Академический Документы

Профессиональный Документы

Культура Документы

The Kinetics of Carbonyl Formation in Asphalt PDF

Загружено:

Arief FathОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

The Kinetics of Carbonyl Formation in Asphalt PDF

Загружено:

Arief FathАвторское право:

Доступные форматы

The Kinetics of Carbonyl Formation in Asphalt

Meng Liu, K. M. Lunsford, R. R Davison, C. J. Glover, and J. A. Buliin

Dept. of Chemical Engineering, Texas A&M University, College Station, TX 77843

The oxidation of asphalt is a major cause of pavement failure. The low-temperature

oxidation kinetics of 14 asphalts are presented. A t constant temperature and oxygen

pressure, asphalt oxidation occurs in two stages: (1) a relatively rapid-rate period, fol-

lowed by (2) a long period of constant rate. Activation energies for the constant-rate

region vary ji-om 64 to 109 kJ/mol, and reaction orders relative to oxygen pressure vary

from 0.25 to 0.61. This variation in activation energy and reaction order leads to skepti-

cism regarding the present practices of eualuating road-condition asphalt-hardening rates

at a single elevated temperature and perhaps at an elevatedpressure. The asphalts occur

in essentially two groups, one at high values of both activation energy and reaction order

and the other at low values of each. The data indicate the existence of an isokinetic

temperature near 100°C. The degree of oxidation that occurs during the initial rapid-rate

region varies inversely with the oxygen reaction order of the constant-rate region.

Introduction

Asphalt is a major by-product of the refining industry. the change in carbonyl content, C.4, is an excellent surrogate

About 28 million ton/yr are produced for use primarily in for the total oxidative changes and a predictor of the result-

road construction and repair. An important factor in road ing changes in physical properties. This is partly explained by

life is the oxidation and subsequent hardening of the asphalt the fact that for each asphalt there is a linear relation be-

binder with age. Many accelerated aging tests have been de- tween carbonyl growth and total oxygen increase, as seen in

vised in an attempt to rank asphalts according to their ten- Figure 1 for two of the test asphalts.

dency to oxidize and harden. These are invariably run at ele- Lau et al. (1992) showed that at 20-atm oxygen pressure

vated temperatures and sometimes at elevated pressures. A and at temperatures from 333 to 366 K (140-200°F) the car-

recent test developed by the Strategic Highway Research

Program (SHRP) specifies the use of air at a pressure of 20

atm and at a temperature of 373 K. 6.0 I . , . . , . . , . . , . I , . . , . .

Although many aging tests exist, there have been few stud- AAA-1 Original

ies of asphalt oxidation kinetics, and almost none to deter- 5.0 - -AAA-l Aged

mine if the activation energies or oxygen reaction orders are AAG-1 Original

different for different asphalts. This is an important practical 4.0 - -AAG-1 Aged

question, for if asphalts are to be compared in tests run at

temperatures and pressures significantly different from road

m 3.0 -

conditions, there is a tacit assumption that all asphalts ex- X

0

hibit the same activation energy and reaction order. .! 2.0 -

&

Several authors have demonstrated that the formation of

carbonyl-containing compounds in an asphalt as a result of

oxidative aging changes the physical properties of the asphalt

1.0 1

in a predictable way (Lee and Huang, 1973; Martin et al., O.O".'. . ' ' ~ " ' ' ~ ' '. '. . ' I4

0.5 1 1.5 2 2.5 3 3.5

1990; Lau et al., 1992; Petersen et al., 1993). This relation- CA

ship is different for different asphalts, but for each asphalt Figure 1. Oxygen percentage vs. carbonyl content for

two POV-aged SHRP asphalts.

Aging temperatures 170",180", and 190°F; aging pressures

Correspondence concerning this article should be addressed to C. J. Glover. 0.2 atm and 20 atm.

AIChE Journal April 1996 Vol. 42, No. 4 1069

bony1 formation rate became constant after an initial more

rapid rate region. These constant rates varied linearly with

reciprocal absolute temperature in the usual Arrhenius form

rCA= A'exp( - E / R T ) .

2.0 1

For the five asphalts studied, there appeared to be minor 3 -e-- 0

variations in the slopes of In rCA vs. 1/T. In the present work, a-

carbonyl formation kinetics are determined for a range of

temperatures and pressures for 14 asphalts to determine def- CA = 0.6487 + 0,023661

initely the effect of these variables on carbonyl formation 0.5 - -- . CA = 0.819 + 0.040231

. . CA = 1.2 + 0.087821

rates. All rates are expressed in arbitrary carbonyl units as

CA/d. These rates could be converted into units of percent 0 10 20 30

oxygen per day using data such as those shown in Figure 1. TIME (day)

The units are immaterial for the purposes of this study, and Figure 2. CA growth for tank and POV-aged Lau3 at

carbonyl is much easier to measure. 355.5 K and different oxygen pressures.

Experimental Design

The integrated peak in the carbonyl region from 1,650 to 1,820

This research was conducted in two phases. In the first cm-' was defined as the carbonyl area, CA, and was used to

phase, the same asphalts studied by Lau et al. (1992) were monitor the progress of oxidation.

oxidized at 0.2, 2- and 20-atm oxygen and at 333.3, 344.4 and Gas-phase diffusion was eliminated by using pure oxygen.

355.5 K (140, 160 and 180°F). The second-phase study in- Diffusion in the asphalt was eliminated by placing the ex-

volved 10 asphalts with one, the Lau4, a repeat from the first posed surface directly on the prism. Since the reflected rays

phase. The rest of phase 2 material comprised two Texas as- only penetrate about one micron, this is essentially a surface

phalts (TX1 and TX2) and 7 asphalts from the SHRP project measurement. Some analyses were also made by mixing the

(AAA-1, AAD-1, AAF-1,AAG-1, AAM-1, AAB-1, AAS-1). film before placing it on the prism. It was found that at 20

The aging conditions used in this phase are listed in Table 1. atm the results were indistinguishable from the surface mea-

In the SHRP aging procedure, asphalts are first aged in surements, and, since easier, the bulk measurements were

the Thin-Film Oven Test (ASTM D-1754) to simulate hot-mix used at this pressure.

aging. To see if this made any difference, many of the sec-

ond-phase samples were run following the equivalent Rolling

Thin-Film Oven Test (ASTM D-2872). Many, but not all, were Discussion of Phase-1 Results

run in duplicate; that is, both virgin asphalt and oven-aged

asphalt were run at the same condition. As determined by Lau et al. (1992), the rates of carbonyl

