Академический Документы

Профессиональный Документы

Культура Документы

PRESSURE DESIGN AND REINFORCEMENT OF STRAIGHT PIPES AND BRANCH CONNECTIONS

Загружено:

Umar AslamИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

PRESSURE DESIGN AND REINFORCEMENT OF STRAIGHT PIPES AND BRANCH CONNECTIONS

Загружено:

Umar AslamАвторское право:

Доступные форматы

PRESSURE DESIGN STRAIGHT PIPE ( RUN PIPE)

GENERAL

tm=t+c

Where

tm minimum required thickness, including mechanical, corrosion, & erosion allowances, mm. 10.86

t pressure design thickness for internal pressure, mm. 9.36

c sum of the mechanical allowances (thread or groove depth) plus corrosion & erosion allowances, mm. 1.5

STRAIGHT PIPE THICKNESS UNDER INTERNAL PRESSURE

1. t=(PxD)/2(SxExW+PxY) 9.36 2. t=P(d+2c)/2[SxExW-P(1-Y)] 8.87

Where

P Internal Design Gauge Pressure, N/mm2. 4.2

D Outside Diameter of Pipe, mm. 406.4

S Stress Value for Material, N/mm2. 88.25

E Quality Factor For Longitudinal Weld Joints in Pipes. 1

W Weld Joint Strength Reduction Factor. 1

Y Coefficient for Materials. 0.7

d Inside Diameter of Pipe, mm. 364.40

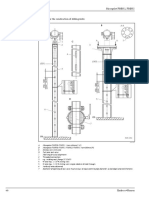

REINFORCEMENT OF WELDED BRANCH CONNECTIONS

h subscript referring to run or header.

b subscript referring to branch.

Th nominal thickness of run or header. 21

Tb nominal thickness of branch. 13

d1 effective length removed from pipe at branch, mm. 199.35

d2 "half width" of reinforcement zone, mm. 199.35

L4 height of reinforcement zone outside of run pipe, mm. 42.19

Tb branch pipe thickness, mm. 11.38

Th header pipe thickness, mm. 18.38

Tr minimum thickness of reinforcing pad, mm. 18.4

th pressure design thickness of run pipe, mm. 9.36

tb pressure design thickness of branch pipe, mm. 5.12

β smaller angle between axis of branch and run. 90

Db outside diameter of branch pipe, mm. 219.10

Dh outside diameter of run pipe, mm. 406.40

1. d1 = [Db - 2(Tb - c)]/sin β 199.35

2. d2= greater of d1 or (Tb - c) + (Th - c) + d1/2 126.43

Therefore d2 199.35

3. L4 = lesser of 2.5(Th - c), mm or 42.19

2.5(Tb - c) + Tr, mm. 43.09

REQUIRED REINFORCEMENT AREA

1. A1 = thd1(2 - sinβ), mm2 1865.70

AVAILABLE AREA

A2 + A3 + A4 >= A1

Where

A2 Area resulting from excess thickness in the run pipe wall, mm2. 1498.33

A3 Area resulting from excess thickness in the branch pipe wall, mm2. 401.51

A4 Area of other metal provided by welds & properly attached reinforcement, mm 2. -34.14

Dr Outside diameter of reinforcement ring, mm. 406.4

Sr Stress value for reinforcement ring material, N/mm2. 88.25

ha Height of the fillet weld between run pipe & reinforcement ring, mm. 3.00

hb Height of the fillet weld between branch pipe & reinforcement ring, mm. 3.00

1. A2 = (2d2 - d1)(Th - th -c) 1498.33

2. A3 = 2L4(Tb - tb - c)/sinβ 401.51

3. A2 + A3 1899.85

Additional reinforcement required NO

A1 - ( A2 + A3 ) <= A4 -34.14

1. Area of reinforcement ring, mm2. 3441.64

2. Area of fillet weld, mm2. 18.00

NOTES:

1. All values are rounded of upto two decimal places.

2. Some nomenclatures which are not present in the figure have been added for carrying out calculations.

3. Height and base of the fillet welds is assumed to be equal.

4. d2 in any case shall not be greater than Dh.

