Академический Документы

Профессиональный Документы

Культура Документы

Cat Switchgear - Eaton Consulting Application Guide

Загружено:

Félix VelascoАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cat Switchgear - Eaton Consulting Application Guide

Загружено:

Félix VelascoАвторское право:

Доступные форматы

Cat Generator Paralleling Switchgear 42.

0-1

June 2006 Home Index

Sheet 1815

Master TOC

Paralleling Switchgear

Cat Generator Contents

CatT Generator Paralleling Switchgear

Introduction

22

23

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.0-2

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.0-4

24

Standard and Custom Configurable Products . . . . . . . . . . . . . . . . . . . 42.1-1

PowerLynx Technology Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.1-2

XLM Switchgear 25

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.2-1

Standard Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.2-2 26

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.2-3

Technical Data — XLM One-Line Diagrams . . . . . . . . . . . . . . . . . . . . . 42.2-4

Functional Sequences of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.2-10

27

EGP Switchgear

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.3-1 28

Standard Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.3-2

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.3-3 29

Technical Data — EGP One-Line Diagrams . . . . . . . . . . . . . . . . . . . . . . 42.3-4

Functional Sequences of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.3-12

LM Switchgear

30

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.4-1

Standard Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.4-2 31

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.4-3

Technical Data — LM One-Line Diagrams . . . . . . . . . . . . . . . . . . . . . . . 42.4-4 32

Functional Sequences of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.4-6

Medium Voltage Systems

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.5-1

33

Technical Data — One-Line Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . 42.5-3

Custom Configurable Systems 34

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.6-1

Technical Data — One-Line Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . 42.6-2 35

Specifications

See Eaton’s Cutler-Hammer Product Specification Guide on enclosed CD-ROM:

1995 CSI Format:

36

Low Voltage XLM UL 1558 Switchgear. . . . . . . . . . . . . . . . . Section 16426E

Low Voltage XLM UL 891 Switchboard . . . . . . . . . . . . . . . . Section 16429E 37

Medium Voltage XLM Metal-Clad Switchgear . . . . . . . . . . Section 16346E

Low Voltage EGP UL 1558 Switchgear . . . . . . . . . . . . . . . . . Section 16426G

38

Low Voltage EGP UL 891 Switchboard . . . . . . . . . . . . . . . . . Section 16429G

Medium Voltage EGP Metal-Clad Switchgear. . . . . . . . . . . Section 16346G

Low Voltage LM UL 1558 Switchgear . . . . . . . . . . . . . . . . . . Section 16426X 39

Low Voltage LM UL 891 Switchboard . . . . . . . . . . . . . . . . . . Section 16429X

Medium Voltage LM Metal-Clad Switchgear . . . . . . . . . . . Section 16346X 40

2004 CSI Format:

Low Voltage XLM UL 1558 Switchgear. . . . . . . . . . . . . . Section 26 23 13.11

Low Voltage XLM UL 891 Switchboard . . . . . . . . . . . . . Section 26 24 13.31

41

Medium Voltage XLM Metal-Clad Switchgear . . . . . . . Section 26 13 13.31

Low Voltage EGP UL 1558 Switchgear . . . . . . . . . . . . . . Section 26 23 13.13 42

Low Voltage EGP UL 891 Switchboard . . . . . . . . . . . . . . Section 26 24 13.33

Medium Voltage EGP Metal-Clad Switchgear. . . . . . . . Section 26 13 13.33

Low Voltage LM UL 1558 Switchgear . . . . . . . . . . . . . . . Section 26 23 13.15

43

Low Voltage LM UL 891 Switchboard . . . . . . . . . . . . . . . Section 26 24 13.35

Medium Voltage LM Metal-Clad Switchgear . . . . . . . . Section 26 13 13.35

CA08104001E For more information visit: www.EatonElectrical.com

42.0-2 Cat Generator Paralleling Switchgear

Introduction Home TOC Index June 2006

Sheet 1816

General Description Master TOC

22 Introduction breaker switchgear and Magnum power ■ Data center/data processing.

circuit breakers with PowerLynxT ■ Healthcare.

CaterpillarT Generator Paralleling control technology. PowerLynx ■ Critical industrial/chemical

Switchgear is a product developed technology is for optimal power gener- processes.

23 through a joint venture between ation and electrical distribution system

performance. It provides advanced, ■ Distributed generation/co-generation.

Caterpillar and Eaton Corporation.

Caterpillar, an industry leader in industry-leading, microprocessor- ■ Water/wastewater treatment

24 electric generator sets, and Eaton, an based engine generator set control ■ Government/military.

industry leader in Low and Medium provided exclusively in Caterpillar ■ Banking/credit card processing.

Voltage Switchgear have combined Switchgear. Medium voltage systems

25 forces to create Caterpillar Generator combine VCP-W breakers and VacClad Caterpillar Switchgear Features

Paralleling Switchgear...the most Metal-Clad switchgear with the same

reliable and feature rich product proven PowerLynx technology. ■ Built-in redundancy.

26 available in the market today! ■ Reliability.

Applications ■ Touchscreen interface.

Caterpillar Switchgear has been

■ Emergency/legally required ■ Simple, intuitive operation.

27 designed to integrate hand-in-glove

standby systems.

with Caterpillar's on-package, ■ Advanced communications

microprocessor-based engine control. ■ Optional standby backup systems. capabilities.

28 Exclusively from your Caterpillar ■ Distributed generation. ■ Integrated digital technology.

dealer, you can now get the market’s ■ Peak shaving. ■ Advanced generator control and

best efficiency, reliability and protection.

■ Prime power.

29 dependability all in one package. ■ Detailed engine and electrical reports.

Reliable, flexible, and powerful. Cater-

Caterpillar Switchgear combines the ■ Best-in-class footprint.

pillar Switchgear is designed with the

30 proven Magnum DS power circuit

most critical power needs in mind:

31

32

33

34

35

36

37

38

39

40

41

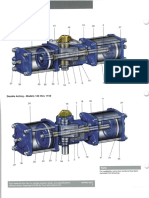

42 XLM EGP LM

43

For more information visit: www.EatonElectrical.com CA08104001E

Cat Generator Paralleling Switchgear 42.0-3

June 2006 Home TOC Index

Introduction

Sheet 1817

Master TOC General Description

Standards

Low Voltage Caterpillar Switchgear

22

conforms to the following applicable

standards: 23

■ NEMAT Standard SG-5

■ CSAT

24

■ ANSI C37.20.1

■ ANSI C37.51

■ ULT Standard 1558 25

■ NFPA 110, NFPA 99 and NFPA 70

The Switchgear utilizes Magnum DS 26

Breakers that are designed to NEMA

Standard SG-3; ANSI Standards

C37.13, C37.16, C37.17 and UL 1066. 27

Optional switchboard construction is

available that is built to UL Standard

891. These switchboards utilize 28

Magnum SB UL1066 Breakers for

generator mains, utility mains Overview

and electrically operated feeders, 29

and molded-case breakers for

non-switched feeders.

30

Medium Voltage Caterpillar

Switchgear conforms to the following

applicable standards: 31

■ NEMA SG-5

■ ANSI/IEEE C37.20.2 32

■ CSA-C22.2 No. 31-M89

■ EEMAC G8-3.2.

■ NFPA 70, 99, 110. 33

The switchgear utilizes VCP-W vacuum

circuit breakers that are designed to 34

meet or exceed all applicable IEEE /

ANSI standards including C37.06.

35

Common Components

Throughout the Entire Facility 36

Caterpillar Generator Paralleling

Detailed Engine Data

Switchgear is built with Eaton's indus-

try-leading Magnum DS low voltage 37

drawout switchgear with Magnum DS

breakers and VacClad medium voltage

switchgear with VCPW vacuum 38

breakers. This now allows the use

of common components on both

the normal power systems and the 39

generator power systems. Common

and interchangeable breakers, relays,

switchgear assembly parts, breaker 40

maintenance procedures, etc. can

be used to help reduce the overall

operating cost and increase the 41

maintainability of the entire facility.

42

43

Generator Set Control Screen

CA08104001E For more information visit: www.EatonElectrical.com

42.0-4 Cat Generator Paralleling Switchgear

Introduction Home TOC Index June 2006

Sheet 1818

Definitions Master TOC

22 Definitions Feeder Breaker Controls: Automation

controls to allow control of the

NPSS Normal Power System Supplier:

Supplier of all the components of the

The below terms and acronyms are distribution feeder devices for load NPS, such as the distribution equip-

referenced throughout this section shed/load add control and monitoring. ment vendor’s authorized distributor.

23 on Generator Paralleling Switchgear.

Generator: A machine for converting Paralleling: The procedure of connect-

These definitions can help the reader

mechanical energy into electrical energy. ing two or more generators, or other

fully understand the topics discussed.

The electrical energy may be direct power sources, of the same phase,

24 Alternator: A device for converting current (dc) or alternating current (ac). voltage and frequency characteristics

mechanical energy into alternating supplying the same load.

