Академический Документы

Профессиональный Документы

Культура Документы

Evaluare Risk Motoferastrau

Загружено:

Dan DumbravescuИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Evaluare Risk Motoferastrau

Загружено:

Dan DumbravescuАвторское право:

Доступные форматы

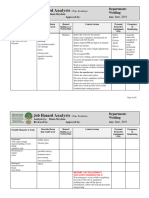

Plant and Equipment Risk Management Form

1. Hazard Management Details – General

Plant/Equipment Item: Chainsaw (Electric) Make/Model No.: Serial No.:

School / Work Location: Region:

Name of Person(s) Conducting Activity: Date Conducted:

Description of Use: Summary of Key Risks:

(refer to appropriate subsections)

An electric chainsaw is a cutting tool

used to cut wooden materials such as Entanglement

logs or branches. A small engine

Impact and cutting

drives a circular chain at speed

around a fixed arm. The chain has Electrical

cutting devices located at fixed Ergonomics

intervals along its length. Noise

Vibration

Slips/trips/falls

Temperature

Other (dust)

Last Updated: 21 August 2018

Plant and Equipment Risk Management Form

2. Documentation

Relevant Legislation/Standards Y/N Comments

Is plant required to be registered? Y N

Is a user license required? Y N

Key Reference material AS 2726.1 Chainsaws - Safety requirements - Chainsaws for general use

AS 2726.2 Chainsaws - Safety requirements - Chainsaws for tree service

AS 2727 Chainsaws- Guide to safe working practices

AS 4024.1 Safety of machinery

AS/NZS 3760 In service safety inspection and testing of electrical equipment

AS/NZS 60745.1 Hand-held motor-operated electric tools - Safety - General requirements

Plant Documentation Y/N Comments

Are operator’s manuals accessible? Y N

Is this a restricted use item? Y N

Does this item require safe use Y N

documents/test?

Chainsaw (Electric) Risk Management Form Page | 2

Plant and Equipment Risk Management Form

3. Hazard Identification

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

ENTANGLEMENT Major Possible Medium Long hair, items of Ensure that clothing, gloves, or

Can anyone’s hair, clothing, gloves, cleaning clothing or other other such items are kept clear

brushes, tools, rags or other materials materials could become of the moving parts when in

become entangled with moving parts of the entangled with the use.

plant or materials? moving chain. Overalls can be used to

restrict loose clothing.

Y N

Ensure gloves are well

fitted.

Plan your work, ensure that

work area is obstacle-free and,

in case of felling, and identify an

escape path from falling trees.

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

IMPACT AND CUTTING INJURIES The chain saw blade may Ensure operator’s hands and

Can anyone be crushed/cut/struck etc. due become stuck creating body parts are kept clear of

to: significant torque with the moving parts during operation

Material falling off the plant? Y N potential for unexpected and maintenance.

movement of the chain

Uncontrolled/unexpected movement of Major Possible High saw. Ensure that operator has been

Y N

plant/load? trained in safe work practices

Lack of capacity to slow, stop or Branches and tree trunks and has appropriate PPE. For

Y N

immobilise plant? may not fall to the ground example:

The plant tipping or rolling over? Y N in the direction intended. Helmet with face visor or

safety glasses

Parts of the plant disintegrating or

Y N Ear protection

collapsing?

Chainsaw (Electric) Risk Management Form Page | 3

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Contact with moving parts during testing, Major Possible High Chips and dust may fly Protective overalls

inspection, operation, maintenance, Y N into the face and eyes of Closed footwear with good

cleaning or repair? the operator. grip.

Being thrown off or under the plant? Y N

Poorly fitted, maintained Ensure the equipment is

Contact with sharp or flying objects? Moderate Possible High or damaged saw blades appropriately maintained and

Y N

(e.g. work pieces being ejected) increases the risk to the serviced regularly in accordance

The mobility of the plant? Y N operator. with manufacturer’s instructions.