The reaction equipment was the same as described by Lau, formation became constant for all five asphalts after an ini-

except that in phase 2, temperature control was improved by tial higher rate period. This is seen in Figure 2, where results

total immersion of the pressure oxygen vessel (POV) in a tri- at all three pressures and at 355.5 K are shown for one as-

ethylene glycol bath. Asphalt samples weighing about 2 to 2.4 phalt, and in Figure 3 where results for all three tempera-

g were melted and placed in 4-cm X 7-cm aluminum trays. This tures are shown at 2 atm. The intercept of the constant-rate

gives a film thickness of 1 mm or less. Each POV holds 60-70 portion regression line is defined as the initial jump, CA,,

of these trays. For each asphalt a tray was removed every few while the slope of the line is the aging rate. From Figures 2

days, depending on the temperature and pressure, with the

maximum time ranging to 180 days at 333.3 K in the first

phase. Oxygen content (Figure 1) was obtained using a Fisons

EA 1108 CHNS-0 Analyzer through direct oxygen measure-

1.6 -

ment. Carbonyl content analysis was by infrared spectra using

a Mattson Galaxy 5000 FT-IR and the attenuated total re-

1.41 O P

flectance (ATR) method as described by Jemison et al. (1992). /

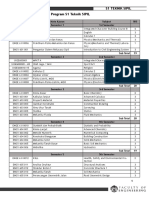

Table 1. Aging Conditions Applied in the Phase-2

Experiments

1 I-

. _

-:::::1

Condition Temperature Pressure + 333.3 K CA = 0.8394 + 0.009121t

- - - CA = 0.7564 + 0.01986t

~

c1 170°F(349.8 K) 20 atm 0.6 - CA = 0.819 + 0.04023t

c2 180°F (355.5 K) 20 atrn

c3 180°F(355.5 K) 10 atm 0.4f

0 10 20

i '

30

I 1

40 50

i ' I

60

I

70 80

I 1

90

c4 190°F(360.9 K) 20 atm

c5 190°F (360.9 K) 0.2 atm TIME (day)

C6 200°F (366.5 K) 0.2 atm

c7

Figure 3. CA growth for tank and POV-aged Lau3 at 2

210°F (372.0 K) 0.2 atrn

atm and different temperatures.

1070 April 1996 Vol. 42, No. 4 AIChE Journal

Table 2. CA Growth Rate for All Asphalts and POV Aging

Conditions in the Phase-1 Experiments

- Q - Lau2

Aging Condition rca X lo3 (CA/day) 0- . Laud

Pres. Temp. Laul Lau2 Lau3 Lau4 Lad

333.3 K 3.24 3.73 4.75 4.19 3.66

0.2 atm 344.4 K 6.85 8.91 11.41 7.87 7.78

355.5 K 18.66 21.32 23.66 19.73 18.62

333.3 K 6.79 6.36 9.12 8.10 6.04

2 atm 344.4 K 14.55 15.74 19.86 13.92 14.80

355.5 K 34.50 37.92 40.23 32.47 28.63

333.3 K 12.34 11.46 18.58 12.40 10.95

20 atm 344.4 K 25.55 31.19 32.88 29.43 29.96

355.5 K 67.02 78.21 87.82 60.18 56.64

10-1 1OC' 10' 102

P (atrn)

Figure 4. CA growth-rate dependence on pressure at

and 3, it is observed that (1) the initial jump is pressure de- 344.4 K for all POV-aged asphalts in the

pendent and not temperature dependent, ( 2 ) aging rate in- phase-1 experiments.

creases with pressure, and (3) aging rate increases with tem-

perature. Rate data for all phase 1 conditions are shown in

Table 2 and CA, - GItank in Table 3. Table 3 shows again

that CA, is a function of pressure but, despite scatter, does Table 4. a for All POV-Aged Asphalts at Different

Temperatures in the Phase-1 Experiments*

not appear to be a function of temperature. Also, these con- ~ ~ ___________

clusions are strongly supported by the phase-2 studies, which (Y

appear in the next section. Temp. Laul Lau2 Lau3 Lau4 Lau5

Figures 2 and 3 suggest that, as in classic kinetics, the ag- 333.3 K 0.290 0.244 0.296 0.236 0.238

ing rate can be expressed as 344.4 K 0.286 0.272 0.230 0.286 0.270

355.5 K 0.278 0.282 0.285 0.242 0.242

rCA= AP"exp( - E/RT), Avg. 0.285 0.266 0.270 0.255 0.250

(2)

*Oxygen pressure from 0.2 to 20 atm.

where A is the frequency factor, a is the reaction order with

respect to oxygen pressure, and E is the activation energy.

For this expression to be valid, it is necessary to verify that a

is temperature independent and E is pressure independent. lo-' , , , , , , , , , , , , , , I , , , ,, , , , , ,

Figure 4 is a plot of aging rates vs. oxygen pressures for all

five asphalts at 344.4 K. Values at all temperatures are listed

in Table 4. The scatter in a appears random, and we con-

clude that a is independent of temperature. An Arrhenius

plot for a11 five asphalts at 0.2 atm is shown in Figure 5 . The

activation energy, E , is calculated from the slope, and values

at all pressures are given in Table 5. Again, the variation

appears random and we conclude that E is independent of

pressure. These results justify the use of Eq. 2.

Equation 2 can be linearized by taking the natural loga-

rithm of both sides

2.8 10.~ 2.9 1 0 . ~ 3.0 1 0 . ~

In rCA= In A + a In P - E/RT. (3)

1/T (K-')

Figure 5. rcm vs. 1 / T at 0.2 atm for all POV-aged as-

Table 3. CA, - CAhnk for All Asphalts and POV Aging Con- phalts in the phase-1 experiments.

ditions in the Phase-1 Experiments

~~

Aging Conditions CA, - CAta"k(CA)

Pres. Temp. Laul Lau2 Lau3 Lau4 Lau5 Table 5. E for All POV-Aged Asphalts at Different Pressures

