Академический Документы

Профессиональный Документы

Культура Документы

Ijciet 10 01 130 PDF

Загружено:

sОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ijciet 10 01 130 PDF

Загружено:

sАвторское право:

Доступные форматы

International Journal of Civil Engineering and Technology (IJCIET)

Volume 10, Issue 01, January 2019, pp. 1418-1430, Article ID: IJCIET_10_01_130

Available online at http://www.iaeme.com/ijciet/issues.asp?JType=IJCIET&VType=10&IType=01

ISSN Print: 0976-6308 and ISSN Online: 0976-6316

© IAEME Publication Scopus Indexed

PREDICTING THE EFFECT OF ADDING THE

NANOALUMINA ON THE

CHARACTERIZATION OF ASPHALT BASE

COMPOSITE

Khalid Mershed Eweed, Ibrahim Abdulwahhabb Atiyah and Rand Salih Al- Jadiri

Material Engineering Department, Faculty of Engineering, Mustansiriyah University,

Baghdad, Iraq

ABSTRACT

Current paper has studied the causes of pavements flexibility besides various

alternatives to solve the problems failure, for example: fatigue ,rutting, cracking of

low temperature which are because of the sensitivity of the temperature and the

susceptibility of the moisture and of either the mixture of the asphalt or

asphalt/aggregate entirely. This study is designed to identify applicability that is

potential and the best amount of Nanoalumina in asphalt in addition to the mixtures

of the asphalt concrete. Most asphalt consists of nitrogen carbon, oxygen, sulfur, and

hydrogen. At low loading or temperature that is high, asphalt acts as a liquid that is

viscous which due to dichotomy that is classical. The paper aims to modify the quality

of bitumen materials by increasing the durability. Five percentage of nanoalumina

(0.5%, 1%, 1.5%, 2%, and 2.5%) (w/w) was added to pure asphalt. According to

Marshall Test Nanoalumina modified the samples. Experimental tests have shown an

improvement in physical and properties that are mechanical of mixtures of asphalt

after adding Nanoalumina. As a result Nanoalumina has the ability to modify asphalt

by reducing penetration and increasing kinematic viscosity.

Keywords: tensile strength that is indirect, asphalt, nanoalumina -asphalt mixture,

asphalt properties that are mechanical, Stiffness of Marshall.

Cite this Article:. Khalid Mershed Eweed, Ibrahim Abdulwahhabb Atiyah and Rand

Salih Al- Jadiri, Predicting the Effect of Adding the Nanoalumina on the

Characterization of Asphalt Base Composite, International Journal of Civil

Engineering and Technology, 10(01), 2019, pp. 1418-1430.

http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=10&IType=01

http://www.iaeme.com/IJCIET/index.asp 1418 editor@iaeme.com

Predicting the Effect of Adding the Nanoalumina on the Characterization of Asphalt Base

Composite

1. INTRODUCTION

Bitumen has a nature that is thermoplastic nature, resistance to water and adhesion to the

majority of the particular substances, is a main material of engineering. Binders of asphalt has

an extensive use in the paving of the road and their properties that are viscoelastic rely on

their structure that is chemical. Using artificial nanoalumina to adapt the performance of the

asphalt binder and extend itslife of paving. Extremely important properties susceptibility that

is thermal, for example ,maturing at intermediate and average temperatures and being

resistant to rutting in addition to the fatigue were improved. To reduce the distress of asphalt

concrete pavement there are many ways, which may extend the duration of pavement the life

of service to generate binder type that is new with better rheological chemical and physical

properties, enhance the design of pavements and mix, and enhance the methods of

construction and techniques of maintenance [1].The use of nanomaterialsis important to

change bitumen by enhancing their properties with performances that are enhanced.

Nanomaterials which are used to change the rheological and physical properties of bitumen

are Aluminum oxide, calcium oxide, Zycotherm Nanomaterial, Basalt, and Limestone. The

nano technology, with the asphalt use of and properties of the mixture of asphalt, leads to

[2]enhance the stability of storage in the modified asphalt of polymer; rise the resistance to

the aging of UV; decrease the weakness of moisture under snow, deicers, and water; enhance

asphalt mixtures properties at temperature that is low ;improve the asphalt pavements

durability; save cost and energy; finally reduce the requirements of maintenance.

