Академический Документы

Профессиональный Документы

Культура Документы

Reporte Informe Hidraulico

Загружено:

Willy RiosИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Reporte Informe Hidraulico

Загружено:

Willy RiosАвторское право:

Доступные форматы

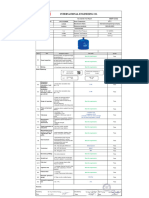

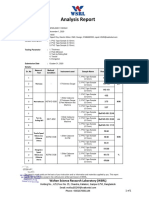

5Elem Material Scientific (Jiangsu) Co.,Ltd.

Hose Inspection Report

5E/QD8.2.4-09a

Standard: SIP Construction:

Single white jacket, polyester filament as warp and filler, EPDM lining,

P/N: MILL HOSE- Syntec #17-25-25 service test pressure: 250PSI, without couplings

Manufacture Date: 2013-7-2

Size & Length: 1 " × 25M QTY of sample inspected: 2 Rolls

Contract No.: PI-STF130510 Sample referrence No.: ①130702D01 ②130702D02

NO. Item Requirement Result Conclusion

Equal weave, clean surface, no knots, no ①√OK

1 Appearance PASS

lumps, no hurts etc. ②√OK

①25.7、26.2mm

2 Internal Diameter 25.0mm~26.5mm PASS

②26.0、26.6mm

Equal thickness, smooth and flat, no ridge, no ①√OK

3 Lining PASS

other defects ②√OK

①25.6m

4 Length ≥25m PASS

②25.6m

①35.7N/25mm

5 Adhesion Strength ≥25N/25mm PASS

②35.5N/25mm

①5.98%

6 Elongation Rate ≤10% PASS

②5.64%

no leakage and damage under test pressure ①no leakage, no damage

7 PASS

2.55MPa over a period of 4 min. ②no leakage, no damage

Hydrostatic Test

①BP: 6.8Mpa

8 Burst Pressure ≥5.1MPa PASS

②BP: 6.9Mpa

Final Conclusion QUALIFIED

Inspector: 袁杰 Checker: 陈娟 Examiner: 郁霞 Date: 2013.7.10

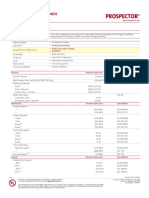

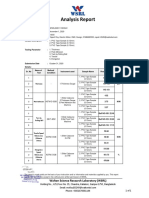

5Elem Material Scientific (Jiangsu) Co.,Ltd.

Hose Inspection Report

5E/QD8.2.4-09a

Standard: SIP Construction:

Single jacket, red coated, polyester filament as warp and filler, EPDM

P/N: MILL HOSE- Syntec #21-38-25 lining, service test pressure: 300PSI, with Aluminium Storz couplings

Manufacture Date: 2013-6-28

Size & Length: 1 1/2 " × 25M QTY of sample inspected: 2 Rolls

Contract No.: PI-STF130510 Sample referrence No.: ①130628F01 ②130628F02

NO. Item Requirement Result Conclusion

Equal weave, clean surface, no knots, no ①√OK

1 Appearance PASS

lumps, no hurts etc. ②√OK

①39.1、39.4mm

2 Internal Diameter 38.0mm~39.5mm PASS

②38.9、39.1mm

Equal thickness, smooth and flat, no ridge, no ①√OK

3 Lining PASS

other defects ②√OK

①25.9m

4 Length ≥25m PASS

②25.8m

①36.7N/25mm

5 Adhesion Strength ≥25N/25mm PASS

②34.5N/25mm

①5.34%

6 Elongation Rate ≤10% PASS

②5.77%

no leakage and damage under test pressure ①no leakage, no damage

7 PASS

3.15MPa over a period of 4 min. ②no leakage, no damage

Hydrostatic Test

①BP: 8.0Mpa

8 Burst Pressure ≥6.3MPa PASS

②BP: 7.9Mpa

Hydrostatic test with The hose and the coupling assembly shall The batch of 130 rolls

9 PASS

couplings show no sign of leakage at 3.15MPa were all tested

Final Conclusion QUALIFIED

Inspector: 袁杰 Checker: 陈娟 Examiner: 郁霞 Date: 2013.7.10

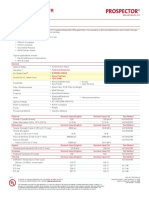

5Elem Material Scientific (Jiangsu) Co.,Ltd.