333.3 K 0.217 0.157 0.205 0.248 0.104 in the Phase-1 Experiments*

0.2 atm 344.4K 0.202 0.180 0.176 0.271 0.142

355.5 K 0.153 0.114 0.187 0.320 0.122 E (kJ/mol)

333.3 K 0.278 0.334 0.377 0.413 0.248 Pres. Laul Lau2 Lad Lau4 Lau5

~~ ~ ~~

2 atm 344.4 K 0.220 0.300 0.294 0.331 0.227 0.2 atm 77.5 77.2 71.2 68.5 72.0

355.5 K 0.295 0.276 0.357 0.352 0.290 2 atm 72.0 79.1 65.8 61.4 68.3

333.3 K 0.253 0.498 0.683 0.570 0.353 20 atm 74.8 85.1 68.6 70.1 72.9

20 atm 344.4 K 0.438 0.548 0.920 0.616 0.376 Avg. 74.8 80.5 68.5 66.7 71.1

~~~~ ~

355.5 K 0.252 0.377 0.738 0.519 0.412

*Aging temperature from 333.3 to 355.5 K.

AIChE Journal April 1996 Vol. 42, No. 4 1071

Table 6. Kinetic Model Parameters for All POV-Aged Table 8. C4, - CAtankof All POV-Aged Asphalts in the

Asphalts in the Phase-1 Experiments Phase-2 Experiments at all Aging Conditions

In ( A ) E Avg. CA, - CAtank(CAI

Asphalt ln(CA/d.atm") kJ/mol ff % Error*

Asphalt C1 C2 C3 C4 C5 C6 C7

Laul 21.71 k 2.60 74.8f7.4 0.285i0.036 7 AAA-1 0.103 0.068 0.024 0.250 0.109 0.082

Lau2 23.83 f 1.55 80.5 4.4 0.266 0.022 4

Lau3

Lau4

19.86+.2.67

19.86k 2.89

68.6 f7.6

66.7k 8.3

*

0.270 0.037

0.255f0.040

7

8

AAA-1 R*

AAD-1

0.092 -0.037

0.225 0.071 0.047

0.320

0.271

0.119

0.134

0.129

0.082

0.250f0.025 5 AAD-1 R* 0.253 0.040 0.292 0.304 0.150

Lau5 20.42k1.77 71.1i5.1

AAF-1 0.782 0.771 0.742 0.336 0.385 0.279

AAF-1 R* 0.755 0.734 0.309 0.415 0.313

AAG-1 1.771 1.686 1.713 0.572 0.473 0.415

*% Error = 100

AAG-1 R* 1.801 1.694 0.630 0.405 0.503

AAM-1 0.780 0.839 0.811 0.402 0.281 0.309

AAM-1 R* 0.782 0.829 0.297 0.284 0.273

AAB-1 0.508 0.393 0.395 0.210 0.198

This equation was used to perform a multivariable regression AAB-1 R* 0.533 0.412 0.358 0.383 0.259 0.223

of rCA as a function of T and P.Table 6 shows the estimated AAS-1 0.404 0.342 0.206

parameters. For each of the parameters, statistical methods AAS-1 R* 0.404 0.350 0.291 0.325 0.225 0.202

were employed to obtain 95% confidence limit, and these are TX1 0.415 0.176

also shown in the table. The error of the estimated rCA is TXl R* 0.447 0.352 0.356 0.361 0.171 0.190

Lau4 0.593

also given. The percent errors are all under 10%. L a d R* 0.501 0.643 0.549 0.706 0.252 0.267

The data in Table 6 show that a 95% confidence limit is TX2 0.365

roughly 15% of the value of the parameter. Unfortunately, TX2 R* 0.371 0.348 0.310 0.280 0.188 0.185

the size of the confidence limit is such that it is difficult to

*Asphalt pretreated by Rolling Thin-Film Oven Test before aging under

conclude if the parameters are dependent on the asphalt the conditions.

source. Since the Arrhenius parameters describe the temper-

ature dependence, and this is the most significant factor af-

fecting the determination of rcA, it appears that the Arrhe- phalts are shown in Figures 6 to 8. The data presented in

nius parameters are probably composition dependent. Figure 6 are for one of the two asphalts that perhaps show

some effect of oven aging on the subsequent POV aging, but

only at 20 atm. We also see that the initial jump CA, - CAtank

Discussion of Phase-2 Results

is extremely small. The data in Figure 7 show no evidence of

The study was greatly expanded to determine definitely if an oven-aging effect, but a larger pressure effect on CA, is

there are significant compositional effects in asphalt kinetics. evident. Figure 8 also shows no oven-test effect, but does show

Ten asphalts were aged at the conditions listed in Table 1. a very large pressure-dependent initial jump. In these runs,

Table 7 shows the rates, and Table 8 shows the correspond- not all conditions were duplicated for both oven-aged and

ing values of 01,- CAtankfor all 10 asphalts. Carbonyl virgin material. Within the scatter of the data in Table 8, 01,

growth with respect to aging time for three of the ten as- appears temperature independent, and all but AAA-1 and

AAD-1 show a definite pressure effect. For these two, CA, -

01tank is negligible.

Table 7. CA Growth Rate for All POV-Aged Asphalts in the

Phase-2 Experiments at all Conditions The constants in Eq. 3 determined by a multivariable re-

gression for the phase-2 asphalts are listed in Table 9. Unlike

rCAx lo3 (CA/d)

Asphalt C1 C2 C3 C4 C5 C6 C7

AAA-1 121.7 179.5 349.6 19.84 48.68 58.77

AAA-1 R* 114.5 181.9 16.29 49.12 54.90

AAD-1 133.3 223.5 403.9 22.53 43.69 60.01

AAD-1 R* 124.6 214.1 22.77 35.30 56.80

AAF-1 63.96 86.40 164.3 31.83 41.63 64.98

AAF-1 R* 65.84 88.55 32.83 37.75 61.61 P c2

AAG-1 74.66 102.0 163.3 41.41 60.17 87.57

AAG-1 R* 69.38 99.67 38.04 69.74 74.55

AAM- 1 52.31 65.36 111.9 22.36 44.56 56.32

AAM-1 R* 50.66 62.15 28.30 45.26 59.33

AAB-1 68.77 132.3 222.2 58.19 80.39

AAB-1 R* 67.15 130.9 101.4 220.2 53.95 77.12

AAS-1 60.49 188.8 64.50

AAS-1 R* 58.19 105.1 86.59 197.8 46.17 64.72

TX1 229.4 85.39

TX1 R* 70.61 132.0 108.5 239.5 62.27 85.27 0.0I I 1 1

Lau4 108.0 0 5 10 15 20

Lau4 R* 79.22 101.3 76.19 149.3 57.92 79.65 TIME (day)

TX2 135.4

TX2 R* 71.27 133.3 108.5 244.4 61.23 75.57 Figure 6. CA growth for tank, RTFOT-aged, and POV-

aged SHRP AAA-1.

*Asphalt pretreated by Rolling Thin-Film Oven Test before aging under Solid: aged after pretreatment of Rolling Thin-Film Oven

the conditions. Test. Open: aged from tank, without pretreatment.

1072 April 1996 Vol. 42, No. 4 AIChE Journal

Table 9. Kinetic Model Parameters of All POV-Aged

Asphalts Studied in the Phase-2 Experiments

3.0 1 c4

0..-'0

i

AAA-1

In A

Asphalt In(Ol/d.atm")

33.28 f10.86

E

kJ/mol

108.5f32.7

ff

0.604f 0.099

Avg.

% Error*

16

AAD-1 30.59rt4.19 100.2*12.6 0.611k0.038 6

AAF-1 22.06rt5.92 75.1k17.8 0.340*0.054 9

AAG-1 20.71k5.08 70.3k 15.3 0.279k0.046 7

AAht-1 19.43f4.67 67.5 f14.1 0.260f 0.042 7

AAB-1

AAS-1

31.60 f4.93

31.98rt5.58

103.2 k 14.9

105.0+16.8

*

0.426 0.047

0.445+0.052

7

6

1 TX1

Lau4

TX2

31.29 f6.82

18.64k 8.51

31.06k13.06

102.1f20.6

64.2 rt 25.6

1.01.5+41.1

0.421 f0.064

0.272 f0.076

0.429k0.122

7

6

9

0.0 I I

0 5 10 15 20 *As defined in Table 6.

TIME (day)

Figure 7. CA growth for tank, RTFOT-aged, and POV-

aged SHRP AAF-1. 370.8 K. In Figures 10 and 11, Arrhenius plots for the 10

Solid: aged after pretreatment of Rolling Thin-Film Oven phase-2 asphalts are shown corrected to 0.2 atm, and the rates

