Академический Документы

Профессиональный Документы

Культура Документы

8044 3 Technical Specification of HT AB Cable 11KV

Загружено:

dkshtdkИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

8044 3 Technical Specification of HT AB Cable 11KV

Загружено:

dkshtdkАвторское право:

Доступные форматы

11KV 3C x95mm2 + 80mm2HT AB CABLE

TECHNICAL SPECIFICATION FOR 11KV, 3C x95mm2 + 80mm2 AERIAL BUNCHED

CABLES FOR OVERHEAD LINES (CROSSED LINKED POLYTHENE DRY GAS CURED)

1. SCOPE

This specification covers requirements of, 3C x95mm2 + 80mm2 XLPE insulated 11 KV Aerial

Bunched Cables for overhead lines.

2. COMPOSITION OF THE CABLE

The composite cable shall comprise three single-core cables twisted around a bare aluminium

alloy messenger wire, which will carry the weight of the cable.

3. RATED VOLTAGE

The rated voltage of the cables shall be 6.35KV/11KV and the maximum operating voltage shall

be 12 KV.

4. APPLICABLE STANDARDS

Unless otherwise stipulated in this Specification, the following Standards shall be applicable:

i) IS: 7098 (Part-II) - 1985 – Cross linked Polyethylene Insulated PVC Sheathed Cables

ii) IS: 8130-1984 - Conductors for Insulated Cables

iii) IS: 398 (Part-IV) - 1979 - Aluminium Alloy Conductors

iv) IEC- 60502 (Part-II) 2005 - Polyethylene Outer Sheath

5. DETAILS OF SINGLE-CORE CABLE

5.1 The cable conductors shall be of round, stranded and compacted aluminium of nominal cross

sectional area 35mm² / 70 mm2 / 95 mm2 /120 mm2. Corresponding nominal conductor

diameter and number of wires in the conductor shall be as given in clause 5.7.

5.2 Conductor Screen

The conductor screen shall be of extruded semi-conducting cross

inked polyethylene compound of thickness not less than 0.5mm.

5.3 Insulation

The insulation shall be of extruded cross linked polyethylene (XLPE), Dry Gas cured, of

nominal insulation thickness 3.6mm and its properties shall conform to IS: 7098 (Part-II).

5.4 Insulation Screen

The insulation screen shall comprise extruded semi-conducting compound and/or semi-

conducting tape. Thickness of the screen shall be not less than 0.6 mm.

5.5 Metallic Screen

The metallic screen shall consist of Copper tape of thickness not less than 0.045mm.

5.6 Outer Sheath

The outer sheath shall be black polyethylene. The nominal thickness of sheath shall be 2 mm

and it shall conform to the technical requirements of ST-7 of IEC-60502 (Part-II) 2005

5.7 Dimensional and Electrical Data

The dimensional and electrical data for single-core cable is given below:

Signature of Tenderer Company’s Round Seal Date: Place:

DGVCL/SP/8044/11KV HT AB Cable/Tech . Spec Page 1 of 9]

11KV 3C x95mm2 + 80mm2HT AB CABLE

Nominal Area of Conductors

Sr.

Description

No. 35mm2 70mm2 95mm2 120mm2

Nominal conductor diameter (mm) / No. of

i) 6.8/6 10/12 11.5/15 13.1/15

wires in conductor

ii) Approx. over dia. of cable (mm) 22 25 26 28

iii) Max. D.C resistance at 20oC Ohm/Km 0.868 0.443 0.320 0.253

iv) Max. SC current for 1 sec. kA 3.3 6.6 8.96 11.32

v) Max. Continuous load (Amps.) 120 180 230 260

6. MESSENGER (NEUTRAL CONDUCTOR)

6.1 The bare messenger wire shall be of 70mm2 / 80mm2 / 100 mm2 (nominal area)

aluminium alloy, generally conforming to IS:398 (Part-IV) - 1994, comprising of 7 strands

and shall be suitably compacted/non compacted to have smooth round surface to avoid

damage to the outer insulating sheath of single-core phase cables twisted around the

messenger.

6.2 There shall be no joints in any wire of the stranded messenger conductor except those

made in the base rod or wires before finally drawing.

6.3 The technical characteristics of the messenger wire shall be as follows:

Sr.

