Академический Документы

Профессиональный Документы

Культура Документы

Banana Fiber Extraction Machine Methodology

Загружено:

Sam CunananОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Banana Fiber Extraction Machine Methodology

Загружено:

Sam CunananАвторское право:

Доступные форматы

BANANA FIBER EXTRACTION MACHINE 19

CHAPTER 3

METHODOLOGY

From the objective to fabricate and conceptualize an electric powered

banana extractor machine that would aid in uplifting the production output and

efficiency, a methodical and comprehensive strategy is made on action. This is

accomplished through following these steps:

3.1 Research Design

3.1.1 Conceptual Components of an Electric-Powered Banana Fiber

Extractor

There are four fundamental components in the extraction machine –

machine frame, driving mechanism, holding mechanism, and the stripping/beating

mechanism. The frame acts as the structural framework that supports and holds the

other mechanisms. It must be firm and sturdy to be able to withstand vibration to

minimum. The next one is the driving mechanism, composed of an electric motor

together with the belt drive

system, rotating shafts with

pulley sheaves of 1:2 speed

ratio. And lastly, the beating

mechanism which is

ultimately consists of a

stripping roller and a roller

with blades equally spaced

around it.

Figure 3.1 3D Perspective of the Extractor

DON HONORIO VENTURA TECHNOLOGICAL STATE UNIVERSITY

BANANA FIBER EXTRACTION MACHINE 20

Conceptual Design of Banana Fiber Extractor

Figure 3.2 Side View

Figure 3.3 Front View

DON HONORIO VENTURA TECHNOLOGICAL STATE UNIVERSITY

BANANA FIBER EXTRACTION MACHINE 21

A. Machine Frame

It is very important that the machine frame is geometrically designed for it

to withstand vibration and give stability to the whole structure. The machine frame

(figure) was welded and assembled from angle bars with sizes 1.5” by 1.5” to

comply with the said requirements.

Figure 3.4 Machine Frame

DON HONORIO VENTURA TECHNOLOGICAL STATE UNIVERSITY

BANANA FIBER EXTRACTION MACHINE 22

B. Driving Mechanism with the Belt Drive Mechanism

The mechanism was composed of an electric motor 1.5Hp, two 2B42 V-

belts and two pulley sheaves. It also used a shaft where the roller is attached.

Figure 3.5 Electric Motor, V-belts, and Pulley Sheaves

DON HONORIO VENTURA TECHNOLOGICAL STATE UNIVERSITY

BANANA FIBER EXTRACTION MACHINE 23

C. Stripping or Beating Mechanism

The stripping/beating mechanism was made by two parts. The first one is a

beater drum made 12 inches long and 6 inches diameter metal pipe attached with 8

(1” by 1”) angle bars spaced around its body. The second one is a roller made

from a metal pipe 19 inches long and 1.5 inches diameter same with the feeder

rollers.

Figure 3.6 Beater drum and Rollers

DON HONORIO VENTURA TECHNOLOGICAL STATE UNIVERSITY

BANANA FIBER EXTRACTION MACHINE 24

3.1.2 Fabricating Stage

After the thorough planning and discussion of the design, the approved

design was then fabricated. The Engineer of the Machine Shop listed all the parts

needed and we researchers purchased them all, after that the assembling followed.

All the parts were assembled at BBM Machine shop located at 116 Mc Arthur

Highway Barangay Sta. Teresita, City of San Fernando Pampanga. The figure

below shows the assemblage of the machine.

Figure 3.7 Day 7 of Fabrication

The machine is already half done. The frame was finished as well as beater

drum.

DON HONORIO VENTURA TECHNOLOGICAL STATE UNIVERSITY

BANANA FIBER EXTRACTION MACHINE 25

3.1.3 Testing Stage

In order to test the effectiveness of the machine, series of experimentations

were undertaken. In this part, numerous modifications were made in order to fulfill

the general objectives of the research study. The aim of the tests was to determine

the ideal parameters for fiber yield of the given banana plant species.