PRESSURE DESIGN STRAIGHT PIPE ( BRANCH PIPE)

GENERAL

tm=t+c

Where

tm minimum required thickness, including mechanical, corrosion, & erosion allowances, mm. 6.62

t pressure design thickness for internal pressure, mm. 5.12

c sum of the mechanical allowances (thread or groove depth) plus corrosion & erosion allowances, mm. 1.5

STRAIGHT PIPE THICKNESS UNDER INTERNAL PRESSURE

1. t=(PxD)/2(SxExW+PxY) 5.12 2. t=P(d+2c)/2[SxExW-P(1-Y)] 4.80

Where

P Internal Design Gauge Pressure, N/mm2. 4.20

D Outside Diameter of Pipe, mm. 219.1

S Stress Value for Material, N/mm2. 88.25

E Quality Factor For Longitudinal Weld Joints in Pipes. 1

W Weld Joint Strength Reduction Factor. 1

Y Coefficient for Materials. 0.4

d Inside Diameter of Pipe, mm. 193.10

Вам также может понравиться

- Branch RF CalcДокумент6 страницBranch RF CalcHarish Harish0% (1)

- Calculation of PipeReinforcement ASMEB31 1Документ4 страницыCalculation of PipeReinforcement ASMEB31 1threedlabsОценок пока нет

- Calculation of Pipe Reinforcement ASME B31 3Документ4 страницыCalculation of Pipe Reinforcement ASME B31 3ArmandoZacariasAcosta0% (1)

- Calculation of RC PAD2Документ1 страницаCalculation of RC PAD2m 418Оценок пока нет

- Pressure Design Straight Pipe (Run Pipe)Документ6 страницPressure Design Straight Pipe (Run Pipe)gembirasekaliОценок пока нет

- Pipe Thickness & RF Pad Calculations As Per Asme b313Документ3 страницыPipe Thickness & RF Pad Calculations As Per Asme b313Gaurav BhendeОценок пока нет

- New - Reinforcement of NozzleДокумент24 страницыNew - Reinforcement of NozzleVaniya GoelОценок пока нет

- Asme Sec 8 Div 1 - App 1-10Документ11 страницAsme Sec 8 Div 1 - App 1-10BibinBabuОценок пока нет

- Checking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumberДокумент1 страницаChecking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumbershazanОценок пока нет

- Hot Tapping Split Tee SpecificationДокумент19 страницHot Tapping Split Tee SpecificationAli ClubistОценок пока нет

- Internal Pipe Distributor Design ProcedureДокумент5 страницInternal Pipe Distributor Design Proceduresenthil kumarОценок пока нет

- Clearance CalculationДокумент12 страницClearance CalculationshazanОценок пока нет

- Dummy Leg & Trunnion Calculation Sheet: Pipe Dia. MM Pipe Nom. THK (Tnom) MMДокумент4 страницыDummy Leg & Trunnion Calculation Sheet: Pipe Dia. MM Pipe Nom. THK (Tnom) MMashish shrivastav50% (2)

- EJMA Calculation Report For Cryostat DNB 7HL9UC v1 3Документ25 страницEJMA Calculation Report For Cryostat DNB 7HL9UC v1 3zstОценок пока нет

- Nozzle Design CalculationДокумент1 страницаNozzle Design CalculationSachin5586Оценок пока нет

- Calculations For: Calculations No. Asme Viii Div 1 Ed 2019Документ21 страницаCalculations For: Calculations No. Asme Viii Div 1 Ed 2019David Vanegas100% (1)

- Bolt Torque Calculation for Girth Flange-T-13311 - D2/D3: G * b * π * 2 g A Документ2 страницыBolt Torque Calculation for Girth Flange-T-13311 - D2/D3: G * b * π * 2 g A Manoj MulikОценок пока нет

- Calculator - U Tubes - HSA & QtyДокумент4 страницыCalculator - U Tubes - HSA & QtyRey Fiedacan100% (1)

- Check 18Документ6 страницCheck 18Anonymous qBwHKusОценок пока нет

- Design Procedure For Aes He PDFДокумент30 страницDesign Procedure For Aes He PDFRyan Goh Chuang HongОценок пока нет

- Tolerance-E and Chord LengthДокумент2 страницыTolerance-E and Chord LengthLcm TnlОценок пока нет

- Shell Thickness CalculationsДокумент2 страницыShell Thickness CalculationsskocogluОценок пока нет

- Asme b31 3 03 PDFДокумент3 страницыAsme b31 3 03 PDFAtallah BoufatahОценок пока нет

- Calculo Brida Ejemplo PV - EliteДокумент8 страницCalculo Brida Ejemplo PV - ElitePedro Montes MarinОценок пока нет

- Hydrostatic Test Pressure Calculation: Pipe DataДокумент2 страницыHydrostatic Test Pressure Calculation: Pipe DataAkram AlhaddadОценок пока нет

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantДокумент49 страницDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536Оценок пока нет

- Cálculo Flange ASME VIII 1 Apendice 2Документ5 страницCálculo Flange ASME VIII 1 Apendice 2Anonymous gfR3btyUОценок пока нет