Item Nominal Area of Messenger

No.

i) Nominal sectional area (mm2) 70 80 100

ii) No. of wires 7 7 7

Nominal dia. of wires/compacted conductor

iii) 3.5/10.5 3.81/11.43 4.26/12.78

(Approx.) mm

iv) Approx. mass Kg/Km 184 218.26 272.86

o

v) DC resistance at 20 C Ohm/Km 0.493 0.425 0.339

vi) Breaking load (KN) 20 23.41 29.26

Note: The value in item (v) above is to be guaranteed. A tolerance of (-) 5% is permissible on the

value in item (vi) above.

7. DESIGNATION AND PARAMETERS OF FINISHED CABLES

The designation and parameters of finished cables are given in the following table:

Complete Bunched Cable

Sr. Designation Overall dia (approx.) Total mass (approx.)

No. mm Kg/Km

i) 3 x 35 mm2 + 70 mm2 53 1450

ii) 3 x 70 mm2 + 70 mm2 59 1900

iii) 3 x 95 mm2 + 80 mm2 62.5 2250

iv) 3 x 120 mm2 + 100 mm2 67 2650

Note: The first part of the designation refers to the number and size of phase conductor and the

second to the size of messenger wire. The sizes shown represent the nominal cross

sectional areas in mm.

Signature of Tenderer Company’s Round Seal Date: Place:

DGVCL/SP/8044/11KV HT AB Cable/Tech . Spec Page 2 of 9]

11KV 3C x95mm2 + 80mm2HT AB CABLE

8. TESTS

All the cable sizes i.e. items offered should have been fully type tested as per the relevant

standards at any NABL accredited/Govt. of India’s recognized Laboratory. The bidder shall

furnish the type test reports along with the offer. These type tests must have been conducted

within last five years prior to date of Bid opening.

For any change in design/type, already type tested and the design / type offered against this

specification, the purchaser reserves the right to demand repetition of type tests without any

extra cost. The purchaser also reserves the right to have tests carried out at his own cost by an

independent agency, whenever there is a dispute regarding the quality of supply.

8.1 The following Type tests shall be carried out on the cables as per IS: 7098 (Part-II) & Type

tests certificates shall be furnished invariably with the offer.

8.1.1 Type Tests

a) Tests on conductor:

i) Tensile test

ii) Wrapping test

iii) Resistance test

b) Tests for thickness of insulation and sheath

c) Physical tests for insulation:

i) Tensile strength and elongation at break

ii) Ageing in air oven

iii) Hot test

iv) Shrinkage test

v) Water absorption

d) Tests for outer sheath: As per IEC-60502 (Part-II) 2005

i) Tensile strength and elongation at break

ii) Ageing in air oven

iii) Shrinkage test

iv) Hot deformation

v) Carbon black content

vi) UV Stability as per ASTM G53 / DIN : 53387

e) Partial discharge test

f) Bending test

g) Dielectric power factor test:

i) As a function of voltage

ii) As a function of temperature

h) Insulation resistance test

i) Heating cycle test

j) Impulse withstand test

k) High voltage test

8.1.2 Acceptance Test

a) Tensile test

b) Wrapping test

c) Conductor resistance test

d) Test for thickness of insulation and sheath

e) Hot set test for insulation

Signature of Tenderer Company’s Round Seal Date: Place:

DGVCL/SP/8044/11KV HT AB Cable/Tech . Spec Page 3 of 9]

11KV 3C x95mm2 + 80mm2HT AB CABLE

f) Tensile strength and elongation at break test for insulation and sheath

g) Partial discharge test

h) High Voltage tes

i) Insulation resistance (volume resistivity) test

8.1.3 Routine Tests

a) Conductor resistance test

b) Partial Discharge test

c) High voltage test

8.2 The following tests shall be carried out on the bare messenger wire in

accordance with IS: 398 (Part-IV).

Type Tests/Acceptance Tests

a) Breaking Load Test (on finished wire)

b) Elongation Test

c) Resistance Test

9. PACKING AND MARKING:

9.1 Packing

Cables shall be supplied in wooden drums conforming to IS: 10418 and packed in drums

suitable for vertical / horizontal transport, as the case may be and shall be suitable to

withstand rough handling during transport and outer storage. The outer surface of the drum

shall be painted with white aluminum pint. Similarly, the inside surface of drum shall have

the protective layer of varnish / paint to protect it from white ants.

