Академический Документы

Профессиональный Документы

Культура Документы

Design of Two Wheel Automatic Electric Forklift For Industry Warehouses& Domestic Purpose

Загружено:

sankaramarayananОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Design of Two Wheel Automatic Electric Forklift For Industry Warehouses& Domestic Purpose

Загружено:

sankaramarayananАвторское право:

Доступные форматы

International Journal For Technological Research In Engineering

Volume 5, Issue 9, May-2018 ISSN (Online): 2347 - 4718

DESIGN OF TWO WHEEL AUTOMATIC ELECTRIC FORKLIFT

FOR INDUSTRY WAREHOUSES& DOMESTIC PURPOSE

Lakshya Garg1, Nitish Chauhan2, Nikhil Tyagi3

12

UG (B.Tech) Students, 3Asst. Prof

Department of Mechanical Engineering, Sunder Deep Engineering College, Ghaziabad

Abstract: The two Wheel Automatic Electric forklift is a

small electrical vehicle designed to build a cheap forklift for

industry warehouses& domestic purpose. A goods

transportation device which can drive by any one. Safe

movement during picking, stacking and traveling with

loads. The dynamics of the vehicle is simple to the control

the vehicle which means that it is stable. This is prevented

by two small supporting wheels for balance the vehicle and

its time derivative, controlling the motors to keep the vehicle

balancing. This kind of vehicle is interesting since it

contains a lot of technology relevant to an environmentally

friendly and energy efficient transportation industry. The

rider controls are supposed to be natural movements;

leaning forwards or backwards and the direction of the Specification

vehicle is obtain by giving the DC supply only one motor Length 500 mm

Keywords: Lower Frame, Upper frame, Fork, Carriage Width 400 mm

Support rod, Axle Shaft Height 25.4 mm

Hole diameter 4 mm

I. INTRODUCTION

Factories, industries and storage go downs need forklifts and (b) Upper Frame

cranes for storage and moving large goods. Also there are a

number of goods weighing around 40 – 60 kg that are

comparatively lighter but cannot be moved around easily by

human labor. To fill this need we here propose a 2 Wheel

Automatic Electric forklift to lift and transport such medium

weight goods across factories & industrial warehouses.

The2 Wheel Automatic Electric forklift is a fast, efficient and

low power consumption vehicle that does not require much

space to move around. The mini forklift will run on 2

Brushless DC motors and can drive small weight with pickup

arrangement across small distances easily. For this we use a

mini 2 wheel vehicle body frame designed with a platform (c) Carriage support rod

with 2 motorized wheel mounts. It has a perpendicular handle The purpose of using the carriage support rod to give the

ahead to hold on the operator. guidance for movement of the carriage when lifting the load.

Also we design a forklift type mechanism on the front handle It gives the smooth sliding of carriage upward and download

of vehicle using 2 bent metal strips and lifting mechanism. direction.

The lift mechanism comprises of large supporting rod for

sliding the carriage. This mechanism is connected to a linear

actuator. We now mount the control circuitry on the vehicle

with wires that allow the vehicle to be controlled by person.

Thus we provide a easily controlled forklift for small goods

transportation in industrial sector. The demonstration version

can lift 40-60 kg to demonstrate the concept.

II. DESIGN PARAMETERS

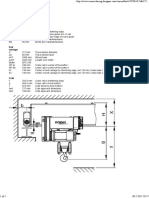

(a) Lower Frame

It is the main part of the chassis in which hub, motor and

actuator are fit. It is made by using rectangular pipes.

www.ijtre.com Copyright 2018.All rights reserved. 3685

International Journal For Technological Research In Engineering

Volume 5, Issue 9, May-2018 ISSN (Online): 2347 - 4718

Specification Iron Strip width 20 mm

Length 300 mm

Height 800 mm Gape b/w Upper & Lower strip 118 mm

Width 90 mm Outer dia. of pipe 28 mm

Outer diameter of rod 25 mm Inner dia. of pipe 26 mm

Inner diameter of rod 16 mm

(d) Fork

The fork is the main part of the forklift. It is used to pick up

the goods from one place to other place. These are two bend

strip made by iron. The face of the fork of is very sharp and

tapered.