Generator Bus Tie: A bus tie used in

current electrical energy. It may also be

25 called an AC or synchronous generator.

XLM type systems for separating the Peak Shaving: Process by which

generator bus and/or loads from the utility customer minimizes utility

ATS: Automatic Transfer Switch. normal utility fed bus and/or loads. charges by either generating power

26 Automatic Transfer Switch: A switch Generator Demand Priority: Controls

and eliminating excessive demand

charges or by shedding load.

designed to sense the loss of one that automatically match the online

power source and automatically trans- engine generator capacity to the PowerLynx Technology: An advanced,

27 fer the load to another source of power. load to avoid unnecessary engine industry-leading microprocessor-

genset operation when loads are low. based engine generator set automa-

Closed-Transition Transfer: A transfer (Alternatively called Load Sense tion processor provided exclusively

28 between sources that provides a Load Demand.) in Caterpillar Switchgear.

momentary paralleling of both power

sources during a transfer in either Generator Tie Breaker: A feeder Prime Power Application: Unlimited

29 direction. This results in no interrup- breaker that is used to connect an hours of usage. Requires generators to

tion of power to the loads during the XLM type system to a separate piece be applied at their Prime Power rating

transfer. The closed transition transfer of Normal (utility) switchgear. with a typical load factor of 70%.

30 is only possible when the sources are

Governor: A device that regulates Processor: A specially configured

properly synchronized and interfaced.

prime mover speed by adjusting the logic controller with appropriate input-

DGPS Distributed Generation Power fuel input to maintain constant speed. output capability and programming.

31 System: Typically a local engine genset

HMI Human Machine Interface: SAW (Surface Acoustic Wave):

and automation connected to the utility

Typically a touchscreen used by A premium touchscreen sensing

system to peak shave or export power.

32 the operator for interfacing with the technology that offers maximum

EGP Switchgear (Engine Generator paralleling generator system. protection from wear or contaminants.

Paralleling Switchgear): Parallels

LM Switchgear (Load Management Station Battery: A power supply

33 multiple engine/gensets to serve loads

Switchgear): A single generator utilized for control of switchgear.

transferred via downstream ATS units.

used in distributed generation

power systems. Includes automation Synchronizer: A device which will syn-

EGPT Switchgear: Same as EGP except

34 with a controlled emergency generator controls which allow for the load to chronize an on-coming electric genera-

be served simultaneously by both tor set with the bus or another electric

bus tie breaker between sets of generators

utility and generator power sources generator set, and allows multiple power

to segregate loads or areas of the bus.

35 EMCP Electronic Modular Control

while managing how much each sources in be connected in parallel.

source contributes. Synchroscope: An instrument that

Panel: A Caterpillar microprocessor

Load Shed/Load Add: Automation provides a visual indication of proper

36 module for engine/genset control.

controls to control distribution devices time for closing of the breaker when

Emergency Generator Bus Tie: A bus (turn OFF and restore ON) when only synchronizing generators to connect

tie breaker used in EGP type systems to partial emergency engine gensets are them in parallel with another source.

37 segregate groups of generators and/or available for duty. Typically accom- TFT (Thin Film Transistor): A type

loads. Emergency Generator Bus Tie plished by assigning Priority levels to of touchscreen display technology

breakers are used where critical loads, each controlled distribution device.

38 used in HMI devices that offers high

required to be powered in 10 seconds,

Master Controls: All processors, levels of brightness and clarity.

exceed the capacity of a single genset.

HMI and programming to implement Utility Protection: A collection of protec-

39 EPS Emergency Power System : The

the desired modes of operation tive relays or a multifunction relay

emergency power sources and emer-

of engine gensets in a paralleling required by the utility to detect abnormal

gency distribution to down-stream loads.

switchgear system. conditions and open the utility breaker.

40 EPSS Emergency Power System Sup-

NFPA 110 — Standard for Emergency XLM Switchgear (Emergency

plier: Supplier of all the components of

and Standby Power Systems: Transfer [Xfer] and Load Management

the EPS, such as the Caterpillar dealer.

Standard for the assembly, installation Switchgear): Parallels multiple

41 Emergency Standby Power and performance of electrical power engine/gensets and the utility to serve

Application: Typical usage of 50 hours systems to supply critical and essential downstream loads. Typically does

per year with a maximum of 200 hours needs during outages of the primary not include downstream ATS units.

42 per year. Generators can be applied power source.

XLMT Switchgear: Same as XLM

at their Standby rating with a typical

NPS Normal Power System: The utility except with a controlled generator

variable load factor of 70%.

43 service entrance equipment and distri- bus tie breaker between the utility

Emergency Tie Breaker: A feeder bution circuits to downstream loads. bus and the engine genset bus.

breaker that is used to connect an

EGP type system to a separate piece

of Normal (utility) switchgear.

For more information visit: www.EatonElectrical.com CA08104001E

Cat Generator Paralleling Switchgear 42.1-1

June 2006 Home TOC Index

Introduction

Sheet 1819

Master TOC Standard and Custom Configurable Products

Standard Configurable EGP Medium Voltage Switchgear 22

Products EGP (Emergency Generator Parallel-

Medium voltage switchgear is

ing) switchgear is used for paralleling

available in any of the standard

Caterpillar Switchgear is available multiple generators that are not 23

configurations (XLM, EGP or LM) that

in three standard, product configura- directly connected to a utility source.

are described above. Medium voltage

tions: XLM (Emergency Transfer EGP switchgear is primarily used

Caterpillar Switchgear utilizes the same

(Xfer) and Load Management), EGP

(Emergency Generator Paralleling)

in applications where downstream

control technology, operator interface, 24

automatic transfer switches provide

and has all of the same features and

and LM (Load Management). These the switching between normal and

functions as the low voltage systems.

configurations are available for both emergency sources. This is what is

At the heart of all medium voltage 25

low voltage and medium voltage typically required in medical facilities,

Caterpillar Switchgear systems is

applications and represent the hospitals, and water/wastewater

Cutler-Hammer Vac-Clad Metal-Clad

most typical paralleling switchgear treatment facilities when multiple

Switchgear with type VCP-W vacuum 26

configurations seen in the industry. generator sets are paralleled.

circuit breakers. For detailed medium

Additional, custom configurations For detailed EGP product description,

voltage (5 and 15 kV class) product

are available to meet the demands specifications, layouts, etc., refer

descriptions, specifications, layouts, 27

of even the most unique and to Section 42.3.

etc., refer to Section 42.5.

complicated systems.

LM 28

XLM LM (Load Management) switchgear is Custom Configurable

XLM (Emergency Transfer (Xfer) a special product offering used for Products 29

and Load Management) switchgear Distributed Generation and Peak

is used when the Generators are Shaving applications. Load Manage- Custom configurable switchgear is

paralleled with a normal utility ment switchgear allows a single available to meet the needs of the

(or multiple utility) power source(s). generator to be paralleled with the most demanding, unique or compli- 30

XLM switchgear allows closed transi- utility. This arrangement can be used to cated system configurations. Custom

tion, soft-loading and unloading from reduce a facility’s demand for utility engineered systems are available for

utility, and peak shaving capability power (peak shaving), or to export special system requirements such 31

where generators operate continu- power onto the utility grid. The LM as: custom sequences of operation,

ously in parallel with the utility. switchgear product is ideal for retrofit special load control requirements,

Typically, XLM switchgear eliminates applications to provide more utilization multiple utility and tie combinations, 32

the need for automatic transfer of existing standby generator assets. unique switchgear locations or lay-

switches. Data centers, industrial In many cases, customers can take outs, etc. No matter how complicated

process, and other critical process advantage of special “limited interrupt- or unique the system, Caterpillar 33

loads are prime candidates for XLM ible” or “peak shaving” utility rates Switchgear has the power and flexibil-

switchgear. For detailed XLM product by using their existing generators to ity to handle it. For detailed custom

description, specifications, layouts, reduce their need for utility fed power. product description, specifications, 34

etc., refer to Section 42.2. For detailed LM product description, layouts, etc., refer to Section 42.6.

specifications, layouts, etc., refer to

Section 42.4. 35

36

37

38

39

40

41

42

43

CA08104001E For more information visit: www.EatonElectrical.com

42.1-2 Cat Generator Paralleling Switchgear

Introduction Home TOC Index June 2006

Sheet 1820

PowerLynx Master TOC

22 PowerLynx Technology Features Touchscreen Interface

PowerLynx technology utilizes a

Features are common to all Low operate in a normal automatic

touchscreen for operator interface,

and Medium Voltage XLM (Emergency mode. An “Instant Auto” switch is

23 monitoring and control of the parallel-

Transfer (Xfer) and Load Management), provided to place all controls to

ing switchgear. The touchscreen

EGP (Emergency Generator Parallel- the Auto position, protecting your

gives the operator an instantaneous,

ing), LM (Load Management), and facility from power outages.