The standard length of the bunched cable in each drum shall be 500 Mtrs (±) 5 %.

The wooden drums shall be reinforced with steel bends and strips for better protection.

The ends of the cable shall be sealed by means of non-hygroscopic sealing materials.

9.2 Marking:

The cable drum shall carry the information as per the requirements of IS: 7098 (Part-II).

The following information may be stenciled on the drum with either water proof ink or oil

paint:

i. Reference of IS / IEC standard.

ii. Manufacturer’s name or trademark.

iii. Type of cable and voltage grade.

iv. No. of cores.

v. Nominal cross-sectional area of conductor.

vi. Cable code.

vii. Length of cable on the drum

viii. No. of lengths on the drum (if more than one)

ix. Direction of rotation of drum (by means of an arrow)

x. Position of outer end of cable

Signature of Tenderer Company’s Round Seal Date: Place:

DGVCL/SP/8044/11KV HT AB Cable/Tech . Spec Page 4 of 9]

11KV 3C x95mm2 + 80mm2HT AB CABLE

xi. Gross weight

xii. Country of manufacture

xiii. Year of manufacture

xiv. Reference of A/T No. & date

xv. Property of UGVCL

xvi. Name of consignee and the destination.

Over and above, name plate of aluminum of suitable size and thickness, containing all the

above information, shall be fixed on the drum in addition to the painting.

9.3 Suitable identification marks shall be given on the outer sheath to clearly distinguish three

phases of the bunched cable.

9.4 Following details of Identification shall be embossed at interval of length of one meter of

cable outer sheath.

(a) Name of Manufacturer (b) Year of Manufacturer (c) Voltage grade (d) Name of Purchaser

“UGVCL”.

10. INSPECTION:

a. STAGE INSPECTION:

The inspection may be carried out by the purchaser at any stage of manufacture. The

successful bidder shall grant free access to the purchaser’s representative at reasonable time,

when the work is in progress. Inspection and acceptance, of any cables under this

specification by the purchaser, shall not relieve the supplier of his obligation of supplying

cable in accordance with the specification and shall not prevent subsequent rejection, if the

cables are found defective.

The supplier shall keep the purchaser informed in advance about the programme of

manufacturing of cables so that arrangement can be made for inspection.

The purchaser reserves the right to insist for witnessing the acceptance / routing tests of the

bought out items.

b. LOT INSPECTION:

All the acceptance tests and inspection shall be made at the place of manufacture

unless otherwise especially agreed upon by the manufacturer and purchaser at the time of

purchase. The manufacturers shall afford the inspector representing the purchaser all

reasonable facilities without charge, to satisfy him that material is being furnished in

accordance with the Specification.

The purchaser has the right to have tests carried out at his own cost by an independent

agency whenever there is a dispute regarding the quality of supply.

11.0 DOCUMENTATION:

The bidder shall furnish following documents along with his offer.

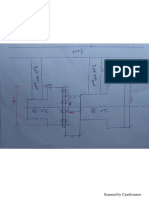

11.1 Sectional view, showing the General constructional feature with conductor / conductor

screen / insulation / insulation screen and outer sheath etc.

11.2 Drawing of cable drums with details of material dimension shall be submitted.

Signature of Tenderer Company’s Round Seal Date: Place:

DGVCL/SP/8044/11KV HT AB Cable/Tech . Spec Page 5 of 9]

11KV 3C x95mm2 + 80mm2HT AB CABLE

11.3 All the required type test reports for offered items tested at any NABL accredited/Govt. of

India’s recognized Laboratory as stated under Clause No. 8.1.

11.4 Literature, pamphlets for the record items.

11.5 List of orders (size wise) executed during last five years for supply of specified sizes of HT

Aerial Bunch/XLPE cables, supplied to State Electricity Boards, Private firms & MGVCL

/DGVCL /UGVCL /PGVCL/ GETCO/GUVNL(formerly GEB) etc. along with quantity, value of

the orders, year of supply and delivery schedule. List of orders executed and under

execution shall be submitted separately. The annual turn over in rupees, of the firms to

whom the cables have been supplied during last two years shall be stated.