Inappropriate parts and accessories Ensure the chain saw is

Y N The chain saw presents

being used? provided with a front hand

risks to the operator if the

Other guard. In a kickback situation

plant is not isolated

during testing, inspection, (where the saw jumps or jerks

Y N maintenance or cleaning. up or backwards) this guard

helps protect the operator’s left

hand or other parts of his/her

body.

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

SHEARING

Can anyone’s body parts be sheared

between two parts of plant, or between a Y N

part of the plant and a work piece or

structure?

PRESSURISED CONTENT

Can anyone come into contact with fluids or

Y N

gases under high pressure, due to plant

failure or misuse of the plant?

ELECTRICITY Damaged or frayed Operator to check for damaged

Can anyone be injured or burnt due to: electrical cords pose an electrical cords prior to use.

Live electrical conductors? (e.g. exposed electrical hazard.

Y N

wires) Operator to exercise vigilance in

Chainsaw (Electric) Risk Management Form Page | 4

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Working in close proximity to electrical Operator may location and positioning of

Y N

conductors? inadvertently cut through electric lead.

Access to electricity? Major Possible High electric lead.

Y N Avoid using chain saw in wet

Damaged or poorly maintained electrical Major Possible High Operation of the weather.

Y N equipment in a wet

leads, cables or switches?

Water near electrical equipment? Major Possible High environment may pose an Ensure equipment is serviced

Y N electrical hazard. on a regular basis, tested and

Lack of isolation procedures? tagged and appropriate isolation

Y N procedures (e.g. lock out tags)

are in place.

Other

Y N

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

ERGONOMICS The use of the chain saw Conduct a risk assessment in

Can anyone be injured due to: may involve repetitive relation to awkward postures

Poorly designed workstation? body movements, and manual handling risk prior

Y N awkward positions and the to undertaking task.

Repetitive body movement? Minor Unlikely Low need for excessive effort.

Y N Ensure the operator uses good

Constrained body posture or the need Moderate Possible Medium manual handling techniques

Y N whilst operating the chainsaw.

for excessive effort?

Design deficiency causing psychological

Y N DO NOT cut above shoulder

stress?

height.

Inadequate or poorly placed lighting?

Y N

Hold the chain saw firmly with

Does the plant impact on the

both hands and maintain a

surrounding workplace and create

secure grip to avoid kickbacks.

potential hazards? (Consider potential Y N

impact on the design and layout of the

workplace)

Chainsaw (Electric) Risk Management Form Page | 5

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Is the location of the plant inappropriate?

(Consider potential effects due to Y N

environmental conditions and terrain)

Other

Y N

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

RADIATION

Can anyone using the plant, or in the vicinity

of the plant suffer injury or illness due to

exposure to radiation in the form of any of

the following: Y N

infra-red radiation

ultra violet light

microwaves

NOISE Moderate Possible Medium Operation of the plant Ensure appropriate hearing

Can anyone using the plant, or in the vicinity equipment can result in protection is worn whilst

Y N

of the plant, suffer injury due to exposure to high noise levels. operating the chain saw.

noise?

Chainsaw (Electric) Risk Management Form Page | 6

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

VIBRATION Moderate Possible Medium The vibration from Use a chainsaw with anti-

Can anyone be injured or suffer ill-health chainsaws can cause vibration mountings and

from exposure to vibration? damage to the hands if ergonomically-angled handles.

they are used for long

periods at a time. Take regular breaks from

continuous operation.

Y N

Wear appropriate PPE (e.g.

gloves) especially in cold

weather.

Sharpen the chainsaw regularly

to ensure smoother cutting and

less vibration.

FRICTION

Can anyone be burnt due to contact with

Y N

moving parts, materials or surfaces of the

plant?

SUFFOCATION

Can anyone be suffocated due to lack of Y N

oxygen, or atmospheric contamination?

CONDITION

Is a hazard likely due to the age and

condition of the plant? (Consider how hard Y N

the machine has been worked, and whether

it is used constantly or rarely).

Can anyone be injured as a result of the

plant not serviced appropriately and/or

maintained in line with manufacturer’s Y N

recommendations?