Test. Open: aged from tank, without pretreatment. do tend to converge in that region.

In Figure 12, we see the strong relation between E and a

with only AAA-1 and AAD-1 appearing anomalous, but these

the phase 1 results, a much wider variation in reaction order, two asphalts are alike in other respects. The confidence lim-

a,and activation energy, E, was obtained. The one duplicate its are higher for the second-phase runs because of fewer

asphalt, Lau4, yielded values very close to those previously experimental conditions and differences in experimental de-

obtained. We have in phase 1 a classic example of the statisti- sign. However, the average errors are not much greater, and

cal danger of small samples. Of the 14 asphalts tested in both the good correlations in Figures 9 and 12, as well as the close

phases, 7 have values of a between 0.25 and 0.29, with oth- agreement between the Lau4 results from each phase, give

ers ranging up to 0.61, yet all five of the asphalts tested by confidence in the results.

Lau and used in phase 1 lie in that narrow range. Similarly, In Figures 9 and 12, we have distinguished between phase

the activation energies for the phase-1 asphalts ranged from 1 and phase 2, which were run a year apart by different re-

about 67 to 81 kJ/mol, while the range of all 14 was 64 to searchers. Both the narrow range of the phase 1 data as well

109. It is interesting that there seems to be distinct groupings as the general agreement with phase 2 results are evident.

of low a,low E asphalts, and high a, high E asphalts with

no values of E between 81 and 100 and only one a between Discussion of Activation Energies and Reaction

0.29 and 0.42. The same kind of variation is seen in In A. Orders

In Figure 9, In A + a In 0.2 (the value of E/RT, where In

rCA= 0 for oxidation pressure of 0.2 atm) is plotted vs. E There are a few activation energies published in the litera-

with remarkable linearity. This indicates that at 0.2-atm oxy- ture for asphalt oxidation. Whether these activation energies

gen pressure there exists an isokinetic temperature (Boudart, were measured for oxygen consumption or carbonyl forma-

1991) where all 14 asphalts will exhibit nearly the same rate. tion is immaterial, because the linear relation between the

From the fit in Figure 9, this temperature is calculated to be two (see Figure 1) results in no effect on either E or a and

only on In A. Most of the published activation energies were

obtained by measuring the rate of oxygen consumption at only

Phase 2 Data

30 Phase 1 Data

-

N

I

'.OL- RTFOT

TIME (day) 5~~

/ 70 80 90 100 110

E (kJlmole)

Figure 8. CA growth for tank, RTFOT-aged, and POV-

aged SHRP AAG-1. Figure 9. lsokinetic diagram for all 15 POV-aged as-

Solid: aged after pretreatment of Rolling Thin-Film Oven

phalts.

Test. Open: aged from tank, without pretreatment. Isokinetic temperature 370.8 K (2703°F).

AIChE Journal April 1996 Vot. 42, No. 4 1073

Phase2Dala

0 Phase 1 Data

0.4 1 0

.

.

p

0.31, 0 ;"o, ,: ;,, , , , , , , , , , , , , , ,

0.2

60 70 80 90 100 110

E (kJ/rnole)

1/T (K-')

Figure 12. Reaction order vs. activation energy for all

Figure 10. Arrhenius plot for five of the ten POV-aged 15 POV-aged asphalts.

asphalts in the phase-2 experiments.

values obtained in this work. Again, it is quite possible that it

two or three temperatures. Van Oort (1956) measured oxy- was measured in the initial-rate region in-which the pressure

gen uptake at about 1 atm at 25, 50 and 75°C. Correcting for effect is quite

diffusion and assuming the reaction to be first order relative

to oxygen pressure, he obtained a value of E of 100 kJ/mol. Initial Rapid-Rate Region

Blokker and van Hoorn (1959) gave the times required for 1 As was previously shown, the initial jump of the rapid-rate

cm3 of oxygen to absorb into a 200-micron film at 30 and region, CA,, and thus CA, - CAtankris not a function of re-

50°C. For the four asphalts they studied, the data yielded action temperature but generally increases with reaction

values of E from 55 to 79 kl/mol. These authors also re- pressure. Also, Tables 8 and 3 show that asphalts with larger

ported a value for a of 0.6, but gave no data. Dickinson and reaction orders LY (e.g., AAA-1 and AAD-1) have smaller ini-

Nicholas (1949) and Dickinson et al. (1958) obtained values tial jumps, compared to those with lower LY (e.g., AAF-1,

of E of 29 and 43 kJ/mol, but concluded these values con- AAG-1, AAM-1, and Lau4). This is particularly clear for the

tained diffusion effects. Verhasselt and Choquet (1991) re- 20-atm data.

ported a value of E for one asphalt of 87 kJ/mol measured To evaluate the initial rapid-rate region, it was assumed

between 343 and 373 K using carbonyl growth as the mea- that the pressure effect could be represented by

surement.

All of these values, except for those recognized as being

CA, - CAtank

= PPY. (4)

affected by diffusion, fall in the range of the present study. It

should be pointed out, however, that several and perhaps all

of them are based on rates measured totally or in part in the All values of CA, - CAtankwere used to fit /3 and y , and the

initial rapid-rate region and may well be different from val- results are given in Table 10. For asphalts AAA-1 and AAD-1,

ues calculated in the constant-rate region. The single value the pressure effects are negligible and were calculated to be

given for the reaction order of 0.6 is at the upper limit of negative, but this is probably an error. Some of these values

are calculated from only two data points. The constant p does

not vary much, but y is plotted vs. a in Figure 13, and sur-

prisingly the pressure effect on CA, varies inversely with a ,

the reaction order with respect to oxygen pressure in the con-

stant-rate region.

Table 10. /3 and y Values of All Asphalts in the Phase-1

and Phase-2 Experiments*

AAA-1 AAD-1 AAF-1 AAG-1 AAM-1

_ _ SHRP AAB-1

p 0.1102 0.1738 0.4492 0.7717 0.4312

_ _ SHRP AAS-1 y -0.2631 -0.1047 0.1741 0.2700 0.2097

--XI

-Lau4 AAB-1 AAS-1 TX1 Lau4+ TX2

TX2 p 0.2755 0.2473 0.2361 0.3514 0.2300

y 0.1383 0.1065 0.1699 0.1881 0.1305

10-3

Laul Lau2 Lau3 Lad* L~US

2.7 1 0 . ~ 2.8 1 0 . ~ 2.9 1 0 ' ~

p 0.2330 0.2340 0.2987 0.3481 0.1938

y 0.1079 0.2498 0.3078 0.1536 0.2449