3.2 Data Collection

In this part of the strategy, the researchers gathered all possible information

from internet, books, journals, connected local departments, and conduct

interviews to the authorities. This stage emphasize in the planning of making a

mechanical banana extractor machine that is more sufficient and convenient than

the manual designs. The researchers will discuss their plan to the adviser in

fabricating the project, and of course discuss also to the clients (farmers) in order

to meet the clients satisfaction to the design.

After gathering all the fundamental data needed, the researchers will start

on working on the expected design of the banana extraction machine. Equipment

and materials needed will also be precisely determined and gathered or purchase in

this stage.

3.2.1 Department of Agriculture

The researchers went to the Department of Agriculture Regional

Field Office III, located at the Capitol Compound, City of San Fernando, and

Pampanga, to confirm if the banana pseudostem contains fiber. They also asked

the locations of the banana plantations in Pampanga and nearer province.

DON HONORIO VENTURA TECHNOLOGICAL STATE UNIVERSITY

BANANA FIBER EXTRACTION MACHINE 26

3.2.2 Department of Science and Technology

In acquiring in-depth knowledge and concepts regarding banana

fiber extraction, the researchers visited the DOST located at Government Center,

Maimpis City of San Fernando, Pampanga. The DOST member mentioned that the

PTRI can answer appropriately the questions.

3.2.3 Philippine Textile Research Institute

The proponents went to the Philippine Textile Research Institute

located at General Santos Avenue Taguig, Metro Manila, as stated by the DOST,

to attest the possible products out of the banana fiber the researchers extracted.

They also confirmed the market value of the banana fiber. An interview with Mr.

Edwardo M. Marin (Science Research Specialist II) was conducted.

3.2.4 Interview

The researchers gathered interviews with some plantations in Region III to

know more about banana cultivation. First, David’s Banana Plantation located at

Palat Porac, Pampanga with Mr Lito David the caretaker. Next is in Garden Grill

Farm sited at Kabuwak II, Tarlac City with Mr Nonoy Engle, an agriculturist.

3.3 Data Analysis Procedure

In this part of the study, presents all the method, concepts and ideas being

used that were considered applicable to the project. It covers all the aspects, from

the instruments and materials used in the fabrication to the experimental approach

itself.

DON HONORIO VENTURA TECHNOLOGICAL STATE UNIVERSITY

BANANA FIBER EXTRACTION MACHINE 27

3.3.1 Department of Agriculture

The researcher Mr. Alexander E. Santos (Science Research Specialist II)

confirmed that the banana cultivars contain fiber but not as strong as the abaca

which is the main source of fiber in the Musa family in the Philippines.

The locations of banana plantations were also revealed in the interview.

Figure 3.8 Volume of Production, Area Planted, and Number of Bearing

Hills for Banana: Philippines, 2013-2017

DON HONORIO VENTURA TECHNOLOGICAL STATE UNIVERSITY

BANANA FIBER EXTRACTION MACHINE 28

Figure 3.9 Distribution of Production for Banana by Region: Philippines, 2017

Figure 3.10 Distribution of Production for Banana by Variety: Philippines, 2017

Source: Crop Statistics of the Philippines (2013-2017)

DON HONORIO VENTURA TECHNOLOGICAL STATE UNIVERSITY

BANANA FIBER EXTRACTION MACHINE 29

Table 3.1 Volume of Production for Banana by Region: 2013-2017 (in metric tons)

Table 3.2 Area Planted for Banana by Region: 2013-2017 (in hectares)

DON HONORIO VENTURA TECHNOLOGICAL STATE UNIVERSITY

BANANA FIBER EXTRACTION MACHINE 30

Table 3.3 Number of Bearing Hills for Banana by Region: 2013-2017

Source: Crop Statistics of the Philippines (2013-2017)

DON HONORIO VENTURA TECHNOLOGICAL STATE UNIVERSITY

BANANA FIBER EXTRACTION MACHINE 31

3.3.2 Philippine Textile Research Institute (DOST)

With the help of Mr Edwardo M. Marin (Science Research Specialist II of

PTRI), the researchers of the study acquired the data regarding the possible

products of the fiber in the textile industry. They also learnt the mechanical

properties as the physical properties of different varieties of banana cultivars.

