Академический Документы

Профессиональный Документы

Культура Документы

Procedure Tolerance

Загружено:

sanrexiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Procedure Tolerance

Загружено:

sanrexiАвторское право:

Доступные форматы

DOCUMENT REVIEW

CLIENT KENCANA HL SDN BHD

Document Title PROCEDURE - TOLERANCE REQUIREMENTS FOR PRESSURE VESSEL

Document No. YLE/ASME/TRFPV Rev. 1

Job/Serial No. YLE/KT/11/02 Client Ref No. P10-1033

Project FCP - Garraf Field Development Project

2 Units Dehydrators (V-1510 & V-1520) and

Item

2 Units Desalters (V-1610 & V-1620) Pressure Vessels

Date Description Rev By Checkd Appd.

03/08/2011 Preliminary for Approval 0 LMH MK AYCC

02/03/2012 Revised per Comments 1 MTY LMH MK

Comment/Client Approval

YLE Replies/Clarification:

1. No indication to the equipments used for measurement and calibration, certificates required.

Measuring equipment calibration certificates attached in Appendix for this revision

2. What is the responsibility of QC department for checking the tolerance.

The QC responsibility already included in YLE QC manual

3. Distance between the tangent lines should check & reported.

The distance will be recorded in dimensional report

4. Provide inspection report forms.

Included in Appendix for this revision

5. Tolerance for misalignments for shell to shell and head to shell are not in record of the

procedure and shell straightness

Included for this revision

6. Update the procedure with new date.

Done as requested

7. Remove the stamp of (( uncontroled copy)).

Done as requested

8. Highlight the inspectors qualification required for checking the tolerance.

Irrelevant

Doc No. YLE/ASME/TRFPV-GFDP

YEE LOONG ENGINEERING SDN BHD Revision No. 1

DCN No. -

TOLERANCE REQUIREMENTS FOR PRESSURE Date 02/03/2012

VESSEL Page 1 of 2

Item TOLERANCE REMARKS

1 Plate thickness Not less than 0.01 in. or 6% of ordered thickness which

ever is less (UG - 16)

2 Formed head Min. formed thickness shall not be less than design

UG-81 Sheet 8, Div 1 thickness stated in drawing

3 Cylindrical Shell Dmax - Dmin must not exceed 1% of nominal diameter

Out of roundness of (Tolerance must be met at all points on shell)

cylindrical shell

4 1 for vessel up to 30ft. Overall length < + 1/2 in.

2 for vessel up to 30ft. Overall length < + 1/8 in / per

Deviation from 10ft. Or max 1 1/2 in.

verticality

5 Manhole

b. Distance from the Must not exceed + 1/2 in

face of manhole to

reference line

c. Projection; shortest Must not exceed + 1/2 in

distance from outside

surface of vessel to

the face of manhole

d. Deviation circumferentially Must not exceed + 1/2 in

measured on the outer

surface of vessel

6 Nozzle, coupling which are not to be The tolerance for manholes shall be applied

connected to piping

7 Nozzle, coupling which are to be

connected to piping

b. Distance from the face of flange or Must not exceed + 1/4 in

centerline of opening to reference

line

c. Projection; shortest distance form Must not exceed + 1/4 in

outside surface of vessel to the

face of opening

d. Deviation circumferentially measured Must not exceed + 1/4 in

on the outer surface of vessel

e. Deviation of bolt holes in any direction Must not exceed + 1/8 in

f. Deviation from horizontal, vertical or Must not exceed + 1/2 degree

the intended position in any direction

8 Nozzle, coupling used for level gauge, level control etc.

Distance between centerline of openings Must not exceed + 1/16 in

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- ASNT NDT Level III Program: Personnel Qualification and Certification in Nondestructive Testing (SNT-TC-1A)Документ6 страницASNT NDT Level III Program: Personnel Qualification and Certification in Nondestructive Testing (SNT-TC-1A)sanrexiОценок пока нет

- 852 Sales TalkДокумент3 страницы852 Sales TalksanrexiОценок пока нет

- Computer Programming (MATLAB) : Sudhanwa Kulkarni / Dr. Samir KaleДокумент32 страницыComputer Programming (MATLAB) : Sudhanwa Kulkarni / Dr. Samir KalesanrexiОценок пока нет

- ASTM E 92 Method For Vickers HardnessДокумент9 страницASTM E 92 Method For Vickers HardnessDiana RiverosОценок пока нет

- Chapter-13 User Defined Functions: DefinitionДокумент10 страницChapter-13 User Defined Functions: DefinitionsanrexiОценок пока нет

- Procedure For Job Safety Analysis (Final CO-HSE)Документ17 страницProcedure For Job Safety Analysis (Final CO-HSE)sanrexiОценок пока нет

- Non-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2Документ242 страницыNon-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2darqm589% (18)

- 70 Brain FactsДокумент33 страницы70 Brain FactsGratian SonuОценок пока нет

- Training Schedule April 2021 To March 22 - 0Документ18 страницTraining Schedule April 2021 To March 22 - 0sanrexiОценок пока нет

- Weld Test PositionsДокумент9 страницWeld Test PositionssanrexiОценок пока нет

- ISO FDIS 19011 2011 Briefing NoteДокумент10 страницISO FDIS 19011 2011 Briefing NotesanrexiОценок пока нет

- Ut NotesДокумент42 страницыUt NotessanrexiОценок пока нет

- 20160215042419-Ki Stahlsortenvergleich Rev0 eДокумент4 страницы20160215042419-Ki Stahlsortenvergleich Rev0 esanrexiОценок пока нет

- Guideto Brazingand SolderingДокумент32 страницыGuideto Brazingand SolderingWill EasleyОценок пока нет