Nanotechnology is defined as the manufacture of new systems, devices, and materials at the

level of molecular related to molecular and atomic relation smanipulating strongly properties

of the material that are macroscopic [3]. Lately, nanotechnology has remarkably been

connected with the field of enhanced asphalt [4]. Recently, nanotechnology became as the

key that is potential to significantly improve the durability and performance of materials of

building. The definition of Nanomaterials is that they are resources with at least single

dimension in scale of the length of 1 - 100 nm. Due to the size that is small and extra or

denary area of surface, the nanomaterials property actually differs from materials that are

micro size [3]. To determine lot of the potential applications, experts have exerted effective

and optimistic efforts act by preparing enhanced asphalt to show the modification mechanism

and the resulting enhancement in the performance [4]. Several researchers demonstrated that

cracking of fatigue, moisture and rutting resistance of binders and blends of asphalt are

enhanced with the addition of nanomaterials [5]. Ghafar poor [6] performed rheological

proportional experiments on mechanical tests and bitumen on asphalt blends inclosing nano-

clay modified and unmodified bitumen. The results have revealed that nano-clay may

enhancethe properties of bitumen like aging resistance and stiffness as well as decreasing the

angle of phase in relation to properties asphalt blend and unmodified asphalt such astensile

strength that is indirect, resilient modulus, and stability.

Nanomaterials have different features that are morphological on the nanoscale, and

particularly have properties that are special springing from their dimensions of nanoscale [7].

Because the preparation of nano composite polyamide 6/clay with the desirable performance

was done by research center of Toyota, the grade nano composites of polymer have included

enormousattention in both industry and academia because of their exclusive magnetic,

electrical, barrier, mechanical, optical, and thermal properties [8, 9]. Material technology and

science research concentrate on materials from nanoscale or macro to micro with a lot of

states of material, liquid that is solid or semi solid .Asphalt is a complex blend that is dark or

black consisting of hydrocarbons with different derivatives that are nonmetallic and

molecular weight. Generally, asphalt is used as a material that is binding and organic for

http://www.iaeme.com/IJCIET/index.asp 1419 editor@iaeme.com

Khalid Mershed Eweed, Ibrahim Abdulwahhabb Atiyah and Rand Salih Al- Jadiri

protection from corrosion, resistance to moisture, and waterproofing [8, 10]. Base asphalt

reformingis needed to enhance the performance of the material, like durability, oxidation,

resistance, temperature sensitivity, aging resistance, adhesion ,and friction properties. There

are several types of modifiers of asphalt, counting different resins, polymers, sulfur, chemical

agents ,metal complexes, rubbers, and fibers [10].

The study aim is to investigate the effects of nanoalumina on the asphalt properties.

2. EXPERIMENTAL WORK

2.1. Materials

2.1.1. Binder of Asphalt

The asphalt binder that is employed in this paper was obtained from the refinery of Daura.

One asphalt grade was used to predict the physical an mechanical properties and it was 60-70

penetration asphalt grade. The properties that are physical like softening point, gravity that is

specific, penetration in addition to other properties are shown below in Table 1.

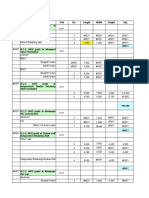

Table 1 The physical and chemical properties of asphalt.

Asphalt grade(60-70) Test method

Penetration (0.1 mm) 69 ASTM –D5

Softening Point R&B (oC) 52 ASTM-D36

Kinematic viscosity(cSt) 360 ASTM-D2170

Solubility in trichloroethylene (% wt) 99.9 ASTM-D86

Asphaltenes %wt. 18 ASTM-D2024

Saturates %wt. 16.2 ASTM-D2024

Naphthene – aromatis %wt. 46 ASTM-D2024

Polar aromatic %wt. 20.8 ASTM-D2024

Loss by heating %wt. 0.46 ASTM-D1754

2.1.2. Aggregate

One type of aggregate is explained in this paper for the production of the mixture of asphalt

to explore the Al2O2 the effect of nanomaterial on their performance and to match them in

relation to the use they have with this material. These aggregates were obtained from Niba’I

region and their aggregate physical properties is given in Table2 and 3

http://www.iaeme.com/IJCIET/index.asp 1420 editor@iaeme.com

Predicting the Effect of Adding the Nanoalumina on the Characterization of Asphalt Base

Composite

Table 2 The gradation of aggregate

Sieve size (mm) Average passing % Passing %

19 100 100

12.5 85-100 91

9.5 75-95 85

4.8 45-60 53

2 26-40 33

0.43 12-20 16

0.2 8-14 11

0.08 3-12 8

Table 3 The physical properties of Aggregate

Aggregate results

Bulk specific gravity of coarse aggregate gm/cm3 2.564

Apparent specific gravity of coarse aggregate gm/cm3 2.676

Bulk specific gravity of fine aggregate gm/cm3

2.634

Apparent specific gravity of fine aggregate gm/cm3

2.694

2.1.3. Alumina nanomaterials

Nano alumina with average particle size of 20-30 nm obtained from nanoshel intelligent

materials PVT. LTD company /USA was used in this study. The properties of alumina are

shown below in Table (4).

