Академический Документы

Профессиональный Документы

Культура Документы

Bitumen

Загружено:

V Venkata NarayanaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Bitumen

Загружено:

V Venkata NarayanaАвторское право:

Доступные форматы

Bitumen

-Bitumen education:

There is bitumen everywhere. Chances are, you got to the

computer where you are reading this by walking over some

bitumen. But where did it come from? How is it made? Read

on to find out.

Bitumen is a lot older than you think. Although now associated

with roads and produced in large, complex, modern refineries

belonging to enormous petrochemical companies (such as Shell),

natural bitumen was found long before this, among the desert dunes of Arabia.

Etymology

The Romans called it gwitu-men (pertaining to pitch) or pixtu-men (bubbling pitch), converted,

after the barbarian invasions to bitumen. The word passed into French, and then, after the

Norman conquest of England in 1066, into English, where it was used interchangeably with

tar for over a thousand years (though tar derives from coal, and bitumen from petroleum).

Early Uses

The earliest recorded use of something like bitumen was by the Sumerians, who ruled from

the ancient city of Ur on the Euphrates river (near present-day Kuwait). There is evidence,

too, that Babylonian King Nebuchadnezzar used it for waterproofing and even as grouting for

stone roads.

The use of bitumen spread further West, and the Bible records a bituminous substance (tar,

asphalt or bitumen, depending on the translation) was used in building the Tower of Babel.

In 1595 Sir Walter Raleigh discovered a thick viscous lake in the jungles of Trinidad. This was

to be the largest natural deposit of bitumen ever found and was used extensively until the mid

1970s.

In the late nineteenth century, however, bitumen began to be used for the major industrial

uses common today, and with those began synthetic production. Shell began major bitumen

production in the UK in 1920, after opening the Shell Haven refinery.

Today, Shell produces bitumen all over the world, and is at the forefront of research into new

applications for this substance people have used since the dawn of civilization.

Rasselsteiner - OMT GmbH.

Gonzagagasse 13, 1010 Vienna, Austria,

Telephone: +43 1 890 40 19, FAX: +43 1 890 40 19 11, E-mail:office@rasselsteiner.com

-Bitumen in General

The building material bitumen is a high-tech product whose quality is controlled in

continuously advancing test procedures. Bitumen is mostly used in roadworks - 90% of the

bitumen used in Austria (500,000 t annually). The remaining 10% are converted into industrial

bitumen (oxidation bitumen).

Example: bitumen consumption for 1 km of the S1

The demand depends on the width of the carriageway, the thickness of the layers and the

type of asphalt. The S1 is an express way and corresponds to a moderately developed

motorway. Its total width is 30 m. The total bitumen required for 1 km of the S1 amounts to

524.6 t. Of the 524.6 t of material, 292.6 t are street construction bitumen and 232 t are

polymer modified bitumen.

Bitumen is a mixture of high and non-boiling crude oil components and is yielded via the

distillation of crude oil. It is not chemically changed during this. Not all crude oils are suitable

for bitumen production: what is decisive is a sufficient amount of residue from the vacuum

distillation with high-boiling components above 500°C.

Bitumen contains, aside from pure hydrocarbon, non-metallic elements in organically bonded

form (oxygen, nitrogen, sulfur), traces of phosphorus and halogens as well as traces of metals

(e.g. nickel, iron and vanadium). The distribution of hydrocarbons - alcanes, naphthenes,

aromatic compounds, resins, asphaltenes - in bitumen varies depending on the origin of the

crude oil.

History of Bitumen

Long before our time, bitumen was known in its natural form as natural asphalt. Natural

asphalt is a relatively hard bitumen that is found in natural deposits; it is solid at 25°C and

liquid at 175°C.

A few examples demonstrate its cultural and historical significance:

In Mesopotamia (present-day Iraq and Turkey) bitumen was used to seal houses and baskets

6,000 years ago - that's around 1,000 years before Oetzi the Iceman lived.

