Академический Документы

Профессиональный Документы

Культура Документы

Control Valve Design Aspects For Critical Applications in Petrochemical Plants - Part 1 Valve World 2004 Part I PDF

Загружено:

onizuka-t2263Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Control Valve Design Aspects For Critical Applications in Petrochemical Plants - Part 1 Valve World 2004 Part I PDF

Загружено:

onizuka-t2263Авторское право:

Доступные форматы

Control valve design aspects

for critical applications in

petrochemical plants – part I

By Dipl. Ing. Holger Siemers, SAMSON AG

With three decades of experience in demanding applications, Mr Control valve design and sizing:

Siemers has a deep appreciation of developments and trends in

Part I

sizing control valves. In this paper, he reviews the past, present

1. Accurate sizing & software tools

and future of valve design and sizing, taking all-important issues 2. Energy saving by plant and valve

such as increasing cost pressure and time pressure into account. optimization

3. Debottlenecking: Can the old valve

This paper is presented in two parts: firstly, how to use

do the new job ?

manufacturer independent software to analyze given or

calculated plant parameters in more detail from an overall point Part II

4. Predictable troubles with control valve

of view with a complete power check and optimizing

sizing in case of sub-critical flow

possibilities. Some case studies are also discussed. The second conditions and in case of flashing.

section, scheduled for a future issue, includes information on to 5. Control valve failures & troubleshooting.

6. The hidden valve enemy: Critical outlet

design, size and use severe service control valves with good

velocities need to take priority

performance for long maintenance intervals. Different

philosophies of valve design (plug design), pressure balance Part III

7. Fugitive emissions philosophies for

systems, stem sealing, actuator sizing, cost philosophies for

control valves

“high end” applications are discussed. 8. Actuator sizing philosophies

9. Control valve design and cost philoso-

ership. phies for “high end” applications

The past, present and future of valve End users increasingly complain about mainte-

design and sizing nance costs and the amount of spare parts re-

Control valves - the workhorses of the control quired which are often the highest after-sales valve manufacturer.

loop - mostly have to convert to 1 to 5 kW cost factors. Nowadays, the contradiction Typical for urgent projects is that, to avoid

heat power (the typical pump power in chemi- often arises that consultants are under signifi- penalties, it is taken into account that some

cal plants) and, furthermore, in the HPI sector cant pressure to keep costs low and opt for control valves are destroyed during the start-

to a range between 5 to 200,000 kW heat other priorities: up process even in large projects, whereas

power - the typical power range with high per- lowest cost of investment during a traditional start-up process, a trou-

formance pumps, flow machines or the total just meeting the specification ble-free commissioning is guaranteed by re-

plant power - blocked by flare shut-off valves Just meeting the warranty time placing any critical valves with fittings and

and control valves. From an economical point e-bidding and e-purchasing. flushing the plant beforehand.A tremendous

of view, these valves often operate more or scope of difficulties can influence the project’s

less successfully under high stress load, charac- In the oil and gas market sector, many valves success if planning mistakes are first detected

terized by additional expenditure for noise-re- are high power [�p x flow] converters and in at this stage because the process condition cal-

ducing insulation and devices or maintenance, combination with fluid corrosion and fluid culations were too inaccurate or the control

or should severe problems arise, plant down- contamination the valve body and trim may be valve selection was “quick and dirty.” Ques-

time, i.e. low or high cost of ownership. parts subject to wear.Time is often all-impor- tions that arise here are: “who is responsible

The following priorities concerning valves are tant during the initial phase involving the plan- for plant safety?” and “has e-commerce (e.g. e-

often specified by end users in the HPI sector: ning, bidding and ordering of the control bidding and e-purchasing) taken place too

safety and reliability valves these days. Unfortunately, this results in quickly for severe service control valves or

control quality valves being selected with a tremendous loss in valves with key functions?”The shorter deci-

environmental aspects detail engineering, yet at the same time, the sion time linked to anonymous bidding could

trouble-free life cycles and lowest cost of own- technical responsibility has been shifted to the mean that key valve features such as plant safe-

Special print from „Valve World“ www.valve-world.net 1

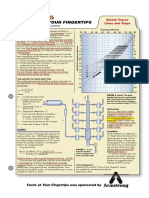

Fig. 1: Calculating installed

valve characteristic schemes.