Hose Inspection Report

5E/QD8.2.4-09a

Standard: SIP Construction:

Single jacket, red coated, polyester filament as warp and filler, EPDM

P/N: MILL HOSE- Syntec #21-52-25 lining, service test pressure: 300PSI, with Aluminium Storz couplings

Manufacture Date: 2013-6-28

Size & Length: 2" × 25M QTY of sample inspected: 2 Rolls

Contract No.: PI-STF130510 Sample referrence No.: ①130628E01 ②130628E02

NO. Item Requirement Result Conclusion

Equal weave, clean surface, no knots, no ①√OK

1 Appearance PASS

lumps, no hurts etc. ②√OK

①52.7、52.9mm

2 Internal Diameter 52.0mm~53.5mm PASS

②53.2、53.0mm

Equal thickness, smooth and flat, no ridge, no ①√OK

3 Lining PASS

other defects ②√OK

①25.9m

4 Length ≥25m PASS

②25.9m

①38.7N/25mm

5 Adhesion Strength ≥25N/25mm PASS

②34.5N/25mm

①5.82%

6 Elongation Rate ≤10% PASS

②5.89%

no leakage and damage under test pressure ①no leakage, no damage

7 PASS

3.15MPa over a period of 4 min. ②no leakage, no damage

Hydrostatic Test

①BP: 7.6Mpa

8 Burst Pressure ≥6.3MPa PASS

②BP: 7.9Mpa

Hydrostatic test with The hose and the coupling assembly shall The batch of 150 rolls

9 PASS

couplings show no sign of leakage at 3.15MPa were all tested

Final Conclusion QUALIFIED

Inspector: 袁杰 Checker: 陈娟 Examiner: 郁霞 Date: 2013.7.10

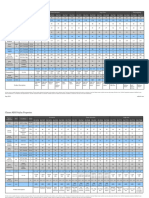

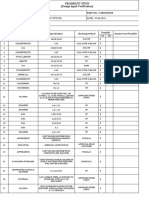

5Elem Material Scientific (Jiangsu) Co.,Ltd.

Hose Inspection Report

5E/QD8.2.4-09a

Standard: SIP Construction:

Single jacket, red coated, polyester filament as warp and filler, EPDM

P/N: MILL HOSE- Syntec #21-65-25 lining, service test pressure: 300PSI, with Aluminium Storz couplings

Manufacture Date: 2013-6-27

Size & Length: 2 1/2" × 25M QTY of sample inspected: 2 Rolls

Contract No.: PI-STF130510 Sample referrence No.: ①130627D01 ②130627D02

NO. Item Requirement Result Conclusion

Equal weave, clean surface, no knots, no ①√OK

1 Appearance PASS

lumps, no hurts etc. ②√OK

①65.2、65.0mm

2 Internal Diameter 64.0mm~65.5mm PASS

②65.1、64.9mm

Equal thickness, smooth and flat, no ridge, no ①√OK

3 Lining PASS

other defects ②√OK

①25.6m

4 Length ≥25m PASS

②25.9m

①36.7N/25mm

5 Adhesion Strength ≥25N/25mm PASS

②38.5N/25mm

①5.93%

6 Elongation Rate ≤10% PASS

②5.83%

no leakage and damage under test pressure ①no leakage, no damage

7 PASS

3.15MPa over a period of 4 min. ②no leakage, no damage

Hydrostatic Test

①BP: 8.0Mpa

8 Burst Pressure ≥6.3MPa PASS

②BP: 7.5Mpa

Hydrostatic test with The hose and the coupling assembly shall The batch of 50 rolls were

9 PASS

couplings show no sign of leakage at 3.15MPa all tested

Final Conclusion QUALIFIED

Inspector: 袁杰 Checker: 陈娟 Examiner: 郁霞 Date: 2013.7.10

Вам также может понравиться

- Ashirvad Pipes Pvt. LTD., Bangalore: Test Report of CPVC Pipes As Per Is 15778Документ7 страницAshirvad Pipes Pvt. LTD., Bangalore: Test Report of CPVC Pipes As Per Is 15778mohd shiraz100% (1)

- Valvula ACI - WefloДокумент2 страницыValvula ACI - WefloWilly RiosОценок пока нет

- DP1100Документ3 страницыDP1100tunradotОценок пока нет

- Trouble Codes C32Документ10 страницTrouble Codes C32AliHabes100% (2)

- 02 Microduct Hdpe Flat Ways 2 - 18.14mm Orange KhomaxДокумент2 страницы02 Microduct Hdpe Flat Ways 2 - 18.14mm Orange KhomaxAlvaro Segura JavierОценок пока нет