Table 4 The properties of alumina

Aluminium oxide nanomaterials

Chemical composition Al2O3

Particle size 15-25 nm

PH 6.7

Appearance White powder

Specific surface area (m3/g) 25-35

Purity < 99.9%

Stability Completely stable

reactivity Non –reactive

http://www.iaeme.com/IJCIET/index.asp 1421 editor@iaeme.com

Khalid Mershed Eweed, Ibrahim Abdulwahhabb Atiyah and Rand Salih Al- Jadiri

2.2. Design of mixtures

The asphalt modification done by adding the alumina nanomaterials directly to asphalt by

five percentages (0.5%, 1%, 1.5%, 2% and 2.5% of Al2O3 while the asphalt is heated at 160

o

C. After the change, the preparation of sections was donefor performing the testing with the

two systems of modification.

2.3. Physical properties

The test of penetration (0.1 mm) with 25°C, and point of softening (oC) were investigated

based on the ASTM D36 and ASTM D5

2.4. Mechanical Properties

2.4.1. marshal test

The use of Marshall Stiffness (MS) is wide to identify the performance that is mechanical of

blends of asphalt concrete. It is regarded as an index that is combined and that shows plastic

flow and stability features of the blend which is found from testing of marshal stability. The

preparation of Marshall samples done with different Asphalt cement nanoalumina

percentages were confirmed to examine Marshall Properties. The procedures, which is used

for identifying these properties are as density that is bulk and identified according tothe

method explained by ASTM D2726 [11]. The samples weight were measured in air and after

that in water at 25°C. Ultimately then, they were measured in condition of surface that is

saturated and of dry condition. The test of flow and Marshall Stability is carried out on each

sample according to the procedure explained by ASTM. Plastic flow Resistance of asphalt

blend happens by using Marshall Apparatus with recording system that is electronic. The

sample is situated in a bath of water at 60 °C and for (30-40) min. The Marshall stability is

shown to bethe maximum load in (KN), whereas the flow of Marshall is the movement that is

total or occurring of strain in the sample between maximum load and no load during the test

of stability.

2.4.2. Indirect Tensile Strength Test

The determination of the properties that are structural of the mixture of the asphalt will

provide the evaluation of asphalt blends moisture susceptibility, and this can be expressed

with the decrease in the loss of tensile strength that is indirect after the samples have

conditioning in water at 60˚C. The calculation of tensile strength that is indirect is given with

the following formula [12]:

St = 2P πdt (1)

Where

St: refers to tensile strength (indirect), P: symbolizes applied load that is maximum, d: is

the diameter of the sample, t: is the height of the sample. The test is performed by

preparation of the samples of marshal of 63.5 mm height and 100 mm diameter, at asphalt

content that is optimum.

2.4.3. Unconfined compressive

The strength test that is unconfined and compressive is done in order to identify the

properties that are compressive of mixtures of bitumen. The strength that is compressive of

the blend scan get through the application of a load of compression on the face that is circular

http://www.iaeme.com/IJCIET/index.asp 1422 editor@iaeme.com

Predicting the Effect of Adding the Nanoalumina on the Characterization of Asphalt Base

Composite

and a sample that is circular as well. The load was risen until failure occurred. The

calculation of the compressive strength can be given by using the equation below [13];

4 Pmax

c (2)

D 2

Where

σc denotes the compressive strength (unconfined), Pmax refers to the compressive load that

is applied (maximum )and, D represents the sample diameter. The best content of asphalt the

blends that are various was obtained from the curves of Marshall Property. The average that

is numerical of the content percentages of the asphalt was identified and it corresponds to the

Marshall Test which is maximum. It is determined according to the process described by the

Asphalt Institute [14].The bulk density was specified according to the method explained by

ASTM D2726. The measure of the sample weight was done in air after that in water at 25°C.

Ultimately then, it was given under the condition of saturated surface and dry situation. The

calculation of the density of the bulk (g/cm3) is then given as shown below[15]:

Wa

Gmb

Wssd Ww (3)

Where:

Gmb = the density of the Bulk of the compacted sample.