�p versus flow and Flow;

Cv versus travel.

ty, control quality and process long-term tar-

gets are easily bypassed.

From the valve manufacturer’s point of view,

the situation is a challenge with regards to ful-

filling both aspects concerning competitive-

ness and reliability. Many well-known compa-

ny brand names and their valve products are

disappearing or have merged to form large

conglomerates.The process of the “synergy ef-

fect” continues more or less successfully. It

should be clear that the chronicle of plant dis-

asters will never cease, but the risk should not

be allowed to increase because valves intended

for severe service are being sized and selected periences or trial-and-error methods.Typical optimization tool for pipelines and pipe de-

in a “quick and dirty” fashion without involving valve characteristics have to be published as vices (Figure 2a), including material and prop-

time-consuming detail engineering.The ques- stipulated in international standards like the erty database for more than 1,000 substances

tion arises: can a happy medium be found to EN IEC 60534.The individual measurements including hydrocarbons. Ethylene, propylene,

meet the demands of both current and future of the actual valve factors or their approxima- chlorine, natural gas AGA 8 and sixty other in-

interests? tions are stored in in-house software of com- dustrial fluids are calculated very accurately

From experience gained from the increasing petent valve companies. using equations of state developed by the Ruhr

amount of troubleshooting required in petro- Cavitation and flashing combined with the in- University of Bochum (see www.conval.de for

chemical plants and refineries over past few fluence of the valve outlet velocity of pure liq- more details).

years, the conclusion that must be drawn is uid or liquid/vapor phase can cause severe If operating conditions are given with one, two

that it is important to make sure that modern trouble and, in the worst case, cause plant or three operating points the plant system is

lightweight globe and rotary valves are only shutdown. Some experiences in this area are defined in the standardized differential pres-

chosen within their limited range of applica- published in Chapter 6.

tion. In the recent past, only heavy-duty valves Most potential problems can be predicted by

such as high performance cage-guided or top using highly sophisticated software when the

and bottom guided globe valves fitted the total operating limits are known and the load-spe-

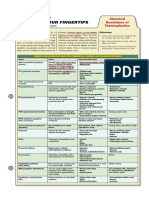

Tool for sizing, calculation and optimization of

range of applications. For less severe applica- cific valve characteristics cv, xFz, Fl, xT, Fd are common plant components:

tions these were over-engineered. Pressure to provided by the valve companies.Warning in- • Control valves

• Steam conditioning valves

reduce costs meant that this valve generation dicators can be activated to indicate a point in • Actuator forces

was replaced in the lower application field by a selected system of valves and pipeline where • Differential pressure flow elements

• Restriction orifice plates

lightweight, inexpensive valves. Low and high mechanical overload occurs due too high ve- • Safety relief valves

performance butterfly valves and other quar- locities or forces or where the noise level does • Tank depressurization

• Pressure loss

ter-turn products have been developed for not comply with the stipulated requirements. • Pressure surge

typical market segments. • Pipes:

• Sizing

Rotary plug valves can save costs when they 1. Accurate Sizing & Software Tools • Pipe compensation

replace globe valves, but there is also a risk if The CONVAL® 6 software treats the plant and • Span calculation

• Pipe wall thickness

engineering competence for critical applica- valve sizing parameters from an overall point • Shell-and –tube heat exchanger

tions is missing.Time and effort must be spent of view, issuing dynamic graphics with in- • Condensers

• Pump motor output

measuring new valve products on test rigs be- stalled characteristics concerning flow, power, Supported by vendor independent device databases

fore they can be launched onto the market. gain and outlet velocity as a function of the (control valves, safety relief valves), fluid property

calculation, material databases, …

Operating data limits above test rig possibili- valve coefficient cv value and the valve travel.

ties are often detected by troubleshooting ex- The software is a manufacturer independent Fig. 2a: CONVAL Tool description.

2 www .valve-world.net Special print from „Valve World“

)

21 )

Fig. 3b: Same plant layout, split into three sections to show

pressure losses.