(f) Hub

A hub is the central part of a wheel that connects the axle to

the wheel itself. Many expressions use the term for a literal

or figurative central structure connecting to a periphery. In

the construction of the forklift 4 hub are used.

Specification

Length of fork 360 mm

Width of fork 44 mm

Height of fork 240mm

Thickness 4mm

(e) Carriage

Carriage is used to support the forks. The fork are fitted on

the carriage. It is made of iron strip having thickness 20 mm.

It also use the four hollow pipe which is slide on the carriage

support rod.

Specification

Length of hub 130 mm

Width of hub 40 mm

Height of hub 60 mm

Outer diameter of bearing 52 mm

Inner diameter of bearing 18 mm

(g) Handle

Specification

Length of carriage 290 mm

Width of carriage 245 mm

www.ijtre.com Copyright 2018.All rights reserved. 3686

International Journal For Technological Research In Engineering

Volume 5, Issue 9, May-2018 ISSN (Online): 2347 - 4718

A handle is a part of, or attachment to, an object that can be (i) Axle Shaft

moved or used by hand. The design of each type of handle A drive shaft, driveshaft, driving shaft, propeller shaft is a

involves substantial ergonomic issues, even where these are mechanical component for transmitting torque and rotation,

dealt with intuitively or by following tradition. Handles for usually used to connect other components of a drive train

tools are an important part of their function, enabling the user that cannot be connected directly because of distance or the

to exploit the tools to maximum effect. In the our forklift need to allow for relative movement between them.

handle is used for only giving the support to the operator not Specification of Shaft

for taking the turning of the forklift.The handle is made by Length of shaft 240 mm

using the hollow iron rod. Diameter of shaft 18 mm

Handle Specification Length of thread on shaft 130 mm

Length of handle 580 mm

Dia. of handle rod 30 mm

Height of handle 205 mm

(h) Wheel

A wheel is a circular component that is intended to rotate on

an axlebearing. The wheel is one of the key components of

the wheel and axle which is one of the six simple machines.

Wheels, in conjunction with axles, allow heavy objects to be

moved easily facilitating movement or transportation while DIFFERENT VIEWS OF FORKLIFT

supporting a load, or performing labor in machines. Wheels (a) Front view

are also used for other purposes, such as a ship's wheel,

steering wheel, potter's wheel and flywheel.

Front view of wheel (b) Orthogonal view

Orthogonal view of wheel

Wheel Specification

Outer diameter of wheel 280 mm

Inner diameter of wheel 18 mm Advantage:

Outer dia. of support wheel 60 mm Less costly.

Inner dia. of support wheel 10 mm Easy to operate.

www.ijtre.com Copyright 2018.All rights reserved. 3687

International Journal For Technological Research In Engineering

Volume 5, Issue 9, May-2018 ISSN (Online): 2347 - 4718

Easily Attachable & Detachable. MIT Electric Vehicle Team, December 2008

Reduce time. [17] Kang, B.; Ceder, G. (2009). "Battery materials for

Require less space for riding, parking. ultrafast charging and discharging". Nature. 458

A clean, green, eco-friendly machine. (7235): 190–193.

[18] Dillow, Clay (21 December 2012). "China Builds

the World's Largest Battery, a Building-Sized, 36-

III. CONCLUSION

Megawatt-Hour Behemoth | Popular Science".

There is a large scope of transportation of goods

Popsci.com. Retrieved 31 July 2013.

from one place to another place easily.

[19] Conway, E. (2 September 2008) "World's biggest

The potential is huge and the return on investment is battery switched on in Alaska"Telegraph.co.uk

also very good. [20] Biello, D. (22 December 2008) "Storing the Breeze:

It require less space for working and parking. New Battery Might Make Wind Power More

It is a clean, green, eco-friendly machine. Reliable"Scientific American.

It uses less time for transportation of heavy

goods(Approximately 40-60 kg) from one place to

another place.

Our forklift would be so simpler that even kids can

drive safely& easily.

REFERENCES

[1] "Underwater Linear Actuator". Ultra Motion.