- Pipíng & Stress Analysis Ref - Sofware Caesar II. 06-09-2017 Autor - Ing R L Morard - U T N 1Документ9 страницPipíng & Stress Analysis Ref - Sofware Caesar II. 06-09-2017 Autor - Ing R L Morard - U T N 1Oswaldo GuerraОценок пока нет

- Stillwell Pipe ArrangementДокумент1 страницаStillwell Pipe ArrangementVishalDhimanОценок пока нет

- Nozzle Reinforcement Calculations: HH1&HH2 (Hand Hole) : Description Regulation Formula Symbol Value UnitДокумент1 страницаNozzle Reinforcement Calculations: HH1&HH2 (Hand Hole) : Description Regulation Formula Symbol Value Unitmiteshpatel191Оценок пока нет

- Saddle AnalysisДокумент17 страницSaddle AnalysisPEJU0007Оценок пока нет

- Nozzle ProДокумент3 страницыNozzle Projojo_323Оценок пока нет

- PCC1 - Addendum - 31210130 (Feb 2013) - GM1-001-G0000-MS-7880-00003Документ2 страницыPCC1 - Addendum - 31210130 (Feb 2013) - GM1-001-G0000-MS-7880-00003Abhay UpadhyayОценок пока нет

- Narrow Face Flange - Slip On Hub TypeДокумент17 страницNarrow Face Flange - Slip On Hub TypeEng-CalculationsОценок пока нет

- Flange calculation as per ASME Section VIIIДокумент9 страницFlange calculation as per ASME Section VIIIDarshan PanchalОценок пока нет

- Tank Baffle Thickness Calculation: Baffle Provided Thickness Is Greater Than Require Thickness Hecnc Design Is SafeДокумент1 страницаTank Baffle Thickness Calculation: Baffle Provided Thickness Is Greater Than Require Thickness Hecnc Design Is SafeABIDEEN BAMNEОценок пока нет

- Nozzle Reinforcement Calculation Excel SheetДокумент3 страницыNozzle Reinforcement Calculation Excel Sheetramesh punjabiОценок пока нет

- Cs & Las Impact Req - Asme Sec Viii Div 2Документ16 страницCs & Las Impact Req - Asme Sec Viii Div 2AmitNarayanNitnawareОценок пока нет

- Tailing LugДокумент2 страницыTailing Lugjagannadha varmaОценок пока нет

- Support Lug CalculationsДокумент26 страницSupport Lug CalculationsDinesh ChouguleОценок пока нет

- PV Elite Vessel Analysis Program HorizontalДокумент55 страницPV Elite Vessel Analysis Program HorizontalMarizta Perdani PutriОценок пока нет

- Spherical Shells en 13445-3 - 7.4.3Документ3 страницыSpherical Shells en 13445-3 - 7.4.3met-calc100% (1)

- ASME Formula DerivationДокумент1 страницаASME Formula Derivationvm153748763Оценок пока нет

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Документ32 страницыPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoОценок пока нет

- Modification Thickness of A FlangeДокумент3 страницыModification Thickness of A FlangePeter PerezОценок пока нет

- Determine Shell ThicknessДокумент53 страницыDetermine Shell ThicknessRajul MuraliОценок пока нет

- Teknologi Dan Rekayasa: Principles of WeldingДокумент23 страницыTeknologi Dan Rekayasa: Principles of WeldingBouzaida MaherОценок пока нет

- Lesson 09 UW16 UG37 New2Документ38 страницLesson 09 UW16 UG37 New2Kandregula Mohan BabuОценок пока нет

- Mozzle Repad Design ToolДокумент2 страницыMozzle Repad Design ToolSiddiqui Muhammad AshfaqueОценок пока нет

- Cylindrical ShellsДокумент3 страницыCylindrical ShellsEng-CalculationsОценок пока нет

- Trunnion Check Calculation (Onsite) : Page No: Contract No: System NoДокумент2 страницыTrunnion Check Calculation (Onsite) : Page No: Contract No: System NoJ A S JAS0% (1)

- 2520 z000 STD 1780 06 - B Anchor Bolt DetailДокумент2 страницы2520 z000 STD 1780 06 - B Anchor Bolt Detailabdul mujeebОценок пока нет

- Flange Pad CalcsДокумент4 страницыFlange Pad CalcstomОценок пока нет

- H H Optimum 0,2: Instructions For Using NomogramДокумент4 страницыH H Optimum 0,2: Instructions For Using NomogrammithunjobsОценок пока нет

- Vortex Shedding Load On PipingДокумент1 страницаVortex Shedding Load On Pipingananyo_sengupta100% (1)

- Stress in ASME Pressure Vessels, Boilers, and Nuclear ComponentsОт EverandStress in ASME Pressure Vessels, Boilers, and Nuclear ComponentsОценок пока нет