Fig. 3a: Typical plant layout (simplified) in a chemical or

petrochemical plant. Fig. 3c: Input values of the pressure loss plant system.

sure versus flow diagram at the left-hand side 2) Energy saving by plant and valve

(see Figure 1).The inherent cv-characteristic optimization

of any valve as well as all other valve character- The first case study shows many aspects of

istics xFz, Fl, xT, Fd, a.s.o. are stored in a large plant optimizing and presents methods to ob-

valve data base in the form of equations or tain the most important parameters for control

polynomial coefficients. Every valve installed valve sizing at two or, even better, three operat-

characteristic like flow, gain and valve authori- ing points.An exceptional amount of over 50

ty, sound, inlet and outlet velocity, as well as % of power and costs could be saved if plant

cavitation, flashing, and choke flow areas are design, pipes and pipe devices such as control

Special valve manufacturer software is presented in graphic form on the right-hand valves were to be sized more rationally.[1]

available and is mainly used for proprietary side.A dynamic ruler publishes all results in- Lower power consumption of control valves re-

control valve series and their special demands. cluding alarms and hints at any valve travel po- duces the cost of investment by using standard

Programs can store several thousand pieces of

sition.The program combines expert valve siz- valve series without noise abatement devices and

valve data like cv characteristics, noise data

ing with powerful plant optimization and trou- increases the life cycle because of the reduced

and noise correction measurements and

ble shooting. amount of wear of the throttling valve parts.

related functions of valve recovery factors

based on flow lab data. Specific actuator

The software provides a bi-directional COM Saving energy means recalculating our figures

sizing or special sizing methods for mixtures link to spreadsheets and CAE systems ( Figure with a lower start pressure of p0 = 6 bar and

and the flashing outlet conditions are available 2b) as well as in-house valve sizing programs optimizing the pipeline and all the pipe de-

as well as having links to quotations, pricing, (Box 1) which companies can use to store vices.The result is, on the one hand, a change

drawing software and to the production units. valve data e.g. sound measurements, adminis- 1) Reference to CAE interface list

tration of inquiry and quotation systems as 2) e.g. SAMSON valve sizing application

Box 1: In-house valve sizing program well as pricing and drawings. F ile F ile F ile F ile

Excel Export

MAPI Client

PDF Export

CONVAL

(Email)

Native

files

Figure 2b: The

CONVAL

Pressure following CAE

tools provide a

C O M In te rfa c e

bi-directional .N e t In te ro p

a s s e m b ly

interface to

COM

COM

.NET

CONVAL® 6.0:

. N E T C lie n t C O M C lie n t

C O M C lie n t In te rfa c e

A p p lic a tio n A p p lic a tio n

Native link

P ro g a m m in g Excel

Fig. 4: Case study 1 -

lan g u a g e s

Access

C lie n t A p p lic a t io n

pressure/flow

.. .

W ord

diagram with P r o g a m m in g

Vendor

p r o g r a m s (2 )

la n g u a g e s

additional data on . ..

CAE

valve power and gain S y s te m s ( 1 )

characteristic. . ..

Special print from „Valve World“ www.valve-world.net 3

Fig. 5: Valve and control loop optimization with operating conditions from Fig. 6: Valve and control loop optimization with operating conditions

Table 1. Start pressure 10 bar. from Table 2. Start pressure 6 bar.

from a DN 3” to a DN 4” pipe system includ- The plant pressure loss calculation of Figure 3 Table 1 lists the different pressures for the nor-

ing the pipe devices. On the other hand, focus- results to the characteristics of up- and down- mal and the more important max. flow rate,

ing on the control valve’s operating point stream pressures; valve power consumption and often the main operating point of process con-

qmax again, the power consumption is re- gain - �q/�s - versus flow shown in Figure 4. trol.The control valve calculation shows a

duced from 60 to 20.3 kW and the total ener-

gy cost from USD 69,445 down to USD

31,203.That equates to an annual savings of Flow Qnorm kg/h Qmax kg/h

roughly USD 38,282.* q [kg/h] 2000 5000

Pressure loss calculation of pipe Case a) Case b) Case a) Case b)