- C150Y LDPE Petlin MalaysiaДокумент1 страницаC150Y LDPE Petlin MalaysiaLong Trịnh ĐìnhОценок пока нет

- Amapro: Certificate of AnalysisДокумент2 страницыAmapro: Certificate of Analysishafwen TranОценок пока нет

- Final Inspection ReportДокумент9 страницFinal Inspection Reporthamza hameedОценок пока нет

- Painitng Cross Cut Test ReportДокумент2 страницыPainitng Cross Cut Test ReporttinzarmoeОценок пока нет

- Ashirvad Pipes Pvt. LTD., Bangalore: Test Report of Upvc Reclaim Pipes As Per Astm D 1785Документ9 страницAshirvad Pipes Pvt. LTD., Bangalore: Test Report of Upvc Reclaim Pipes As Per Astm D 1785mohd shirazОценок пока нет

- Torch BondДокумент2 страницыTorch Bondmk779900mkОценок пока нет

- Lldpe HD21HS Qamar SPDC SpecsДокумент2 страницыLldpe HD21HS Qamar SPDC SpecsChu ChuОценок пока нет

- Drum Data Sheet: Ctci CorporationДокумент4 страницыDrum Data Sheet: Ctci Corporationjdaig17Оценок пока нет

- Ega CatalogueДокумент13 страницEga CatalogueaaquilОценок пока нет

- PVC-FR Compound Test ReportДокумент1 страницаPVC-FR Compound Test ReportjamilОценок пока нет

- Firecel SR 114h CertificatesДокумент20 страницFirecel SR 114h CertificatesMohammed MustafaОценок пока нет

- Pa6 GF30 - Dupont Zytel® 73G30HSL BK416Документ2 страницыPa6 GF30 - Dupont Zytel® 73G30HSL BK416armandoОценок пока нет

- ULTEM™ AUT230 Resin: SABIC Innovative PlasticsДокумент4 страницыULTEM™ AUT230 Resin: SABIC Innovative PlasticsLeandro LacerdaОценок пока нет

- Elastimold 156LR Catalog + Installation InstructionДокумент6 страницElastimold 156LR Catalog + Installation InstructionJoseph JoeОценок пока нет

- Technical Report: 2179C Fiber Optic Splice CaseДокумент8 страницTechnical Report: 2179C Fiber Optic Splice CaseHữu Khánh NguyễnОценок пока нет

- Technical Report: 2179C Fiber Optic Splice CaseДокумент8 страницTechnical Report: 2179C Fiber Optic Splice CaseHữu Khánh NguyễnОценок пока нет

- Modified Silicone Polymer Silane-Modified Polymer Elastic Adhesive BaseДокумент1 страницаModified Silicone Polymer Silane-Modified Polymer Elastic Adhesive BaseabheypriyaОценок пока нет

- 22 Practical Visual InspectionДокумент9 страниц22 Practical Visual InspectionudomОценок пока нет

- Test ReportДокумент1 страницаTest ReportPiyush GuptaОценок пока нет

- Bopp TapeДокумент1 страницаBopp TapebouzirpafОценок пока нет

- Tristar® PC-05GFRДокумент3 страницыTristar® PC-05GFRRhekron PlasticsОценок пока нет

- Test Report: Page: 1 of 4 Date: May 26, 2010Документ4 страницыTest Report: Page: 1 of 4 Date: May 26, 2010rqfsiypisnvabmtusrОценок пока нет

- Ficha Tecnica Material BcoДокумент1 страницаFicha Tecnica Material BcoDaniel NavaОценок пока нет

- Mining Rock Mass RatingДокумент5 страницMining Rock Mass RatingMarcelo PironiОценок пока нет

- Chimei Brochure CombinedДокумент3 страницыChimei Brochure CombinedArtiom SîrbuОценок пока нет

- 22 Practical Visual InspectionДокумент9 страниц22 Practical Visual InspectionAdhanom G.Оценок пока нет

- SL - No. Inspection Parameter Specification Observation: Type Test ReportДокумент1 страницаSL - No. Inspection Parameter Specification Observation: Type Test ReportmaheshgkuОценок пока нет

- WSRL2020111003341 ThicknessPeelTensileElongationBallДокумент1 страницаWSRL2020111003341 ThicknessPeelTensileElongationBallRajesh RoyОценок пока нет

- WSRL2020111003341 ThicknessPeelTensileElongationBallДокумент1 страницаWSRL2020111003341 ThicknessPeelTensileElongationBallRajesh RoyОценок пока нет