Chainsaw (Electric) Risk Management Form Page | 7

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

SLIPS/TRIPS/FALLS Due to the uncontrolled Operator to inspect work

Can anyone using the plant, or in the vicinity outdoor environment and environment for hazards prior to

of the plant, slip, trip or fall due to: diverse range of commencing work.

Uneven, slippery or steep work Major Possible High circumstances that the

Y N

surfaces? chain saw may be Ensure the chain saw comes to

Poor housekeeping, e.g. spillage in the Major Possible High operated in, there is a a complete stop before moving

Y N slip, trip and fall risk to or placing the chainsaw down.

vicinity?

Obstacles being placed in the vicinity of Major Possible High the operator.

Y N Ensure appropriate working at

the plant?

Inappropriate or poorly maintained floor Major Possible High heights risk controls are in place

or walking surfaces (i.e. lack of a slip- when working from a ladder or

Y N work platform.

resistant surface, unprotected holes,

penetrations or gaps?)

If operating or maintaining plant at height Wear appropriate footwear.

can anyone slip, trip or fall due to:

Use of work platforms, stairs or ladders? Major Possible High

Y N

Lack of guardrails or other suitable edge

Y N

protection?

Other

Y N

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

FIRE AND EXPLOSION

Y N

Can anyone be injured by fire?

Can anyone be injured by explosion of

gases, vapours, liquids, dusts, or other Y N

substances?

Chainsaw (Electric) Risk Management Form Page | 8

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

TEMPERATURE/MOISTURE The chain can get hot Ensure appropriate PPE is used

Can anyone come into contact with objects Y N during repeated operation. (e.g. gloves and overalls).

at high or low temperatures?

Can anyone suffer ill-health due to Minor Possible Medium

Y N

exposure to high or low temperatures?

Can anyone be injured or suffer ill-health

Y N

due to exposure to moisture?

OTHER The operation of the chain Ensure the chain saw is only

Can anyone be injured or suffer ill-health saw may produce dust. used where there is adequate

from exposure to: ventilation.

Chemicals? Y N

Toxic gases or vapours? Y N

Fumes/Dusts? Y N Minor Possible Medium

Other? (please specify) Y N

4. Risk Assessment Signoff

Authorised By: Signature: Date:

Chainsaw (Electric) Risk Management Form Page | 9

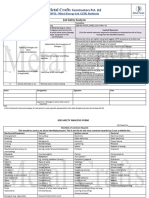

Plant and Equipment Risk Management Form

1. Consequence - Evaluate the consequences of a risk occurring according 2. Likelihood - Evaluate the likelihood of an incident occurring according to the

to the ratings in the top row ratings in the left hand column

Descriptor Level Definition

Descriptor Level Definition

Rare 1 May occur somewhere, sometime (“once in a life time /

Insignificant 1 No injury once in a hundred years”)

Minor 2 Injury/ ill health requiring first aid Unlikely 2 May occur somewhere within the Department over an

extended period of time

Moderate 3 Injury/ill health requiring medical

attention Possible 3 May occur several times across the Department or a

region over a period of time

Major 4 Injury/ill health requiring hospital

admission Likely 4 May be anticipated multiple times over a period of time

May occur once every few repetitions of the activity or

Severe 5 Fatality event

Almost 5 Prone to occur regularly

3. Risk level - Calculate the level of risk by finding the intersection between the

Certain It is anticipated for each repetition of the activity of event

likelihood and the consequences

Likelihood Consequence 4. Risk Level/Rating and Actions

Insignificant Minor Moderate Major Severe Descriptor Definition

Almost Medium High Extreme Extreme Extreme

Certain

Likely Medium Medium High Extreme Extreme Extreme: Notify Workplace Manager and/or Management OHS

Possible Low Medium Medium High Extreme Nominee immediately. Corrective actions should be taken

Unlikely Low Low Medium Medium High immediately. Cease associated activity.

Rare Low Low Low Medium Medium High: Notify Workplace Manager and/or Management OHS

Nominee immediately. Corrective actions should be taken

within 48 hours of notification.

Medium: Notify Nominated employee, HSR / OHS Committee.