24 easy to understand view of the entire

Custom assembly configurations.

5. Each Remote operator station or system. This feature is standard in all

monitoring station operates com- Caterpillar Switchgear.

Redundancy and Fault Tolerance

25 PowerLynx technology provides

pletely independently of the local

To access system controls, all you

operator interface touchscreen.

maximum efficiency and reliability. have to do is touch the corresponding

If the local operator interface

With traditional engine generator con- portion of the screen. The entire

26 trol switchgear, if a single component

touchscreen fails, it will not affect

engine generator set can be controlled

the operation of any of the remote

shuts down, the entire system may not from one touchscreen. The easy-

stations connected to the system.

to-use touchscreen interface makes

27 operate. With PowerLynx technology,

single points of failure are eliminated 6. For systems with utility interconnec- it possible to view, monitor and

because of the levels of redundancy tions (XLM type systems), redun- perform multiple functions including:

dant utility failure signals are sent to

28 and fault tolerance built into the

each processor. This ensures that

■ Metering.

automation system: (Figure 42.1-1).

the system is always alerted of a ■ Engine data.

1. True distributed control processors utility outage so generators can be ■ Protective relay settings.

29 for each power source ensure the started and power can be restored. ■ Annunciators.

system continues to operate even if

7. In the highly unlikely case of a com- ■ Adjust load shed controls and

a single automation processor fails.

30 plete loss of system automation, dis- generator demand priority.

2. The main control network is tributed manual control is available. ■ Synchronize and parallel.

redundant. ■ Set modes of operation.

31 3. In the event of a failure of a master

8. Control power is protected against

■ Voltage and frequency adjustments.

single point of failure by the utili-

control processor, PowerLynx's zation of a 24 Vdc Best Source

32 “Moving Master” feature auto- DC system. Each Engine battery

matically transfers master control and a Station Battery are con-

functions to the next available nected to a common dc bus.

33 generator control processor. Each Engine battery and the

4. If the operator interface touch- Station Battery are furnished

screen fails, the system can still with their own battery charger.

34

Touchscreen

35 Remote Monitor/

Control PC e

36

d ATS

37 ATS

For systems with utility

Interconnect (XLM Type)

ATS b

38

Touchscreen

39 Processor

Gen. 1 ac Gen. 2 ac Gen. X ac Utility Tie Distribution

40 Typical ac Util.

Relay

Bus Power PowerLynx 3000

f Transducers

41 Generator Power Utility Power

Transducers

With PowerLynx technology, it’s simple.

Transducers All the critical information you need is

displayed in a manner that is easy to

42 Figure 42.1-1. PowerLynx Automation Redundancy and Fault Tolerance understand. Graphics look exactly like

1 Distributed Control — separate processors for each source. the meters and gauges on conventional

2 Redundant network connections. switchgear. At a glance, users can easily

43 3 Moving Master — Any of the source processors can assume the “Master” control functions see how the system is performing and,

for the switchgear. based on real-time information can

4 System continues to operate in fully automatic mode even without the operator touchscreen. quickly do what’s necessary to correct

5 Each remote PC work station works independently of the local touchscreen. or optimize system performance.

6 Redundant Utility Fail Indication.

For more information visit: www.EatonElectrical.com CA08104001E

Cat Generator Paralleling Switchgear 42.1-3

June 2006 Home TOC Index

Introduction

Sheet 1821

Master TOC PowerLynx

Table 42.1-1. PowerLynx Control Technology Comparison Integrated Digital Technology

Features PowerLynx PowerLynx PowerLynx Integrated with Caterpillar on-package

22

3000 2000 1000

genset controls, PowerLynx has

Redundancy and Fault Tolerance Features built-in synchronizer, power factor

True Distributed Processing Yes Yes Yes controller and load sharing functions.

23

Best Source 24 Vdc System Yes Yes Yes Caterpillar switchgear products

Moving Master Redundancy Yes Yes Yes

Redundant Control Network Yes Yes No

do not require additional discrete 24

Redundant Utility/Tie Automation Processors Yes Yes No components, such as synchronizers,

cross-current compensation devices,

Display Features and Options

Local Touchscreen Display 15" color 12" color 6" or 10" mono

speed/voltage droop controllers, 25

load sharing modules, etc.

3-D Generator View for Engine Data Yes Yes No

Dynamic System Overview Oneline Yes Yes Yes

Full Redundant Touchscreen Available Yes Yes Yes

Advanced Generator Protection 26

System Tuning Capabilities via Touchscreen Yes Yes Yes Caterpillar switchgear performs

Balance of Plant Monitoring or Control Yes No No generator protective functions inter-

Logging and Reporting Features nal to the PowerLynx processor. 27

Historic Trending Yes No No With PowerLynx technology, you can

Real-Time Trend Yes Limited Limited monitor, process, compare, display

Alarm and Event Logging Unlimited 500 events 500 events and transmit data with a high degree 28

Save / Export Alarm logs Yes No No of precision and control — and that

Full Feature Remote Monitoring/Control Available Yes Yes Yes control translates into high reliability

Automated Reporting Yes Yes Yes and functionality. 29

Custom Automated Reporting (JCAHO test report, etc.) Yes No No

Optional Connectivity Features to BMS or SCADA systems Yes Yes Yes PowerLynx technology provides

ATS Monitoring and Control Caterpillar switchgear with enhanced 30

Caterpillar ATS Monitoring and Control Yes No No features available from no other

Caterpillar ATS Remote Settings Capability via Touchscreen Yes No No manufacturer.

Caterpillar UPS Monitoring Only

Non-Caterpillar ATS Monitoring Only

Yes

Yes

No

Yes

No

No ■ Unequaled fault tolerance.

31

Non-Caterpillar UPS Monitoring Only Yes No No

■ World-leading operator interface.

PowerLynx Control Technology PowerLynx 1000 ■ Sophisticated communications abilities. 32

■ Superior connectivity.

Caterpillar Switchgear offers three ■ 6 or 10" monochrome TFT touchscreen.

different levels of touchscreen opera- ■ High reliability resistive LCD Caterpillar power systems protect 33

tor interface. Each level gives different touchscreen technology. your power every second of every day.

options for trending, reporting, and ■ Limited Alarm and Event logging. It is crucial to keep a power generation

logging capabilities. ■ Monochrome graphical interface.

or electrical distribution system 34

operating around-the-clock, especially

PowerLynx 3000 in applications that rely heavily on

High-Speed Integrated Control System

■ 15" color LCD TFT touchscreen. emergency/standby systems, such as: 35

■ SAW (surface acoustic wave) PowerLynx technology uses a high-

speed industrially hardened network ■ Hospitals/medical centers.

LCD touchscreen technology for

unsurpassed reliability. for system control. PowerLynx 3000 ■ Electrical, water and gas utilities. 36

and 2000 systems feature a redundant ■ Government institutions.

■ Historical trending of engine

supervisory communication network. ■ Data centers.

generator and electrical parameters.

■ Unlimited Alarm and Event logging.

This ensures that the loss of one or

■ Critical industrial/chemical processes.

37

more processors or a supervisory

■ Ability to Save and Archive Trend communication network will not Additional PowerLynx technology

and Logging data. affect the integrity of the switchgear 38

advantages include:

■ Automated reporting capability. automation. This essential feature

❑ Alarm reports ensures proper system performance ■ Less installation wiring.

❑ Log reports under any condition. ■ Smaller footprint provides better 39

❑ Generator system reports utilization of available space.

❑ JCAHO compliant reports

Best-in-Class Footprint ■ Detailed engine and electrical reports.

■ Optional Automatic Transfer PowerLynx technology uses less than ■ Low cost redundancy. 40

Switch Control. 1/3 of the components of conventional ■ Enhanced performance.

switchgear. This translates into less

■ Moving Master.

wiring, a smaller footprint, higher

■ UL, NFPA, CSA and IEEE compliant. 41

■ Redundant Network. mean time between failures, and lower Caterpillar Switchgear was designed

PowerLynx 2000 mean time to repair. with your critical power needs in mind.

42

■ 12" color TFT touchscreen.

■ High reliability resistive LCD

touchscreen technology. 43

■ Limited Alarm and Event logging.

■ Moving Master.

■ Redundant Network.

CA08104001E For more information visit: www.EatonElectrical.com

42.1-4 Cat Generator Paralleling Switchgear

Introduction Home TOC Index June 2006

Sheet 1822

PowerLynx Master TOC

Advanced Communications Remote Communications Communications with Building

22 Capabilities PowerLynx makes it easy to remotely Management or SCADA Systems

view, or view and control your Genera- PowerLynx can also easily communi-

PowerLynx technology is equipped tor or Caterpillar Switchgear system. cate data to third party Building

23 with exceptional remote communica- Whether an on-site remote, or an off- Management, SCADA or other moni-

tions technologies, enabling you to site remote, the PowerLynx remote toring systems. For these applications,

control and monitor your engine gen- communications package gives you the a data concentrator processor acts as

24 erator sets from anywhere at anytime. identical interface and same capabili- a "firewall" between your Caterpillar

Whether at home, in the office, or on Switchgear system and the Building

ties as standing in front of the genera-

the road, you can access controls and Management or SCADA System.

tor or Caterpillar switchgear. Although

25 information on a real-time basis and

identical, the remote communications The data concentrator serves up the

respond immediately...even control requested data to the third party moni-

run completely independent of the

multiple facilities from a single toring system, but stays completely

paralleling switchgear automation.