- Q1Co 3000 Q1Co 3520 3520-LIT - 381Документ3 страницыQ1Co 3000 Q1Co 3520 3520-LIT - 381Jhonatan RodriguezОценок пока нет

- Inspection Guideline For Soil To Air Interface PipingДокумент14 страницInspection Guideline For Soil To Air Interface PipingBenjapon bt750% (2)

- Wallnut DatasheetДокумент14 страницWallnut DatasheetajengОценок пока нет

- Microc Series D 1489614Документ17 страницMicroc Series D 1489614João Oliveira BentesОценок пока нет

- Plastic Deformation in Tensile Testing: Renewable Energy Equipment DesignДокумент17 страницPlastic Deformation in Tensile Testing: Renewable Energy Equipment DesignNoman AhmedОценок пока нет

- Q1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionДокумент2 страницыQ1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionJHONATAN RODRIGUEZ VENTOОценок пока нет

- Body Design FeasibilityДокумент4 страницыBody Design FeasibilityPrakash kumarTripathiОценок пока нет

- Premier Coatings Premtape TropicalДокумент2 страницыPremier Coatings Premtape TropicalIm ChinithОценок пока нет

- Duocheck SBMДокумент1 страницаDuocheck SBMNicolás FriasОценок пока нет

- Acrylic Foam Tape: RT8000 SeriesДокумент5 страницAcrylic Foam Tape: RT8000 SeriesHerman SujarwantoОценок пока нет

- New Atlanta Permaline 2021 0Документ2 страницыNew Atlanta Permaline 2021 0Kerr Nell AsuncionОценок пока нет

- Akulon F136-C1: DSM Engineering Materials - Polyamide 6Документ2 страницыAkulon F136-C1: DSM Engineering Materials - Polyamide 6bobОценок пока нет

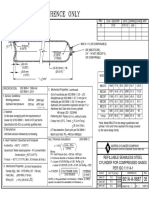

- Refillable Seamless Steel Cylinder For Compressed Gases PER ISO 11114-1Документ1 страницаRefillable Seamless Steel Cylinder For Compressed Gases PER ISO 11114-1bkprodhОценок пока нет

- RT02Документ1 страницаRT02اسران احمدОценок пока нет

- PEI Ultem 2310R 30%GLДокумент4 страницыPEI Ultem 2310R 30%GLcountzeroaslОценок пока нет

- DRK109A&B Touch-Screen Bursting Strength TesterДокумент2 страницыDRK109A&B Touch-Screen Bursting Strength Testermohamadreza1368Оценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Ul1911 (25KV) 18 FT110824Документ2 страницыUl1911 (25KV) 18 FT110824Trần Long VũОценок пока нет

- Radiographic Interpretation Table: Defects Mentioned Are Based On 300Mm (12") Long WeldДокумент2 страницыRadiographic Interpretation Table: Defects Mentioned Are Based On 300Mm (12") Long WeldbmkaleОценок пока нет

- E1e 014Документ8 страницE1e 014Cong BuiОценок пока нет

- MeasurementДокумент6 страницMeasurementCuan HappyОценок пока нет

- Trelleborg ATP Ballast Mat BrochureДокумент8 страницTrelleborg ATP Ballast Mat BrochureÜmit KukulaОценок пока нет

- Weekly Report W2Документ12 страницWeekly Report W2GiaBảoDươngОценок пока нет

- PG Pressure GaugeДокумент2 страницыPG Pressure GaugeAr RahmanОценок пока нет

- Sikawall®-75 Weatherseal Spray & Roll-On: Ficha Técnica de ProdutoДокумент3 страницыSikawall®-75 Weatherseal Spray & Roll-On: Ficha Técnica de ProdutoJaime Pinn RegliОценок пока нет

- Vee Pack Sets: Technical DetailsДокумент2 страницыVee Pack Sets: Technical DetailsRPINILLA (EICO S.A.)Оценок пока нет

- Vee Pack Sets: Technical DetailsДокумент2 страницыVee Pack Sets: Technical DetailsAlejandro MejíasОценок пока нет

- Certene™ Llbf-218aДокумент1 страницаCertene™ Llbf-218aJose FernandezОценок пока нет

- Invoice LucesДокумент1 страницаInvoice LucesWilly RiosОценок пока нет

- FH Series: 60 HZ 60 HZ 60 HZ 60 HZ 60 HZДокумент132 страницыFH Series: 60 HZ 60 HZ 60 HZ 60 HZ 60 HZWilly RiosОценок пока нет