Wa = Weight of sample in air (gm).

Wssd = Saturated surface dry sample weight (gm).

Ww = Sample weight in water(gm)

3. RESULTS AND DISCUSSION

Figure 1 reflects that, with rising the content ofnanoalumina, the point of the penetration of

the bitumen that is modified reduces, more than that of the bitumen that is unmodified. The

maximum reduction was investigated with 2% content of nanoalumina. Thisrefers that, the

stiffness and hardness of bitumen were risen when modifiers of nanoalumina were added.

80

70

penetration (0.1 mm)

60

50

40

30

20

10

0

0 0.5 1 1.5 2 2.5 3

nanoalumina content %

Figure 1 The effect of nanoalomina content percent on the mixture of modified bitumen penetration

http://www.iaeme.com/IJCIET/index.asp 1423 editor@iaeme.com

Khalid Mershed Eweed, Ibrahim Abdulwahhabb Atiyah and Rand Salih Al- Jadiri

Figure 2.reflects that asphalt content that is similar, the point of softening of improved

blends is higher than the one of the blends that are unmodified. This refers that addition of

nanoalumina to asphalt includes a huge effect on enhancing its ability of resisting

deformation and flow. The rise in the point of softening when nanoalumina were put together

is a behavior that is expected because of the development of nanoalumina network that is

continuous inside the range of the blend of asphalt that decreases the distance that is

interpartical between the particle of the blend, which rises the point of softening of the blend

of nano-asphalt. Thus, nano modified asphalt can function better in areas having hot climate

in comparison to asphalt that is unmodified [16].

90

85

80

softining point (oC)

75

70

65

60

55

50

45

0 0.5 1 1.5 2 2.5 3

nanoalumina content

Figure 2 The effect of nanoalumina contentthe percentat the point of softening for bitumen blend

that is modified.

The Marshall Stability tests result for each sample is reflected in figure 3 and figure 4.

Figure 3 reflects the stability of Marshall for different modified blends and unmodified ones

against asphalt content percentage. Figure 4 shows the Marshall stability for different

modified blends and unmodified ones against nanoalumina content percentage. It reflects that

stability values for different blends are rising with the asphalt content percent until a value

that is maximumis recorded to be 6.5% asphalt content after which the stability starts

reducing. Also the Marshall stability for different modified blend are higher as compared

with unmodified blends. Often additives in the mixture improve its performance and thus

improve most of its properties [17, 18]. The Marshall Stability of the modified blends rises

with the rise of the percent of the nanoalumina content until a value that is maximum is

obtained2% the content of nanoalumina after which the stability starts reducing. Additionally,

the Marshall stability for blend that is modified and different is higher in comparison with

mixtures that are unmodified because of the noticeable rise in the improved bitumen blends

viscosity, make possible the formation of a thicker blend film in asphalt. Which get a long

service life and additional flexible pavement.

http://www.iaeme.com/IJCIET/index.asp 1424 editor@iaeme.com

Predicting the Effect of Adding the Nanoalumina on the Characterization of Asphalt Base

Composite

13

12

marashal stability KN

11

nanoalumina 0%

10 nanoalumina 0.5%

9 nanoalumina 1%

nanoalumina 1.5%

8

nanoalumia 2%

7

nanoalumia 2.5%

6

4.5 5 5.5 6 6.5 7 7.5

asphalt content %

Figure.3 The effect of the asphalt content percent on the Marshall stability ofmixture of asphalt

that is modified and unmodified.

13

12

asphalt content 4.5

marashal stability KN

11 asphalt content 5%

10 asphalt content 5.5%

asphalt content 6%

9

asphalt content 6.5%

8

asphalt content 7%

7

6

0 0.5 1nanoalumina

1.5 content%2 2.5 3

Figure 4 The effect of the nanoalumina contentpercent on the Marshall stability of mixture of

asphalt modified and unmodified.

