Академический Документы

Профессиональный Документы

Культура Документы

Ls02 Cap Bank

Загружено:

delvin26Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ls02 Cap Bank

Загружено:

delvin26Авторское право:

Доступные форматы

L-S2 (April 1999)

SPECIFICATION FOR LOW VOLTAGE AUTOMATIC POWER FACTOR

CORRECTION EQUIPMENT

ITEM CONTENTS PAGE

1.0 General 1

2.0. Capacitors 1

2.1. Type 1

2.2. Standard 1

2.3. Losses 2

2.4. Protection 2

2.5. Discharge Device 2

2.6. Ambient Temperature 2

2.7. Voltage Rating And Maximum Permissible Current 2

2.8. Housing 3

2.9. Test Results 3

3.0 Series Blocking Reactors 3

4.0 Power Factor Correction Regulators 4

4.1 Type 4

4.2 Switching Sequence 4

4.3 Setting And Display 5

4.4 Alarm 5

4.5 Mode Of Operation 6

5.0 Switchgears 6

5.1 Moulded Case Circuit Breakers 6

5.2 Switching Contactors 7

6.0 Power Factor Correction Boards 8

6.1 Enclosures 8

6.2 Busbars 9

SPECIFICATION FOR LOW VOLTAGE AUTOMATIC POWER FACTOR CORRECTION EQUIPMENT

©Hak Cipta : 1999 Cawangan Elektrik JKR Malaysia

i/ii

L-S2 (April 1999)

6.3 Shop Drawings 9

7.0 Testing And Test Certificates 9

8.0 Service And Maintenance 11

9.0 As-installed Drawings, Manuals And Tools 11

10.0 Appendix A : Schedule Of Technical Data And Guarantee I - IV

SPECIFICATION FOR LOW VOLTAGE AUTOMATIC POWER FACTOR CORRECTION EQUIPMENT

©Hak Cipta : 1999 Cawangan Elektrik JKR Malaysia

ii/ii

L-S2 (April 1999)

SPECIFICATION FOR LOW VOLTAGE AUTOMATIC POWER FACTOR

CORRECTION EQUIPMENT

1.0 GENERAL

This section of the Specification describes and specifies requirements for the

supply, delivery, installation, testing, commissioning, handing over in approved

working order and maintenance thereafter during the Defects Liability Period of

the low voltage automatic power factor correction equipment in accordance with

the Specification, Supplementary Notes, Bill of Quantities, Condition of

Contracts and Drawings.

All items incorporated for the complete installation of the automatic power factor

correction equipment not specifically covered by this Specification shall be

deemed to comply with the relevant sections and requirements as prescribed in

other Specifications included herewith this Specification.

Tenderer shall submit together with his tender catalogues and literatures

describing the capacitors, series blocking reactors and power factor

regulators offered in addition to filling in Appendix A (Schedule of

Technical Data and Guarantee) to this Specification.

2.0 CAPACITORS

2.1 TYPE

The power factor correction capacitor (hereinafter referred to as “capacitor”)

shall be of dry type and self-healing. The dielectric medium shall be metallised

polypropylene film or foil. The elements shall be insulated with fire-proof

material. The capacitor shall be environmentally-friendly.

2.2 STANDARD

The capacitor shall comply with IEC 60831 Part 1 and Part 2.

SPECIFICATION FOR LOW VOLTAGE AUTOMATIC POWER FACTOR CORRECTION EQUIPMENT

©Hak Cipta : 1999 Cawangan Elektrik JKR Malaysia

1/13

L-S2 (April 1999)

2.3 LOSSES

The losses of the capacitor shall be not more than 0.5 watt per kvar at the

specified ambient temperature measured at the connecting terminals.

2.4 PROTECTION

The capacitor shall be provided with overload disconnector which will interrupt

the internal connection and disconnect the capacitor from the circuit in the event

of pressure built-up within the capacitor.

2.5 DISCHARGE DEVICE

Each capacitor shall be provided with suitable means to discharge the capacitor to

50 volts or less within 60 seconds from an initial peak voltage of √2 times the

rated voltage. No isolating device, fuse or otherwise shall be placed between the

capacitor and the discharge device.

2.6 AMBIENT TEMPERATURE

The capacitor shall be Category C rated and suitable for operation under tropical

ambient conditions with the highest mean temperature of 40 0C over a 24 hour

period of continuous operation.

2.7 VOLTAGE RATING AND MAXIMUM PERMISSIBLE CURRENT

Capacitor shall be rated at 525 volts, 50 Hz.

The capacitor shall be suitable for continuous operation at an r.m.s. line current

of 1.3 times the rated current that occurs at the rated sinusoidal voltage and rated

frequency of the supply source. The rated short time peak current of the capacitor

shall be at least 140 times the rated current.

SPECIFICATION FOR LOW VOLTAGE AUTOMATIC POWER FACTOR CORRECTION EQUIPMENT

©Hak Cipta : 1999 Cawangan Elektrik JKR Malaysia

2/13

L-S2 (April 1999)

2.8 HOUSING

The capacitor shall be housed in container fabricated from heavy metal sheet steel

coated with non-corrosive polyurethane resin enamel or in extrusion-processed

aluminium container.