The noise from the control valve is reduced

Section a) p1 bar_abs 10 6 10 6

from 98 dB(A) to 88 dB(A) with the lower

p2 bar_abs 9.937 5.973 9.65 5.866

power consumption.Therefore the cost for the

Power [kWatt] 0.3664 0.257 5.005 3.253

larger pipes and their devices are compensated Optimization of flow meters

for as there is no need for any noise abatement p1 bar_abs 9.937 5.973 9.65 5.866

device in the valve and the maintenance costs p2 bar_abs 9.894 5.916 9.374 5.479

are significantly reduced as well. Power [kWatt] 0.242 0.541 4.21 9.59

The plant layout is simplified in Figure 3a and Pressure loss calculation of pipe

split up into three sections in Figure 3b to Section b) p1 bar_abs 9.894 5.916 9.374 5.479

show the pressure loss of the devices from the p2 bar_abs 9.879 5.873 8.668 5.193

start pressure P0=10 bar_abs. For example, in Power [kWatt] 0.584 0.401 10.83 7.436

Figure 3b, section a refers to the distance be- Examine the pressure differential of the control valve = p2 section b) - p1 section c)

p1 bar_abs 4.3 4.09 5.61 4.48

tween the tank or pump and the flow meter

p2 bar_abs 3.999 4.0 4.02 4

orifice.The next section, section b, takes into

Power [kWatt] 3.9 1.134 45 15.33

consideration the distance between the flow

Operation conditions of the control valve:

meter and the control valve. Finally, section c p1 bar_abs 9.879 5.873 8.668 5.193

represents the distance downstream of the p2 bar_abs 4.3 4.09 5.61 4.48

control valve to the place of production with Control valve sizing and optimisation

the plant end pressure of p_end = 4 bar_abs. Cv - Value 12.37 24.7 40.6 101.2

Figure 3c summarizes all input values of the Sound Pressure 97 90 98 89

pressure loss plant system in this case study for Level SPL dB(A)

a compressible fluid: dry air at a temperature Power [kWatt] 45.4 19.8 59.3 20.3

of 100 °C. Total balance of power and energy and yearly consumption cost

After this preparation, the features of CON- Power [kWatt] 50.49 22.1 124.34 55.91

Energy [kWatth] 403,93 177,04 994,77 447,28

VAL can work out how to obtain optimum

yearly

control valve sizing parameters in less than 30

*without grade of Yearly 15,850 12,368 USD 69,494 31,246 USD

minutes and, moreover, it can optimize con-

electrical effectiveness consumption cost Saving:

trol loop parameters as well as power, energy of the flow machine Approx. 2001 38,295 USD/year

and cost parameters as shown in Figures 5 & 6.

Table 2: Power and energy optimization of a plant Comparison of results with different start-up

*regional average 1999. pressures case a) 10 bar or case b) 6 bar

4 www .valve-world.net Special print from „Valve World“

power consumption of 60 kWatt and a predict- Rule of thumb for plant designers:

new

ed sound pressure level SPL of 98 dB (A). keep a min. pressure differential for

control valves with equal percentage

�p100

Flow q kg/h 2000 5000 �p 0 old characteristics.

Pressure p1 bar_abs 9.879 8.668

Pressure p2 bar_abs 4.3 5.61 Flow 100 % �p100/ �p 0 = 0.1

Flow 90 % �p 90/ �p 0 = 0.27

Table 1: Control valve optimization from an Flow 80 % �p 80/ �p 0 = 0.42

overall point of view.

3. Debottle-necking: can the old valve

305t/h 380t/h

do the new job?

When looking to increase the productivity of Fig. 9: Case study 2: Old and new upstream pressure line to increase the flow.

an existing plant, engineers have to take con-

trol valves into account.This second case study

for an existing application to control a liquid

medium flow presents the troubleshooting

measures to increase a plant’s productivity to

meet current market demands.

This example looks at an existing 8” cage valve

(Figures 7 and 8) optimized for 85 dB (A) with

an additional multi-hole baffle (Figure 12) and

provides an easy method to obtain new valve

parameters without having to start a new

time-consuming total plant pressure loss cal-

xF

xFz_cage

Fig. 10: Case study 2: Calculation of the cage retained seat valve with max. SPL

[LpAa] > 91 dB(A).