3.3.2.1 Physico-chemical properties of decorticated fibers

Although all the banana fibers under investigation belong to genus Musa,

their physico-chemical characteristics vary to some extent. The important physico-

chemical properties of the decorticated banana varieties are presented in the table

below.

Tensile Strength,

Variety RGC% Fineness, Denier

kgf-m/g

Bongolan 42.85 b 30.89 b 74.40 ab

Lakatan 43.84 b 36.47 c 85.27 c

Pakil 47.33 b 32.59 bc 93.35 c

Saba 40.03 a 29.84 b 83.33 bc

Saksik 47.03 c 23.03 a 91.75 c

Tordan 47.97 c 32.51 bc 67.69 a

Cavendish 40.29 c 35.45 c 67. 20 a

Table 3.4

DON HONORIO VENTURA TECHNOLOGICAL STATE UNIVERSITY

BANANA FIBER EXTRACTION MACHINE 32

Figure 3.11 Different Kinds of Fiber from PTRI

DON HONORIO VENTURA TECHNOLOGICAL STATE UNIVERSITY

BANANA FIBER EXTRACTION MACHINE 33

3.3.3 Interview

The interview was conducted with Noynoy Engle, an agriculturist and the

owner of the Garden Grill Farm. According to him, the one hectare farm started

last 2012 containing 900 banana plants majority of which is cardava. He revealed

that in every pile, there should be only three banana plants, the mother, follower,

and the sucker (suli). Also, he mentioned that banana bear fruit after 18 months,

and the peak season is during the rainy days which starts at August.

The researchers at the same time confirmed that after the fruit has been

obtained, the banana plant must be cut down to give space for another one, and the

plant will only go as waste or making it only a fertilizer cited by Agriculturist

Noynoy. Weekly, the numbers of fully grown pseudostem being cut are 20 pieces.

Figure 3.12 Interview

DON HONORIO VENTURA TECHNOLOGICAL STATE UNIVERSITY

BANANA FIBER EXTRACTION MACHINE 34

3.3.4 Fabrication Stage

After 20 days of construction, the machine was fully fabricated.

Figure 3.13 Final Product

DON HONORIO VENTURA TECHNOLOGICAL STATE UNIVERSITY

BANANA FIBER EXTRACTION MACHINE 35

3.3.5 Testing Stage

Testing Procedure:

The main steps of the testing process were as follows:

1. The feed system has an initial blade clearance of 5mm, and the nuts of

the carriage assembly secured.

2. The motor supplying power to the drum was started and its speed slowly

increased to approximately 700 rpm.

3. The pseudostem sheath were weighed and fed into the feeding roll, for a

period of 2s. For safety reasons, only a portion of the sheaths were processed,

while the remaining piece served as a handle. To account for the unprocessed

material, the remaining stumps were cut free from the fibres and the difference in

mass measured.

4. The motor was then switched off and the clearance adjusted. The entire

procedure was repeated for clearances of 2 mm and 1 mm.

5. The fiber extracted was sun dried for half day, to get rid of its remaining

moisture content. Then, it was weighed.