2.9 TEST RESULTS

Factory certified test results for routine test shall be provided for the capacitors

supplied. The routine tests according to IEC 60831 shall include -

(a) Test voltage between terminals - 1.75 times capacitor

rated voltage for 2

seconds

(b) Measuring voltage - 525 V, 50 Hz

(c) Voltage test between

terminals and container - 3000 V, 50 Hz for 10

seconds; or 3600 V,

50 Hz for 2 seconds

(d) Capacitance measurement

(e) Loss measurement

3.0 SERIES BLOCKING REACTORS

Where series blocking reactors (hereafter referred as “reactor”) are specified in

the Drawings and/or Bill of Quantities, they shall be of dry type copper windings

rated at 440 volts 50 Hz. class H insulation connected in series with the

capacitors suitable to operate in ambient temperature up to 40 0C. Unless

otherwise specified in the Drawings and/or Bill of Quantities, the kvar rating

(reactance) of the reactor shall be 6 % to the kvar rating (reactance) of the

capacitor to where the reactor will be connected.

The reactors shall be securely fastened and installed in a separate compartment of

the power factor correction board. If necessary, rubber pad shall be used to

reduce noise.

SPECIFICATION FOR LOW VOLTAGE AUTOMATIC POWER FACTOR CORRECTION EQUIPMENT

©Hak Cipta : 1999 Cawangan Elektrik JKR Malaysia

3/13

L-S2 (April 1999)

4.0 POWER FACTOR REGULATOR

4.1 TYPE

The power factor regulators (hereinafter referred to as “regulator”) shall be

micro-processor based, solid state in construction, compact, easy to install and

use. The regulator shall automatically and/or manually step-in or step-out

various capacitors to correct the power factor to the required pre-set level.

The regulator shall be insensitive to harmonics and screened from stray electric

and magnetic interference and shall be housed in case suitable for panel mounting.

Operating ambient temperature shall be up to 60 0C.

The regulator shall be 6 or 12 steps type as specified in the Drawing and/or Bill

of Quantities. No-voltage trip and zero current trip shall be provided. For a

voltage loss of longer than 15 ms or current loss of longer than 3 s, all capacitor

stages connected shall be switched off. until discharged. After voltage or current

is restored the regulator switches the required steps on.

4.2 SWITCHING SEQUENCE

The regulator shall incorporate minimum following automatic switching sequence

modes, viz. cyclic switching sequence and multi-step switching sequence allowing

minimum following combinations of switching programme of capacitor stages:

(a) 1:1:1:1:1:1 … (b) 1:1:2:2:2:2 …

(c) 1:1:2:2:4:4 … (d) 1:2:2:2:2:2 …

(e) 1:2:4:4:4:4 … (f) 1:2:4:8:8:8 …

The first three control output may be allowed to be set as fixed steps which are

not included in the normal control cycle but are switched on immediately after the

regulator is switched on and always remain switched on.

SPECIFICATION FOR LOW VOLTAGE AUTOMATIC POWER FACTOR CORRECTION EQUIPMENT

©Hak Cipta : 1999 Cawangan Elektrik JKR Malaysia

4/13

L-S2 (April 1999)

4.3 SETTING AND DISPLAY

The following settings and displays shall be incorporated :-

(a) Continuous digital actual power factor display

(0.00 inductive - 1.00 - 0.00 capacitive);

(b) Capacitor step indication;

(c) C/k inductive setting and display;

(d) C/k capacitive setting and display;

(e) Target power factor setting and display

(0.80 inductive - 1.00 - 0.80 capacitive);

(f) Operation delay setting and display (5 s to 300 s);

(g) Apparent current display or Active/Reactive current displays;

(h) Flashing display when alarm is activated.

If specified in the Drawing and/or Bill of Quantities, the following setting and

display shall be incorporated in addition to the above :-

(a) Harmonics content display (5th, 7th and 11th harmonics on

voltage);

4.4 ALARM

Provision of following alarm shall be incorporated :-

(a) Power factor alarm :

If the threshold values set for ‘switch-on’ and ‘switch-off’ are

exceeded and no further change can take place in the output

steps, the alarm signal functions.

If specified in the Drawing and/or Bill of Quantities, the following alarms shall be

incorporated in addition to the above :-

SPECIFICATION FOR LOW VOLTAGE AUTOMATIC POWER FACTOR CORRECTION EQUIPMENT

©Hak Cipta : 1999 Cawangan Elektrik JKR Malaysia

5/13

L-S2 (April 1999)

(a) Harmonic Alarm :

When the harmonics threshold values are exceeded, the alarm

goes off; and

(b) Over-current alarm :

If the capacitor current exceeded the rated current set, the alarm

goes off.

4.5 MODE OF OPERATION

When the regulator is in manual operation mode, the capacitor steps can be

switched in step by step and switched out in reverse step by step manually. The

step that is being switched on shall be displayed.

With the regulator in OFF mode, all equipment shall be switched off and de-

energised.