26 centralized site.

This ensures remote communication independent of all critical generator

devices or systems will not affect the control automation. This ensures

reliability of your Caterpillar Switchgear. remote communication devices or

27 Figures 42.1-2 – 42.1-6 show examples systems will not affect the reliability

of remote communication connections of your Caterpillar Switchgear.

to the Caterpillar Switchgear.

28

Caterpillar Switchgear

29

30

Cat. 5 cable (up to approx. 300’)

31 Ethernet Port Ethernet Port

32

Key Points:

Switchgear PC 1. Single Ethernet (cross over) Cable End User PC

33 - Dedicated Static I.P. Address

- Ethernet Port

(approx. 300' standard, optional up to

5000' via Fiber Optics)

- Full Control or View Only

(depending on password)

2. Supports one client. - Dedicated Static I.P.

Address

34 - Ethernet Port

35 Figure 42.1-2. PowerLynx On-Site Remote — Ethernet Network with SINGLE User

36 End User PC

- Full Control or View Only

(depending on password)

37 - Dedicated Static

I.P. Address

38

Caterpillar Switchgear End User PC

HUB or Switch - Full Control or View Only

39 (depending on password)

- Dedicated Static

I.P. Address

Cat. 5 cable (up to approx. 300’)

40 Ethernet Port

End User PC

- Full Control or View Only

41 Key Points:

(depending on password)

- Dedicated Static

Switchgear PC I.P. Address

1. Dedicated Ethernet LAN

- Dedicated Static

42 I.P. Address or

- Ethernet Port

2. Utilize customers' LAN — Coordination

with network administrators may be

43 necessary for connection and security issues.

3. Supports multiple clients.

Figure 42.1-3. PowerLynx On-Site Remote — Ethernet Network with MULTIPLE Users

For more information visit: www.EatonElectrical.com CA08104001E

Cat Generator Paralleling Switchgear 42.1-5

June 2006 Home TOC Index

Introduction

Sheet 1823

Master TOC PowerLynx

22

End User PC

- 1 single point to point connection

- Full Control (depending on password)

23

Caterpillar Switchgear - 56k Modem

24

56k Modem 56k Modem

25

26

Key Point:

Switchgear PC

1. Standard Dial-up Analog Telephone Line

- 56k Modem with

phone line 27

28

Figure 42.1-4. PowerLynx Off-Site Remote — Dial-up Telephone Network

29

On-Site Off-Site 30

Provided with View Only Remote Client

- Web Browser

Caterpillar Switchgear

View Only

31

Your Company

Remote Client

Network - Web Browser

VPN Device 32

Caterpillar Switchgear VPN TUNNEL

33

Firewall Device

VP

- VPN Access

N

Ethernet Port

TU 34

N

N

Remote Client

Switchgear PC Cat. 5 cable - Web Browser EL

- 1 Web Server

- Ethernet Port

(up to approx. 300')

Remote Client 35

- Web Browser

Firewall Device 36

- VPN Access

37

Figure 42.1-5. PowerLynx Off-Site Remote — (TCP-IP) Web-Based Connection with MULTIPLE Users (View Only)

38

39

40

41

42

43

CA08104001E For more information visit: www.EatonElectrical.com

42.1-6 Cat Generator Paralleling Switchgear

Introduction Home TOC Index June 2006

Sheet 1824

PowerLynx Master TOC

22

Provided by others

23

Remote Client

- VPN Client

24 Provided with - Terminal Services Client

- View only or Full Control

Caterpillar Switchgear

(Depending on password)

25

VPN Device

26 ISP Provider

Remote Client

VPN TUNNEL - VPN Client

- Terminal Services Client

Caterpillar Switchgear - View only or Full Control

27 (Depending on password)

HUB or Switch Firewall Device

28 Ethernet Port - VPN Access

Remote Client

Switchgear PC Equipment Center PC with

29 - Dedicated Static Microsoft Windows Terminal Server

- VPN Client

- Terminal Services Client

I.P. Address - View only or Full Control

- 1 Network Interface Card (Depending on password)

- Ethernet Port

30 - 1 Virus Protection

Cat. 5 cable - Configured as a VPN Server

(up to approx. 300')

31

32 Figure 42.1-6. PowerLynx Off-Site Remote — (TCP-IP) Connection with MULTIPLE Users

33

34

35

36

37

38

39

40

41

42

43

For more information visit: www.EatonElectrical.com CA08104001E

Cat Generator Paralleling Switchgear 42.2-1

June 2006 Home TOC Index

XLM Switchgear

Sheet 1825

Master TOC General Description

XLM Product Description ■ Closed transition transfer to

22

Emergency Mode to facilitate

Caterpillar XLM Switchgear — maintenance, or for storm threat

Generator Paralleling Switchgear for avoidance with soft loading and

Emergency Transfer (Xfer) and Load unloading of generator system. 23

Management control of multiple ■ Load shed/add.

engine generator sets with one utility ■ Generator demand priority.

source. For systems with multiple 24

■ Cost-effective, technically superior

utility and/or tie breakers, please

alternative to conventional ATS

refer to the Custom Configurable

Switchgear Section 42.6.

arrangement. 25

Caterpillar Switchgear brings the

■ Automatic Transfer to Emergency

power and reliability of microproces-

upon Utility failure.

sor technology to your generator 26

■ Automatic start, synchronize, switchgear application. Through

parallel, and load share on a com- the use of the PowerLynx operator

mon bus for emergency operation. interface touchscreen display with 27

■ Closed transition transfer back to easy-to-follow graphical representa-

utility upon stable return of power, tions, the PowerLynx technology

with soft generator unloading. product merges the features of:

28

■ Closed transition Load Management

■ Power monitoring.

Mode with soft loading and unload- 29

ing of generator system. ■ Switchgear automation.

■ Generator set control.

■ Optional remote communications. 30

31

XLM2 Switchgear (PowerLynx 3000 Shown)

32

33

34

35

a 36

37

38

39

40

41

42

43

Figure 42.2-1. XLM2 Switchgear

1 PR = Protective Relay.

CA08104001E For more information visit: www.EatonElectrical.com

42.2-2 Cat Generator Paralleling Switchgear

XLM Switchgear Home TOC Index June 2006

Sheet 1826

Standard and Optional Equipment Master TOC

22 Equipment ■ System status and alarm annucia- ■ PowerLynx remote software for

tion with color display and 85 dbA additional on-site monitoring and

alarm horn with silence button. control work stations.

Standard Equipment — XLM

■ Password secured settings and ■ PowerLynx remote software for

23 ■ Low voltage XLM systems utilize adjustments for generator and sys- off-site monitoring and control.

Magnum DS power circuit breaker tem setups and protective relaying. ■ Building Automation System

switchgear and Magnum power

■ Alarm summary reports. or SCADA communications —

24 circuit breakers. For complete

Modbus or Ethernet.

technical details on Magnum DS ■ Settings reports.

switchgear, see Section 20. ■ Engine and generator load charts. ■ Remote notification.

25 ■ Operator Interface Touchscreen ■ 3-D engine data. ■ Historical data trending.

(Choose one below): ■ UL 891 listed and labeled or UL 1558

❑ PowerLynx 3000, 15-inch listed and labeled. Tie Breaker Application

26 surface acoustic wave LCD TFT ■ NEMA 1, deadfront freestanding Many systems require the use of tie

color touchscreen construction. breakers to meet Code or system per-

formance requirements. Tie breakers

27 ❑ PowerLynx 2000, 12-inch resis- ■ IEEE 1547 compliant, when a compli-

can be used anywhere throughout the

tive LCD TFT color touchscreen ant utility protective relay is selected.

line-up to segment or isolate desired

❑ PowerLynx 1000, 6-inch resistive ■ UL or CSA listed. sources, loads or sections of bus.

28 LCD monochrome touchscreen ■ Copper bus, braced for 100 kA.

for XLM1, 10-inch resistive LCD ■ 3-phase, 4-wire, 100% neutral, Generator Bus Tie

monochrome touchscreen for 1/4-inch x 2-inch copper ground bus. Generator Bus Ties can be used to

29 XLM2-XLM4 separate the normal electric service

■ Available in 600 V, 480/277 V or

■ Direct data communication to 208/120 V, 60 Hz. sources from the generator sources.

Caterpillar microprocessor-based This can also allow separation of load

30 engine generator set control network.