Banana Sheath Duration Weight Input Excess Weight

1 26 s 0.5625 kg 0.1875 kg

2 27 s 0.5625 kg 0.0625 kg

3 24 s 0.75 kg 0.0625 kg

4 24 s 0.8125 kg 0.25 kg

5 17.5 s 0.3125 kg 0.3125 kg

DON HONORIO VENTURA TECHNOLOGICAL STATE UNIVERSITY

BANANA FIBER EXTRACTION MACHINE 36

6 22.5 s 0.5 kg 0.125 kg

7 40 s 0.75 kg 0.25 kg

8 39.2 s 1 kg 0.25 kg

9 17 s 0.3125 kg 0.0625 kg

10 29.5 s 0.5 kg 0.125 kg

Data:

Total Weight Input = 6.0625 kg

Total Weight Excess = 1.6875 kg

Total Weight Output = 0.375 kg

Formula:

Wnet=

% Yielding =

Wnet= (6.0625 – 1.6875) kg

Wnet= 4.375 kg

% Yielding 8.57 %

DON HONORIO VENTURA TECHNOLOGICAL STATE UNIVERSITY

Вам также может понравиться

- Development of Multipurpose Fiber Extracting Machine FinalДокумент25 страницDevelopment of Multipurpose Fiber Extracting Machine FinalZandro A. GagoteОценок пока нет

- Automated Banana Fiber Extraction MachineДокумент4 страницыAutomated Banana Fiber Extraction MachineChristian TabonОценок пока нет

- Paes 204 Mechanical Rice Thresher SpecificationsДокумент8 страницPaes 204 Mechanical Rice Thresher SpecificationsEdsel Jay RaperОценок пока нет

- Philippine Agricultural Engineering Standard Paes 420:2002 Agricultural Structures - Farm Workshop and Machinery ShedДокумент10 страницPhilippine Agricultural Engineering Standard Paes 420:2002 Agricultural Structures - Farm Workshop and Machinery ShedMario Labitad Anore Jr.Оценок пока нет

- Continuing Professional Development (CPD) CPD Council For Agricultural and Biosystems Engineering List of Accredited ProgramsДокумент3 страницыContinuing Professional Development (CPD) CPD Council For Agricultural and Biosystems Engineering List of Accredited ProgramsPRC BoardОценок пока нет

- Practice Problems in Seeders/Crop Planters: NoteДокумент2 страницыPractice Problems in Seeders/Crop Planters: NoteFelizardo Guianan0% (1)

- What Is Agricultural Material HandlingДокумент4 страницыWhat Is Agricultural Material HandlingpawanОценок пока нет

- Design, Development and Fabrication of Precision Corn Seeder (Title Defense)Документ14 страницDesign, Development and Fabrication of Precision Corn Seeder (Title Defense)BlessyJoyPunsalanОценок пока нет

- AME-Chap17-Economic Analysis of Agricultural MachinesДокумент5 страницAME-Chap17-Economic Analysis of Agricultural MachinesJordan YapОценок пока нет

- Water Hyacinth Fiber Sorting and Cutting Machine For Handicraft and Furniture ProductsДокумент15 страницWater Hyacinth Fiber Sorting and Cutting Machine For Handicraft and Furniture ProductsCrystian Kobee EmpeynadoОценок пока нет

- Agricultural Engineering ReviewerДокумент5 страницAgricultural Engineering ReviewerTina Soriano100% (1)

- Clsu Abe Review Abe LawsДокумент208 страницClsu Abe Review Abe LawsMicah Tanjusay PonsicaОценок пока нет

- Pandanus Leaves S Litter PresserДокумент6 страницPandanus Leaves S Litter PresserEdson BachaОценок пока нет

- Usep Paper - Development of A Mechanical Mango Fruit PickerДокумент10 страницUsep Paper - Development of A Mechanical Mango Fruit PickerRoger Montepio100% (1)

- Area 1Документ7 страницArea 1Krisher DhayОценок пока нет

- PAES 129-2002 Electric Motor - SpecificationsДокумент22 страницыPAES 129-2002 Electric Motor - SpecificationsRosei Duites100% (1)