In the automatic mode, the regulator shall switched in or switched out the required

capacitors without undue switching on and switching off at any particular step to

reach the nominal target power factor.

In any event the zero voltage release function must take precedent at all modes of

operation to prevent capacitive current surge.

5.0 SWITCHGEARS

All switchgears shall have voltage and frequency rating suitable for the power

system to which they are connected to. The current rating shall not be less than

that specified in the Drawings and/or Bill of Quantities. They shall conform to

the latest relevant IEC Standards.

5.1 MOULDED CASE CIRCUIT BREAKERS

Moulded case circuit breakers (mccb) shall have the number of poles as specified

in the Drawings and/or Bill of Quantities. They shall comply with IEC 60947-1

SPECIFICATION FOR LOW VOLTAGE AUTOMATIC POWER FACTOR CORRECTION EQUIPMENT

©Hak Cipta : 1999 Cawangan Elektrik JKR Malaysia

6/13

L-S2 (April 1999)

and IEC 60947-2. They shall be fully tropicalised and suitable to be used up to

an ambient temperature of 40 0C, enclosed in glass-reinforced polyester moulded

case and suitable for use on 240/415 V, 50 Hz. a.c. supply system.

They shall be of the quick-make, quick-break type having manually operable

toggle type handle. Permanent position indicators shall be provided to show status

of the breaker. When tripping occurs, the handle shall be in the `trip' position

midway between the 'OFF' and 'ON' or ‘Ο’ and ‘|’ position so as to provide

positive indication of automatic interruption. The operating mechanism shall

be non-tamperable.

The mccb shall have trip-free feature to prevent the breaker from being closed

against fault conditions. Multipole mccb shall have common-trip operating

mechanism for simultaneous operation of all poles.

The tripping units shall be of thermal-magnetic type with bimetallic elements for

inverse time-delay overload protection and magnetic elements for short circuit

protection.

An arc extinguisher shall be incorporated to confine, divide and extinguish the arc

drawn between the breaker contacts each time a breaker interrupts current. The

contacts shall be of non-welding type.

Unless otherwise specified in the Drawings and/or Bill of Quantities, the

minimum a.c. interrupting capacity of the mccb shall be 50 kA rms (symmetrical)

for 1 second at 415 V. The rated service short-circuit breaking capacity (Ics) of

the mccb shall be 100% of the rated ultimate short-circuit breaking capacity (Icu)

at 415 volts. Unless otherwise specified in the Drawings and/or Bill of

Quantities, the minimum continuous current ratings for the mccb shall be of

155 % of the rated capacitor currents.

5.2 SWITCHING CONTACTORS

The switching contactors shall comply with IEC 60947-4-1 and shall be of

utilization category AC-6B rated for switching low inductance capacitors.

They shall be fully tropicalised, suitable for use on 240/415 V, 50 Hz. a.c.

system. The operating coil shall be 240 V 50 Hz. a.c. type and shall operate

satisfactorily when the voltage at the coil terminals is between 85% and 110% of

the nominal voltage. The electro-magnet shall be of laminated type.

SPECIFICATION FOR LOW VOLTAGE AUTOMATIC POWER FACTOR CORRECTION EQUIPMENT

©Hak Cipta : 1999 Cawangan Elektrik JKR Malaysia

7/13

L-S2 (April 1999)

Unless otherwise specified in the Drawing and/or Bill of Quantities, the minimum

continuous current ratings for the switching contactors and the connection cables

shall be of minimum 135 % of rated capacitor currents.

6.0 POWER FACTOR CORRECTION BOARDS

6.1 ENCLOSURES

The power factor correction boards (hereinafter referred to as “board”) shall be

suitable for operation on a 240/415 V, 3 phase, 4 wire, 50 Hz. system with solidly

earthed neutral. Unless otherwise specified, the board shall be capable of

withstanding the fault condition of not less than 50 kA at 415 V for 1 s as defined

in IEC 60439-1.

The board shall not form part of but shall be independent and match the height

and depth of the switchboard it is connected to. The board shall be self-contained,

floor mounted, flush fronted, metalclad cubicle suitable for front and rear

access, fabricated from rolled steel sections of thickness not less than 2.5 mm

for framework and 2.0 mm for all panels, covers, and doors. They shall be of

Form 2b separation with busbars separated from the switchgears and the

incoming and outgoing terminals by metallic or non-metallic rigid barriers or

partitions.

The board shall provide adequate dimensions for efficient natural heat dissipation

of the capacitors and reactors at normal ambient temperature. The capacitors

shall be separated at not less than 80 mm apart. All ventilation vent shall be

provided with filter. In addition, ventilation fan with automatic shutter of

capacity not less than 200 cubic metre per hour shall be installed. The fan

complete with control switch and indicating lamp shall operate either

automatically and/or manually with thermostat control at preset temperature.

The board shall undergo de-rusting treatment, anti-rust treatment and be finished

with epoxy dry-powder and oven baked semi-gloss enamel grey.