In the ziggurats in Mesopotamia between 3,000 and 2,000 B.C., bitumen was used as a

binding agent 10% of the time. For an average-sized temple (surface area: 60 x 45 m, height:

90m), the Sumerians, Arcadians or Babylonians used around 50,000 m3 of bitumen,

corresponding to a month's worth of production of the Schwechat refinery.

The word mummy, which derives from the Phoenician "mumia", means bitumen. Bitumen was

only used rarely to embalm the dead in ancient Egypt; for the most part, plant oil was used.

The Phoenician word "mumia" does mean bitumen, but it was actually plant oils were mostly

used to embalm the dead in ancient Egypt. (Source: Corbis)

Rasselsteiner - OMT GmbH.

Gonzagagasse 13, 1010 Vienna, Austria,

Telephone: +43 1 890 40 19, FAX: +43 1 890 40 19 11, E-mail:office@rasselsteiner.com

In a royal gravesite in Ur, the Sumerian capital (in present-day Iraq) around 2600 B.C., a

board game was found in which bitumen was used as a bonding agent for the inlays and the

black coloring.

In early antiquity, the main deposits of naturally occurring petroleum and/or bitumen were by

the Black Sea. The export of these products brought a certain level of wealth to the people

living in the area.

Bitumen & Road Construction

In the road construction industry, bitumen with varying consistency is used. Depending on the

requirements at hand, harder bitumen can provide increased sturdiness, while softer bitumen

can provide higher flexibility. Harder bitumen can be processed at higher temperatures, but is

more sensitive to environmental influences. Softer bitumen provides better resistance against

environmental influences, but is also less sturdy when exposed to greater stress. The

situation in Austria's alpine regions, where street paving is exposed to extreme fluctuations in

temperature, places great demands on the quality of the bitumen.

Conventional distillation bitumen was mainly used as a binding agent in road construction.

The residue after the distillation contains enough high-molecular asphaltenes.

Ideal crude oils for exclusive bitumen production come from Central America, for example.

They contain up to 60% bitumen and are viscous. Austria imports bitumen crude oils from

Saudi Arabia, Iran, Iraq and Russia.

Bitumen & Polymers

Polymer-modified bitumen is bitumen to which certain plastics and polymers

(macromolecules: chemical combinations of a multitude of smaller molecules) have been

added. This special kind of bitumen is used for road construction in areas where heavy traffic

and great stress on the paving is anticipated (e.g. motorway). Polymer-modified bitumen is

more resistant to deformation and makes asphalt covers extremely durable.

Bitumen is yielded during the distillation of crude oil. It is used mainly in road construction.

The modification with plastics influences the properties of conventional bitumen. To improve

its elastic behavior, the softening point (around 70°C) is raised, the plasticity span increased

and the elasticity thus improved (less deformation).

The following polymers are added to bitumen:

Rasselsteiner - OMT GmbH.

Gonzagagasse 13, 1010 Vienna, Austria,

Telephone: +43 1 890 40 19, FAX: +43 1 890 40 19 11, E-mail:office@rasselsteiner.com

¾ Thermoplastics (plastomers) consist of linear polymers with little branching. They

are softened when warmed and hardened when cooled (even repeatedly). This

addition raises the viscosity and stiffness of the bitumen, but not its elasticity.

¾ Elastomers consist of long, sometimes balled-up polymer chains that are linked

with a wide mesh. They are rubbery elastic at low temperatures all the way to

decomposition temperatures, but cannot be re-melted after being processed

once. Their addition increases the viscosity of the bitumen while only marginally

increasing elasticity.

¾ Thermo-elastic plastics turn soft (not liquid) like a thermoplastic at temperatures

above their service temperature and can then be shaped. They combine

properties of rubber and thermoplastics.

Oxidation Bitumen

Oxidation bitumen is used in industrial applications, e.g. to manufacture roof and sealing

sheets, or for coatings and joint sealing compounds.

Oxidation bitumen is produced by having oxygen (controlled injection) act on bitumen at

230°C to 270°C. By attachment of oxygen, the proportion of resins and asphaltenes rises,

which leads to higher viscosity and a clear hardening of the binding agent.