(K-')

1IT

*CAo - CAtank= PPY.

Figure 11. Arrhenius plot for five of the ten POV-aged 'By data of the phase-2 experiments.

asphalts in the phase-2 experiments. 'By data of the phase-I experiments.

1074 April 1996 Vol. 42, No. 4 AIChE Journal

0.4, I , , . . , . . , I , , . . , (C3-C6). By contrast, asphalt is a very complex petroleum

residue consisting of thousands of compounds of much higher

carbon number and widely varying functionalities. The exis-

i tence of the isokinetic phenomenon in such a material is likely

to be a valuable observation for understanding and describ-

1/

ing the aging mechanism.

0.0

.Lau4(93)

. Conclusions

-0.2-

. When asphalts are oxidized at constant oxygen pressure and

constant temperature in the absence of diffusion, the car-

bony1 growth undergoes a period of rapid growth and then a

-0.4 . ‘ ~ ~ ‘ i . “ . . i ~ ~

lengthy period of constant rate. The kinetics of the constant-

rate region are represented by Eq. 2, with both E and a

being asphalt dependent and strongly cross-correlated in that

generally high values of E accompany high values of a.

The initial jump, CA,, is also highly asphalt dependent and

is pressure dependent according to Eq. 4, but correlates in-

versely with the constant-rate reaction order. From these re-

Implications of the Results sults it is apparent that any attempt to use relative asphalt-

aging rates at elevated temperatures and pressures and to

The results of this work have profound significance in the assume they represent relative rates at road conditions could

development of a reliable aging test, as well as in the evalua- be highly misleading.

tion of asphalt-binder quality.

The fact that each asphalt has a specific set of kinetic pa-

rameters gives a guidance in developing a reliable aging test. Acknowledgments

Data in Table 9 show that asphalts from different sources Support for this work came from the Texas Department of Trans-

may exhibit far different reaction orders and activation ener- portation (TxDOT), in cooperation with the U.S. Department of

Transportation, and the Federal Highway Administration (FHWA).

gies. Therefore, the relative aging rates that exist at one tem- This work also supported by the U.S. Department of Energy (DOE),

perature and pressure may be reversed at another tempera- Assistant Secretary for Energy Efficiency and Renewable Energy,

ture and/or pressure. Any test using the information of only under DOE Albuquerque Operation Office Cooperative Agreement

one aging experiment performed at a single elevated temper- DE-FC04-93AL94460.The technical contributions of Mrs. Ann Ferry

are greatly appreciated.

ature and/or elevated pressure is not reliable. Furthermore, The contents of this article reflect the views of the authors who are

if the aging experiment is conducted within the initial rapid- responsible for the facts and accuracy of the data presented. The

rate region, the resulting relative rates also cannot represent contents do not necessarily reflect the official views or policies of the

the constant-rate-period relative rates that are relevant in the Federal Highway Administration, the Texas Department of Trans-

pavement. Based on this work, we conclude that a reliable portation, or the US. Department of Energy. This report does not

constitute a standard, specification, or regulation.

aging test can only be conducted by running aging experi-

ments at multiple temperatures and/or pressures to measure

the kinetic parameters. The kinetic parameters can then be Notation

used to determine the aging rates at road conditions. The A’ =Arrhenius constant in Eq. 1, CA/d

optimum protocol for such a testing procedure is yet to be CA,,,, = carbonyl content of virgin asphalt

established. P =oxygen pressure, atm

R =universal gas constant

The differences between the kinetic parameters also indi- T =temperature, K

cate that aging characteristics are an important part of as- =model parameter in Eq. 4

phalt binder quality. Since the asphalts have an isokinetic y =model parameter in Eq. 4

temperature near 100°C, those with higher activation ener-

gies will have a lower oxidation rate at road conditions. Also,

Literature cited

a small initial jump is desirable. On the other hand, as shown

Blokker, P. C., and H. van Hoorn, “Durability of Bitumen in Theory

in Figures 12 and 13, the reaction order a, the activation and Practice,” proc. world tong,, 417 (1959).

energy E , and the jump pressure dependence factor 7’ Boudart, M., Kinetics of Chemical Process, Butterworth-Heinemann,

are closely correlated. Since the kinetic parameters should be Stoneham, MA (1991).

a manifestation of the chemical compositions of the asphalts, Dickinson, E. J., and J. H. Nicholas, “The Reaction of Oxygen with

improvements in aging quality can be realized through com- Tar oilsi”Road Tech., No. 16, (1949).

Dickinson, E. J., J. H. Nicholas, and S. Boas-Traube, “Physical Fac-

positional manipulations. The compositional dependence of tors Affecting the Absorption of by Thin Film of Bitumen

the activation energy, reaction order, and initial jump is Cur- Road Binders,”J. Chem,. 8. 673 (1958).

rently under investigation. Further results may yield tech- Jemison, H. B.,’B. L.LBurr, R. R. Davison, J. A. Bullin, and C. J.

niques to manufacture asphalts with superior aging charac- Glover, “Application and Use of the ATR, FT-IR Method to As-

phalt Aging Studies,” Fuel Sci. Technol., 10, 795 (1992).

teristics. Lau, C. K., K. M. Lunsford, C:. J. Glover, R. R. Davison, and J. A.

Finally, the idCk$ic phenomenon as shown in Figure is Bullin, “Reaction Rates and Hardening Susceptibilities as Deter-

remarkable, and of fundamental significance. Boudart (1991) mined from POV Aging of Asphalts,” Trans. Res. Rec., 1342, 50

reported an isokinetic diagram for hydrocarbon cracking (1992).

AIChE Journal April 1996 Vol. 42, NO. 4 1075

Lee, D. Y.,and R. J. Huang, “Weathering of Asphalts as Character- Van Oort, W. P., “Durability of Asphalt, Its Aging in the Dark,”Ind.

ized by Infrared Multiple Internal Reflection Spectra,” Anal. Eng. Chem., 48, 1196 (1956).

Chem., 46, 2242 (1973). Verhasselt, A. F., and F. S. Choquet, “A New Approach to Studying