SPECIFICATION FOR LOW VOLTAGE AUTOMATIC POWER FACTOR CORRECTION EQUIPMENT

©Hak Cipta : 1999 Cawangan Elektrik JKR Malaysia

8/13

L-S2 (April 1999)

6.2 BUSBARS

Busbars shall conform to BS 159 and shall be tinned hard drawn high

conductivity copper with an adequate uniform rectangular cross section to carry

continuously their rated current without overheating. They shall be rigidly

mounted on non-hygroscopic insulators so as to withstand any mechanical

stresses to which they may be subjected under maximum fault condition.

Busbar sizes must not be less than that specified in the Drawings. However if the

busbar sizes are not specified, then the busbar rating shall be based on a current

density of not more than 1.5 A/sq. mm. In any case, the busbars rating shall not

be less than the rating of the incoming switchgear. Where multiple parallel bars

are used, they shall be separated by tinned copper spacers at spacing equal to the

busbar thickness.

The main busbars shall be run for the full length of the board without reduction in

size. Neutral busbar shall be of full size and full length as the phase busbars.

Connections shall be made up with bronze or other copper alloy bolts and nuts

utilising tension washers on both outer faces.

Tinned copper earthing bar of cross sectional area not less than 50 mm x 6 mm

shall run along the board for its entire length.

6.3 SHOP DRAWINGS

Two copies of shop drawings for the board showing the dimensional general

arrangement and layout of the equipment and the schematic line diagram shall be

submitted to the S.O.’s Representative for approval. No fabrication of the board

shall proceed without the shop drawings being approved by the S.O.’s

Representative.

7.0 TESTING AND TEST CERTIFICATES

After the installation work has been completed and before Certificate of Practical

Completion is issued, the whole electrical installation covered under this part of

the Contract shall be tested as prescribed in Electricity Regulations 1994 and IEC

60364 and any other tests deem necessary by the S.O.'s Representative. In the

SPECIFICATION FOR LOW VOLTAGE AUTOMATIC POWER FACTOR CORRECTION EQUIPMENT

©Hak Cipta : 1999 Cawangan Elektrik JKR Malaysia

9/13

L-S2 (April 1999)

event the installation fails to pass any of these tests, the Electrical Contractor

shall take such measures as are necessary to remedy the defects and the

installation shall not be considered as completed until all such tests have been

passed.

The tests to be carried out by the Electrical Contractor shall consist of the

following tests as a minimum requirement:-

(a) Continuity of protective conductors including main and

supplementary equipotential bonding;

(b) Insulation resistance;

(c) Polarity;

(d) Functional testing - operational tests for regulators and circuit

breakers, on-off test for switches, etc.

All protection relays and device and power factor regulators shall be checked,

tested and calibrated by an Electrical Services Engineer registered with Jabatan

Bekalan Elektrik Malaysia. Stability and functionality test shall also be carried

out to ensure the installation is in safe and good working order. The Electrical

Contractor shall arrange with the Electrical Services Engineer to conduct and

carry out the necessary check, test and calibration of the protection relays and

device and regulators.

Fee required for the check, test and calibration as described above is deemed

to be included in the Contract.

The S.O.'s Representative reserves the right to be present at all tests and the

Electrical Contractor shall give at least one week notice in writing to the S.O.'s

Representative for this purpose. In any case, no test shall be carried out without

prior approval of the S.O.'s Representative. Copies of all the tests certificates

together with as-installed Drawings properly bound and titled shall be submitted

to the S.O.'s Representative within one week after the completion of the testing.

Two sets of Supervision and Completion Certificate and Test Certificate including

copies of all the test results and drawings as prescribed in Electricity Regulations

1994 shall be submitted to the S.O.’s Representative within two weeks after the

completion of the testing. The aforesaid Certificates shall be properly bound in

hard cover and titled

SPECIFICATION FOR LOW VOLTAGE AUTOMATIC POWER FACTOR CORRECTION EQUIPMENT

©Hak Cipta : 1999 Cawangan Elektrik JKR Malaysia

10/13

L-S2 (April 1999)

8.0 SERVICE AND MAINTENANCE

During the Defects Liability Period, the Electrical Contractor shall be responsible

for making good all defects for the complete installation. The Electrical

Contractor shall bear all cost incurred to rectify the defects.

The rectification work to be performed shall include but not limited to the

following:-

(a) Replacing or making good all regulators, control gears,

capacitors, reactors, fuses, mccb, contactors, etc.

(b) Replacing and making good all loose and burnt cables and

termination, all mechanical support linkage, etc.

(c) Making good any damage to roads, buildings, drains, cables,

pipes, concrete areas, paved areas etc. which had not been

properly made good arising out of his work.

(d) All other works as deemed necessary by the S.O.'s

Representative.

All works shall be carried out as soon as the Electrical Contractor is informed by

the S.O.'s Representative or the occupant and shall be completed within a

reasonable time except under emergency situation as stipulated in the

Supplementary Conditions for Electrical Work. If the Electrical Contractor fails

to comply with the above requirements, the S.O.'s Representative reserves the

right to engage another party to carry out the work, in which case, the Electrical

Contractor shall be responsible for all the expenses incurred.