[2] "Linear Actuator Guide", Anaheim Automation,

retrieved May 12, 2016

[3] "Electric Actuators", Baelz Automatic, retrieved

May 12, 2016

[4] "Firgelli voted best Linear Actuators, TV Lifts &

desk Lifts". www.firgelliauto.com. Retrieved 10

September 2017.

[5] Firgelli Automations - Basics of Linear Actuators,

[6] "Electric Micro Linear Actuators - Actuonix Motion

Devices". www.actuonix.com. Retrieved 10

September 2017.

[7] Battery History, Technology, Applications and

Development. MPower Solutions Ltd. Retrieved 19

March 2007.

[8] Borvon, Gérard (10 September 2012). "History of

the electrical units". Association S-EAU-S.

[9] "Columbia Dry Cell Battery". National Historic

Chemical Landmarks. American Chemical Society.

Archived from the original on 23 February 2013.

Retrieved 25 March 2013.

[10] Alkaline Manganese Dioxide Handbook and

Application Manual (PDF). Energizer. Retrieved 25

August 2008.

[11] Dynasty VRLA Batteries and Their

ApplicationArchived 6 February 2009 at the

Wayback Machine..C&D Technologies, Inc.

Retrieved 26 August 2008.

[12] USBCELL – Revolutionary rechargeable USB

battery that can charge from any USB port.

Retrieved 6 November 2007.

[13] "Spotlight on Photovoltaics& Fuel Cells: A Web-

based Study & Comparison" (PDF). pp. 1–2.

Retrieved 14 March 2007.

[14] Battery Knowledge – AA Portable Power Corp.

Retrieved 16 April 2007.Archived 23 May 2007 at

the Wayback Machine.

[15] "Battery Capacity". techlib.com.

[16] A Guide to Understanding Battery Specifications,

www.ijtre.com Copyright 2018.All rights reserved. 3688

Вам также может понравиться

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheОт EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Weld Like a Pro: Beginning to Advanced TechniquesОт EverandWeld Like a Pro: Beginning to Advanced TechniquesРейтинг: 4.5 из 5 звезд4.5/5 (6)

- VP 72Gs2: Pipelayer Equipment Designed and Manufactured byДокумент8 страницVP 72Gs2: Pipelayer Equipment Designed and Manufactured byRaúl R RiveraОценок пока нет

- Design & Fabrication of 360° Flexible Drilling MachineДокумент4 страницыDesign & Fabrication of 360° Flexible Drilling MachineSumit ShuklaОценок пока нет

- Pedal Operated ForkliftДокумент56 страницPedal Operated Forkliftfahamith ahamed100% (1)

- Light Industrial Conveyor ENДокумент6 страницLight Industrial Conveyor ENMumu moemoeОценок пока нет

- Design & Fabrication of Tri-Wheel Stair Case Climbing Hand TrolleyДокумент4 страницыDesign & Fabrication of Tri-Wheel Stair Case Climbing Hand TrolleyRohith RaviОценок пока нет

- Mini Excavator: 1035 KG 402J-05 IG84555R 5,9 KN 10 KNДокумент8 страницMini Excavator: 1035 KG 402J-05 IG84555R 5,9 KN 10 KNnqqcm6fw5nОценок пока нет

- Ys-2140a Lite InfoДокумент5 страницYs-2140a Lite InfoSjoling8211Оценок пока нет

- Methods India PVT LTD.: A Report On Internship atДокумент20 страницMethods India PVT LTD.: A Report On Internship atHarsha ShreyasОценок пока нет

- Design & Fabrication of 360° Flexible Drilling Machine: ArticleДокумент5 страницDesign & Fabrication of 360° Flexible Drilling Machine: ArticleDeep PatelОценок пока нет

- 68 PDFДокумент6 страниц68 PDFVicky SuryawanshiОценок пока нет

- NEW Colchester Typhoon Twin Spindle CNC Turning Centre Brochure 2018Документ12 страницNEW Colchester Typhoon Twin Spindle CNC Turning Centre Brochure 2018Marlon GilerОценок пока нет

- XCMG QY50K Operation ManualДокумент10 страницXCMG QY50K Operation ManualElxan ShaheliyevОценок пока нет