Nominated employee, OHS Representative / OHS Committee

is to follow up that corrective action is taken within 7 days.

Low Notify Nominated employee, HSR / OHS Committee.

Nominated employee, HSR / OHS Committee is to follow up

that corrective action is taken within a reasonable time.

Chainsaw (Electric) Risk Management Form Page | 10

Вам также может понравиться

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralДокумент9 страницPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDan Dumbravescu100% (1)

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralДокумент11 страницPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralAlejandro Campomar100% (1)

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralДокумент11 страницPlant and Equipment Risk Management Form: 1. Hazard Management Details - Generalum erОценок пока нет

- Plant and Equipment Risk Management Form: Plant/Equipment Item: High Pressure Water Cleaner Make/Model No.: Serial No.Документ9 страницPlant and Equipment Risk Management Form: Plant/Equipment Item: High Pressure Water Cleaner Make/Model No.: Serial No.Letlape SamuelОценок пока нет

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralДокумент10 страницPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralsamОценок пока нет

- Stivuitor ElectricДокумент10 страницStivuitor ElectricDan DumbravescuОценок пока нет

- Hand and Power Tools Safety PDFДокумент18 страницHand and Power Tools Safety PDFTim YapОценок пока нет

- CNC Maching Ceneter Risk MGT FormДокумент8 страницCNC Maching Ceneter Risk MGT FormAhsan RiazОценок пока нет

- JHA MaintenanceДокумент9 страницJHA Maintenancejherson gravidesОценок пока нет

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralДокумент9 страницPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralJigar VekariyaОценок пока нет

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralДокумент9 страницPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralJigar VekariyaОценок пока нет

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralДокумент11 страницPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralAlejandro CampomarОценок пока нет

- Hydraulic Press Risk MG T FormДокумент10 страницHydraulic Press Risk MG T FormAndrei VОценок пока нет

- Ransburg 76652 01 - 04Документ24 страницыRansburg 76652 01 - 04enticoОценок пока нет

- JHA Welding Pipe BenderДокумент2 страницыJHA Welding Pipe Bendermohammad arshadОценок пока нет

- 17-Using Portable Power ToolsДокумент2 страницы17-Using Portable Power Toolshsse.maltaОценок пока нет

- Estudio EEUU Accidentes MotosierraДокумент2 страницыEstudio EEUU Accidentes MotosierraPedro David Pacheco MoraОценок пока нет

- Screen Cutting Tool - Reviewed - Photo AddedДокумент4 страницыScreen Cutting Tool - Reviewed - Photo AddedAchuuОценок пока нет

- SSERC RAPlastic Trimming 240516Документ3 страницыSSERC RAPlastic Trimming 240516Shoaib ManzoorОценок пока нет

- r12 3000 Rectifier Um1r123000Документ22 страницыr12 3000 Rectifier Um1r123000Pradeep UpadhyayОценок пока нет

- ELEMENT 9 Work Equipment1Документ24 страницыELEMENT 9 Work Equipment1Aaquil RaziОценок пока нет

- Melab 2 Final ReportДокумент5 страницMelab 2 Final ReportVierzon TiamzonОценок пока нет

- Plant and Equipment Risk Assessment Fgoc - NewДокумент12 страницPlant and Equipment Risk Assessment Fgoc - Newmajid khanОценок пока нет

- RA04 General Office EquipmentДокумент3 страницыRA04 General Office EquipmentM Hammad KothariОценок пока нет

- Arc - Jha No. 2016-0001 - Swro-1 Co2 Dehumidifier Defect RectificationДокумент1 страницаArc - Jha No. 2016-0001 - Swro-1 Co2 Dehumidifier Defect RectificationarulsethuОценок пока нет

- PEOLevel2SampleChapter PDFДокумент40 страницPEOLevel2SampleChapter PDFFiona EdwardesОценок пока нет

- Serra Mármore - DeWALT - DW860 - Manual de InstruçõesДокумент28 страницSerra Mármore - DeWALT - DW860 - Manual de Instruçõesmazzalimania0% (1)