9.0 AS INSTALLED DRAWINGS, MANUALS AND TOOLS

Within three calendar months after the practical completion of the project, one set

of true to scale negative (155/115 gm/sq. ISO AO or A1 size) and four sets of

prints for each of the following drawings shall be submitted:-

(a) Site plan;

(b) Schematic Wiring Diagram and Electrical Layout Plans;

SPECIFICATION FOR LOW VOLTAGE AUTOMATIC POWER FACTOR CORRECTION EQUIPMENT

©Hak Cipta : 1999 Cawangan Elektrik JKR Malaysia

11/13

L-S2 (April 1999)

(c) Control Circuits drawings;

(d) Layout plans of cable routes and earthing points with reference

to easily recognisable buildings and structures.

These drawings shall be properly stenciled and shall have at the lower right hand

corner the Electrical Contractor's name and address, date of commissioning, scale,

drawing number (the drawing number to be obtained from the S.O.'s

Representative), title and following particulars:-

JABATAN KERJA RAYA

CAWANGAN ELEKTRIK

CONTRACT NO.:

TENDER NO.:

If the drawings submitted are not acceptable by the S.O.'s Representative, the

Electrical Contractor shall amend and re-submit the drawings within two weeks

from the date of return of the drawings.

If required and specified elsewhere, in addition to the aforesaid negatives and

prints, as installed drawings shall be stored in electronic media or any other

media as specified. For electronic media they shall be either in floppy disks

format or CD rewritable (CD-RW ) optical disks format as specified which can

be easily retrieved by computer. The software programme shall be AutoCAD

of latest release. Two sets or copies in either format as specified, appropriately

titled and stored in container or casing, shall be submitted.

In addition, four sets of the following manuals and documents for regulators,

capacitors, reactors, mccb and other important electrical switchgears shall be

supplied:-

(a) Installation manual;

(b) Operation manual;

(c) Service and Maintenance Manual;

(d) Parts List;

(e) Product Data and catalogue;

(f) Product Test Certificates;

SPECIFICATION FOR LOW VOLTAGE AUTOMATIC POWER FACTOR CORRECTION EQUIPMENT

©Hak Cipta : 1999 Cawangan Elektrik JKR Malaysia

12/13

L-S2 (April 1999)

Each of the above sets of prints together with the manuals shall be in a stiff cover

ring file.

The cost of all these prints, manuals, tools etc. is deemed to be included in the

Contract.

* * * * * * * * * * * * * * * * * * * *

SPECIFICATION FOR LOW VOLTAGE AUTOMATIC POWER FACTOR CORRECTION EQUIPMENT

©Hak Cipta : 1999 Cawangan Elektrik JKR Malaysia

13/13

L-S2 (April 1999)

APPENDIX A

SCHEDULE OF TECHNICAL DATA AND GUARANTEE

(Note: Unless otherwise specified elsewhere, the information indicated in italic are as

stated in the Specification)

(A) CAPACITORS

(1) Make :....................................

(2) Country of Manufacture :....................................

(3) Model No. :....................................

(4) Type (Dry Type) :....................................

(5) Losses (Not more than 0.5 watts per kvar) :....................................

(6) Rated Voltage (525 V) :....................................

(7) Ambient Operating Temperature (40 0C) :....................................

(8) Maximum Permissible Current

(1.3 times rated current) :....................................

(9) Housing :....................................

(B) SERIES BLOCKING REACTORS

(1) Make :....................................

(2) Country of Manufacture :....................................

(3) Model No. :....................................

SPECIFICATION FOR LOW VOLTAGE AUTOMATIC POWER FACTOR CORRECTION EQUIPMENT

©Hak Cipta : 1999 Cawangan Elektrik JKR Malaysia

I/IV

L-S2 (April 1999)

(4) Type :....................................

(5) Winding (Copper) :....................................

(6) Rated Voltage (440 V) :....................................

(7) Ambient Operating Temperature (40 0C) :....................................

(C) POWER FACTOR REGULATORS

(1) Make :....................................

(2) Country of Manufacture :....................................

(3) Model No. :....................................

(4) Type (Micro-processor Based) :....................................

(5) Number of Steps :....................................

(6) Rated Voltage :....................................

(7) Ambient Operating Temperature (40 0C) :....................................

(8) Modes of Operation

(Manual/Cyclic/Multi Steps) :....................................

(9) Settings and Displays

(a) Power Factor Display :.............. Yes / No

(b) Capacitor Step Indication :.............. Yes / No

(c) C/k Inductive Setting and Display :.............. Yes / No

(d) C/k Capacitive Setting and Display :.............. Yes / No

(e) Target Power Factor Setting and Display:.............. Yes / No

SPECIFICATION FOR LOW VOLTAGE AUTOMATIC POWER FACTOR CORRECTION EQUIPMENT

©Hak Cipta : 1999 Cawangan Elektrik JKR Malaysia

II/IV

L-S2 (April 1999)

(f) Operation Current Setting and Display :.............. Yes / No

(g) Apparent Current Display :.............. Yes / No

(h) Flashing Display When Alarm Activated:............... Yes / No

(i) Harmonics Content Display :.............. Yes / No

(10) Alarm

(a) Power Factor Alarm :.............. Yes / No

(b) Harmonic Alarm :.............. Yes / No

(c) Over-current Alarm :.............. Yes / No

(D) MOULDED CASE CIRCUIT BREAKERS

(1) Make :....................................