- Xtralis VESDA LCD Programmer Quick Reference Guide: Xtralis VESDA VLP Xtralis VESDA VLS Xtralis VESDA VLCДокумент6 страницXtralis VESDA LCD Programmer Quick Reference Guide: Xtralis VESDA VLP Xtralis VESDA VLS Xtralis VESDA VLCWilly RiosОценок пока нет

- Ventilation System: SectionДокумент16 страницVentilation System: SectionWilly RiosОценок пока нет

- BC 20s HandbuchДокумент173 страницыBC 20s HandbuchmanoharОценок пока нет

- SYNC2000 - 4.00.022014 Protocol ConverterДокумент2 страницыSYNC2000 - 4.00.022014 Protocol ConverterAnasSalemОценок пока нет

- Head & Combo: Manual 1.0Документ11 страницHead & Combo: Manual 1.0NielsvdorstОценок пока нет

- Using A GMR Effect Sensor To Measure The Current in A Wire by Means of Its Magnetic FieldДокумент6 страницUsing A GMR Effect Sensor To Measure The Current in A Wire by Means of Its Magnetic FieldManeesha WijesingheОценок пока нет

- UntitledДокумент34 страницыUntitledRayudu VVSОценок пока нет

- BX-74 / BX-78: Sliding Gate Operator BX SeriesДокумент24 страницыBX-74 / BX-78: Sliding Gate Operator BX SeriesStefce PetrovОценок пока нет

- ASHRAE Fundamentals 2005 - SI Units - Extract of Tables PDFДокумент40 страницASHRAE Fundamentals 2005 - SI Units - Extract of Tables PDFSufian SarwarОценок пока нет

- Section 1: Identification: TurpentineДокумент10 страницSection 1: Identification: TurpentineRobertОценок пока нет

- ARO Pump ManualДокумент8 страницARO Pump Manualrazaq athabОценок пока нет

- Operational Definition of TermsДокумент2 страницыOperational Definition of TermsHazel Grace Tugado Torrecampo67% (3)

- Nickel-Titanium Alloys: A Systematic Review: Original ArticleДокумент12 страницNickel-Titanium Alloys: A Systematic Review: Original ArticleMudavath BaburamОценок пока нет

- CSC 263Документ108 страницCSC 263osecaloОценок пока нет

- Millikan Oil Drop ExperimentДокумент6 страницMillikan Oil Drop ExperimentruleevanОценок пока нет

- Mep Material Submittals LogДокумент1 страницаMep Material Submittals LogSanthosh KumarОценок пока нет

- Home,: A Solace To Which A Journey Is Never Too Long..Документ25 страницHome,: A Solace To Which A Journey Is Never Too Long..Duvonto RealtyОценок пока нет

- CFD Analysis of First Stage Nozzle Cooling Optimization in Gas TurbinesДокумент7 страницCFD Analysis of First Stage Nozzle Cooling Optimization in Gas TurbinesMahmood ElnagarОценок пока нет

- 1st Indian Near Surface Geophysics BrochureДокумент4 страницы1st Indian Near Surface Geophysics BrochureAdarsh TanejaОценок пока нет

- ProjectДокумент34 страницыProjectSarvajeet Kshirsagar100% (1)

- Stelzer Catalog PDFДокумент12 страницStelzer Catalog PDFlhphong021191Оценок пока нет

- Pavement Evaluation and Overlay Des - DR MSA - LatestДокумент103 страницыPavement Evaluation and Overlay Des - DR MSA - LatestSreedhar BhuduruОценок пока нет

- DUNAN Fan Coil UnitДокумент14 страницDUNAN Fan Coil UnitDjordjeОценок пока нет

- September 2015Документ2 страницыSeptember 2015Patriziah Marie SeldaОценок пока нет

- 02 MF Anchors PDFДокумент13 страниц02 MF Anchors PDFThaksenОценок пока нет

- L1F1Документ5 страницL1F1DanielОценок пока нет

- Epi Gear 1 PDFДокумент21 страницаEpi Gear 1 PDFTrevaughn ParkinsonОценок пока нет

- SAX Brochure - Web ReadyДокумент4 страницыSAX Brochure - Web ReadyEng-Ahmad Abo-AledousОценок пока нет

- Hindalco Aluminium Catalogue PDFДокумент4 страницыHindalco Aluminium Catalogue PDFVansu Saini0% (1)

- First-Man-Up User ManualДокумент24 страницыFirst-Man-Up User ManualJoshuaОценок пока нет