- Manual Book Esc - Pillar PLC PDFДокумент27 страницManual Book Esc - Pillar PLC PDFWinОценок пока нет

- 73 Scissor Lift Eel734Документ4 страницы73 Scissor Lift Eel734Quezon I DEO ESUОценок пока нет

- Design & Analysis of Improvised Clutch Pedal Linkage Mechanism Using Catia V5Документ8 страницDesign & Analysis of Improvised Clutch Pedal Linkage Mechanism Using Catia V5TJPRC PublicationsОценок пока нет

- Advance Manufacturing Process (Amp) Project FinalДокумент12 страницAdvance Manufacturing Process (Amp) Project FinalAyyan Gaonkhadkar100% (3)

- Crane Girder Beam Design - ExampleДокумент6 страницCrane Girder Beam Design - Exampledinesh100% (3)

- Lec2 Lathe MachineДокумент70 страницLec2 Lathe MachineFELIX KEUYAОценок пока нет

- Bamboo SplitterДокумент7 страницBamboo SplitterDemeke Gezahegn TeseraОценок пока нет

- Design and Fabrication PDFДокумент3 страницыDesign and Fabrication PDFSuresh IndiaОценок пока нет

- XC740KXC760K MinicargadorДокумент4 страницыXC740KXC760K Minicargadorfernando ivan castillo rojasОценок пока нет

- Presentation On Internship AT "D U Industries PVT - LTD": Prepared By: Guided byДокумент37 страницPresentation On Internship AT "D U Industries PVT - LTD": Prepared By: Guided byNIRAJ PATELОценок пока нет

- GargAamod GantryGirdersinIndiaДокумент6 страницGargAamod GantryGirdersinIndiaTinu JainОценок пока нет

- Jack NNNN 11Документ38 страницJack NNNN 11abiy balkewОценок пока нет

- Design and Fabrication of Automatic Spray Painting MachineДокумент44 страницыDesign and Fabrication of Automatic Spray Painting MachineDinesh Kumar100% (1)

- Project Report DrillДокумент22 страницыProject Report DrillSTAR PRINTINGОценок пока нет

- 360 Degree Conveyor Belt PDFДокумент4 страницы360 Degree Conveyor Belt PDFUpendra BingundiОценок пока нет

- Ransomes Mounted 214 SpecДокумент2 страницыRansomes Mounted 214 Specbwh jessenОценок пока нет

- Hobbing Machines LC 80-180Документ8 страницHobbing Machines LC 80-180Abdisalaam mohamudОценок пока нет

- Jack NNNNДокумент32 страницыJack NNNNabiy balkewОценок пока нет

- Brushcutters AEHQ5847 01 08 08Документ2 страницыBrushcutters AEHQ5847 01 08 08Carlo PoliОценок пока нет

- ProjectДокумент21 страницаProjectzaheer bhОценок пока нет

- Lathe MachineДокумент70 страницLathe MachineAlvis MwangiОценок пока нет

- Features:: WWW - Zoomlion.nt-Rt - Ru - .: ZNM@Документ9 страницFeatures:: WWW - Zoomlion.nt-Rt - Ru - .: ZNM@Ko LinnОценок пока нет

- Catalogo KerkДокумент200 страницCatalogo KerkGaby Becerril GonzalezОценок пока нет

- B1000×3000 板式喂料机 B1000×3000 Apron FeederДокумент10 страницB1000×3000 板式喂料机 B1000×3000 Apron FeederRahmat YusufОценок пока нет

- TDTG Bucket ElevatorДокумент20 страницTDTG Bucket ElevatorVictor Julio Torres Daza0% (1)

- Star Wire FilesДокумент32 страницыStar Wire FilesMehtaMilanОценок пока нет

- XC740K and XC760KДокумент4 страницыXC740K and XC760KLorre HuОценок пока нет

- Universal Wheel Nut Tool: Features and BenefitsДокумент1 страницаUniversal Wheel Nut Tool: Features and BenefitsSACHIDHANANDHAM AОценок пока нет

- Customized Concrete Printer SpecificationДокумент10 страницCustomized Concrete Printer SpecificationAnirudh SabooОценок пока нет