The curves in figure 5. and 6. showed the test of flow for the different blends that are

unmodified and modified. Figure 5 reflects test values of flow in relation to the content of

asphalt. It is obvious that the flow values of different asphalt blend that are modified and

unmodified rises as the asphalt content rises. Figure 6 reflects the test of the flow as nano

content function. The flow result demonstrated that blends of asphalt, modified with

nanoalumina have flow value that is lower in comparison with the base asphalt blend. The

decrease had the range from 13 to 15 when nano mixed with the blend of the asphalt. This is

because of the effect of flexibility of nano in comparison to the bitumen blend that is

unmodified. The value of Marshall Stiffness exists in figure (7). It is specified that the

Marshall Stiffness value is developed for the nano blends that is modified than the one

regarded as its counterpart for blends that are unmodified. Likewise show that the Marshall

Stiffness rises with the content of nano rising to 2.5% content of nano afterward Marshall

stiffness starts declining. The Marshall stiffness of a blends relies on the inner cohesion and

http://www.iaeme.com/IJCIET/index.asp 1425 editor@iaeme.com

Khalid Mershed Eweed, Ibrahim Abdulwahhabb Atiyah and Rand Salih Al- Jadiri

friction. Cohesion is caused bythe ability of bitumen bending [19]. High Marshall Stiffness of

the enhanced bitumen blends result from the blend workability that is high with

nanomaterials. The tensile test that is indirect was improved to identify the properties of

tensile of bitumen blend through load compression application besides the specimens.

3.6

3.4

3.2 nano 0%

flow mm

nano 0.5%

3

nano 1%

2.8 nano 1.5%

nano 2%

2.6

nano 2.5%

2.4

4 5 6 7 8

asphalt %

Figure 5 The effect of the asphalt content percent of the flow of Marshall for bitumen mixture that is

modified and unmodified.

3.6

3.4

3.2

asphalt content 4.5%

flow mm

3 asphalt content 5%

2.8 asphalt content 5.5%

asphalt content 6%

2.6

asphlt content 6.5%

2.4

asphalt content 7%

2.2

0 1 2 3

nano %

Figure 6 The effect of the nano content percent of the flow of Marshall for bitumen mixture that

is modified.

http://www.iaeme.com/IJCIET/index.asp 1426 editor@iaeme.com

Predicting the Effect of Adding the Nanoalumina on the Characterization of Asphalt Base

Composite

8

marashal stiffness KN

7 asphalt 4.5%

asphalt 5%

6

asphalt 5.5%

5 asphalt 6%

asphalt 6.5%

4

asphalt 7%

3

0 0.5 1 1.5 2 2.5 3

nano %

Figure 7 the effect of the nano content percent of the Marshall stiffness for bitumen mixture that

is modified.

Figure 8. reflects the weight values that are unite for different blends as an asphalt content

function .In Figure 8the weight curves that are unitefor both unmodified and modified blends

reflect similar trend that is probably from blends that are hot, done with different asphalt

contents where the unite weight rises with the content of the asphalt increasing up a value that

is maximum after which the bulk density reduces. Similarly, Figure 8. reflects that the unit

weight for mixes of control is higher than the one of modified blends that are various for the

same asphalt content. These unit weight values reductions for blends that are modified are

caused by the gravity that is specific and low of the content of nanocontent. The asphalt

content that is optimum for blends that are unmodified is recorded to be 6.5%, while for the

asphalt content that is optimum for mixtures that are modified are recorded to be (6.5).

Figure 9 shows the curves that refer to the values of tensile strength that are indirect for

all blend specimens as nanomaterials and asphalt content function. Figure 9 demonstrates that

for blends that are modified, the tensile strength that is indirect rises with an nanomaterials

content rising until 2 percentages then, the tensile strength that is indirect reduces. It is

obvious that modified nanomaterial blends have tensile strength that is indirect and highest,

while the blends that are unmodified have tensile strength that is the indirect and lowest. This

gives an idea that modification has enhanced the toughness and tensile blends of asphalt. The

nanomaterial blend that is modified has highest indirect tensile strength in comparison with

asphalt that is unmodified. Hence, it can be deduced that the nanomaterials has ability to rise

the blends resistance and toughness to stresses of tensile. The strength test that is compressive

and unconfined was achievedin order to identify the properties that are compressive of the

studies ofblends. The calculation of the strength that is compressive and unconfined for

different blends was done according to equation 3. Figure 10 reflects then anomaterials

percent effect of unconfined and compressive strength. As shown in figure 9. the strength that

is unconfined and compressive in total mix rises with the rise of nanomaterials. This shows

the improvement in the resistance of the mixture to stresses that are compressive because of

adding modifiers of nanomaterials. Viewingthe result abovementioned, it is clear that the

mechanical properties of mixtures hugely rose when nanomaterialswere added. This is

analytic of a development in the strength that is interfacial between the component and the

binder. This can be connected with the ability of nanomaterials of rising the bond that is

http://www.iaeme.com/IJCIET/index.asp 1427 editor@iaeme.com

Khalid Mershed Eweed, Ibrahim Abdulwahhabb Atiyah and Rand Salih Al- Jadiri

adhesive between other component and asphalt. The mixtures that are modified are because

of the fact that the nanomaterials can enhance the mixture stiffness and elasticity as well.