■ UL 1066 listed power circuit breakers to either side of the generator

breakers, 100 kAIC, two-step stored bus tie breaker in order to allow isola-

■ Full function 0.5% accuracy analog energy drawout mounted electri- tion of load banks, or dedicated emer-

31 and digital ac metering for utility: cally operated with long time and gency loads. This separation also may

voltage 1-2, 2-3, 3-1; current 1, 2, 3; instantaneous trip, and circuit

frequency; power factor; kW; kvar. be required by NFPA or local Codes.

breaker control switch with lights.

32 ■ Full function 0.5% accuracy analog ■ Continuous cross bus ratings up Generator Bus Tie breakers can be

and digital ac metering for genera- to 6000 amperes at 600 Vac. applied to serve several purposes.

tors: voltage 1-2, 2-3, 3-1; current 1, 2,

■ Mechanical lugs for incoming and

33 3; frequency; power factor; kW; kvar.

outgoing conductors.

1. Starting of large loads — the

Generator Bus Tie can be opened

■ Full function engine gauges; RPM,

■ Top or bottom conduit entry. to allow multiple generators to be

dc battery voltage, oil pressure,

34 engine coolant temperature, engine ■ Plug together control connections paralleled before being connected

across shipping split. to large load(s). Once multiple

hours, number of starts.

generators are paralleled, the

■ Full function synchronizing and par-

35 alleling controls with selection for Optional Equipment — XLM

Generator Bus Tie can be closed

to power the large loads.

automatic or manual synchronizing.

■ Distribution sections with 2. Load banks — the Generator Bus

36 ■ NFPA 110 engine/generator status,

electrically operated drawout Tie can allow the generators to be

pre-alarm, lamp test button, shut-

down fault annunciation and 85 dBA UL 1066 circuit breakers. isolated from the normal utility fed

■ Circuit breaker trip functions — short bus. Having a distribution breaker

37 alarm horn with silence button.

time and/or ground fault (in addition or set of load take-off lugs on the

■ Full function 0.5% accuracy analog

to long time and instantaneous). generator side of the bus allows

and digital ac metering for system:

the generators to be load bank

38 voltage 1-2, 2-3, 3-1; current 1, 2, 3; ■ Steel barriers between switchboard

tested without affecting any

frequency; power factor; kW; kvar. or switchgear sections for compart-

mentalization. normal utility fed loads.

■ System control functions for auto

39 (standby for emergency), closed ■ Bus/cable barriers. 3. Emergency Standby systems with

transition to emergency and load ■ Distribution sections with group Automatic Transfer Switches —

management. mounted UL 489 molded case circuit the Generator Bus Tie provides

40 ■ Automatic load shed control with breakers. (UL 891 construction only). isolation between the Normal

on-screen operator adjustments ■ Also available in 150 kA or 200 kA and Emergency buses. During a

for essential (1 level of essential bus bracing configurations. loss of utility power, the Generator

41 for every generator in the system) Bus Tie can be opened to isolate

■ Also available in 8000 and 10,000

and 1 level of non-essential auto- all Normal loads and allow resto-

amperes continuous cross bus

matic or manual load shed/load ration of power to Emergency

42 add control.

ratings at 600 Vac.

loads. Once Emergency loads

■ Also available with 4000, 5000 and are restored, the Emergency

■ Automatic generator demand 6000 ampere UL1066 breakers. Bus Tie can be reclosed to

43 priority with on-screen operator

■ Trip unit metering and communica- restore power to Normal loads.

adjustments for automatic addition

tions (Digitrip 520M, 520MC and 1150).

and removal of generator to the Note: See Page 42.2-8 for an example

load bus. ■ Also available in 5 kV and 15 kV class of an XLM system with Generator Bus

configurations (See Section 42.5). Tie breaker.

For more information visit: www.EatonElectrical.com CA08104001E

Cat Generator Paralleling Switchgear 42.2-3

June 2006 Home TOC Index

XLM Switchgear

Sheet 1827

Master TOC Features

Caterpillar XLM Switchgear Engine Monitoring and Alarms ■ PowerLynx 1000, 6-inch or 10-inch

22

monochrome.

■ Low coolant temperature pre-alarm.

Utility Metering ■ Screen enable/disable key switch

■ High coolant temperature pre-alarm (PowerLynx 3000 only).

■ 0.5% accuracy. and shutdown. 23

■ Voltage 1-2, 2-3, 3-1; current 1, 2, 3; ■ Low oil pressure pre-alarm and Power Supply

frequency; power factor; kw; kvar; shutdown.

synchroscope. ■ Low fuel alarm (diesel only).

■ Automatic best dc source selector. 24

■ 24 Vdc station battery, sealed jar,

■ Low engine battery alarm. 4-hour, external 120 Vac emergency

Utility Protective Relaying

■ 27/59 — under/overvoltage relay.

■ Overcrank shutdown. power required for charger. 25

■ Overspeed shutdown. ■ Power from 24 Vdc engine cranking

■ 81 O/U — under/overfrequency relay. batteries.

■ Multi-function utility grade, Engine/Generator Control ■ Processor power supplies — 24 Vdc.

26

drawout with: ■ Automatic engine start.

❑ 47 — phase sequence/phase ■ Adjustable engine cooldown timer. Technology Communications 27

failure relay

■ 15 — automatic synchronizer. ■ Automation network — high speed,

❑ 32 — reverse direction relay, high reliability, industrially hardened.

■ 65 — microprocessor engine gover-

utility grade, drawout nor load sharing and soft loading ■ Optional remote communications 28

❑ 32/51 — reverse direction control. network — Ethernet, Modem.

overcurrent relay, utility grade, ■ 90 — var/PF and cross current ■ Optional communication to

drawout compensation controller. building automation or SCADA 29

❑ 32/62 — reverse direction timing systems for general monitoring —

relay, utility grade, drawout System Metering ModbusT RTU or Modbus TCP-IP.

■ 86 — reverse power lockout relay,

30

■ 0.5% accuracy.

manual reset. Circuit Breakers

■ Voltage 1-2, 2-3, 3-1; current 1, 2, 3;

■ 25 — synch check relay, (hardware frequency; power factor; kw; kvar ■ 100% Rated UL 1066 power circuit 31

redundant protective device). breakers available 800 – 6000 A with

System Protective Relaying two-step stored energy mechanism.

Generator Metering ■ 27/59 — bus under/overvoltage relay. ■ 100 kAIC standard (200 kA optional). 32

■ 0.5% accuracy. ■ 81 O/U — bus under/overfrequency

■ Drawout mounted (fixed optional).

■ Voltage 1-2, 2-3, 3-1; current 1, 2, 3; ■ 5 cycle closing.

frequency; power factor; kw; kvar;

relay. 33

■ 15 — auto synchronizer. ■ Electrically operated.

synchroscope. ■ Auxiliary and bell alarm contacts.

Generator Protective Relaying

System Control ■ Electronic trip unit with long time 34

■ Automatic standby mode. and instantaneous trip functions

■ 27/59 — under/overvoltage relay. (short time and ground fault

■ Emergency mode with closed 35

■ 81 O/U — under/overfrequency relay. transition to normal. optional).

■ 32 — reverse power relay. ■ Closed transition to emergency mode. Enclosure and Bussing

■ 40 — loss of excitation (reverse var) ■ Load management mode.

■ Available as UL 1558, UL 891 or CSA

36

relay.

■ Automatic load shed control with listed and labeled.

■ 25 — synch check relay (hardware bus underfrequency protection and

redundant protective device). one 4-pole,10 A,120 Vac, Form C, ■ Optionally service entrance rated. 37

dry contact output for each load ■ NEMA 1, deadfront freestanding

Engine Gauges shed level (1 level of essential for construction.

■ RPM meter. each generator in the system). ■ Copper bus. 38

■ Engine battery volt meter. ■ Automatic generator demand ■ 100 kA bus bracing (200 kA optional).

priority control.

■ Oil pressure gauge. ■ 3-phase, 4-wire, 100% neutral bus, 39

■ Engine coolant temperature gauge. ■ Master shutdown button. 1/4-inch x 2-inch ground bus.

■ Seismic qualified to exceed

Touchscreens the requirements of the Uniform 40

■ PowerLynx 3000, 15-inch SAW Building CodeT (UBC), California

LCD TFT color. Building Code (CBC) and IBC.

■ PowerLynx 2000, 12-inch LCD TFT ■ Also available in UL listed and 41

resistive color. labeled medium voltage.

Environment 42

■ 0°C to 50°C.

■ 0 to 95% humidity, non-condensing. 43

CA08104001E For more information visit: www.EatonElectrical.com

42.2-4 Cat Generator Paralleling Switchgear

XLM Switchgear Home TOC Index June 2006

Sheet 1828

Technical Data Master TOC

22 XLM Switchgear — One-Line Diagrams

23

24

25

26

27

28

29

30

31

32

Figure 42.2-2. Typical Electrical System with XLM1 Switchgear (1-Generator Source, 1-Utility Source) —

(For Multiple Utility Sources, see Custom Configurable Switchgear Section 42.6)

33 1 PR = Protective Relay.