(2) Country of Manufacture :....................................

(3) Model No. :....................................

(4) Type :....................................

(5) Rated Voltage :....................................

(6) Rated Interrupting Current Capacity (50 kA, 1 s) :....................................

(7) Rated Service Short Circuit

Breaking Capacity (100%) :....................................

(E) SWITCHING CONTACTORS

(1) Make :....................................

(2) Country of Manufacture :....................................

SPECIFICATION FOR LOW VOLTAGE AUTOMATIC POWER FACTOR CORRECTION EQUIPMENT

©Hak Cipta : 1999 Cawangan Elektrik JKR Malaysia

III/IV

L-S2 (April 1999)

(3) Model No. :....................................

(4) Type :....................................

(5) Utilization Category (AC-6b) :....................................

(6) Rated Voltage :....................................

(7) Rated Voltage for Operating Coil (240 V) :....................................

(F) VENTILATION FANS

(1) Make :....................................

(2) Country of Manufacture :....................................

(3) Model No. :....................................

(4) Type :....................................

(5) Diameter :....................................mm

(6) Air Exchange (200 cmh) :....................................

...................................................................... ..................................

(Cop dan Tandatangan Kontraktor Elektrik) (Tarikh)

SPECIFICATION FOR LOW VOLTAGE AUTOMATIC POWER FACTOR CORRECTION EQUIPMENT

©Hak Cipta : 1999 Cawangan Elektrik JKR Malaysia

IV/IV

Вам также может понравиться

- LS - 2 Power FactorДокумент33 страницыLS - 2 Power FactorsugunavengadasonОценок пока нет

- LS-1 Specification For Low Voltage Internal Electrical InstallationДокумент64 страницыLS-1 Specification For Low Voltage Internal Electrical Installationkmleongmy100% (2)

- Specification For 11 KV Dry-Type Distribution TransformersДокумент48 страницSpecification For 11 KV Dry-Type Distribution TransformerssaifulОценок пока нет

- ILSAS DistributionДокумент15 страницILSAS DistributionFaizal FezalОценок пока нет

- Cable Slab TNBДокумент20 страницCable Slab TNBPoi 3647Оценок пока нет

- TNBДокумент26 страницTNBJeff Erick Firas100% (1)

- LS02Документ33 страницыLS02nazmiОценок пока нет

- JKR 11kV Transformer TestДокумент29 страницJKR 11kV Transformer TestSeanChanОценок пока нет

- Esah 3.1Документ34 страницыEsah 3.1maurice86100% (1)

- HT System Design and Criteria: The 2 Most Common HT Supplies Provided by TNB Are 11 KV and 33 KVДокумент1 страницаHT System Design and Criteria: The 2 Most Common HT Supplies Provided by TNB Are 11 KV and 33 KVLeong KmОценок пока нет

- CPL King Centre Stutong DecДокумент1 страницаCPL King Centre Stutong DecMadeline Chia100% (1)

- JKR Specification For 11 KV High VoltageДокумент16 страницJKR Specification For 11 KV High VoltageCherry AngОценок пока нет

- Past Year Q For Wireman 2Документ52 страницыPast Year Q For Wireman 2Polycarp Danson Sigai100% (1)

- Space and Room Requirement For Electrical WorksДокумент8 страницSpace and Room Requirement For Electrical WorksLoh Wan CheanОценок пока нет

- Elec - Cirt - JKRДокумент4 страницыElec - Cirt - JKRAyda JohariОценок пока нет

- Dokumen - Tips Form Testing JKRRCCB Rev 1Документ2 страницыDokumen - Tips Form Testing JKRRCCB Rev 1muhammadfaizmuhamadОценок пока нет

- InternshipДокумент26 страницInternshipfawwaz sazalliОценок пока нет

- Bab Elektrik: Suatu PengenalanДокумент82 страницыBab Elektrik: Suatu PengenalanSeindahNyaОценок пока нет

- L s9 Specification For LightningДокумент19 страницL s9 Specification For Lightningsuges85100% (1)

- Load Summary for Demand Under 100kVAДокумент2 страницыLoad Summary for Demand Under 100kVAPacu BerjemaahОценок пока нет

- EHLV - First Half PDFДокумент41 страницаEHLV - First Half PDFShahril ShahibullahОценок пока нет

- Minimum RequirementsДокумент12 страницMinimum RequirementsTeo Yan TeeОценок пока нет

- Li TNB PresentationДокумент13 страницLi TNB Presentationalif ismaОценок пока нет

- TNB Electricity System Voltages, Frequencies, Earthing Systems and Supply OptionsДокумент4 страницыTNB Electricity System Voltages, Frequencies, Earthing Systems and Supply OptionsSaiful RizamОценок пока нет

- EarthingДокумент65 страницEarthingAzura Abu100% (1)