2.8

2.7

unit weight gm/cm3

2.6

asphalt 4.5%

2.5 asphalt 5%

2.4 asphalt 5.5%

asphalt 6%

2.3

asphalt 6.5%

2.2

asphalt 7%

2.1

0 0.5 1 1.5 2 2.5 3

nanomaterials %

Figure 8 The effect of the copolymer content percent on the weight of unit for bitumen mixture that

are modified and unmodified

20.1 asphalt 4.5%

18.1 asphalt 5%

indirect tensile strength

16.1 asphalt 5.5%

14.1

asphalt 6%

12.1

asphalt 6.5%

10.1

asphalt 7%

8.1

6.1

4.1

2.1

0 0.5 1 1.5 2 2.5 3

nanomaterials %

Figure 9 The effect of the copolymer content percent on the tensile strength that is indirect for

bitumen mixture that is modified

http://www.iaeme.com/IJCIET/index.asp 1428 editor@iaeme.com

Predicting the Effect of Adding the Nanoalumina on the Characterization of Asphalt Base

Composite

0.75

unconfined compressive strength

0.7

0.65

0.6 asphalt 4.5%

0.55 asphalt 5%

0.5 asphalt 5.5%

0.45 asphalt 6%

0.4 asphalt 6.5%

0.35 asphalt 7%

0.3

0 0.5 1 1.5 2 2.5 3

nanomaterial %

Figure 10 The effect of the nanomaterialsthe percent on the strength that is compressive and

unconfined for asphalt mixture that is modified.

Figure 11 shows the the particles collected during asphalt preparation.

a-Microstructure of asphalt without addition b-Microstructure of asphalt with addition of

nanomaterials

Figure 11 The microstructure of modified asphalt

4. CONCLUSION

In this study can be concluded that the nano modification improved properties that are

physical of mixtures of asphalt, the penetration of the asphalt reduces with rising th econtent

of copolymer, the stiffness and hardness of asphalt have been risen when adding nano

modifiers; putting nano to asphalt affects considerably enhancing its resistance to

deformation and flow. The Marshall stability for mixture that is different and modified is

higher in comparison with mixtures that are unmodified. The Marshall Stability of the

mixturesthat are modified rise with rising the nano content percent until a maximum value

records 2.5% nano content; when nano is added, thisresults in reducing the value of flow; the

weight of unit for mixes of control is higher than the one of modified and various mixes. The

asphalt content that is optimum for a mixture that isunmodified is 6.5%. The tensile strength

indirect rises with a rising content of polymer until 11% is recorded and after that the tensile

strength that is indirect reduces .The modifier of nanomaterials has an ability to rise the

mixtures resistance and toughness to the stress of tensile, and the strength that is

compressive and unconfined in total mixtures rise with the rise of nanomateriala.

http://www.iaeme.com/IJCIET/index.asp 1429 editor@iaeme.com

Khalid Mershed Eweed, Ibrahim Abdulwahhabb Atiyah and Rand Salih Al- Jadiri

REFERENCES

[1] Whiteoak C D 1990 The Shell Bitumen Handbook.

[2] Yang, J and Tigheb S 2013 A Review of Advances of Nanotechnology in Asphalt

Mixtures. Procedia Social and Behavioral Sciences, 96, 1269-1276.

[3] You, Z., Mills-Beale, J., Foley, J.M., Roy, S., Odegard, G.M., Dai, Q. and Goh, S.W.

2011 Nanoclay-Modified Asphalt Materials Preparation and Characterization.

Construction and Building Materials, 25, 1072-1078.

[4] Fang, C Yu, R Liu S 2013 Nano Materials Applied in Asphalt Modification: A Review.

Journal of Materials Science and Technology 29, 589-594.

[5] Ameri M , Kouchaki, S and Roshani H 2013 Laboratory estimate of the Effect of Nano

Organosilane Anti Stripping Additive on the Moisture Susceptibility of HMA Mixtures

under FreezeThaw Cycles Construction and Building Materials, 48, 1009-1016.

[6] Shafabakhsh Gh , Mirabdolazimi, S and Sadeghnejad M Evaluation the Effect of Nano-

TiO2 on the Rutting and Fatigue Behavior of Asphalt Mixtures. Construction and

Building Materials, 54, 566-571

[7] J.S. Zhang, Z Li M T Li, J Xu, W J Yin, L Liu, Highway 2005 142 e146 in Chinese.