12.0 The firm shall be responsible for any damage to the cables during transit due to improper

and inadequate packing. Wherever necessary, proper arrangement for lifting, such as

lifting hooks, shall be provided. Any cable found short inside the packing cases shall be

supplied by the supplier, without any extra cost.

13.0 Each consignment shall be accompanied by a detailed packing list, containing the

following information:

(a) Name of consignee

(b) Details of consignment

(c) Destination

(d) Total weight of consignment

(e) Handling and unpacking instruction

(f) Bill of materials, indicating contents of each package.

14.0 TECHNICAL AND GUARANTEED PARTICULARS:

The bidder shall furnish all Guaranteed Technical Particulars, as called for, in Appendix - I

of this Specification. Particulars, which are subject to guarantee, shall be clearly

identified. Offer not containing this information will not be considered for acceptance.

15.0 PERFORMANCE CERTIFICATE:

Bidders shall also submit performance reports for the specified size of cables supplied to

other State Electricity Boards / reputed firms, with the clear indication of the period

since when the cables performed satisfactory service.

16.0 LEGIBLE SUBMISSION:

Only required relevant, legible documents shall be submitted to avoid delay due to back

reference.

Signature of Tenderer Company’s Round Seal Date: Place:

DGVCL/SP/8044/11KV HT AB Cable/Tech . Spec Page 6 of 9]

11KV 3C x95mm2 + 80mm2HT AB CABLE

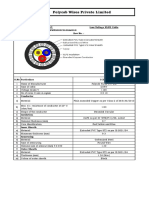

APPENDIX – I

2 2

SCHEDULE OF GUARANTEED TECHNICAL PARTICULARS FOR 11KV, 3C x95mm + 80mm

AERIAL BUNCH CABLE

(To be filled in and signed by the Tenderer)

1.0 GENERAL:

1.1 Brand Name or Trade Mark :

1.2 Name & Address of Manufacturer :

1.3 Rated voltage :

Note: (Fill – up separate column for the following particulars for each type & size

of cable)

2.0 PHASE CONDUCTOR:

2.1 Material :

2.2 Class / Grade :

2.3 Shape of conductor :

2.4 Nominal cross section area (mm Sq.) :

2.5 Approximate dia. of conductor (mm) :

Maximum DC resistance at 20o C OHM /

2.6 :

KM

3.0 CONDUCTOR SCREENING:

3.1 Material :

3.2 Minimum thickness (mm) :

4.0 INSULATION:

4.1 Material :

4.2 Nominal thickness (mm) :

4.3 Tolerance on thickness :

5.0 INSULATION SCREENING:

Signature of Tenderer Company’s Round Seal Date: Place:

DGVCL/SP/8044/11KV HT AB Cable/Tech . Spec Page 7 of 9]

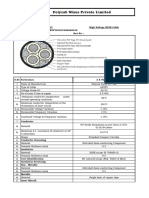

11KV 3C x95mm2 + 80mm2HT AB CABLE

Material

5.1 1) Non Metallic :

2) Metallic

Thickness (mm)

5.2 1) Non Metallic :

:

2) Metallic

6.0 POLYETHYLENE SHEATH OVER CORE:

6.1 Material :

6.2 Nominal thickness (mm) :

7.0 MESSENGER WIRE :

7.1 Material & its applicable standard :

7.2 Shape of conductor :

7.3 Nominal cross section area (mm Sq.) :

7.4 No of strands in conductor :

7.5 Diameter of each strands (mm) :

7.6 Approximate cond. Diameter (mm) :

7.7 DC resistance at 20o C (Ohm/Km)

7.8 Approximate breaking load ( KN) :

8.0 CABLES: :

8.1 Continuous current carrying capacity in air

:

at Ambient Temp.40º C (Amp)

8.2 Maximum short circuit current for 1 Sec.

(KA)

8.3 Identification of Power Core. :

8.4 Laying up of Power Core :

and with AAAC Messenger wire

8.5 Approximate overall diameter of cable :

8.6 Approximate total weight of cable :

KG / KM.

Signature of Tenderer Company’s Round Seal Date: Place:

DGVCL/SP/8044/11KV HT AB Cable/Tech . Spec Page 8 of 9]

11KV 3C x95mm2 + 80mm2HT AB CABLE

8.7 Standard length of cable in each :

drum in meter

Tolerance on drum length.