OMV uses a specially developed procedure (Biturox procedure) for the oxidation technology

and uses high-performance air injection reactors that inject and distribute air and water across

large surfaces.

Test Procedures

The properties of bitumen that are used in Austria and Europe are primarily evaluated by

means of empirical test procedures. Among other things, these describe their elasticity and

viscosity, their adhesion behavior, their solubility, their hardening stability, their flash point,

their paraffin content and their shelf life.

Recently, examinations of bitumen have focused on the rheological properties of bitumen.

Rheology is the science of flowing substances and describes, using physical characteristics,

the deformation of a substance when subjected to loading by external forces. This can be

described by physical parameters such as shear modulus, phase difference or tensile

stiffness. Bitumen is a visco-elastic substance, i.e. its behavior can be described using an

elastic and a viscous component. This behavior can be presented with the aid of the Maxwell

model.

The rheometer measures the properties of bitumen especially in the upper temperature rang

Rasselsteiner - OMT GmbH.

Gonzagagasse 13, 1010 Vienna, Austria,

Telephone: +43 1 890 40 19, FAX: +43 1 890 40 19 11, E-mail:office@rasselsteiner.com

-Solutions for Bitumenpacking

Today there is only limited solutions for Bitumen packing in the market. The only widespread

transport tool established are so far bitumen drums , containing many disadvantages. Gasoili

engineering has new solutions to offer for Bitumen packing, containing various logistical and

financial advantages compared to drums.

Please contact us for further information.

Rasselsteiner - OMT GmbH.

Gonzagagasse 13, 1010 Vienna, Austria,

Telephone: +43 1 890 40 19, FAX: +43 1 890 40 19 11, E-mail:office@rasselsteiner.com

Вам также может понравиться

- Box Cell Structures at a GlanceДокумент3 страницыBox Cell Structures at a GlanceV Venkata NarayanaОценок пока нет

- Box Cell Structures at a GlanceДокумент3 страницыBox Cell Structures at a GlanceV Venkata NarayanaОценок пока нет

- Note 07-Jul-2019 at 9 - 41 - 15 PMДокумент1 страницаNote 07-Jul-2019 at 9 - 41 - 15 PMV Venkata NarayanaОценок пока нет

- Venkat Rigid Pavement Tables of Joints and SteelДокумент2 страницыVenkat Rigid Pavement Tables of Joints and SteelV Venkata NarayanaОценок пока нет

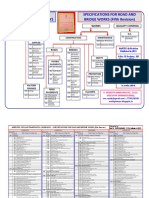

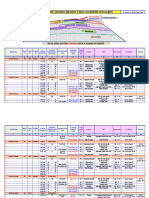

- 56 - Venkat - MoRTH 5th Revision Essential Tables For Highway Field Engineers PrintДокумент34 страницы56 - Venkat - MoRTH 5th Revision Essential Tables For Highway Field Engineers PrintV Venkata Narayana100% (4)

- Venkats Interpretation On Configuration of MORTHДокумент29 страницVenkats Interpretation On Configuration of MORTHV Venkata Narayana100% (3)

- 60 - Master Gradation Table of All Aggregates For Pavements and Cement ConcretesДокумент1 страница60 - Master Gradation Table of All Aggregates For Pavements and Cement ConcretesV Venkata Narayana100% (3)

- Road Safety Measures on National HighwaysДокумент4 страницыRoad Safety Measures on National HighwaysDhiren PatelОценок пока нет

- Venkat Rigid Pavement Tables of Joints and Steel PDFДокумент2 страницыVenkat Rigid Pavement Tables of Joints and Steel PDFV Venkata NarayanaОценок пока нет

- 57 - MoRTH 5th RVN What Is Where and Where Is What - Venkata Narayana - PrintДокумент4 страницы57 - MoRTH 5th RVN What Is Where and Where Is What - Venkata Narayana - PrintV Venkata Narayana100% (2)