- Feroxyle Test Procedur eДокумент9 страницFeroxyle Test Procedur esanrexiОценок пока нет

- Steel GradesДокумент8 страницSteel GradesSanket Arun MoreОценок пока нет

- E8045-P2 H4RДокумент2 страницыE8045-P2 H4RsanrexiОценок пока нет

- STF 05530Документ13 страницSTF 05530aby_abraham5005Оценок пока нет

- CP Brochure PDFДокумент5 страницCP Brochure PDFRazzer RameshОценок пока нет

- Iso 9001:2015Документ0 страницIso 9001:2015asadqhse100% (3)

- Internal Audit ChecklistДокумент5 страницInternal Audit ChecklistsanrexiОценок пока нет

- ISO 9001 Evidence ChecklistДокумент40 страницISO 9001 Evidence ChecklistsanrexiОценок пока нет

- Purge Film Apf LFT A4 Ag01-Web-pДокумент2 страницыPurge Film Apf LFT A4 Ag01-Web-psanrexiОценок пока нет

- Aws Welding 201308 PDFДокумент122 страницыAws Welding 201308 PDFsubash sivalingamОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Modern Day DevelopmentДокумент2 страницыModern Day DevelopmentJimiel Chifamba83% (6)

- Renewable Energy Engineering: CoursesДокумент14 страницRenewable Energy Engineering: CoursesAmal ChinthakaОценок пока нет

- Bridge Manual (Metric)Документ501 страницаBridge Manual (Metric)Anonymous PjmE9RJcghОценок пока нет

- Is 457 1957Документ49 страницIs 457 1957Robim7vermaОценок пока нет

- PPT Introduction To Power Electronics (Benny)Документ8 страницPPT Introduction To Power Electronics (Benny)saqibmaqboolОценок пока нет

- Resume PremДокумент4 страницыResume PrempremОценок пока нет

- 2013 SKF Training Handbook: Reliability Maintenance InstituteДокумент134 страницы2013 SKF Training Handbook: Reliability Maintenance InstituteBalázs HernádiОценок пока нет

- Profile - Mr. Irfan AliДокумент8 страницProfile - Mr. Irfan AliIrfan AliОценок пока нет

- CV Elva 2010 S1Документ3 страницыCV Elva 2010 S1Lawlite RyukОценок пока нет

- An Example of The Effectiveness of Directional Overcurrent Relays (ANSI 67, 67N) - EEPДокумент3 страницыAn Example of The Effectiveness of Directional Overcurrent Relays (ANSI 67, 67N) - EEPcatalinccОценок пока нет

- Warehouse Design & LayoutДокумент39 страницWarehouse Design & Layoutarya ramadhanuОценок пока нет

- Compaction Test Report No. / Izvestaj Ispitivanja Zbijenosti BRДокумент1 страницаCompaction Test Report No. / Izvestaj Ispitivanja Zbijenosti BRveljko2008Оценок пока нет

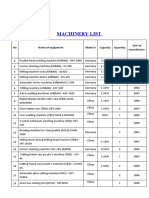

- Machinery List-1Документ2 страницыMachinery List-1Hồng HạnhОценок пока нет

- Continuous Improvement Leader in Macon GA Resume Bennie GrayДокумент2 страницыContinuous Improvement Leader in Macon GA Resume Bennie GrayBennieGrayОценок пока нет

- Software Engineering, 8th Ed PDFДокумент865 страницSoftware Engineering, 8th Ed PDFabagirshaОценок пока нет

- Design Criteria Stru.Документ9 страницDesign Criteria Stru.Ar John Bernard AbadОценок пока нет

- Power System GroundingДокумент2 страницыPower System GroundingMujtaba HusseinОценок пока нет

- Procedure - Fit-Up & AssemblyДокумент8 страницProcedure - Fit-Up & AssemblyRakesh RanjanОценок пока нет

- PlanholdersДокумент4 страницыPlanholdersAdam Abraham0% (1)

- Science, Technology, & Society: DevelopingДокумент6 страницScience, Technology, & Society: Developingapp practiceОценок пока нет

- WE20 DrillPlan Coherent Well Construction Planning Solution Product SheetДокумент2 страницыWE20 DrillPlan Coherent Well Construction Planning Solution Product SheetWaleedm MariaОценок пока нет

- Euro CokeДокумент13 страницEuro Cokedhawal gargОценок пока нет

- Lecture 10 (Process Optimization Introduction)Документ15 страницLecture 10 (Process Optimization Introduction)Hoàng KhôiОценок пока нет

- Introduction To ABAQUS 2013 - 14Документ11 страницIntroduction To ABAQUS 2013 - 14nicholasomodingОценок пока нет

- (RES) Back Up Prot. Isolation and Normalization List - Sejingkat 132-33Kv 80MVA TXF No.2Документ9 страниц(RES) Back Up Prot. Isolation and Normalization List - Sejingkat 132-33Kv 80MVA TXF No.2ericОценок пока нет

- BIBLIOGRAFIE Design de ProdusДокумент3 страницыBIBLIOGRAFIE Design de ProdusAna Izabela MunteanuОценок пока нет

- EssayДокумент2 страницыEssayEar Choungchhay100% (6)

- Brochure ClimbingBracket BMK USAДокумент4 страницыBrochure ClimbingBracket BMK USAgrishil07Оценок пока нет

- Mobile Lubrication Bijur DelimonДокумент12 страницMobile Lubrication Bijur DelimonFAVIOОценок пока нет

- 16 Sindur P Mangkoesoebroto PaperДокумент16 страниц16 Sindur P Mangkoesoebroto PaperfadliamaliaОценок пока нет