8.8 Max. conductor Temp. during Short circuit.

8.9 Bending radius of the cable. :

8.10 Manufacturer identification mark. :

9.0 Whether details shall be embossed as :

stated under Cl. 9.3 & 9.4 of Technical

Specification (Yes/No)

10.0 Whether type test reports submitted, as :

stated under Cl. 8.1 of Technical

Specification (Yes/ No)

11.0 :

Whether drawings submitted. (Yes/ No)

12.0 Whether un priced schedule of offered :

items submitted with Technical offer.

(Yes/ No)

_______________ ________________________

SEAL OF FIRM SIGNATURE OF TENDERER DATE:

NOTE: Please sign & seal on each page above.

Signature of Tenderer Company’s Round Seal Date: Place:

DGVCL/SP/8044/11KV HT AB Cable/Tech . Spec Page 9 of 9]

Вам также может понравиться

- Self Assessment ASPДокумент104 страницыSelf Assessment ASPTarek San100% (1)

- Qualitative Analysis of CationsДокумент12 страницQualitative Analysis of CationsRegina Morales0% (1)

- HT Cable RFQ Specifications PDFДокумент7 страницHT Cable RFQ Specifications PDFAshil ThomasОценок пока нет

- Technical Specification For 33 KV Aerial Bunched Cable - 2Документ7 страницTechnical Specification For 33 KV Aerial Bunched Cable - 2BijuОценок пока нет

- Isolation and Purification of AlkaloidsДокумент14 страницIsolation and Purification of AlkaloidsLuděk SpurnýОценок пока нет

- 11kv CablesДокумент46 страниц11kv CablesS.k. RathОценок пока нет

- GN01 - ILP Guidance Note 1 The Reduction of Obtrusive Light - 2021 V2-60iqakДокумент25 страницGN01 - ILP Guidance Note 1 The Reduction of Obtrusive Light - 2021 V2-60iqakdkshtdkОценок пока нет

- Pid819510 PDFДокумент5 страницPid819510 PDFdkshtdkОценок пока нет

- Puvvnl GTPДокумент3 страницыPuvvnl GTPshivam dwivediОценок пока нет

- Tech - Spec.-Aerial Bunched Cable-XLPE Insulated H.T. Cable.Документ6 страницTech - Spec.-Aerial Bunched Cable-XLPE Insulated H.T. Cable.Bilal AhmadОценок пока нет

- Technical Specifications For 33 KV Xlpe Insulated Underground Cables 1. ScopeДокумент22 страницыTechnical Specifications For 33 KV Xlpe Insulated Underground Cables 1. Scopethumula.rameshОценок пока нет

- Domestic Exterior Lighting: Getting It Right!: Guidance Note 9/19Документ6 страницDomestic Exterior Lighting: Getting It Right!: Guidance Note 9/19dkshtdkОценок пока нет

- 18.1-1996 Aerial Bundled ConductorsДокумент11 страниц18.1-1996 Aerial Bundled ConductorsnilushkaaОценок пока нет

- LT Aerial Bunch Cable (3C X 95 SQMM)Документ541 страницаLT Aerial Bunch Cable (3C X 95 SQMM)Biju100% (5)

- Technical Specification: 2Cx16+25 SQ - MM LT Xlpe Ab CableДокумент9 страницTechnical Specification: 2Cx16+25 SQ - MM LT Xlpe Ab CableRamesh Arjun TОценок пока нет

- XLPE Power Cable 11 & 33 KVДокумент9 страницXLPE Power Cable 11 & 33 KVArjun M KumarОценок пока нет

- Specification No.: Ministry of Electricity Planning and Studies Office Baghdad - IraqДокумент9 страницSpecification No.: Ministry of Electricity Planning and Studies Office Baghdad - IraqAhmed JaОценок пока нет

- Polycab 10mm 3 Core Copper Armoured Cable Specification SheetДокумент2 страницыPolycab 10mm 3 Core Copper Armoured Cable Specification SheetbharathОценок пока нет

- Reservoir Management Session 3 W Solutions PDFДокумент39 страницReservoir Management Session 3 W Solutions PDFEmad ZakiОценок пока нет