- Venkat - MoRTH 5th Revision Essential Tables For Highway Field EngineersДокумент68 страницVenkat - MoRTH 5th Revision Essential Tables For Highway Field EngineersV Venkata Narayana96% (28)

- 57 - MoRTH 5th RVN What Is Where and Where Is What - Venkata Narayana - PrintДокумент4 страницы57 - MoRTH 5th RVN What Is Where and Where Is What - Venkata Narayana - PrintV Venkata Narayana100% (2)

- 60 - Master Gradation Table of All Aggregates For Pavements and Cement ConcretesДокумент1 страница60 - Master Gradation Table of All Aggregates For Pavements and Cement ConcretesV Venkata Narayana100% (3)

- Venkat Master SemiLog CurvesPlainДокумент28 страницVenkat Master SemiLog CurvesPlainV Venkata NarayanaОценок пока нет

- Venkat Master Semi-Log Curves For Metal GradationДокумент28 страницVenkat Master Semi-Log Curves For Metal GradationV Venkata Narayana100% (1)

- IRC 85 1983 Part2 PDFДокумент11 страницIRC 85 1983 Part2 PDFV Venkata NarayanaОценок пока нет

- Venkat Master SemiLog CurvesPlainДокумент28 страницVenkat Master SemiLog CurvesPlainV Venkata NarayanaОценок пока нет

- Morth400 Sub-Bases and Bases Tables of Gradation Tests LimitsДокумент5 страницMorth400 Sub-Bases and Bases Tables of Gradation Tests LimitsV Venkata Narayana100% (2)

- Bituminous Mixtures in Roads - 1Документ586 страницBituminous Mixtures in Roads - 1V Venkata Narayana100% (1)

- VenkatBox Box Culverts AbstractДокумент1 страницаVenkatBox Box Culverts AbstractV Venkata Narayana0% (1)

- VVN Irc37 ShortДокумент4 страницыVVN Irc37 ShortV Venkata NarayanaОценок пока нет

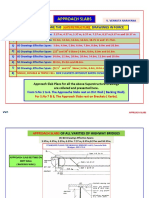

- Approach Slab Plans for Highway BridgesДокумент9 страницApproach Slab Plans for Highway BridgesV Venkata Narayana100% (1)

- ViscosityДокумент20 страницViscosityOnur CelikkanОценок пока нет

- d36 Softening Point Test Ring and BallДокумент5 страницd36 Softening Point Test Ring and BallNurul RizalОценок пока нет

- Great Wars and Great Leaders A Libertarian RebuttalДокумент265 страницGreat Wars and Great Leaders A Libertarian RebuttalMadu BiruОценок пока нет

- The Modern Asphalt Pavement 1904 PDFДокумент617 страницThe Modern Asphalt Pavement 1904 PDFV Venkata NarayanaОценок пока нет

- 2526 Auditoriums and Conference HallsДокумент22 страницы2526 Auditoriums and Conference HallsV Venkata Narayana100% (1)

- ViscosityДокумент20 страницViscosityOnur CelikkanОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- HexagonДокумент15 страницHexagonKiran Kumar YadaОценок пока нет

- Download Tally Ledger List in ExcelДокумент7 страницDownload Tally Ledger List in ExcelAnonymous 3yqNzCxtTz100% (1)

- The Joy of Living Dangerously PDFДокумент4 страницыThe Joy of Living Dangerously PDFMax MoralesОценок пока нет

- Fs Item Master 06.08.21Документ81 страницаFs Item Master 06.08.21Prem RathoreОценок пока нет

- Astm C31-C31M-23Документ7 страницAstm C31-C31M-23mustafa97a141Оценок пока нет

- Taylor & Francis, Ltd. Public Performance & Management ReviewДокумент26 страницTaylor & Francis, Ltd. Public Performance & Management ReviewRamadona SimbolonОценок пока нет

- Strama CHP1Документ7 страницStrama CHP1Gelliza Mae MontallaОценок пока нет

- Plan Clock ProjectДокумент2 страницыPlan Clock Projectapi-209169836Оценок пока нет