34 3 Generator Dimensions

Breaker Size

Breaker Size

Max. Feeder

Max. Utility

Bus Rating

Bkr. Size 1

Generator

kW (480 V)

Lbs. (kg)

35

Weight

Min. Max. Height Width Depth

Main

36 800 0 532 800 1600 1600 99.00 44.00 72.00 3300

(2514.6) (1117.6) (1828.8) (1498)

3

1600 533 1064 1600 1600 1600 3400

37 (1544)

2000 1065 1330 2000 2000 2000 3600

T (1634)

38 3000 1331 2000 3000 3200 3200 78.00 3700

(1981.2) (1680)

1 4000 A, 5000 A and 6000 A breakers available in 44" wide structure.

39 Contact your local Caterpillar Electric Power dealer for more details.

2 Low voltage switchgear for up to 3500 kW generator set ratings

at 480 V is also available. Contact local Caterpillar Electric Power

40 3

dealer for more details.

66.00 (1676.4) with D1.

Conduit Space for 22.00-Inch (558.8 mm) Wide Structures —

41 Top or Bottom Entry

Structure Rear Conduit Opening Recommended

Depth Width Depth Number of 3.5”

42 or 4” Conduits

22.00 (558.8) 22.00 (558.8) 22.00 (558.8) 66.00 (1676.4) 16.00 (406.4) 19.30 (490.2) 9

72.00 (1828.8) 16.00 (406.4) 25.30 (642.6) 12

43 78.00 (1981.2) 16.00 (406.4) 31.30 (795.0) 15

84.00 (2133.6) 16.00 (406.4) 37.30 (947.4) 18

Figure 42.2-3. XLM1 Switchgear Layout

For more information visit: www.EatonElectrical.com CA08104001E

Cat Generator Paralleling Switchgear 42.2-5

June 2006 Home TOC Index

XLM Switchgear

Sheet 1829

Master TOC Technical Data

22

23

24

25

26

27

28

29

30

31

32

Figure 42.2-4. Typical Electrical System with XLM2 Switchgear (2-Generator Sources, 1-Utility Source) —

(For Multiple Utility Sources, see Custom Configurable Switchgear Section 42.6)

1 PR = Protective Relay. 33

Generator Dimensions

34

Breaker Size

Breaker Size

3

Max. Feeder

Max. Utility

Bus Rating

Bkr. Size 1

Generator

kW (480 V)

Lbs. (kg)

Weight

Min. Max. Height Width Depth

35

Main

Feeder

Breaker

Controls

800 0 532 800 1600 1600 99.00 66.00 72.00 5000 36

(2514.6) (1676.4) (1828.8) (2270)

1600 533 1064 1600 1600 1600 5200

(2361) 37

2000 1065 1330 2000 2000 2000 5600

T

(2542)

3000 1331 2000 3000 3200 3200 84.00 5800 38

(2133.6) (2633)

1 4000 A, 5000 A and 6000 A breakers available in 44" wide structure.

2

Contact your local Caterpillar Electric Power dealer for more details. 39

Low voltage switchgear for up to 3500 kW generator set ratings

at 480 V is also available. Contact local Caterpillar Electric Power

dealer for more details.

40

Conduit Space for 22.00-Inch (558.8 mm) Wide Structures —

Top or Bottom Entry

Structure Rear Conduit Opening Recommended 41

Depth Width Depth Number of 3.5”

or 4” Conduits

66.00 (1676.4) 16.00 (406.4) 19.30 (490.2) 9

42

22.00 (558.8) 22.00 (558.8) 22.00 (558.8) 72.00 (1828.8) 16.00 (406.4) 25.30 (642.6) 12

78.00 (1981.2) 16.00 (406.4) 31.30 (795.0) 15

84.00 (2133.6) 16.00 (406.4) 37.30 (947.4) 18 43

Figure 42.2-5. XLM2 Switchgear Layout

CA08104001E For more information visit: www.EatonElectrical.com

42.2-6 Cat Generator Paralleling Switchgear

XLM Switchgear Home TOC Index June 2006

Sheet 1830

Technical Data Master TOC

22

23

24

25

26

27

28

29

30

31

32

Figure 42.2-6. Typical Electrical System with XLM3 Switchgear (3-Generator Sources, 1-Utility Source) —

(For Multiple Utility Sources, see Custom Configurable Switchgear Section 42.6)

33 1 PR = Protective Relay.

34

3 4 Generator Dimensions

Breaker Size

Breaker Size

Max. Feeder

Max. Utility

Bus Rating

Bkr. Size 1

Generator

kW (480 V)

35

Lbs. (kg)

Weight

Min. Max. Height Width Depth

Main

36 Feeder

Breaker 800 0 532 800 1600 1600 99.00 88.00 72.00 7100

Controls

(2514.6) (2235.2) (1828.8) (3223)

1600 533 1064 1600 1600 1600 7300

37 (3314)

2000 1065 1330 2000 2000 2000 7700

LY

LYNX

L

(3496)

38 T

3000 1331 2000 3000 3200 3200 84.00 7800

(2133.6) (3541)

1

39 4000 A, 5000 A and 6000 A breakers available in 44" wide structure.

Contact your local Caterpillar Electric Power dealer for more details.

2 Low voltage switchgear for up to 3500 kW generator set ratings

at 480 V is also available. Contact local Caterpillar Electric Power

40 dealer for more details.

Conduit Space for 22.00-Inch (558.8 mm) Wide Structures —

41 Top or Bottom Entry

Structure Rear Conduit Opening Recommended

Depth Width Depth Number of 3.5”

42 or 4” Conduits

66.00 (1676.4) 16.00 (406.4) 19.30 (490.2) 9

22.00 (558.8) 22.00 (558.8) 22.00 (558.8) 22.00 (558.8)

72.00 (1828.8) 16.00 (406.4) 25.30 (642.6) 12

43 78.00 (1981.2) 16.00 (406.4) 31.30 (795.0) 15

84.00 (2133.6) 16.00 (406.4) 37.30 (947.4) 18

Figure 42.2-7. XLM3 Switchgear Layout

For more information visit: www.EatonElectrical.com CA08104001E

Cat Generator Paralleling Switchgear 42.2-7

June 2006 Home TOC Index

XLM Switchgear

Sheet 1831

Master TOC Technical Data

22

23

24

25

26

27

28

29

30

31

32

Figure 42.2-8. Typical Electrical System with XLM4 Switchgear (4-Generator Sources, 1-Utility Source) —

(For Multiple Utility Sources, see Custom Configurable Switchgear Section 42.6)

1 PR = Protective Relay. 33

34

3 4 5 Generator Dimensions

Breaker Size

Breaker Size

Max. Feeder

Max. Utility

Bus Rating

Bkr. Size 1

Generator

kW (480 V)

Lbs. (kg)

35

Weight

Min. Max. Height Width Depth

Main

Feeder

Breaker

Controls

800 0 532 800 1600 1600 99.00 110.00 72.00 9100 36

(2514.6) (2794.0) (1828.8) (4131)

1600 533 1064 1600 1600 1600 9300

(4222) 37

T

2000 1065 1330 2000 2000 2000 9500

(4313)

3000 1331 2000 3000 3200 3200 84.00 9800

38

(2133.6) (4449)

1 4000 A, 5000 A and 6000 A breakers available in 44" wide structure.

Contact your local Caterpillar Electric Power dealer for more details. 39

2 Low voltage switchgear for up to 3500 kW generator set ratings

at 480 V is also available. Contact local Caterpillar Electric Power

dealer for more details. 40

Conduit Space for 22.00-Inch (558.8 mm) Wide Structures —

Top or Bottom Entry 41

Structure Rear Conduit Opening Recommended

22.00 (558.8) 22.00 (558.8) 22.00 (558.8) 22.00 (558.8) 22.00 (558.8)

Depth Width Depth Number of 3.5”

or 4” Conduits

42

66.00 (1676.4) 16.00 (406.4) 19.30 (490.2) 9

72.00 (1828.8) 16.00 (406.4) 25.30 (642.6) 12

78.00 (1981.2)

84.00 (2133.6)

16.00 (406.4)

16.00 (406.4)

31.30 (795.0)

37.30 (947.4)

15

18

43

Figure 42.2-9. XLM4 Switchgear Layout

CA08104001E For more information visit: www.EatonElectrical.com

42.2-8 Cat Generator Paralleling Switchgear

XLM Switchgear Home TOC Index June 2006

Sheet 1832

Technical Data Master TOC

22

23

24

25

26

27

28

29

30

31

32

Figure 42.2-10. Typical Electrical System with XLMT4 Switchgear (4-Generator Sources, 1-Utility Source, 1-Generator Bus Tie Breaker)

(For Multiple Utility Sources, see Custom Configurable Switchgear Section 42.6)

33 1 PR = Protective Relay.