Martin, K. L., R. R. Davison, C. J. Glover, and J. A. Bullin, “Asphalt the Kinetics of Bitumen Aging,”Proc. Int. Symp. Chemkty of Bitu-

Aging in Texas Roads and Test Sections,” Trans. Res. Rec., 1269, 9 mens, Vol. 11, Rome, Italy, p. 686 (June 5-8, 1991).

(1990).

Petersen, J. C., J. F. Branthaver, R. E. Robertson, P. M. Harns-

berger, J. J. Duvall, and E. K. Ensley, “Effects of Physicochemical

Factors on Asphalt Oxidation Kinetics,” Trans. Res. Rec., 1391, 1

(1993). Manuscript receiwd Apr. 5, 1995, and revision receiued June 23, 1995.

1076 April 1996 Vol. 42, No. 4 AIChE Journal

Вам также может понравиться

- Jurnal Perancangan AlatДокумент6 страницJurnal Perancangan AlatFreeQueenОценок пока нет

- 1995-Kinetics of absorption of CO2 into aqueous solutions of 2-amino-2-methyl-1-propanolДокумент12 страниц1995-Kinetics of absorption of CO2 into aqueous solutions of 2-amino-2-methyl-1-propanolbaohongqian2020Оценок пока нет

- Acidity and Basicity of Metal Oxide Surfaces 1 II. Determination by Catalytic Decomposition of IsopropanolДокумент9 страницAcidity and Basicity of Metal Oxide Surfaces 1 II. Determination by Catalytic Decomposition of Isopropanolnguyennha1211Оценок пока нет

- Intrinsic and Global Reaction Rate of Methanol Dehydration Over G Al2O3 Pellets 1992 Industrial and Engineering Chemistry Research1992Документ7 страницIntrinsic and Global Reaction Rate of Methanol Dehydration Over G Al2O3 Pellets 1992 Industrial and Engineering Chemistry Research1992pannita.kОценок пока нет

- Hydrogen Production by Catalytic Decomposition of Methane Over Activated Carbons - Kinetic StudyДокумент7 страницHydrogen Production by Catalytic Decomposition of Methane Over Activated Carbons - Kinetic Studyjocy1989Оценок пока нет

- Structural Modifcations of Petroleum Asphaltenes by Reductive AlkylationДокумент9 страницStructural Modifcations of Petroleum Asphaltenes by Reductive AlkylationNatalia KovalovaОценок пока нет

- A Fluid Dynamics Simulation of Chromium Recovery From AOD Slags During Reduction With Ferrosilicon AdditionsДокумент8 страницA Fluid Dynamics Simulation of Chromium Recovery From AOD Slags During Reduction With Ferrosilicon AdditionsandselvanОценок пока нет

- Magnesium & Aluminum in Water FuelsДокумент10 страницMagnesium & Aluminum in Water FuelsCliff ThriveОценок пока нет

- ArticleДокумент9 страницArticleYoucef FermiОценок пока нет

- Biblio 3-November 2003Документ4 страницыBiblio 3-November 2003bedghiou djohraОценок пока нет

- TGA Limestone DegradationДокумент18 страницTGA Limestone DegradationTammie HendersonОценок пока нет

- Ftir Study of A Nanostructured Aluminum Nitride Powder Surface: Determination of The Acidic/Basic Sites by Co, Co2 and Acetic Acid AdsorptionsДокумент11 страницFtir Study of A Nanostructured Aluminum Nitride Powder Surface: Determination of The Acidic/Basic Sites by Co, Co2 and Acetic Acid AdsorptionsNurulAtirahNoroziОценок пока нет

- 10 1016@j Ces 2006 05 023Документ10 страниц10 1016@j Ces 2006 05 023fonsОценок пока нет

- Recent Advances in Carbonate Stimulation IPTC 10693 MSДокумент8 страницRecent Advances in Carbonate Stimulation IPTC 10693 MSBolsec14Оценок пока нет

- Model NSR Catalysts Fabrication and Reactivity of Barium at Room TemperatureДокумент16 страницModel NSR Catalysts Fabrication and Reactivity of Barium at Room TemperatureSabri AeroChemОценок пока нет

- Bauer1981 Componentes Carbonatados en Ceniza VolanteДокумент6 страницBauer1981 Componentes Carbonatados en Ceniza VolanteMireliz CorillocllaОценок пока нет

- Calcium Carbonate Decomposition Under External Press Ure Pulsat IonsДокумент20 страницCalcium Carbonate Decomposition Under External Press Ure Pulsat IonsTryas MunarsyahОценок пока нет

- W Applied Catalysis: Kinetic Study of The Reverse Water-Gas Shift Reaction CatalystsДокумент17 страницW Applied Catalysis: Kinetic Study of The Reverse Water-Gas Shift Reaction CatalystsManuel Álvarez RodríguezОценок пока нет

- Study On The Differences in The Oxidation CharacteДокумент5 страницStudy On The Differences in The Oxidation CharacteSarwan RifanОценок пока нет

- AkineticsandsurfaceWGS-Ross-1973 ImportДокумент8 страницAkineticsandsurfaceWGS-Ross-1973 ImportleonardoОценок пока нет

- Applied Catalysis, 31 (1987) 113-118 Elsevier Science Publishers B.V., Amsterdam - Printed in The Netherlands 113Документ6 страницApplied Catalysis, 31 (1987) 113-118 Elsevier Science Publishers B.V., Amsterdam - Printed in The Netherlands 113snurain_3Оценок пока нет

- Chemical-Kinetic Parameters of Hyperbolic Earth Entry: Eloret Corporation, Moffett Field, California 94085Документ15 страницChemical-Kinetic Parameters of Hyperbolic Earth Entry: Eloret Corporation, Moffett Field, California 94085Heri SalmasОценок пока нет

- Hu 2016Документ9 страницHu 2016KaterinaОценок пока нет

- Aic 690380506Документ22 страницыAic 690380506Jefferson DavidОценок пока нет

- Electrical Conductivity and The Surface Characteristics of Kaolinitic Clays and Clay-Humic Acid ComplexesДокумент6 страницElectrical Conductivity and The Surface Characteristics of Kaolinitic Clays and Clay-Humic Acid ComplexesLarisa ChindrișОценок пока нет

- Activities and Selectivities Temperatures Relevant Chemical Interconversions Copper Metal-Oxide Catalysts at Heat-Pumps Based Isopropanol/ AcetoneДокумент4 страницыActivities and Selectivities Temperatures Relevant Chemical Interconversions Copper Metal-Oxide Catalysts at Heat-Pumps Based Isopropanol/ AcetoneOlga ĆalasanОценок пока нет

- Optimal Pore Size of Catalysts For Hydrodemetallation ReactionsДокумент2 страницыOptimal Pore Size of Catalysts For Hydrodemetallation ReactionsAdhil RissallahОценок пока нет

- Basicities of Alumina-Supported Alkaline Earth Metal Oxides Yu-Wen Chen', Hsueh-Ying Chen B and Wen-Fa Lin BДокумент4 страницыBasicities of Alumina-Supported Alkaline Earth Metal Oxides Yu-Wen Chen', Hsueh-Ying Chen B and Wen-Fa Lin Bnatalia_campeloОценок пока нет

- Corrosion Performance of Al-Si-Cu Hypereutectic Alloys in A Synthetic Condensed Automotive SolutionДокумент5 страницCorrosion Performance of Al-Si-Cu Hypereutectic Alloys in A Synthetic Condensed Automotive SolutionHamilta De Oliveira SantosОценок пока нет

- Catalytic Ammonia Decomposition Over Ru Carbon CatalystsДокумент7 страницCatalytic Ammonia Decomposition Over Ru Carbon CatalystsLuong NguyenОценок пока нет