- Work Experience - Tham Chung MengДокумент6 страницWork Experience - Tham Chung MengCm Tham (Facebook)Оценок пока нет

- Feeder PillarsДокумент43 страницыFeeder PillarsRyan BrittОценок пока нет

- Pendawaian Bawah Tanah PDFДокумент14 страницPendawaian Bawah Tanah PDFHisham AyobОценок пока нет

- Batt Cables: Current Rating 4D1A 4D1BДокумент1 страницаBatt Cables: Current Rating 4D1A 4D1BSaufiОценок пока нет

- Past Year Q For Wireman 1Документ18 страницPast Year Q For Wireman 1陈系铭100% (1)

- Connection Charges Guidelines 2020Документ20 страницConnection Charges Guidelines 2020Scalper100% (5)

- JKR Malaysia cable management technical guideДокумент0 страницJKR Malaysia cable management technical guideYoke ShuОценок пока нет

- 132kV Relay Cal Tender 17 June 2014Документ5 страниц132kV Relay Cal Tender 17 June 2014amirahОценок пока нет

- JKR IT Labelling Standard PDFДокумент7 страницJKR IT Labelling Standard PDFsean100% (1)

- 17.0 Lightning Protection Ms 1 Hingga 18Документ22 страницы17.0 Lightning Protection Ms 1 Hingga 18Leong KmОценок пока нет

- AMSGB Power Transformer Brochure (Final 27.05.2010)Документ4 страницыAMSGB Power Transformer Brochure (Final 27.05.2010)winston11Оценок пока нет

- Piawai Jambatan BombaДокумент5 страницPiawai Jambatan BombaKeen LoongОценок пока нет

- SOR Civil 2010Документ26 страницSOR Civil 2010Zool HilmiОценок пока нет

- Plan Bilik SDF TMДокумент46 страницPlan Bilik SDF TMCasper Chiang100% (1)

- KDK Exhaust Fans DatasheetsДокумент44 страницыKDK Exhaust Fans DatasheetsMujahed KhatibОценок пока нет

- Guideline On Indoor Air Quality Service For Hospital Support ServiceДокумент53 страницыGuideline On Indoor Air Quality Service For Hospital Support ServiceLee Jing YangОценок пока нет

- L-S03 Specification For Low Voltage Underground CableДокумент34 страницыL-S03 Specification For Low Voltage Underground CableMuhammad KhudriОценок пока нет

- TNB Metering Requirements for Distributed Generation FacilitiesДокумент8 страницTNB Metering Requirements for Distributed Generation FacilitiesAzree Mohd NoorОценок пока нет

- JKR Specs L-S1 Specification For Low Internal Electrical Installation May-2011 Rev.2Документ114 страницJKR Specs L-S1 Specification For Low Internal Electrical Installation May-2011 Rev.2Leong Km86% (7)

- 11kV 3 Core PILC SWA BS6480 Cable SpecificationДокумент3 страницы11kV 3 Core PILC SWA BS6480 Cable SpecificationMuhammad TaufiqОценок пока нет

- BQ 13 Street Lighting and Traffic PDFДокумент11 страницBQ 13 Street Lighting and Traffic PDFNurly SafОценок пока нет

- Single Phase Drawing Course InformationДокумент15 страницSingle Phase Drawing Course Informationmr_rizal2110Оценок пока нет

- Record For RCCB Test - JKRДокумент2 страницыRecord For RCCB Test - JKRBas Kontot100% (4)

- Load Summary for Premise Under 100kVAДокумент2 страницыLoad Summary for Premise Under 100kVAMuhammad Zulhelmi ZawawiОценок пока нет

- JKR Specification For Low VoltageДокумент55 страницJKR Specification For Low VoltageSiddiq Rahim100% (1)

- TNB Substation Design NotesДокумент1 страницаTNB Substation Design NotesMohamad JohairieОценок пока нет

- Variable Frequency Speed Controllers ProjectДокумент8 страницVariable Frequency Speed Controllers ProjectNicodemus Ervino MandalaОценок пока нет

- jf5061-00 - SpecificationДокумент14 страницjf5061-00 - Specificationoscar gonzalo mondalgo ortizОценок пока нет

- PCT 1548495Документ13 страницPCT 1548495saba.excel7698Оценок пока нет

- (G+P+5) Mep Specifications B7-136-150Документ15 страниц(G+P+5) Mep Specifications B7-136-150Ahmad El KhatibОценок пока нет

- Delta DPR-1200B-48 Functional Description ManualДокумент20 страницDelta DPR-1200B-48 Functional Description ManualSiul Itnas100% (2)

- Partbii IIIДокумент388 страницPartbii IIIsaravananОценок пока нет

- Consultant Specification Capitole 40Документ12 страницConsultant Specification Capitole 40ericОценок пока нет

- Suggested Specification For Automatic Transfer Switches: 10-2006 1 Publication 3163Документ12 страницSuggested Specification For Automatic Transfer Switches: 10-2006 1 Publication 3163Pardeep KhosaОценок пока нет