- OPGW Specifications: GeneralДокумент18 страницOPGW Specifications: GeneralMubashir HussainОценок пока нет

- Polycab 16mm 3 Core Copper Armoured Cable Specification SheetДокумент2 страницыPolycab 16mm 3 Core Copper Armoured Cable Specification SheetbharathОценок пока нет

- 7UT51x Manual UsДокумент232 страницы7UT51x Manual UsMtdb Psd100% (1)

- N2 XSEKFGb YДокумент5 страницN2 XSEKFGb YRinda_RaynaОценок пока нет

- Na2Xsekfgby 3 X (25-300) MM 3.6/6 KVДокумент5 страницNa2Xsekfgby 3 X (25-300) MM 3.6/6 KVRinda_RaynaОценок пока нет

- Ddugjy TS of HT AB CableДокумент7 страницDdugjy TS of HT AB CableJaks JaksОценок пока нет

- Technical Specification For 3C XPLE CableДокумент9 страницTechnical Specification For 3C XPLE Cableramana3339Оценок пока нет

- 3C-ABC-Technical Spec 948Документ9 страниц3C-ABC-Technical Spec 948Kanwalnain madaanОценок пока нет

- Technical Specification For KV Grade 1C X 630 Sqmmxlpe Insulatedpvc Sheathed Armoured Aluminum CableДокумент5 страницTechnical Specification For KV Grade 1C X 630 Sqmmxlpe Insulatedpvc Sheathed Armoured Aluminum Cableyash prajapatiОценок пока нет

- 10X4 A2xfy Alum - ArmdДокумент2 страницы10X4 A2xfy Alum - ArmdParth DhobiОценок пока нет

- CSC-XII 1 C Is 7098 Part 2Документ8 страницCSC-XII 1 C Is 7098 Part 2Ashish bhattОценок пока нет

- 10X4 A2xfy (FRLS) Alum ArmdДокумент2 страницы10X4 A2xfy (FRLS) Alum ArmdParth DhobiОценок пока нет

- 400PX3CHT33UEFLATДокумент2 страницы400PX3CHT33UEFLATjayesh95395Оценок пока нет

- 3-Low Voltage Aerial Bundle Cables (6001000V)Документ11 страниц3-Low Voltage Aerial Bundle Cables (6001000V)apranaguptaОценок пока нет

- HT Ab CableДокумент3 страницыHT Ab CableShailesh SinghОценок пока нет

- 1C 500 MM (A2xHSYRa2Y) 18 30 (36) KV CABLESДокумент3 страницы1C 500 MM (A2xHSYRa2Y) 18 30 (36) KV CABLESanamulk-1Оценок пока нет

- 1C 240 MM (NYYF-FRLS YYF-FRLS) 0.6 1.0 (1.2) KV CABLESДокумент2 страницы1C 240 MM (NYYF-FRLS YYF-FRLS) 0.6 1.0 (1.2) KV CABLESanamulk-1Оценок пока нет

- Cable GTPДокумент1 страницаCable GTPtukaram.pawarОценок пока нет

- 3 - AAAC-Tech. SpecДокумент7 страниц3 - AAAC-Tech. SpecSumit TyagiОценок пока нет

- F. Tech. Specifications - 166-216Документ51 страницаF. Tech. Specifications - 166-216mhafeez835156Оценок пока нет

- ANNEX E - Amended - Technical Specs of L.T TWISTED INSULATED CABLEДокумент7 страницANNEX E - Amended - Technical Specs of L.T TWISTED INSULATED CABLEsajjad_pirzadaОценок пока нет

- LT Xlpe Cable: Design Code: Lvis09Cxswyl002C1.5Sa004S Document ID:TE/QMS/F/02Документ2 страницыLT Xlpe Cable: Design Code: Lvis09Cxswyl002C1.5Sa004S Document ID:TE/QMS/F/02y8jkfz98m9Оценок пока нет

- Tech Specs 1Документ22 страницыTech Specs 1headqcОценок пока нет

- Electro Cable Egypt Co.: 3x3 MM CU/PVC/PVC 300 / 500 VДокумент1 страницаElectro Cable Egypt Co.: 3x3 MM CU/PVC/PVC 300 / 500 VKareem Abo SeifОценок пока нет