- Effect of Electrolyte Temperature On The Polarization Characteristics of An Ai-Li-Cu-Mg Alloy Innaoh C Thakur and R BalasubramaniamДокумент9 страницEffect of Electrolyte Temperature On The Polarization Characteristics of An Ai-Li-Cu-Mg Alloy Innaoh C Thakur and R Balasubramaniamkk ooОценок пока нет

- Industrial Catalysis, The Science and The Challenge. Conversion of Fossil FuelsДокумент21 страницаIndustrial Catalysis, The Science and The Challenge. Conversion of Fossil FuelsMeita PratiwiОценок пока нет

- Reactivity of CaoДокумент5 страницReactivity of CaoAlberto Moreno GomezОценок пока нет

- Kinetic Modeling PFR - FluidizedДокумент8 страницKinetic Modeling PFR - FluidizedTeo Han ChuinОценок пока нет

- G.A. Risha Et Al - Combustion of Nano-Aluminum and Liquid WaterДокумент8 страницG.A. Risha Et Al - Combustion of Nano-Aluminum and Liquid WaterJuaxmawОценок пока нет

- Ethylene Epoxidation in A Catalytic Packed-Bed Membrane ReactorДокумент14 страницEthylene Epoxidation in A Catalytic Packed-Bed Membrane ReactorLim Xiu XianОценок пока нет

- UPC Tech009Документ9 страницUPC Tech009Luz SmithОценок пока нет

- Spe 738 PaДокумент6 страницSpe 738 PaAliОценок пока нет

- Decrease in Carbonyl Sulfide in The Feed To Claus Converters Shift CatalystsДокумент3 страницыDecrease in Carbonyl Sulfide in The Feed To Claus Converters Shift CatalystsJoel OngОценок пока нет

- 4 ToghianiДокумент6 страниц4 ToghianiFiorela VillalobosОценок пока нет

- Simulation of a Circulating Fluidized Bed Combustor ModelДокумент10 страницSimulation of a Circulating Fluidized Bed Combustor ModelMárcia CardosoОценок пока нет

- Kinetics of Amines With Primary and Secondary in Aqueous SolutionsДокумент7 страницKinetics of Amines With Primary and Secondary in Aqueous SolutionsJack SutherlandОценок пока нет

- IPTC 10693 Recent Advances in Carbonate Stimulation: Fig. 1-Normalized and Averaged Reactivity of CarbonatesДокумент8 страницIPTC 10693 Recent Advances in Carbonate Stimulation: Fig. 1-Normalized and Averaged Reactivity of CarbonatesJose Miguel GonzalezОценок пока нет

- ChE426 Final Exam 2005Документ2 страницыChE426 Final Exam 2005احمد الدلالОценок пока нет

- Carbon Dioxide Absorption Into Promoted Carbonate SolutionsДокумент10 страницCarbon Dioxide Absorption Into Promoted Carbonate SolutionsDunyu LiuОценок пока нет

- Kinetics of MethanationДокумент12 страницKinetics of MethanationGabriela Campos DávilaОценок пока нет

- COS-Forming Reaction Between CO and Sulfur: A High-Temperature Intrinsic Kinetics StudyДокумент8 страницCOS-Forming Reaction Between CO and Sulfur: A High-Temperature Intrinsic Kinetics StudyMos-ta-fa Man-GalОценок пока нет

- Effect of Non-Ionic Reagents on Zeta Potential of Fine Coal ParticlesДокумент13 страницEffect of Non-Ionic Reagents on Zeta Potential of Fine Coal ParticlesummuОценок пока нет

- 1 s2.0 S0926860X9700149X MainДокумент7 страниц1 s2.0 S0926860X9700149X Mainzahira.mohamedseghirОценок пока нет

- In-Situ Upgrading of Heavy Oil/Bitumen During Steam Injection by Use of Metal Nanoparticles: A Study On In-Situ Catalysis and Catalyst TransportationДокумент12 страницIn-Situ Upgrading of Heavy Oil/Bitumen During Steam Injection by Use of Metal Nanoparticles: A Study On In-Situ Catalysis and Catalyst TransportationWan Mohd ShaharizuanОценок пока нет

- Heterogeneous Reactor Modeling For Simulation of Catalytic OxidationДокумент9 страницHeterogeneous Reactor Modeling For Simulation of Catalytic OxidationserchОценок пока нет

- Kinetic Aspects in The OxidationДокумент5 страницKinetic Aspects in The OxidationKatiane MesquitaОценок пока нет

- Modelling Ammonia Oxidation in Gauze ReactorsДокумент7 страницModelling Ammonia Oxidation in Gauze ReactorsJosiah UyОценок пока нет

- Hydrogen Storage in Solar Produced Single-Walled Carbon NanotubesДокумент6 страницHydrogen Storage in Solar Produced Single-Walled Carbon NanotubesMohammad Javad TavakkoliОценок пока нет

- Dry Reforming of Methane Over The Cobalt Catalyst Theoretical Insights Into The Reaction Kinetics and Mechanism For Catalyst DeactivationДокумент9 страницDry Reforming of Methane Over The Cobalt Catalyst Theoretical Insights Into The Reaction Kinetics and Mechanism For Catalyst DeactivationJin WangОценок пока нет

- Review Article The Pressure-Temperature Phase and Transformation Diagram For Carbon Updated Through 1994Документ13 страницReview Article The Pressure-Temperature Phase and Transformation Diagram For Carbon Updated Through 1994cris1104Оценок пока нет

- Phase Behaviors of Room Temperature IoniДокумент5 страницPhase Behaviors of Room Temperature Ionihusainramadhan784Оценок пока нет

- Kinetics and Modeling of Carbon Dioxide Absorption Into Aqueous Solutions of DiethanolamineДокумент8 страницKinetics and Modeling of Carbon Dioxide Absorption Into Aqueous Solutions of Diethanolaminefarah al-sudaniОценок пока нет

- 95/03527 About Using Fly Ash As Raw Material For Cellular-Expanded ConcreteДокумент1 страница95/03527 About Using Fly Ash As Raw Material For Cellular-Expanded ConcreteGriefer NoobierОценок пока нет

- WWW Kuyhaa MeДокумент1 страницаWWW Kuyhaa MeviaОценок пока нет

- Soal Rivaldo PDFДокумент1 страницаSoal Rivaldo PDFArief FathОценок пока нет

- Soal Rivaldo PDFДокумент1 страницаSoal Rivaldo PDFArief FathОценок пока нет

- Soal Rivaldo PDFДокумент1 страницаSoal Rivaldo PDFArief FathОценок пока нет

- REGRESSION FOR Aging Variable Vs FTIRДокумент46 страницREGRESSION FOR Aging Variable Vs FTIRArief FathОценок пока нет

- Id I25 250KДокумент1 страницаId I25 250KSyahbana Endra PrakosoОценок пока нет

- Arief Fath (Type The Sender Company Name) (Type The Sender Company Address)Документ1 страницаArief Fath (Type The Sender Company Name) (Type The Sender Company Address)Arief FathОценок пока нет

- Book 1Документ7 страницBook 1Arief FathОценок пока нет

- Linear 2017 - NonLinear (EDIT)Документ64 страницыLinear 2017 - NonLinear (EDIT)Arief FathОценок пока нет

- Constitutive Modeling of Oxidative Aging Effects on Damage Response of Asphalt ConcreteДокумент22 страницыConstitutive Modeling of Oxidative Aging Effects on Damage Response of Asphalt ConcreteArief FathОценок пока нет

- Aging and Constitutive Modeling of Asphalt Mixtures: Research Developments in BrazilДокумент13 страницAging and Constitutive Modeling of Asphalt Mixtures: Research Developments in BrazilArief FathОценок пока нет