[8] J S Zhang, A Q Zhang, M T Li, J Xu, Z.H Wang, W J Yin, H M Zhao, Mater Rev 19

(2005) 87 e90 (in Chinese).

[9] S.S. Ray Okamoto Progress Polymer Sciences 28 (2003) 1539 e1541.

[10] A Shen, Pavement Performance of Asphalt and Asphalt Concrete, China Communication

Press, Beijing, 2011 (in Chinese).

[11] ASTM D 8-83 Standard Definitions Of Terms Relating To Materials For Roads .

[12] Behiry A 2013“Laboratory Evaluation of Resistance to Moisture Damage in Asphalt

Mixtures”. Ain Shams EngineeringJournal, 4, 351-363.

[13] Y Ahmed And Ayman M O 2005, Journal Of Engineering Sciences, Vol.33 No.2.

[14] The Asphalt Institute,'' Mix Design Method For Asphalt Concrete And Other Hot Mix

Types'', Manual Series, No.2 MS.2 , U S A, May 1984.

[15] ASTM Standard '' Road And Paving Materials Traveled Surface Characteristics' Annual

Book Of American Society For Testing And Materials Standard.

[16] ASTM Standard,'' Road And Paving Materials; Traveled Surface Characteristics' Annual

Book Of American Society For Testing And Materials Standard.

[17] Mahmood Raouf, R Abdul Wahab Z Azowa Ibrahim, Abidin Talib Z., & Chieng, B. W.

(2016). “Transparent blend of poly (methylmethacrylate)/cellulose acetate butyrate for the

protection from ultraviolet”. Polymers, 8(4), 128.

[18] Raouf, R M , Wahab, Z. A., Ibrahim, N. A., & Talib, Z. A. 2015 Polysulfone/Cellulose

Acetate Butyrate Environmentally Friendly Blend to minimize the Impact of UV

Radiation”. J Material Sci Eng, 5 219 2169-0022.

[19] Heukelom W 1969 ,'' A Bitumen Test Data Chart For Showing the Effect of Temperature

onthe Mechanical Behavior Of Asphaltic Bitumen's”, Journal Of Institute Of Petroleum,

Vol.55 No 546.

http://www.iaeme.com/IJCIET/index.asp 1430 editor@iaeme.com

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Solution ManualДокумент162 страницыSolution Manual186627281% (16)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- HayesДокумент14 страницHayesMurugananthamParamasivamОценок пока нет

- MSC Tutorial Simple Cantilever BeamДокумент8 страницMSC Tutorial Simple Cantilever BeampicilonОценок пока нет

- Bridge 4Документ6 страницBridge 4sОценок пока нет

- Bridge Estimate3Документ10 страницBridge Estimate3sОценок пока нет

- Example 5.1.10 (Page 109) : 1) Input Design DataДокумент12 страницExample 5.1.10 (Page 109) : 1) Input Design DatasОценок пока нет

- Bridge Estimate2Документ6 страницBridge Estimate2sОценок пока нет

- Bridge 4Документ6 страницBridge 4sОценок пока нет

- Bridge 3Документ7 страницBridge 3sОценок пока нет

- Book 11Документ2 страницыBook 11sОценок пока нет

- Bridge 2Документ11 страницBridge 2sОценок пока нет

- Bridge 2Документ11 страницBridge 2sОценок пока нет

- Bridge 3Документ8 страницBridge 3sОценок пока нет

- Bridge 1Документ8 страницBridge 1sОценок пока нет

- Bridge 2Документ9 страницBridge 2sОценок пока нет

- Bridge 4Документ6 страницBridge 4sОценок пока нет

- Bridge 2Документ11 страницBridge 2sОценок пока нет

- Bridge 1Документ11 страницBridge 1sОценок пока нет

- Bridge 2Документ11 страницBridge 2sОценок пока нет

- Bridge 1Документ11 страницBridge 1sОценок пока нет

- Bridge 8Документ5 страницBridge 8sОценок пока нет

- Bridge 2Документ11 страницBridge 2sОценок пока нет

- Bridge 2Документ11 страницBridge 2sОценок пока нет

- Bridge 2Документ11 страницBridge 2sОценок пока нет

- Bridge 2Документ11 страницBridge 2sОценок пока нет

- Bridge 2Документ11 страницBridge 2sОценок пока нет

- Bridge Estimate2Документ7 страницBridge Estimate2sОценок пока нет

- Bridge Estimate2Документ11 страницBridge Estimate2sОценок пока нет

- Bridge 2Документ11 страницBridge 2sОценок пока нет

- Bridge Estimate2Документ11 страницBridge Estimate2sОценок пока нет

- Bridge 2Документ11 страницBridge 2sОценок пока нет

- Bridge 1Документ7 страницBridge 1sОценок пока нет

- Bridge Estimate2Документ11 страницBridge Estimate2sОценок пока нет

- Cements For Long Term Isolation - Design Optimization by Computer Modelling andДокумент14 страницCements For Long Term Isolation - Design Optimization by Computer Modelling andQutluq Caferzade100% (1)