- Paes 201 Heated-Air Mechanical Grain Dryer SpecsДокумент8 страницPaes 201 Heated-Air Mechanical Grain Dryer SpecsEdsel Jay RaperОценок пока нет

- Module in ABE 311 SOM 2 P2 3 8Документ20 страницModule in ABE 311 SOM 2 P2 3 8Clarisse DiconОценок пока нет

- Agricultural Power, Machinery and Allied Subjects Part 1Документ27 страницAgricultural Power, Machinery and Allied Subjects Part 1agricultural and biosystems engineeringОценок пока нет

- ProblemsДокумент25 страницProblemsJohn Paul JuegoОценок пока нет

- I-1e FarmMech 1-19Документ20 страницI-1e FarmMech 1-19Hanz Learny LalisanОценок пока нет

- ECO Agricultural Machinery - Proposal and ProblemsДокумент18 страницECO Agricultural Machinery - Proposal and ProblemsRyan Carlo Conde0% (1)

- Area Ii With AnswersДокумент16 страницArea Ii With AnswersJUNDAVE BORJAОценок пока нет

- Project Report On Field Testing and Performance Evaluation of Axial Flow Combine Harvester in Paddy CropДокумент47 страницProject Report On Field Testing and Performance Evaluation of Axial Flow Combine Harvester in Paddy CropMadhuri Gupta100% (5)

- Agricultural Machinery and EquipmentДокумент42 страницыAgricultural Machinery and EquipmentIremar Joseph AmplayoОценок пока нет

- Final Write Up - Dehusking Machine-2020Документ55 страницFinal Write Up - Dehusking Machine-2020Zainal MohdОценок пока нет

- PAES Agricultural Engineering StandardsДокумент5 страницPAES Agricultural Engineering StandardsYsmael Alongan B. MangorsiОценок пока нет

- Lab 7 Sprinkler EkitДокумент17 страницLab 7 Sprinkler EkitRuby Ekit100% (1)

- Design and Evaluation of a Bignay Juice ExtractorДокумент11 страницDesign and Evaluation of a Bignay Juice ExtractorPatrizaОценок пока нет

- Rasper PDFДокумент6 страницRasper PDFShah WaliullahОценок пока нет

- Preboard - Part I PDFДокумент7 страницPreboard - Part I PDFKelvin Michael A. CrystalОценок пока нет

- Abe 424 Farm Structures and Environmental ControlДокумент42 страницыAbe 424 Farm Structures and Environmental ControlAmabi SilasОценок пока нет

- Circuitous Plowing Pattern 270 Degree TurnsДокумент3 страницыCircuitous Plowing Pattern 270 Degree Turnsditz_n90805Оценок пока нет

- FTECH 3310 Food Engg Lecture 1Документ11 страницFTECH 3310 Food Engg Lecture 1Joann DavidОценок пока нет

- 3 - Review Notes - AGRICULTURAL MECHANIZATIONДокумент12 страниц3 - Review Notes - AGRICULTURAL MECHANIZATIONJoey camalitaОценок пока нет

- Agri Engineering Profession Roadmap PresentationДокумент24 страницыAgri Engineering Profession Roadmap PresentationKaren Joy BabidaОценок пока нет

- Preboards Exam Part II Answer Key 1Документ12 страницPreboards Exam Part II Answer Key 1Peter ian AutenticoОценок пока нет

- Part 1 Mock Questions-YeahДокумент4 страницыPart 1 Mock Questions-YeahMisheru Misaki AyuzawaОценок пока нет

- Innovation of Selected Root Vegetable Cleaner With Recirculating Filtered Water and Dryer Blower 3Документ36 страницInnovation of Selected Root Vegetable Cleaner With Recirculating Filtered Water and Dryer Blower 3Maryam LagorzaОценок пока нет

- Crop Protection Machinery GuideДокумент12 страницCrop Protection Machinery GuideKenth Reynard MuñozОценок пока нет