- Dewalt d25601 Manual de UsuarioДокумент39 страницDewalt d25601 Manual de UsuarioLUIS GERARDO URREA JIMENEZОценок пока нет

- Angle Polisher Variable Speed Pulidora Angular Velocidad VariableДокумент20 страницAngle Polisher Variable Speed Pulidora Angular Velocidad VariableBrian TorresОценок пока нет

- En FR de It NL Es PT Da El TRДокумент32 страницыEn FR de It NL Es PT Da El TRMaría Giménez MugicaОценок пока нет

- 188524-01, DW502 DW504 La - EngДокумент9 страниц188524-01, DW502 DW504 La - EngCilvio LewlawskyjОценок пока нет

- Op Test PaperДокумент7 страницOp Test PaperSynergy Dato co A member of Synergy GroupОценок пока нет

- Workshop One Notes-1Документ40 страницWorkshop One Notes-1jeff madibaОценок пока нет

- Job Safety Manual Form ExampleДокумент1 страницаJob Safety Manual Form ExampleUmer Farooque AligarhianОценок пока нет

- Operator'S Manual Manuel de L'Utilisateur Manual Del OperadorДокумент13 страницOperator'S Manual Manuel de L'Utilisateur Manual Del OperadorAbnesis NesisОценок пока нет

- Portable Power Tools - Risk Assessment2Документ3 страницыPortable Power Tools - Risk Assessment2Basit Nawaz100% (1)

- Festool RO 150 E ManualДокумент21 страницаFestool RO 150 E ManualpatriciaОценок пока нет

- TA-Replacing Floor TilesДокумент8 страницTA-Replacing Floor TilesShannon MooreОценок пока нет

- RISK ASSESSMENT Cleaning TankДокумент5 страницRISK ASSESSMENT Cleaning TankYoussef HdiaОценок пока нет

- C99131613 DV18V 806Документ8 страницC99131613 DV18V 806Rachel Du PreezОценок пока нет

- JSA PlumberДокумент2 страницыJSA PlumberNaresh KumarОценок пока нет

- JsaДокумент13 страницJsaArnold Roy Coballes Manalo100% (1)

- Jsa-006 Use of Hand Power ToolsДокумент2 страницыJsa-006 Use of Hand Power ToolsDamien MonizeОценок пока нет

- Qualcast 1300W Lawn Rake and Scarifier: Instruction ManualДокумент28 страницQualcast 1300W Lawn Rake and Scarifier: Instruction ManualArmoured SmilerОценок пока нет

- PC 250 MTДокумент36 страницPC 250 MTTerrmosTerrmosОценок пока нет

- GRADE-10 TLE Electronic Products Assembly and Servicing Week OneДокумент15 страницGRADE-10 TLE Electronic Products Assembly and Servicing Week OneSer Takeshi100% (1)

- Doable Guide For Electrical Tools and Instruments in EIM NCIIДокумент9 страницDoable Guide For Electrical Tools and Instruments in EIM NCIIJA BlairОценок пока нет

- Nsid 415 Manual T15Документ17 страницNsid 415 Manual T15Sebastian GutiérrezОценок пока нет

- Risk AssessmentДокумент2 страницыRisk AssessmentTop EventsОценок пока нет

- Sop Drill Electric HandДокумент2 страницыSop Drill Electric HandLOCAL ExplorerОценок пока нет

- Quarter 1 Week 1 FinalДокумент10 страницQuarter 1 Week 1 FinalEl G. Se ChengОценок пока нет

- Excavation (Company Name) : Safe Work Plan (SWP) /phase Hazard Analysis (Pha)Документ11 страницExcavation (Company Name) : Safe Work Plan (SWP) /phase Hazard Analysis (Pha)PABITRA PANDAОценок пока нет

- 4297 1kibiyckvghjtgdxhjvДокумент25 страниц4297 1kibiyckvghjtgdxhjvalejandro.morenoОценок пока нет

- TA-Replacing Floor TilesДокумент8 страницTA-Replacing Floor TilesShannon MooreОценок пока нет