- AS LAB Man IДокумент84 страницыAS LAB Man IVadivel AeroОценок пока нет

- Composite Steel-Concrete StructuresДокумент35 страницComposite Steel-Concrete Structuresmishu01Оценок пока нет

- Material Dan MetalurgiДокумент32 страницыMaterial Dan MetalurgiPrengki WijayaОценок пока нет

- Combined Hardening Behavior PDFДокумент31 страницаCombined Hardening Behavior PDFDiegoHenaoLeonОценок пока нет

- New Crystal Structure and Discharge Efficiency of Poly (Vinylidene Uoride-Hexa Uoropropylene) /poly (Methyl Methacrylate) Blend FilmsДокумент7 страницNew Crystal Structure and Discharge Efficiency of Poly (Vinylidene Uoride-Hexa Uoropropylene) /poly (Methyl Methacrylate) Blend FilmssalmanОценок пока нет

- Sectional Properties For RectangleДокумент2 страницыSectional Properties For RectangleYau Ka Ki JackyОценок пока нет

- A Study On Compatibility of Concrete Repair MaterialsДокумент21 страницаA Study On Compatibility of Concrete Repair MaterialsMahmoud HakimОценок пока нет

- FinalBE QuestionДокумент14 страницFinalBE QuestionDhaval MistryОценок пока нет

- Direct Numerical Simulations of Non-Equilibrium Dynamics of ColloidsДокумент33 страницыDirect Numerical Simulations of Non-Equilibrium Dynamics of ColloidsmortezagashtiОценок пока нет

- SuperalloyДокумент5 страницSuperalloyJayanthi Arumugam JayanthiОценок пока нет

- Understanding Geometric NonlinearitiesДокумент4 страницыUnderstanding Geometric NonlinearitiesPramod KulkarniОценок пока нет

- Lab 1 - Flexural Strength of Ceramic MaterialsДокумент5 страницLab 1 - Flexural Strength of Ceramic Materialsharlow6winfield6adamОценок пока нет

- AOT-PO Sucker Rod ManualДокумент40 страницAOT-PO Sucker Rod ManualJose Silvestre GuevaraОценок пока нет

- Nanolithography - Processing Methods PDFДокумент10 страницNanolithography - Processing Methods PDFNilesh BhardwajОценок пока нет

- Materials Science & Engineering BДокумент31 страницаMaterials Science & Engineering BExtrusion TutorialsОценок пока нет

- Ap R462 14Документ133 страницыAp R462 14AnantОценок пока нет

- Formula Sheet For MECH4400Документ2 страницыFormula Sheet For MECH4400Raverl XОценок пока нет

- Surface Vehicle Information: Rev. AUG2002Документ29 страницSurface Vehicle Information: Rev. AUG2002Julio Herrera VenegasОценок пока нет

- Triaxial UUДокумент3 страницыTriaxial UUDemetrio Carranza PeñaОценок пока нет

- High Strength Bolts - KulakДокумент21 страницаHigh Strength Bolts - KulakalmeteckОценок пока нет

- Mathematical Modeling of Copper and Brass UpcastingДокумент24 страницыMathematical Modeling of Copper and Brass UpcastingMoreno MarcatiОценок пока нет

- Geot 2007 57 3 289 PDFДокумент13 страницGeot 2007 57 3 289 PDFDaniel Felipe Ruiz RestrepoОценок пока нет

- Bonding PowerpointДокумент14 страницBonding Powerpointᴍɪᴋᴋɪᴋᴀᴢᴇ100% (1)

- Civil V Sem Sa-I Ce 6501Документ16 страницCivil V Sem Sa-I Ce 6501Meeran MohamedОценок пока нет

- Turcite B LeafletДокумент2 страницыTurcite B LeafletJorge Gustavo HilgenbergОценок пока нет

- QUESTIONSДокумент4 страницыQUESTIONSANMOLОценок пока нет