- Reference2 - Development of An Automated Coconut Scraping MachineДокумент14 страницReference2 - Development of An Automated Coconut Scraping MachineRenz Callejo100% (1)

- Department of Civil EngineeringДокумент6 страницDepartment of Civil EngineeringNaa WinОценок пока нет

- Acoustic/Ultrasonic Properties of Fresh ProduceДокумент14 страницAcoustic/Ultrasonic Properties of Fresh ProduceAlvin Jay Castillo100% (1)

- Chapter 1 and 2-Very-Very-FinalДокумент20 страницChapter 1 and 2-Very-Very-FinalCharlyn FloresОценок пока нет

- Status of Agricultural Waste and Utilization in The PhilippinesДокумент36 страницStatus of Agricultural Waste and Utilization in The PhilippinesaefОценок пока нет

- Agri Paper 1 Soil ErosionДокумент26 страницAgri Paper 1 Soil Erosionnitin khariОценок пока нет

- Criteria for Selecting Small Water Impounding Project SitesДокумент24 страницыCriteria for Selecting Small Water Impounding Project SitesNeil ClimacoОценок пока нет

- Seatwork6 Withanswer Final PDFДокумент2 страницыSeatwork6 Withanswer Final PDFLester John PrecillasОценок пока нет

- Full Text Agricultural Engineer Board ExamДокумент2 страницыFull Text Agricultural Engineer Board ExamTheSummitExpressОценок пока нет

- Advert - Industrial Practical TrainingДокумент2 страницыAdvert - Industrial Practical TrainingAmosi Amosi100% (1)

- 138 ReviewerДокумент247 страниц138 Reviewerkayle navaja0% (1)

- Preboard Exam 2007 Part 3Документ9 страницPreboard Exam 2007 Part 3Jirah Mae T. CATALU�AОценок пока нет

- Definition of MechanizationДокумент5 страницDefinition of Mechanizationtibem100% (1)

- Design & Fabrication of Portable Organic Waste Chopping Machine To Obtain CompostДокумент8 страницDesign & Fabrication of Portable Organic Waste Chopping Machine To Obtain CompostIJIRSTОценок пока нет

- Machinery TextДокумент25 страницMachinery TextMd Firoz Alam Khan100% (1)

- ABE Review 2022 - AMEДокумент23 страницыABE Review 2022 - AMEJirah Mae T. CATALU�AОценок пока нет

- Design of An Innovative Coconut Grating Machine Using TinkercadДокумент5 страницDesign of An Innovative Coconut Grating Machine Using TinkercadChristopher Ysit100% (1)

- Design and Simulation of Bamboo Sprout Scalding Processing MachineДокумент40 страницDesign and Simulation of Bamboo Sprout Scalding Processing MachineBRYAN DEXTER ARCEОценок пока нет

- Fabrication and Testing of Abaca Fiber DecorticatorДокумент7 страницFabrication and Testing of Abaca Fiber Decorticatorbojik2Оценок пока нет

- Design and Development of Raspador Machine: Ankit J. Desai, Akash B. Chovatiya, Haresh R. GhoniyaДокумент9 страницDesign and Development of Raspador Machine: Ankit J. Desai, Akash B. Chovatiya, Haresh R. GhoniyasarasОценок пока нет

- AlgebraДокумент263 страницыAlgebraeric salesОценок пока нет

- Camote-Q ReviewДокумент219 страницCamote-Q ReviewSam Cunanan100% (1)

- Getting Started with Workplace Health and Safety PoliciesДокумент32 страницыGetting Started with Workplace Health and Safety PoliciesMuhammad SaeedОценок пока нет

- Solution Refresher Pipe 1 2 3 PDFДокумент31 страницаSolution Refresher Pipe 1 2 3 PDFSam CunananОценок пока нет

- Solution Refresher Pipe 1 2 3 PDFДокумент31 страницаSolution Refresher Pipe 1 2 3 PDFSam CunananОценок пока нет

- Camote-Q ReviewДокумент219 страницCamote-Q ReviewSam Cunanan100% (1)

- Steam Table Englishhvv PDFДокумент9 страницSteam Table Englishhvv PDFSam CunananОценок пока нет

- WelcomeДокумент5 страницWelcomeCatОценок пока нет

- Gas Turbine Chapter Explains Brayton Cycle & ComponentsДокумент52 страницыGas Turbine Chapter Explains Brayton Cycle & ComponentsSam CunananОценок пока нет

- MD BY CAPOTE Black and White PDFДокумент1 713 страницMD BY CAPOTE Black and White PDFSam CunananОценок пока нет

- MDSP Set 1Документ32 страницыMDSP Set 1Jan Edward L. Suarez50% (2)

- Gas Turbine Chapter Explains Brayton Cycle & ComponentsДокумент52 страницыGas Turbine Chapter Explains Brayton Cycle & ComponentsSam CunananОценок пока нет

- MD BY CAPOTE Black and White PDFДокумент1 713 страницMD BY CAPOTE Black and White PDFSam CunananОценок пока нет

- MDSP Set 1Документ32 страницыMDSP Set 1Jan Edward L. Suarez50% (2)

- MD BY CAPOTE Black and White PDFДокумент1 713 страницMD BY CAPOTE Black and White PDFSam CunananОценок пока нет

- MATH 109 Basic ProbabilityДокумент5 страницMATH 109 Basic ProbabilitySam CunananОценок пока нет

- MD BY CAPOTE Black and White PDFДокумент1 713 страницMD BY CAPOTE Black and White PDFSam CunananОценок пока нет

- Solution Refresher Pipe 1 2 3 PDFДокумент31 страницаSolution Refresher Pipe 1 2 3 PDFSam CunananОценок пока нет

- Ipcrf 2018Документ24 страницыIpcrf 2018Mich Berdan-DomingoОценок пока нет

- Elementary PDFДокумент399 страницElementary PDFPhilBoardResultsОценок пока нет

- HW01 8th EdДокумент4 страницыHW01 8th EdJM Jusay CarabLeОценок пока нет

- Auto-SF2: InstructionsДокумент101 страницаAuto-SF2: InstructionsSam CunananОценок пока нет

- This Voucher Entitles You To: Tahanan NG PagmamahalДокумент1 страницаThis Voucher Entitles You To: Tahanan NG PagmamahalSam CunananОценок пока нет

- GTX 560 User GuideДокумент31 страницаGTX 560 User GuideSlobodan GaricОценок пока нет

- New Application Adult01 2 PDFДокумент2 страницыNew Application Adult01 2 PDFNerizzah BautistaОценок пока нет

- Thermodynamics 3Документ23 страницыThermodynamics 3Jo Ces27% (11)

- Coverendoackabst PrintingДокумент10 страницCoverendoackabst PrintingSam CunananОценок пока нет

- ISO Letterhead 2Документ2 страницыISO Letterhead 2Sam CunananОценок пока нет

- DepEd VISION, MISSION, VALUES at San Carlos ElementaryДокумент5 страницDepEd VISION, MISSION, VALUES at San Carlos ElementarySam CunananОценок пока нет

- Family Day and Christmas PartyДокумент1 страницаFamily Day and Christmas PartySam CunananОценок пока нет

- BCMV SeedsДокумент8 страницBCMV SeedsTriEka HeryaОценок пока нет

- PhotoperiodismДокумент14 страницPhotoperiodismArun Sreenivasan IyengarОценок пока нет

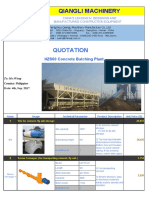

- HZS60 Concrete Batching Plant QuotationДокумент5 страницHZS60 Concrete Batching Plant QuotationsherwinОценок пока нет

- (TH) Practice Test - MarchДокумент17 страниц(TH) Practice Test - MarchThuyanhdanОценок пока нет

- 3-Water Leaf or Ceylon Spinach (Ok)Документ2 страницы3-Water Leaf or Ceylon Spinach (Ok)Gandikota Brahmani - M.Sc. Horticulture (VS)Оценок пока нет

- Sexual Propagation - Advantages and DisadvantagesДокумент2 страницыSexual Propagation - Advantages and DisadvantagesAR Mics100% (1)

- TTPB23 Abridged 24Документ24 страницыTTPB23 Abridged 24AbdullahОценок пока нет

- Your recycling collection calendarДокумент2 страницыYour recycling collection calendarLukeОценок пока нет

- RDO 1 Zonal ValuesДокумент850 страницRDO 1 Zonal ValuesAssessor Pagudpud82% (11)

- Polygenic InheritanceДокумент2 страницыPolygenic InheritanceAppuОценок пока нет

- Chapter 14Документ35 страницChapter 14nfacmaОценок пока нет

- Edexcel Cert Single Award Biol SOW KBI0 CVRДокумент31 страницаEdexcel Cert Single Award Biol SOW KBI0 CVRFathimath IrashaОценок пока нет

- Neem (Azadirachta Indica) : Prehistory To Contemporary Medicinal Uses To HumankindДокумент2 страницыNeem (Azadirachta Indica) : Prehistory To Contemporary Medicinal Uses To HumankindV Ardent TechnocratesОценок пока нет

- SEAC-AGENDA-0000000054: 22.number of Buildings & Its ConfigurationДокумент143 страницыSEAC-AGENDA-0000000054: 22.number of Buildings & Its ConfigurationChaitanya IdateОценок пока нет

- Data Base Questions PhotosynthesisДокумент10 страницData Base Questions PhotosynthesisValeCalderónОценок пока нет

- Microfiche Reference Library Details BETTER FARMING SERIES on BananasДокумент36 страницMicrofiche Reference Library Details BETTER FARMING SERIES on BananasPat BomilleОценок пока нет

- Garpenberg 20030407Документ7 страницGarpenberg 20030407Nils Johan BolinОценок пока нет

- Week 6Документ28 страницWeek 6api-295423685Оценок пока нет

- Biodiversity in Wild Vegetables of Konkan Region - MaharashtraДокумент16 страницBiodiversity in Wild Vegetables of Konkan Region - MaharashtraThiên ĐịaОценок пока нет

- Jurnal Aroma TerapiДокумент246 страницJurnal Aroma Terapidewi100% (1)

- Antimicrobial Activity of Carica Papaya (Pawpaw Leaf) On Some PatДокумент13 страницAntimicrobial Activity of Carica Papaya (Pawpaw Leaf) On Some PatMargaretha RennyОценок пока нет

- Miscanthus FloridulusДокумент3 страницыMiscanthus FloridulusAnonymous uPsfLxPMDYОценок пока нет

- Dihybrid CrossДокумент2 страницыDihybrid CrossAditi KathaitОценок пока нет

- Needs Assessment QuestionnaireДокумент6 страницNeeds Assessment QuestionnaireREY PEPITO100% (3)

- I Q Test FinalДокумент51 страницаI Q Test FinalKapil KumarОценок пока нет

- Plant Extracts For Purification of Industrial Waste WaterДокумент20 страницPlant Extracts For Purification of Industrial Waste WaterdscaoОценок пока нет

- Kerala CuisineДокумент19 страницKerala CuisineApoorva Khurjekar100% (1)

- Lemon Grass Scented CandleДокумент4 страницыLemon Grass Scented CandlePaul Victor TamuriaОценок пока нет

- Herbal MedicineДокумент8 страницHerbal MedicineStephanie Joy EscalaОценок пока нет

- Meghalaya State InformationДокумент5 страницMeghalaya State InformationCHAITANYA SIVA100% (1)