- Eyes Open 2 WorkbookДокумент104 страницыEyes Open 2 WorkbookLiden Denz92% (12)

- BEA 242 Introduction To Econometrics Group Assignment (Updated On 10 May 2012: The Change in Highlighted)Документ4 страницыBEA 242 Introduction To Econometrics Group Assignment (Updated On 10 May 2012: The Change in Highlighted)Reza Riantono SukarnoОценок пока нет

- Social Issues and The EnvironmentДокумент8 страницSocial Issues and The EnvironmentRahul100% (6)

- SQL COMMANDS FOR HIGH SCHOOL DATABASEДокумент47 страницSQL COMMANDS FOR HIGH SCHOOL DATABASESooraj Rajmohan75% (28)

- Cygnus Garden 【H】 Guitar Arr. V2 by SpiceyBeefJerkyДокумент3 страницыCygnus Garden 【H】 Guitar Arr. V2 by SpiceyBeefJerkyRima K.Оценок пока нет

- FREE Shapes AssessmentДокумент10 страницFREE Shapes AssessmentVicky ChowОценок пока нет

- Fiitjee: JEE (Advanced) - 2019Документ16 страницFiitjee: JEE (Advanced) - 2019Jyotiraditya BoseОценок пока нет

- Liability Is Something A Person or Company Owes, Usually A Sum of Money. ... Recorded OnДокумент5 страницLiability Is Something A Person or Company Owes, Usually A Sum of Money. ... Recorded OnedrianclydeОценок пока нет

- Is English's Status as the Global Language AssuredДокумент5 страницIs English's Status as the Global Language AssuredfsdfsdfasdfasdsdОценок пока нет

- ABAP CDS Table Functions with AMDPДокумент3 страницыABAP CDS Table Functions with AMDPanup kumarОценок пока нет

- Dove AdsДокумент3 страницыDove Adsapi-528509195Оценок пока нет

- 2011 ASHRAE Handbook - HVAC ApplicationДокумент1 049 страниц2011 ASHRAE Handbook - HVAC ApplicationwdyouQОценок пока нет

- Commercial CO Refrigeration Systems: Guide For Subcritical and Transcritical CO ApplicationsДокумент44 страницыCommercial CO Refrigeration Systems: Guide For Subcritical and Transcritical CO ApplicationsChrise5502Оценок пока нет

- Sample3-351, Online - Sfsu.edu Quiz and SolutionДокумент5 страницSample3-351, Online - Sfsu.edu Quiz and SolutionBikal MagarОценок пока нет

- Student Assignment Analyzes Statistics ProblemsДокумент2 страницыStudent Assignment Analyzes Statistics ProblemsKuberanОценок пока нет

- Emergency Kit A Edition 12 Rev 2 Kit Revision FinalДокумент32 страницыEmergency Kit A Edition 12 Rev 2 Kit Revision FinalMorris MorrisonОценок пока нет

- Johann Sebastian Bach Raaf Hekkema: Suites BWV 1007-1012Документ22 страницыJohann Sebastian Bach Raaf Hekkema: Suites BWV 1007-1012Stanislav DimОценок пока нет

- Sophie Greenberg ResumeДокумент1 страницаSophie Greenberg Resumeapi-317439954Оценок пока нет

- Nonstandard Description of Squeezed StatesДокумент22 страницыNonstandard Description of Squeezed StatesI.B. BirulaОценок пока нет

- BookletДокумент5 страницBookletRanipuji ApriliaОценок пока нет

- Design and Development of Power Inverter Using Combinational Switches For Improvement of Efficiency at Light LoadsДокумент3 страницыDesign and Development of Power Inverter Using Combinational Switches For Improvement of Efficiency at Light LoadsEditor IJRITCCОценок пока нет

- MSME Marketing Mix Practices During COVID-19Документ77 страницMSME Marketing Mix Practices During COVID-19JoicyPadillaОценок пока нет