- Basics of Equipment Guarding: Mining and Petroleum Training ServiceДокумент51 страницаBasics of Equipment Guarding: Mining and Petroleum Training ServiceKim Lien TrinhОценок пока нет

- Measurements 1 PDFДокумент164 страницыMeasurements 1 PDFgiangОценок пока нет

- JSA 03-Rev.02 - BlindingDebliding Under Nitrogen PurgingДокумент2 страницыJSA 03-Rev.02 - BlindingDebliding Under Nitrogen PurginggolusinghdataОценок пока нет

- CSS - Proper Use and Maintenance of ToolsДокумент1 страницаCSS - Proper Use and Maintenance of ToolsRowell Marquina100% (1)

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesОт EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesРейтинг: 5 из 5 звезд5/5 (1)

- Dangerous Goods Guidance Note 10 PDFДокумент3 страницыDangerous Goods Guidance Note 10 PDFDan DumbravescuОценок пока нет

- en - GCU Appendix 9Документ115 страницen - GCU Appendix 9Dan DumbravescuОценок пока нет

- Hand Tools: (Contained in Individual Sets or The Tool Crib in Sufficient Quantities To Permit Efficient Instruction)Документ14 страницHand Tools: (Contained in Individual Sets or The Tool Crib in Sufficient Quantities To Permit Efficient Instruction)Dan DumbravescuОценок пока нет

- Era TD 2012 04 Int en PDFДокумент15 страницEra TD 2012 04 Int en PDFDan DumbravescuОценок пока нет

- 89-96 I IvankovicДокумент8 страниц89-96 I IvankovicDan DumbravescuОценок пока нет

- Audit Guide Full DayДокумент17 страницAudit Guide Full DayDan DumbravescuОценок пока нет

- KST Druckgeraeterichtl GBДокумент18 страницKST Druckgeraeterichtl GBDan DumbravescuОценок пока нет

- API RP 571 - Damage Mechanisms Spreadsheet Damage MechanismsДокумент38 страницAPI RP 571 - Damage Mechanisms Spreadsheet Damage MechanismsDan DumbravescuОценок пока нет

- Safe Work Procedure: Last Updated: 22 August 2018Документ2 страницыSafe Work Procedure: Last Updated: 22 August 2018Dan DumbravescuОценок пока нет

- Stivuitor ElectricДокумент10 страницStivuitor ElectricDan DumbravescuОценок пока нет

- Qatar Engineering & Construction Company WLL (Qcon)Документ12 страницQatar Engineering & Construction Company WLL (Qcon)Dan DumbravescuОценок пока нет

- Strain 45 4 2009 PDFДокумент45 страницStrain 45 4 2009 PDFDan DumbravescuОценок пока нет

- CP0191 FullДокумент8 страницCP0191 FullDan DumbravescuОценок пока нет

- Samsung HT x30 HT x40 HT Tx35 HT Kx30 HT Tkx35Документ41 страницаSamsung HT x30 HT x40 HT Tx35 HT Kx30 HT Tkx35Dan DumbravescuОценок пока нет

- Cap 1004Документ22 страницыCap 1004Dan DumbravescuОценок пока нет

- Fb37 1rev0 Checkliste WPK Metallkonstruktionen EnglischДокумент13 страницFb37 1rev0 Checkliste WPK Metallkonstruktionen EnglischDan DumbravescuОценок пока нет

- CE Mark en 1090 Iso 3834 Manual DocumentsДокумент10 страницCE Mark en 1090 Iso 3834 Manual DocumentsDan DumbravescuОценок пока нет

- Classification of ToolsДокумент73 страницыClassification of ToolsNathaniel Pili De Jesus100% (1)

- Toolbox Safety Talks: Topic - Chain SawsДокумент3 страницыToolbox Safety Talks: Topic - Chain SawsHtoo Htoo KyawОценок пока нет

- Stihl 251Документ136 страницStihl 251mazatlОценок пока нет

- AFA 10 Agri-Crop-Q2W3Документ28 страницAFA 10 Agri-Crop-Q2W3Rene Rulete MapaladОценок пока нет