- Datasheet For Cable: 1 Pair Overall Shielded Armoured Cable, Type F (Single Pair Cable Shall Have Only Overall Shielding)Документ4 страницыDatasheet For Cable: 1 Pair Overall Shielded Armoured Cable, Type F (Single Pair Cable Shall Have Only Overall Shielding)AnamulKabirОценок пока нет

- Cables Specifications VFДокумент13 страницCables Specifications VFraiutkarshОценок пока нет

- Lvis09axsfy23 5c300sa002sДокумент1 страницаLvis09axsfy23 5c300sa002sVishal SharmaОценок пока нет

- TECHNICAL SPECIFICATION - INSTRUMENT & CONTROL CABLE-Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022Документ9 страницTECHNICAL SPECIFICATION - INSTRUMENT & CONTROL CABLE-Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022nnОценок пока нет

- L T A B Cable Spec 08.08.2019Документ17 страницL T A B Cable Spec 08.08.2019Ashish bhattОценок пока нет

- Technical Data Sheets & Cross Sectional Details of 33kV XLPE CablesДокумент4 страницыTechnical Data Sheets & Cross Sectional Details of 33kV XLPE CablesRamaKrishna AОценок пока нет

- LVIS09CXSFYL004C010SA001SДокумент1 страницаLVIS09CXSFYL004C010SA001Ssuvir VigneshОценок пока нет

- Technical Details of 24 Fibre (g652d)Документ2 страницыTechnical Details of 24 Fibre (g652d)ahmedshah512Оценок пока нет

- 8019 - (3) - 1C LT ABC - Tech. SpecДокумент9 страниц8019 - (3) - 1C LT ABC - Tech. Specdeepthik27Оценок пока нет

- Polycab 300mm 3 Core Aluminium Armoured Cable Specification SheetДокумент2 страницыPolycab 300mm 3 Core Aluminium Armoured Cable Specification SheetZIRWA ENTERPRISESОценок пока нет

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C070SA002S Date: Rev No.Документ2 страницыManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C070SA002S Date: Rev No.JayagurunathanОценок пока нет

- 1 Triad AbcДокумент4 страницы1 Triad AbcAnamulKabirОценок пока нет

- B-09 HT Power CablesДокумент8 страницB-09 HT Power Cablesrahul patraОценок пока нет

- Sr. No. 3A Datasheet 4PX3CYWY 100Документ2 страницыSr. No. 3A Datasheet 4PX3CYWY 100hemantmech099200Оценок пока нет

- Technical Specification - LV Control Cable - WP4Документ10 страницTechnical Specification - LV Control Cable - WP4nnОценок пока нет

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C010SA003S Date: Rev No.Документ2 страницыManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C010SA003S Date: Rev No.rajesh1200100% (1)

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C006SA002S Date: Rev No.Документ2 страницыManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C006SA002S Date: Rev No.maharia_22Оценок пока нет

- 400PX3 5caywyxlpeДокумент2 страницы400PX3 5caywyxlpeAnonymous SDeSP1Оценок пока нет

- Technical Specification - Instrument Cable - WP4Документ7 страницTechnical Specification - Instrument Cable - WP4nnОценок пока нет

- TS-OPGW 1.4 9feb2017Документ18 страницTS-OPGW 1.4 9feb2017asim204Оценок пока нет

- Cable GTPДокумент1 страницаCable GTPAnwar HussainОценок пока нет

- Cable TriadaДокумент4 страницыCable TriadaRaymundo Maldonado AlvarezОценок пока нет

- Irs 30-2005Документ62 страницыIrs 30-2005Pratyaksh AgarwalОценок пока нет

- Use This Sheet To Track Your PPF If You Have Extended It at The End of The 15 Year PeriodДокумент2 страницыUse This Sheet To Track Your PPF If You Have Extended It at The End of The 15 Year PerioddkshtdkОценок пока нет

- PPF Calculator: Output Values Input Parameters CalculationsДокумент4 страницыPPF Calculator: Output Values Input Parameters CalculationsdkshtdkОценок пока нет

- Your Sanctuary of Peace & CalmДокумент14 страницYour Sanctuary of Peace & CalmdkshtdkОценок пока нет

- KS1 & KS2Документ2 страницыKS1 & KS2dkshtdkОценок пока нет

- Shiv Construction: DevelopersДокумент17 страницShiv Construction: DevelopersdkshtdkОценок пока нет

