Composite Girder Bridge 2016Muchtar SufaatОценок пока нет

- Astm D4833-07Документ4 страницыAstm D4833-07Jluis Ipn100% (1)

- Part1 Static 1 1Документ12 страницPart1 Static 1 1Hemn Rafiq TofiqОценок пока нет

- Littelfuse LED Protector PLED Ultra Low Holding Current Datasheet PDFДокумент4 страницыLittelfuse LED Protector PLED Ultra Low Holding Current Datasheet PDFEsas ElektronikОценок пока нет

- QuestionnaireДокумент6 страницQuestionnaireElaine Carmelle Bernate DacanayОценок пока нет

- Me2351 GDJPДокумент193 страницыMe2351 GDJPkalaiОценок пока нет

- Properties Measurement/pvtДокумент22 страницыProperties Measurement/pvtNurwani Hussin87% (15)

- Flow Under Sluice Gate & Demonstration of H.Jump & Flow Over A Triangular WeirДокумент12 страницFlow Under Sluice Gate & Demonstration of H.Jump & Flow Over A Triangular WeirGertjan DuniceriОценок пока нет

- Assignment 4Документ33 страницыAssignment 4عمر صرانОценок пока нет

- Bernoulli Chapter 3 PDFДокумент45 страницBernoulli Chapter 3 PDFMirrovshan SagdullaevОценок пока нет

- SUMMER VACATION Chemistry 9Документ7 страницSUMMER VACATION Chemistry 9jshndОценок пока нет

- Gaussian Disorder ModelДокумент40 страницGaussian Disorder ModelJC XmanОценок пока нет

- T-Roff Girder DesignДокумент41 страницаT-Roff Girder Designlinda100% (1)

- 2018 Summer Model Answer PaperДокумент19 страниц2018 Summer Model Answer PaperVineet Chaudhari VCОценок пока нет

- CompressorsДокумент43 страницыCompressorsyashvantОценок пока нет

- Unionocel Big-New enДокумент24 страницыUnionocel Big-New encristi_amaОценок пока нет