34 3 4 5 6

Generator Dimensions

Breaker Size

Breaker Size

Max. Feeder

Max. Utility

Bus Rating

Bkr. Size 1

Generator

kW (480 V)

Lbs. (kg)

35

Weight

Min. Max. Height Width Depth

Main

2

Feeder Feeder

Breaker Breaker

Controls Controls

36 800 — 532 800 1600 800 99.00 132.00 72.00 9100

(2514.6) (3352.8) (1828.8) (4131)

3

Tie 1600 — 1064 1600 1600 1600 78.00 9300

37 L Breaker

Controls (1981.2) (4222)

2000 — 1330 2000 2000 2000 84.00 9500

(2133.6) (4313)

38 3000 — 2000 3000 3200 3200 9800

(4449)

1 4000 A, 5000 A, and 6000 A breakers available in 44" wide structure.

39 Contact your local Caterpillar Electric Power dealer for more details.

2 Low voltage switchgear for up to 3500 kW generator set ratings

at 480 V is also available. Contact local Caterpillar Electric Power

40 3

dealer for more details.

66.00 (1676.4) with D1.

Conduit Space for 22.00-Inch (558.8 mm) Wide Structures —

41 22.00 (558.8) 22.00 (558.8) 22.00 (558.8) 22.00 (558.8) 22.00 (558.8) 22.00 (558.8)

Top or Bottom Entry

Structure Rear Conduit Opening Recommended

Depth Number of 3.5”

42 Width Depth

or 4” Conduits

66.00 (1676.4) 16.00 (406.4) 19.30 (490.2) 9

43 72.00 (1828.8)

78.00 (1981.2)

16.00 (406.4)

16.00 (406.4)

25.30 (642.6)

31.30 (795.0)

12

15

84.00 (2133.6) 16.00 (406.4) 37.30 (947.4) 18

Figure 42.2-11. XLMT4 Switchgear Layout

For more information visit: www.EatonElectrical.com CA08104001E

Cat Generator Paralleling Switchgear 42.2-9

June 2006 Home TOC Index

XLM Switchgear

Sheet 1833

Master TOC Technical Data

Table 42.2-1. Typical Control Circuit Wiring — Low Voltage Systems 1

Function (Quantity)/Size/ Signal Description 22

Type of Cable 2 Type 3

Generator Control

Caterpillar Engine Generator Set Diesel — (1) x #16 AWG Shielded Signal Level Network Communications for Monitoring

23

Communications Twisted Pair (Belden 8719) and Display of Engine Data to Switchgear

Gas — (1) x #16 AWG Shielded Signal Level

Twisted Quad 24

Control Panel Discrete Control Interface (16) x 1/c #14 AWG (Includes Spares) dc Control ≤ 30 Vdc Discrete Control (Start/Stop, Emergency Stop

and Crank Terminate, Includes Spares, etc.)

Best Source 24 Vdc (4) x 1/c #10 AWG dc Control ≤ 30 Vdc + / - 24 Vdc from Generator Battery System to

25

(2 x + 24 Vdc & 2 x – 24 Vdc) Supplement Switchgear 24 Vdc Control Voltage

Voltage Regulation (VR) Control (1) x #16 AWG Twisted pair Signal Level Bi-polar dc Bias Signal for Voltage Control

(Belden 8719) 26

(3) x 1/c #14 AWG (Additional for CDVR dc Control ≤ 30 Vdc

Only)

Speed Control (Governor) Type 2301A Speed Controller — dc Control ≤ 30 Vdc Bi-polar dc Bias Signal for Speed Control 27

(2) x #16 AWG Shielded

Twisted Pair (2301A)

ADEMIII Speed Controller — Signal Level 28

(1) x #16 AWG Shielded Twisted

Triplet (Belden 8618)

(Additional for Pro Act Gov. Only)

(3) x #14 AWG XHHW Cu

dc Control ≤ 30 Vdc 29

Air Fuel Ratio (AFR) Controller Gas Only — (1) x #16 AWG Shielded Signal Level For Gas Engines Equipped with AFR

Twisted Pair Controller Only

30

Battery Systems

Power for 24 Vdc Station Battery Charger (3) x 1/c #12 AWG ac Control 120 Vac/20 A Emergency Circuit for 24 Vdc

(in Master Section) Battery Charger Power 31

24 Vdc Station Batteries (4) x 1/c #10 AWG (2 x + 24 Vdc & dc Control ≤ 30 Vdc 24 Vdc Supply to Switchgear Controls from

2 x – 24 Vdc) (Next to Switchgear) 24 Vdc Battery System

24 Vdc Station Battery Charger Malfunction (2) x 1/c #14 AWG dc Control ≤ 30 Vdc Alarms 32

Generator Battery Charger Malfunction (2) x 1/c #14 AWG dc Control ≤ 30 Vdc Alarms

Fuel Systems

Low Fuel Tank Level (Master Fuel Tank) (2) x 1/c #14 AWG dc Control ≤ 30 Vdc Alarms

33

Fuel Tank Rupture Basin (Master Fuel Tank) (2) x 1/c #14 AWG dc Control ≤ 30 Vdc Alarms

High Fuel Tank Level (Master Fuel Tank) (2) x 1/c #14 AWG dc Control ≤ 30 Vdc Alarms

Other Fuel Tank Alarms (Master Fuel Tank) (2) x 1/c #14 AWG (Each) dc Control ≤ 30 Vdc Alarms 34

Low Fuel Tank Level (Day Tank) (2) x 1/c #14 AWG dc Control ≤ 30 Vdc Alarms

Fuel Tank Rupture Basin (Day Tank) (2) x 1/c #14 AWG dc Control ≤ 30 Vdc Alarms

High Fuel Tank Level (Day Tank) (2) x 1/c #14 AWG dc Control ≤ 30 Vdc Alarms 35

Other Fuel Tank Alarms (Day Tank) (2) x 1/c #14 AWG (Each) dc Control ≤ 30 Vdc Alarms

Generator Protection Systems

Genset Mounted CB Status

Generator Differential CTs

(2) x 1/c #14 AWG

(6) x 1/c #10 AWG (at Gen.)

dc Control ≤ 30 Vdc

ac Control

Alarms

87G Relay Alarm/Shutdown

36

Generator RTD Leads (1) x #14 AWG Shielded Twisted Quad dc Control ≤ 30 Vdc Indication/Alarms/Shutdown

per Reading (at Gen.)

37

Engine Thermo-Couples (2) x 1/c #14 AWG Thermo-Couple Wire dc Control ≤ 30 Vdc Indication/Alarms/Shutdown

per Reading (at Gen.)

Automatic Transfer Switch Interface (Per ATS) 38

Caterpillar ATS Monitoring and Control (1) x #16 AWG Shielded Twisted Pair Signal Level Monitoring and Control of ATS Functions

(Belden 8471)

Engine Start (2) x 1/c #14 AWG dc Control ≤ 30 Vdc Engine Start Request 39

Discrete ATS Position (4) x 1/c #14 AWG dc Control ≤ 30 Vdc Normal and Emergency ATS Status

ATS Load Shed (2) x 1/c #14 AWG dc Control ≤ 30 Vdc Load Shed / Load Add

Miscellaneous (Optional) 40

Miscellaneous Enclosure Alarms (2) x 1/c #14 AWG per Required Alarm dc Control ≤ 30 Vdc Alarms/Shutdown

Miscellaneous Aux. Equipment Alarms (2) x 1/c #14 AWG per Required Alarm dc Control ≤ 30 Vdc Alarms/Shutdowns

Switchgear 120 Vac Space Heaters (3) x 1/c #10 AWG per 10 Structures ac Control 120 Vac for Space Heaters (1-Phase/30 Ampere)

Remote Monitoring/Control PC (1) x 4 Pair #24 AWG UTP Cat. 5 Signal Level Communication Signal to Remote

41

(Ethernet) -— or — (1) 4 Conductor Monitoring/Control PC Workstation or LAN

Fiber Optic Cable (Belden I100466 —

Varies Based on Installation 42

Requirements)

Building Management / SCADA Interface (1) x #18 AWG Shielded Twisted Pair Signal Level Communication Signal to Building

(Belden 3073) Management or SCADA System 43

1 All control wiring to be stranded copper unless specified otherwise. Conductor size may have to be increased for Voltage Drop over long distances.

2 Recommend 20% spares of each size single conductor and (1) of each multi-conductor cable.

3 Separate metallic conduits should be used for each Signal Type. 'Signal Level' and 'dc Control Signal ≤ 30 Vdc' wires may be combined in the same conduit.

Note: Specific project and equipment requirements will determine exact number and type of control wiring required.