- Soundness of Aggregates by Use of Sodium Sulfate or Magnesium SulfateДокумент5 страницSoundness of Aggregates by Use of Sodium Sulfate or Magnesium SulfateArief FathОценок пока нет

- Construction and Building Materials: Hui Yao, Qingli Dai, Zhanping YouДокумент10 страницConstruction and Building Materials: Hui Yao, Qingli Dai, Zhanping YouArief FathОценок пока нет

- Of In: The Kinetics Carbonyl Formation AsphaltДокумент8 страницOf In: The Kinetics Carbonyl Formation AsphaltArief Fath100% (1)

- Predicting The Dynamic Modulus of Asphalt Concrete by Binder DSR TestingДокумент8 страницPredicting The Dynamic Modulus of Asphalt Concrete by Binder DSR TestingArief FathОценок пока нет

- Characterization of Aging on Asphalt Mixture SurfacesДокумент11 страницCharacterization of Aging on Asphalt Mixture SurfacesArief FathОценок пока нет

- Readme KmsДокумент1 страницаReadme KmsAnasCrispОценок пока нет

- Soundness of Aggregates by Use of Sodium Sulfate or Magnesium SulfateДокумент5 страницSoundness of Aggregates by Use of Sodium Sulfate or Magnesium SulfateArief FathОценок пока нет

- S1 Teknik Sipil Kurikulum 2016Документ23 страницыS1 Teknik Sipil Kurikulum 2016AlwendiОценок пока нет

- Determining The Percentage of Fractured Particles in Coarse AggregateДокумент6 страницDetermining The Percentage of Fractured Particles in Coarse AggregateArief FathОценок пока нет

- D5821 39690Документ5 страницD5821 39690Arief FathОценок пока нет

- VSS Image PDFДокумент12 страницVSS Image PDFIsaac LimОценок пока нет

- D2419 3434Документ10 страницD2419 3434Arief FathОценок пока нет

- Determining The Percentage of Fractured Particles in Coarse AggregateДокумент6 страницDetermining The Percentage of Fractured Particles in Coarse AggregateArief FathОценок пока нет

- Itenerary Winter Vacation 2017Документ2 страницыItenerary Winter Vacation 2017Arief FathОценок пока нет

- Determining The Percentage of Fractured Particles in Coarse AggregateДокумент6 страницDetermining The Percentage of Fractured Particles in Coarse AggregateArief FathОценок пока нет

- Extensometer Install ProceduresДокумент2 страницыExtensometer Install ProceduresArief FathОценок пока нет

- Sap2000 GeneralДокумент64 страницыSap2000 GeneralInsa Intameen100% (1)

- Track EngineeringДокумент14 страницTrack EngineeringArief FathОценок пока нет

- ! - 2008 - Zhang - (Hanover) Calculation of Pressure and Temperature in Medium-Voltage Electrical InstallationsДокумент12 страниц! - 2008 - Zhang - (Hanover) Calculation of Pressure and Temperature in Medium-Voltage Electrical InstallationsMikeОценок пока нет

- Cigre SF6 234Документ60 страницCigre SF6 234spock2030100% (2)

- Chemical Equilibrium MisconceptionДокумент9 страницChemical Equilibrium MisconceptionSumathi GanasenОценок пока нет

- 2 Synthesis of PFDДокумент65 страниц2 Synthesis of PFDMelissa HuynhОценок пока нет

- Hex A Heli Cenar Chiv Date IДокумент6 страницHex A Heli Cenar Chiv Date IKatherine PunoОценок пока нет

- Patrick A. Domenico, Franklin W. Schwartz Physical and Chemical Hydrogeology PDFДокумент554 страницыPatrick A. Domenico, Franklin W. Schwartz Physical and Chemical Hydrogeology PDFJose Suarez100% (6)

- Coordination Chemistry Reviews: Organocatalytic and Metal-Mediated Asymmetric (3 + 2) Cycloaddition ReactionsДокумент15 страницCoordination Chemistry Reviews: Organocatalytic and Metal-Mediated Asymmetric (3 + 2) Cycloaddition ReactionsvortexDBОценок пока нет

- Research ProposalДокумент6 страницResearch ProposalTaibi AyoubОценок пока нет

- Recovery of Sulfwr From Sour AcidДокумент20 страницRecovery of Sulfwr From Sour AcidAnnejan VisserОценок пока нет

- SPM Chemistry Revision Module On The BasicsДокумент64 страницыSPM Chemistry Revision Module On The Basicssuritanu96Оценок пока нет

- Rules For Assigning Oxidation Numbers To ElementsДокумент6 страницRules For Assigning Oxidation Numbers To ElementsAlyssa CoderiasОценок пока нет

- Iit Jee Main SyllabusДокумент25 страницIit Jee Main SyllabusIITIAN SANJEEV[IITK]Оценок пока нет

- India Sol-Gel AOS PDFДокумент38 страницIndia Sol-Gel AOS PDFsethupathiОценок пока нет

- UTAR Chem Lab 1 Full Report Exp17Документ4 страницыUTAR Chem Lab 1 Full Report Exp17Izykiel EdwardОценок пока нет

- 12 - Alkanes Lecture NotesДокумент15 страниц12 - Alkanes Lecture Notesقاتل مستأجرОценок пока нет

- Experiment 1: Reactions of Aliphatic HydrocarbonsДокумент8 страницExperiment 1: Reactions of Aliphatic HydrocarbonsTHASVIN OFFICIAL NETWORKОценок пока нет

- CHEM 210-1 Organic Chemistry NotesДокумент26 страницCHEM 210-1 Organic Chemistry NotesRobert GardnerОценок пока нет

- RevisionSheet 7 Chemistry FinalДокумент4 страницыRevisionSheet 7 Chemistry FinalalexlolzОценок пока нет

- Overview of CSTR Design With MatlabДокумент3 страницыOverview of CSTR Design With MatlabhlvijaykumarОценок пока нет

- Process Details: Reactor Feed Preheat/ Effluent CoolerДокумент4 страницыProcess Details: Reactor Feed Preheat/ Effluent CoolerMohamed TarekОценок пока нет

- Primary and Secondary MetabolitesДокумент1 страницаPrimary and Secondary Metabolitesahmalh01Оценок пока нет

- Chem 17 Formal ReportДокумент4 страницыChem 17 Formal Reportchemeister111Оценок пока нет

- Erdi+Toth MassactionДокумент284 страницыErdi+Toth Massactionmathbiology100% (1)

- Carbon Compounds MCQsДокумент10 страницCarbon Compounds MCQssenjicsОценок пока нет

- Types of Chemical Reactions ExplainedДокумент36 страницTypes of Chemical Reactions ExplainedAira Villarin100% (2)

- Manfred Baerns Catalyst Deactivation 110121 PDFДокумент38 страницManfred Baerns Catalyst Deactivation 110121 PDFRaghunath VenkatramananОценок пока нет

- A Feasibility Study Analysing Various Process Routes of The Production of Ethyl AcetateДокумент17 страницA Feasibility Study Analysing Various Process Routes of The Production of Ethyl AcetateNastase DamianОценок пока нет

- Test Bank For Chemistry An Atoms Focused Approach 3rd Edition Thomas R Gilbert Rein V Kirss Stacey Lowery Bretz Natalie FosterДокумент13 страницTest Bank For Chemistry An Atoms Focused Approach 3rd Edition Thomas R Gilbert Rein V Kirss Stacey Lowery Bretz Natalie Fosterupbreakneginothf4bОценок пока нет

- Dichtol WFT SD - 1532 - EN - 2Документ8 страницDichtol WFT SD - 1532 - EN - 2gersomОценок пока нет

- PekaДокумент64 страницыPekamasitahadenanОценок пока нет