Fig. 7: Case study 2: The old specification data.

Fig. 8: Case study 2: The old 8” cage pressure- Fig. 11: Case study 2: Sizing of the existing cage valve with multi-hole baffle to

balanced control valve. reduce the noise from 91 to 85 dB(A).

Special print from „Valve World“ www.valve-world.net 5

Fig. 15: Case Study 2: Sound optimisation for < 85 dB(A) noise limit

with the unique AC Trim System and highest xFz characteristic of

control valves today.

culation.At least with just one more powerful pump the new operat-

ing point can be kept controllable. However, severe cavitation in-

creases the noise to 96 dB (A) with the existing control valve.The

unique new development of an anti-cavitation trim “AC Trim System”

can solve cavitation problems and reduce the sound < 85 dB (A)

within the entire control range (see Chapter 5).

Fig. 12: Case study 2: Calculation and construction of downstream The software provides the user with new calculation methods includ-

resistance structures like single and multi-baffles. ing graphic supports to help check the control valve performance as

well as leading to the most economic solution to reduce noise (Fig-

ures 9, 10 and 11).

The question arises: can the existing control valve be updated taking

noise limitation of 85 dB(A) into account ?

The case study is based on a real situation where the productivity had

to be increased, while keeping the noise level (SPL) within the exist-

Fig. 13: Case study 2: CFD optimization of anti-cavitation trim design - ing regulations. If the old DN 8” valve just fulfilled the noise require-

computer flow simulation. Shown is SAMSON’s AC Trim I System ments of 85 dB(A) by using a baffle or silencer, then the solution for

Parabolic plug top and seat guided. Seat and plug CFD optimized. the revised valve presents a real challenge.

The cage retained seat valve has been operating for some five years

without complaints, but cannot be used after debottle-necking to

control 30% more flow because of increasing sound-pressure-level >

95 dB(A).The new pump-impeller increases the power to such a

level that there is no economic solution available with the old valve.

Fortunately the development and research program of SAMSON AG

has presented the unique anti-cavitation AC Trim System.This fulfils

the 85 dB(A) requirement and replaces the existing cage trim design

(Figures 13 and 14).

Successful debottle-necking after increasing the pump

power (Figure 15)

The new pump impeller increases the plant upstream pressure and

the power and noise as well.The old cage valve now generates 96

dB(A).There is no chance to keep the low noise level with the exist-

Fig. 14: Case Study 2: AC Trim System. The result of flow research (patent ing valve.The new valve with AC Trim System shows no cavitation at

pending) Natural low noise, dirt and vibration insensitive. Top and seat the operating point 380t/h 65 dB(A) and less cavitation < 85 dB(A)

guided low noise parabolic trim, no risk of stroke blocking. in the entire range of control. �

6 www .valve-world.net Special print from „Valve World“

Вам также может понравиться

- Plant Design & CV SelectionДокумент7 страницPlant Design & CV SelectionIAmaeyОценок пока нет

- Dynamic Process Simulation When Do We Really Need ItДокумент4 страницыDynamic Process Simulation When Do We Really Need ItDenis GontarevОценок пока нет

- Process Simulation Essentials - Example BookДокумент63 страницыProcess Simulation Essentials - Example BookRebeca LópezОценок пока нет

- Aspen Plus® Tips: Tips and Frequently Asked QuestionsДокумент16 страницAspen Plus® Tips: Tips and Frequently Asked QuestionsayshahrosliОценок пока нет

- Chemicalengineeringmagzinenov2012 PDFДокумент77 страницChemicalengineeringmagzinenov2012 PDF施君儒Оценок пока нет

- Select Best Model Two-Phase Relief Sizing: The ForДокумент9 страницSelect Best Model Two-Phase Relief Sizing: The ForjowarОценок пока нет

- Pilot-Operated Safety Relief Valves A Simple, Effective Plant Upgrade - HP - Nov 2011 PDFДокумент5 страницPilot-Operated Safety Relief Valves A Simple, Effective Plant Upgrade - HP - Nov 2011 PDFonizuka-t2263Оценок пока нет

- Processing May 2013Документ119 страницProcessing May 2013triuneenergy100% (1)

- