Академический Документы

Профессиональный Документы

Культура Документы

Getter PDF

Загружено:

Salivahan Maitra0 оценок0% нашли этот документ полезным (0 голосов)

7 просмотров7 страницОригинальное название

getter.pdf

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

7 просмотров7 страницGetter PDF

Загружено:

Salivahan MaitraАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 7

Gettering

Gettering is a process by which unwanted impurities are removed by providing

an alternative location (a “getter”) where they prefer to reside (their energy is

lower).

Gettering originated in vaccuum tubes, where Ti was used to getter trace rem-

nant gases.

Similarly in Si ICs we may want to get rid of unwanted trace elements.

For integrated circuits, the primary unwanted impurities are metals, whi

Increase recombination.

— Increase junction leakage.

— Reduce life-times (reduces solar cell efficiency, DRAM efficiency).

~ Reduce in BJT’s.

« Segregate to interfaces resulting in interface states.

~ Noise.

— Threshold voltage shifts by trapping charges.

— Degraded Si/SiO» interface.

© Precipitate.

— Alternative conducting paths.

It is desirable, therefore to remove metals from the active device regions to

either the backside or to the bulk of the wafer.

Sources of unwanted impurities include:

© Initial melt

Chemicals (cleaning /etching solutions, photoresist)

¢ Handling (wafer tracks, tweezers, boxes, particles etc.)

# Process chambers (stainless steel, quartz)

‘The first requirement of successful gettering is providing a region away from

the active device regions to which metals will segregate in a strongly preferential

fashion.

Possible extrinsic getters include:

Damage: Rather than being a distortion within the crystal lattice, the metal

may prefer to be in a damaged region, where it may be satisfying some dangling

bonds, or simply causing less distortion, thereby reducing total free energy.

¢ Mechanical Damage: Roughening with abrasive or scribing with diamond scribe.

¢ Laser Damage: Cleaner. Generates amorphous or polysilicon region.

«Ion Implantation (Ar ions): Generates an amorphous layer and high density

of Ar inhibits recrystallization.

Film Deposition: — Preferential segregation and grain boundaries.

Polysilicon Films: Grain boundaries provide gettering sites.

« Deposited Nitride Film: Not as effective but has been used.

Heavy Doping: _ Preferential segregation to heavily doped regions due to Fermi

level effects, pairing, decoration of precipitates.

« Phosphorus: N-type doping most effective.

Outdiffusion: Reaction of metals to form volatile compounds.

e HCl: Used in inert or oxidizing ambient.

Important Note: Getter has to be stable over the entire process.

For example, if ion-implantation damage anneals out during subsequent process-

ing, the previously gettered metals are re-released. (Reason for use of Ar rather

than Si implantation.)

‘The second requirement for gettering is that the target impurities must be able

to diffuse from active device regions to getter (often this means through full wafer

thickness).

The diffusion coefficients of metals in Si is generally orders of magnitude higher

than B or P etc. (dopants), but there is a large range.

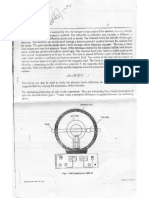

1200 1000_ 800. 600

DIFFUSION COEFFICIENT (cm2/sec)

06 0.7 08 09 10 11 12

1000/T (K")

Slow diffusers are difficult to remove, but also less likely to arise from contami-

nation late in process.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Symon-Mechanics Text PDFДокумент570 страницSymon-Mechanics Text PDFSalivahan Maitra100% (1)

- Guter 2009Документ4 страницыGuter 2009Salivahan MaitraОценок пока нет

- Basic Planar ProcessДокумент15 страницBasic Planar ProcessSmitha KollerahithluОценок пока нет

- EmДокумент8 страницEmSalivahan MaitraОценок пока нет

- Basic Planar ProcessДокумент15 страницBasic Planar ProcessSmitha KollerahithluОценок пока нет

- p4 Series ComparisonДокумент1 страницаp4 Series ComparisonSalivahan MaitraОценок пока нет

- (Ebook - PDF) A History of Electricity & Magnetism - HerbertДокумент343 страницы(Ebook - PDF) A History of Electricity & Magnetism - HerbertOsman Atam100% (5)