CA08104001E For more information visit: www.EatonElectrical.com

42.2-10 Cat Generator Paralleling Switchgear

XLM Switchgear Home TOC Index June 2006

Sheet 1834

Functional Sequence of Operations Master TOC

22 XLM Functional Sequence of Operations 6. The system is now running in Emergency Mode.

b. Exit from Emergency Mode

A. The EPS Automation shall be provided with the

1. The operator removes the System Mode Selector

following Modes of Operation:

23 1. Automatic/Standby Mode

Switch from Transfer to Emergency position and

returns it to the Auto position.

a. The utility main breaker is closed serving utility 2. Following an adjustable time delay (which can be

24 power to the generator/load bus. abbreviated by the operator), the generator plant

b. The generator main breakers are open. is passively synchronized and paralleled to the

c. The automation is standing by to act in response to a utility source by closing the utility main breaker.

25 utility failure. 3. The generator plant is soft ramp unloaded until

2. Emergency Mode the utility source is nominally serving the entire

system load.

26 a. Utility Failure

4. The generator breakers are opened .

1. Utility protective relaying senses utility voltage

or frequency out of tolerance. OR

27

2. The utility main breaker is opened. 4. [With Generator Bus Tie Breaker] The generator

3. A run request is sent to the generator plant. bus tie breaker is opened and then all of generator

28 4. The first generator up to voltage and frequency

breakers are opened.

is closed to the bus. 5. The generators are allowed to run for their

programmed cooldown period.

29 5. [With Generator Bus Tie Breaker]

6. The system is now back in Automatic/Standby Mode.

The generator bus tie breaker is closed.

6. The remaining generators are synchronized and 4. Load Management Mode

30 paralleled to the bus as they come up to voltage a. Entry

and frequency. 1. Select one of the modes of operation:

7. The system is now in Emergency Mode.

31 i. Import Limit — The user places the Import/

b. Utility Restoration and Exit from Emergency Mode Export toggle switch in the Import position

1. Utility protective relaying senses utility voltage and places the Base Load/Utility Tracking

32 and frequency within tolerance. toggle switch in the Utility Tracking position.

The user sets the Utility Import Set point to

2. Following an adjustable time delay (which can be the desired amount of kW that they want

abbreviated by the operator) to ensure that the

33 utility power source is stable, the generator plant

to import through the Utility Circuit Breaker

during Load Management Mode.

is passively synchronized and paralleled to the

utility source by closing the utility main breaker. ii. Export Limit — The user places the Import/Export

34 toggle switch in the Export position and places

3. The generator plant is soft ramp unloaded until the Base Load/Utility Tracking toggle switch in the

the utility source is nominally serving the entire Utility Tracking position. The user sets the Utility

35 system load. Export Set point to the desired amount of kW

4. The generator breakers are opened. that they want to export through the Utility

5. The generators are allowed to run for their Circuit Breaker during Load Management Mode.

36 programmed cooldown period. iii. Base Load Import — The user places the

6. The system is now back in Automatic/Standby Mode. Import/Export toggle switch in the Import

position and places the Base Load/Utility

37 3. Transfer to Emergency Mode Tracking toggle switch in the Base Load posi-

a. Entry tion. The user sets the Base Load Set point to

the desired amount of kW that they want the

38 1. The operator places the System Mode Selector Switch

generator plant to assume during Load Man-

into the Closed Transfer to Emergency position.

agement Mode. The controls shall not allow

2. A run request is sent to the generator plant. the generator plant to export kW through

39 3. The first generator up to voltage and frequency the Utility Circuit Breaker and shall always

is closed to the bus at no load. maintain a nominal amount of Utility kW

40 4. The remaining generators are synchronized and imported through the Utility Circuit Breaker.

paralleled to the bus at no load as they come up iv. Base Load Export — The user places the

to voltage and frequency. Import/Export toggle switch in the Export

41 5. When all generators are on the bus they are soft position and places the Base Load/Utility

ramp loaded until the generator plant is serving Tracking toggle switch in the Base Load

nominally the entire load on the bus and the position. The user sets the Base Load Set

42 utility main breaker is opened. point to the desired amount of kW that they

want the generator plant to assume during

OR Load Management Mode. The controls shall

43 5. [With Generator Bus Tie Breaker] When all generators allow the generator plant to export kW

are on the bus, they are paralleled across the genera- through the Utility Circuit Breaker.

tor bus tie breaker. They are then soft ramp loaded

until the generator plant is serving nominally all of

the load on the bus and the utility main is opened.

For more information visit: www.EatonElectrical.com CA08104001E

Cat Generator Paralleling Switchgear 42.2-11

June 2006 Home TOC Index

XLM Switchgear

Sheet 1835

Master TOC Functional Sequence of Operations

2. The user places the System Mode Selector 6. Utility Fail Test Mode

Switch in the Load Management position. 22

a. Entrance into Utility Fail Test Mode

3. A run request is sent to the generator plant. 1. The Utility Fail Test Switch is placed in the

4. The generators are allowed to run for a five- ON position. 23

minute warm-up time (which can be abbreviated 2. Voltage sensing at the utility protective relay is

by the operator). opened, which simulates a loss of utility. 24

5. The generators are synchronized and paralleled 3. The system enters into Emergency Mode

to the bus at no load after completion of the as described in the “Emergency Mode”

warm-up time. sequence above. 25

6. When all generators are on the bus they are soft b. Exit from Utility Fail Test Mode

ramp loaded until the generator plant is serving

1. The Utility Fail Test Switch is placed in the 26

nominally the required amount of the load on the

bus to meet the mode of operation selected. OFF position.

7. The generator output is dynamically adjusted to 2. Voltage sensing at the utility protective relay 27

maintain the set point to meet the mode of opera- is restored, which simulates the return of

tion selected. If at any time the system is unable utility power.

to maintain the set point then a “Set point 3. The system exits from Emergency Mode

28

Exceeded” alarm shall be sounded. as described in the “Emergency Mode”

8. Should the utility fail at any time during Load sequence above. 29

Management operation, the utility protective B. When the Generator Sets are carrying the facility load,

relays shall cause the utility main to open and be the EPS Automation shall support two (2) sub-modes:

locked out, thus placing the system in Emergency Load Shed/Load Add, and Generator Demand Priority. 30

Mode until the Utility is restored (as described in

Emergency Mode exit). 1. Load Shed Control

a. The System Controls shall include a Load Shed

31

b. Exit

1. The operator removes the System Mode Selector Control function to control the loads served by the

Switch from Load Management position and generator plant. 32

returns it to the Auto position. b. The Load Shed Control shall have one Essential Load

Shed Priority Level for each generator in the system

2. The generator plant is soft ramp unloaded until plus one Non-Essential Load Shed Priority Level 33

the utility source is nominally serving the entire (which is always shed in the Emergency Mode

system load and the generator main breakers of operation).

are opened.

c. The Load Shed Control shall control each of the 34

3. The generators are allowed to run for their distribution circuit breakers that are shown on the

programmed cooldown period. drawings. Distribution circuit breakers to be con-

trolled shall be electrically operated. Each electrically 35

4. The system is now back in Automatic/Standby Mode. operated distribution circuit breaker shall be field

selectable to be assigned to any of the available

5. No Load Test Mode

Load Shed Priority Levels. 36

a. Entrance into No Load Test Mode 1. Provide the following controls for each

1. The No Load Test Switch is placed in the Essential Load Shed Priority Level 37

ON position.

i. Shed Delay Timer, adjustable from

2. All available generators are started. 0 to 1024 seconds

38

3. All generators come up to voltage and frequency ii. Add Delay Timer, adjustable from

and remain running disconnected from the bus. 0 to 1024 seconds

4. The system is now in No Load Test Mode. iii. Load Shed Override Selector (shed/auto//add)

39

b. Exit from No Load Test Mode iv. Status indicators to show whether the

1. The No Load Test Switch is placed in the Priority Level is Added or Shed 40

OFF position. 2. Provide the following controls for each

2. The generators are allowed to run for their Non-Essential Load Shed Priority 41

programmed cooldown period. i. Load Shed Override Selector (shed/auto//add)

3. The system is now back in Automatic/Standby Mode. ii. Status indicators to show whether the 42

Priority Level is Added or Shed

43

CA08104001E For more information visit: www.EatonElectrical.com

42.2-12 Cat Generator Paralleling Switchgear

XLM Switchgear Home TOC Index June 2006

Sheet 1836

Functional Sequence of Operations Master TOC

3. Additionally, the Load Shed Controls shall have: NOTE: The following applies to systems with two or

22 more generators.

i. Load Shed Control Switch (On/Off)

2. Generator Demand Priority Control

ii. User-settable Load Shed % (as a function of

23 on-line generator capacity) a. The System Controls shall include a Generator

Demand Priority Control function to automatically

iii. User-settable Load Shed Time Delay match the on-line generator capacity to the loads to

24 iv. User-settable Load Add % (as a function of

avoid unnecessary operation of all the generators

when the loads are low.

on-line generator capacity)

b. The following controls shall be provided for each