- Work Completion CertДокумент1 страницаWork Completion CertdkshtdkОценок пока нет

- OE Spec MTU16V2000DS1100 3B FC 50Hz 2 14Документ4 страницыOE Spec MTU16V2000DS1100 3B FC 50Hz 2 14dkshtdkОценок пока нет

- Charming Kerala: INR 58,848 For 2 PeopleДокумент18 страницCharming Kerala: INR 58,848 For 2 PeopledkshtdkОценок пока нет

- New Doc 2017-05-19Документ1 страницаNew Doc 2017-05-19dkshtdkОценок пока нет

- Stepper Motors VsServo MotorsДокумент2 страницыStepper Motors VsServo MotorsEhab MohamedОценок пока нет

- As Work Energy and Power QuestionsДокумент35 страницAs Work Energy and Power Questionstougao222Оценок пока нет

- Week11 Turton - Cost of ManufacturingДокумент32 страницыWeek11 Turton - Cost of ManufacturingNrl Nbl Rmln100% (1)

- Questions and Solutions at End of Chapter 2: Measurement and Instrumentation. © 2016 Elsevier Inc. All Rights ReservedДокумент14 страницQuestions and Solutions at End of Chapter 2: Measurement and Instrumentation. © 2016 Elsevier Inc. All Rights ReservedKevin AzizОценок пока нет

- ApatitДокумент9 страницApatittrinh xuan hiepОценок пока нет

- Flexibility FactorsДокумент61 страницаFlexibility FactorsCarlos BorgesОценок пока нет

- Adavances in Positioning and FramesДокумент407 страницAdavances in Positioning and Framesoliwia.tolloczkoОценок пока нет

- INFO-Sheet Fumis ALPHAДокумент2 страницыINFO-Sheet Fumis ALPHAAnthony GilmoreОценок пока нет

- The Multiple Directions of Antiferromagnetic Spintronics Nature Physics PDFДокумент4 страницыThe Multiple Directions of Antiferromagnetic Spintronics Nature Physics PDFLog LouОценок пока нет

- Physics Form 3Документ88 страницPhysics Form 3caphus mazengera100% (1)

- Module1 - MagnetismДокумент35 страницModule1 - MagnetismJoicsha Nicole FerrerОценок пока нет

- Form 4 Chemistry Yearly Plan 2019Документ2 страницыForm 4 Chemistry Yearly Plan 2019Jenny WeeОценок пока нет

- Materials and Approaches For On Body Energy HarvestingДокумент8 страницMaterials and Approaches For On Body Energy HarvestingShotech EngineeringОценок пока нет

- 3 IntroductionДокумент5 страниц3 IntroductionKhamvanh PhengnaoneОценок пока нет

- General Contractor, Supplier, Independent Survey, Ship Service & IndustrialДокумент24 страницыGeneral Contractor, Supplier, Independent Survey, Ship Service & IndustrialNicoОценок пока нет

- Stiffness Analysis of FramesДокумент37 страницStiffness Analysis of FramesCarolina VacaОценок пока нет

- Downhill Simplex AlgorithmДокумент2 страницыDownhill Simplex AlgorithmKtk ZadОценок пока нет

- 4x & 6x Night Vision Weapon Sights Operator ManualДокумент15 страниц4x & 6x Night Vision Weapon Sights Operator Manualakms1982Оценок пока нет

- 2nd PUC Question Papers Physics 2006-2010Документ21 страница2nd PUC Question Papers Physics 2006-2010Mohan Kumar P100% (1)

- 413 Impurities Testing in MedicalДокумент2 страницы413 Impurities Testing in MedicalIsmail MathakiyaОценок пока нет

- Centrifugal Pump Test RigДокумент4 страницыCentrifugal Pump Test RigSameer Tamboli100% (1)

- Modeling and Simulation: Qiu-Zhou Runall - Tex - 12/25/2008 3:19am Page 13Документ51 страницаModeling and Simulation: Qiu-Zhou Runall - Tex - 12/25/2008 3:19am Page 13Samuel ChanОценок пока нет

- Shodex SEC ColumnsДокумент40 страницShodex SEC ColumnsAlfred HuangОценок пока нет