- Fabrication of Screw JackДокумент10 страницFabrication of Screw JackPRAVEEN RAJОценок пока нет

- Yarn Lab ReportДокумент6 страницYarn Lab ReportYeasin ArafatОценок пока нет

- Core Cutting Machine Ijariie12718Документ5 страницCore Cutting Machine Ijariie12718Habteyes AbateОценок пока нет

- H4091-Mm24-Lathe FinalДокумент73 страницыH4091-Mm24-Lathe FinalАндрей РознатовскийОценок пока нет

- Datasheet Kleemann MOBIBELT MBT 20Документ2 страницыDatasheet Kleemann MOBIBELT MBT 20Kevin GuoОценок пока нет

- Lynx 220LSYC 030615Документ15 страницLynx 220LSYC 030615Operations ManagerОценок пока нет

- Project Report DrillДокумент22 страницыProject Report Drillsumit bijwe100% (1)

- Me6601 QB 4 PDFДокумент15 страницMe6601 QB 4 PDFpremgmech762Оценок пока нет

- Scisor Jack PresentationДокумент21 страницаScisor Jack Presentationgemechu mengistu100% (1)

- Design and Fabrication of Multi Process Machine Using Scotsh Yoke Mechanism IJERTCONV7IS06031Документ2 страницыDesign and Fabrication of Multi Process Machine Using Scotsh Yoke Mechanism IJERTCONV7IS06031Sushant GhurupОценок пока нет

- Optimization of Wagon ChassisДокумент8 страницOptimization of Wagon ChassisTJPRC PublicationsОценок пока нет

- Study and Operation of An Engine Lathe.: Course No: Ipe-108 Course Title: Workshop PracticeДокумент9 страницStudy and Operation of An Engine Lathe.: Course No: Ipe-108 Course Title: Workshop PracticeSazzadОценок пока нет

- DimenziiiДокумент2 страницыDimenziiiSlavce ZdravevОценок пока нет

- Ctalogo Romi C830-C1000Документ12 страницCtalogo Romi C830-C1000juanchavarri_22Оценок пока нет

- Design of Transmission Systems (ME61) Two MarksДокумент14 страницDesign of Transmission Systems (ME61) Two Marksgpskumar22Оценок пока нет

- Pallet Jack PTH 50s Brochure PDFДокумент2 страницыPallet Jack PTH 50s Brochure PDFMA TotalforkliftОценок пока нет

- Automatic Side Stand Retrival SystemДокумент4 страницыAutomatic Side Stand Retrival SystemsankaramarayananОценок пока нет

- Automatic Side StandДокумент9 страницAutomatic Side StandsankaramarayananОценок пока нет

- Automatic Paper Cutting Using Geneva MechanismДокумент4 страницыAutomatic Paper Cutting Using Geneva MechanismsankaramarayananОценок пока нет

- Roller Bending MachineДокумент7 страницRoller Bending MachinesankaramarayananОценок пока нет

- Regenerative Braking SystemДокумент12 страницRegenerative Braking SystemsankaramarayananОценок пока нет

- IDDS Botswana EZ NCORO Washing Machine ReportДокумент21 страницаIDDS Botswana EZ NCORO Washing Machine ReportsankaramarayananОценок пока нет

- Double Acting Hacksaw PDFДокумент8 страницDouble Acting Hacksaw PDFsankaramarayanan100% (1)

- Cam Operated Double Jaw ViseДокумент4 страницыCam Operated Double Jaw VisesankaramarayananОценок пока нет

- Design and Analysis of Two Wheel Drive Forklift For Industrial Warehouses IJERTCONV6IS04053Документ4 страницыDesign and Analysis of Two Wheel Drive Forklift For Industrial Warehouses IJERTCONV6IS04053sankaramarayananОценок пока нет

- Motorized Turning MechanismДокумент44 страницыMotorized Turning MechanismsankaramarayananОценок пока нет

- ATS Monitoring Device InstructionsДокумент25 страницATS Monitoring Device InstructionsVinhОценок пока нет

- Seal Kit Seal KitДокумент61 страницаSeal Kit Seal KitМаксим Стратила0% (1)

- Assignment 2Документ3 страницыAssignment 2Hannah Van GeeresteinОценок пока нет

- Lesson Plan #4 - Electrostatic ForceДокумент4 страницыLesson Plan #4 - Electrostatic Forcedmart033100% (1)

- 6-Boundary and Initial ConditionsДокумент8 страниц6-Boundary and Initial ConditionsqazwsxОценок пока нет

- Jurnal Internasional Pijat BayiДокумент5 страницJurnal Internasional Pijat BayiAna SafitriОценок пока нет

- CEC CategoryДокумент4 страницыCEC CategoryQ8123Оценок пока нет

- Non-Parametric TestsДокумент1 страницаNon-Parametric TestssdvdsvОценок пока нет

- Eng8Quarter1Week1 2Документ6 страницEng8Quarter1Week1 2Duero-Hadjilatip KayeОценок пока нет

- 040 X52-62-72 UNIC-flex V1Документ63 страницы040 X52-62-72 UNIC-flex V1Антон Сорока100% (2)

- Reference Manual: Buildings and Infrastructure Protection SeriesДокумент514 страницReference Manual: Buildings and Infrastructure Protection SeriesmydearteacherОценок пока нет

- Xpert R410a Onoff Ar Na 230613Документ62 страницыXpert R410a Onoff Ar Na 230613Wilson Segovia CarrascoОценок пока нет

- Surveying Lab ManualДокумент76 страницSurveying Lab ManualIan Lawrence YupanoОценок пока нет

- Karma: "Dove La Legge Della Grazia È Attiva, Finisce La Legge Del Karma"Документ37 страницKarma: "Dove La Legge Della Grazia È Attiva, Finisce La Legge Del Karma"Lars JensenОценок пока нет

- 2ND Quarter MTB - Mle Lesson Plan December 2, 2022Документ4 страницы2ND Quarter MTB - Mle Lesson Plan December 2, 2022sherry ann corderoОценок пока нет

- Nexys 2Документ12 страницNexys 2sacramusОценок пока нет

- Blue A Ks2 Test3Документ6 страницBlue A Ks2 Test3Mateo García-PumarinoОценок пока нет

- Mid 221Документ28 страницMid 221danecuprijaОценок пока нет

- Standard Support: Figure 1: Pressing F1 Redirects User To A Bing SearchДокумент4 страницыStandard Support: Figure 1: Pressing F1 Redirects User To A Bing SearchDbluepengLumОценок пока нет

- Lesson Outline: Introduction To LeadershipДокумент2 страницыLesson Outline: Introduction To LeadershipAmritpal SinghОценок пока нет

- Eaton Industrial Special Process List (SPL)Документ5 страницEaton Industrial Special Process List (SPL)amirkhakzad498Оценок пока нет

- Report On Industrial Visit ScribdДокумент11 страницReport On Industrial Visit ScribdJakeer CJОценок пока нет

- Probability DistributionsДокумент167 страницProbability DistributionslihaiyangОценок пока нет

- Design MatrixДокумент1 страницаDesign MatrixThakur Kali DassОценок пока нет

- Audit Sampling (Chapter 9)Документ25 страницAudit Sampling (Chapter 9)cris100% (2)

- Is - 2026-4Документ27 страницIs - 2026-4jm.mankavil6230Оценок пока нет

- Additional Instructions For Mailing Your Package: Drop Off LocatorДокумент2 страницыAdditional Instructions For Mailing Your Package: Drop Off LocatorEthanОценок пока нет

- Variables That Affect Teachers' Attitudes Towards Disability and Inclusive Education in Mumbai, IndiaДокумент12 страницVariables That Affect Teachers' Attitudes Towards Disability and Inclusive Education in Mumbai, IndiaSumaiya HossainОценок пока нет

- Piping and Plumbing Symbols ListДокумент1 страницаPiping and Plumbing Symbols Listsiddarth amaravathiОценок пока нет

- SIP Report-PRATYUSH (1950-113) - 1Документ49 страницSIP Report-PRATYUSH (1950-113) - 1LOKESH KUMAR SINHAОценок пока нет