- Calculation of Pipe Reinforcement Asme b31 3Документ3 страницыCalculation of Pipe Reinforcement Asme b31 3KomedianTunggalОценок пока нет

- Calculation of Pipe Reinforcement ASME B31.3Документ9 страницCalculation of Pipe Reinforcement ASME B31.3yhnsharma80% (5)

- CFD Simulation of MSW Combustion and SNCR in A Commercial IncineratorДокумент10 страницCFD Simulation of MSW Combustion and SNCR in A Commercial Incineratorvitor_alberto_7Оценок пока нет

- Sur - Erection BOQ - Electr Equipm - RevAДокумент11 страницSur - Erection BOQ - Electr Equipm - RevAshaikhsajid242100% (1)

- Sika Hydrotite CJ-Type 2012-01-1Документ5 страницSika Hydrotite CJ-Type 2012-01-1pandavision76Оценок пока нет

- Mechanical equipment schedule and legendДокумент2 страницыMechanical equipment schedule and legendarief bahtiarОценок пока нет

- Bulk BOQUpload TemplateДокумент12 страницBulk BOQUpload TemplatemargamvivekkumarОценок пока нет

- Powder Metallurgy: Dr. Chaitanya Sharma Phd. Iit RoorkeeДокумент46 страницPowder Metallurgy: Dr. Chaitanya Sharma Phd. Iit RoorkeeShivam DixitОценок пока нет

- Raceways, Boxes and FittingsДокумент10 страницRaceways, Boxes and FittingssallammohamedОценок пока нет

- CAT Engine Driving TipsДокумент2 страницыCAT Engine Driving Tipsjinxy5779Оценок пока нет

- Appendix A References: EM 1110-2-2000 1 Feb 94Документ4 страницыAppendix A References: EM 1110-2-2000 1 Feb 94ماقوريОценок пока нет

- Science ProbeДокумент258 страницScience ProbeoakesmОценок пока нет

- Mechanical One Line NotesДокумент35 страницMechanical One Line NotesVikky DhapodkarОценок пока нет

- Tank ComponentsДокумент12 страницTank Componentsstefanovicana1Оценок пока нет

- Strengthening Mechanisms PDFДокумент11 страницStrengthening Mechanisms PDFSelva BabuОценок пока нет

- Hdpe Ips Submittal PDFДокумент2 страницыHdpe Ips Submittal PDFJESUS HUAMANIОценок пока нет

- Rexroth Hi DR Valves GuideДокумент2 страницыRexroth Hi DR Valves GuideJesus OsunaОценок пока нет

- Variables For Welding 11-3-2016 - 264B1DF6 PDFДокумент2 страницыVariables For Welding 11-3-2016 - 264B1DF6 PDFSameh AminОценок пока нет

- EV Battery Disposal and EДокумент3 страницыEV Battery Disposal and EAvnip Sharma100% (1)

- Vibration - Drilling DynamicsДокумент41 страницаVibration - Drilling DynamicsKaleem Ullah100% (1)

- ACI 211.1 - Mix Deisgn of ConcreteДокумент7 страницACI 211.1 - Mix Deisgn of ConcreteleorОценок пока нет

- Separation of Rayon Thread Thread Using Filter PaperДокумент14 страницSeparation of Rayon Thread Thread Using Filter PaperPandi Selvi ASОценок пока нет

- Thermal Mass Flow Controller Scaling RelationsДокумент13 страницThermal Mass Flow Controller Scaling Relationsccwang100% (1)

- Essppecificações Turbina AuroraДокумент7 страницEssppecificações Turbina AuroraLeonardo PachecoОценок пока нет

- Excavation Removal-PlanДокумент34 страницыExcavation Removal-PlanABDELKADER BENABDALLAHОценок пока нет

- Ryebrassware 0505Документ40 страницRyebrassware 0505api-36492444Оценок пока нет

- MSE Wall Shop Drawing Checklist (Rev 3)Документ3 страницыMSE Wall Shop Drawing Checklist (Rev 3)lcruz117Оценок пока нет

- Colacor 93Документ1 страницаColacor 93mndmattОценок пока нет

- 8 4078a PDFДокумент5 страниц8 4078a PDFarasОценок пока нет

- Guide To VRLA Batteries 1927Документ8 страницGuide To VRLA Batteries 1927caplukОценок пока нет

- Lubricant Viscocities 140hДокумент8 страницLubricant Viscocities 140hPablo Gaspar D'Agostini AmengualОценок пока нет

- Foilroom Full - RepДокумент14 страницFoilroom Full - RepiordacheОценок пока нет