- Stihl Ms 250 Owners Instruction ManualДокумент132 страницыStihl Ms 250 Owners Instruction ManualDouglakdОценок пока нет

- 369 Sve o BeograduДокумент64 страницы369 Sve o BeograduBosko LjubisavljevicОценок пока нет

- Ms - 390 Stihl Chainsaw ManualДокумент126 страницMs - 390 Stihl Chainsaw ManualErica Brown100% (1)

- Husqvarna 181 Workshop ManualДокумент33 страницыHusqvarna 181 Workshop ManualNicolau FerreiraОценок пока нет

- ECC 1: Chainsaw Maintenance and Crosscutting Assessment Activities Assessment CriteriaДокумент5 страницECC 1: Chainsaw Maintenance and Crosscutting Assessment Activities Assessment Criteriak_goulasОценок пока нет

- Stihl Ms 150 TC Owners Instruction ManualДокумент128 страницStihl Ms 150 TC Owners Instruction ManualalexОценок пока нет

- Instructions For Use: Accu ChainsawДокумент32 страницыInstructions For Use: Accu ChainsawEmaОценок пока нет

- Jonsered Cs 2152 Operators Manual 161373Документ36 страницJonsered Cs 2152 Operators Manual 161373Michael SauschlagerОценок пока нет

- Craftsman Chainsaw ManualДокумент24 страницыCraftsman Chainsaw ManualanananОценок пока нет

- Range of Palax Firewood Processors: Combi M Ii KS 35 Power 70S Power 100SДокумент7 страницRange of Palax Firewood Processors: Combi M Ii KS 35 Power 70S Power 100SpevitolaОценок пока нет

- AKE40 ManualДокумент17 страницAKE40 ManualBand Dvesto Plus CrepajaОценок пока нет

- Brochure MS 462Документ9 страницBrochure MS 462JuОценок пока нет

- Chainsaw Milling GuideДокумент15 страницChainsaw Milling GuideBobОценок пока нет

- Husqvarna 266Документ8 страницHusqvarna 266Joe EisentragerОценок пока нет

- Poulan 3816 Owners ManualДокумент20 страницPoulan 3816 Owners ManualChuckDaddyОценок пока нет

- STIHL MS 460 ManualДокумент124 страницыSTIHL MS 460 ManualScott FullerОценок пока нет

- User Manual GMT 050 Felling Grapple Serial Number: 053 Up To and Including 254Документ38 страницUser Manual GMT 050 Felling Grapple Serial Number: 053 Up To and Including 254Jorge Reyes AguilarОценок пока нет

- Original Instructions Alkuperäiset Ohjeet Αρχικýj Οδηγßεj: Rev. 4 5/31/11 BrwДокумент32 страницыOriginal Instructions Alkuperäiset Ohjeet Αρχικýj Οδηγßεj: Rev. 4 5/31/11 BrwnikosvitalОценок пока нет

- JSA For Vegetation ClearingДокумент4 страницыJSA For Vegetation ClearingSawLaiBoyan33% (3)

- Lubricants Comparision Between Brands PDFДокумент6 страницLubricants Comparision Between Brands PDFbdsisiraОценок пока нет

- Ryobi PCN4545 45cc ManualДокумент25 страницRyobi PCN4545 45cc ManualTholaka Senaratne100% (1)

- Manual000033356 PDFДокумент49 страницManual000033356 PDFmfm2k2Оценок пока нет

- Chain Saw: Identify Carpentry Power Tools and Their UsageДокумент3 страницыChain Saw: Identify Carpentry Power Tools and Their UsageJc SantosОценок пока нет

- Hi Tech Engineering SDN BHD Permit To Work System - Job Hazard AnalysisДокумент3 страницыHi Tech Engineering SDN BHD Permit To Work System - Job Hazard AnalysisPHH9834Оценок пока нет

- ELEMENT 9 Work Equipment1Документ24 страницыELEMENT 9 Work Equipment1Aaquil RaziОценок пока нет

- Manual m8 enДокумент40 страницManual m8 endejanoski_aОценок пока нет