- 3 4D Recloser G2801041Документ11 страниц3 4D Recloser G2801041Rehan KhalilОценок пока нет

- Amer - Final Format Approved 04-18-13Документ166 страницAmer - Final Format Approved 04-18-13rowatersОценок пока нет

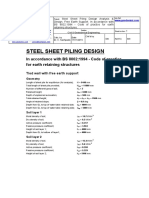

- Steel Sheet Piling Design: in Accordance With BS 8002:1994 - Code of Practice For Earth Retaining StructuresДокумент5 страницSteel Sheet Piling Design: in Accordance With BS 8002:1994 - Code of Practice For Earth Retaining StructuresrowatersОценок пока нет

- New Doc 21Документ1 страницаNew Doc 21rowatersОценок пока нет

- The Rational Method-David B.thompson 2006Документ7 страницThe Rational Method-David B.thompson 2006Dani Tun TunОценок пока нет

- D Internet Myiemorgmy Intranet Assets Doc Alldoc Document 13074 SPJ S11-LuarДокумент41 страницаD Internet Myiemorgmy Intranet Assets Doc Alldoc Document 13074 SPJ S11-LuarMuhammad Hafizuddin100% (1)

- Lasermap Asia: Your Lasermapping TeamДокумент2 страницыLasermap Asia: Your Lasermapping TeamrowatersОценок пока нет

- Work Program GuidelinesДокумент29 страницWork Program Guidelinesrowaters100% (3)

- Sachpazis Cantilever Steel Sheetpile Retaining Wall Analysis Design Free Earth Support To Eurocode 7Документ14 страницSachpazis Cantilever Steel Sheetpile Retaining Wall Analysis Design Free Earth Support To Eurocode 7rowatersОценок пока нет

- Anchored Piled Retaining Wall 24-06-2016Документ9 страницAnchored Piled Retaining Wall 24-06-2016rowatersОценок пока нет

- Tropical Residual Soil Properties On Slopes: M.F.Ishak, M.F. Zolkepli and M.AffendyДокумент9 страницTropical Residual Soil Properties On Slopes: M.F.Ishak, M.F. Zolkepli and M.AffendyrowatersОценок пока нет

- 06 (86-87)Документ3 страницы06 (86-87)rowatersОценок пока нет

- Probable Maximum Precipitation Analysis BakunДокумент7 страницProbable Maximum Precipitation Analysis BakunrowatersОценок пока нет

- 2 PDFДокумент10 страниц2 PDFrowatersОценок пока нет

- 3 PBДокумент7 страниц3 PBrowatersОценок пока нет

- Esy FenceДокумент6 страницEsy FencerowatersОценок пока нет

- 2017 Tekla Steel Fabrication Ebook Part1 enДокумент10 страниц2017 Tekla Steel Fabrication Ebook Part1 enrowatersОценок пока нет

- Technical Specification and Performance Curve for PL 7040 PumpДокумент7 страницTechnical Specification and Performance Curve for PL 7040 PumprowatersОценок пока нет

- PDFДокумент20 страницPDFrowatersОценок пока нет

- PL7040 FSI SUMP DESIGN 1 Model PDFДокумент1 страницаPL7040 FSI SUMP DESIGN 1 Model PDFrowatersОценок пока нет

- Pl7040 Fsi Sump Design 1 ModelДокумент1 страницаPl7040 Fsi Sump Design 1 ModelrowatersОценок пока нет

- Periodic Structural Inspection of Existing BuildingДокумент14 страницPeriodic Structural Inspection of Existing BuildingSarah SullivanОценок пока нет

- PL7040 FДокумент6 страницPL7040 FrowatersОценок пока нет

- TDS-PLC 118 STДокумент1 страницаTDS-PLC 118 STrowaters100% (1)

- Underground Cable System Design Manual Laying Cables Pipes DuctsДокумент6 страницUnderground Cable System Design Manual Laying Cables Pipes Ductsmajorabs100% (3)

- RTS 18 New Zealand On-Road Tracking Curves For Heavy Motor VehiclesДокумент20 страницRTS 18 New Zealand On-Road Tracking Curves For Heavy Motor VehiclesRipper RipperripperОценок пока нет

- Frequently Asked Questions ON Scale of FeesДокумент2 страницыFrequently Asked Questions ON Scale of FeesrowatersОценок пока нет

- Turn Pathsem1Документ1 страницаTurn Pathsem1rowatersОценок пока нет

- Access For Appliances and Fire-Fighting Facilities For Fire & Rescue Service UseДокумент9 страницAccess For Appliances and Fire-Fighting Facilities For Fire & Rescue Service UserowatersОценок пока нет

- Wind-Resistant Design of High Mast Structures: Journal of The Chinese Institute of Engineers, Vol 33, No 4 (2010)Документ1 страницаWind-Resistant Design of High Mast Structures: Journal of The Chinese Institute of Engineers, Vol 33, No 4 (2010)rowatersОценок пока нет

- Freak Downpour, Winds Wreck Havoc in PenangДокумент2 страницыFreak Downpour, Winds Wreck Havoc in PenangrowatersОценок пока нет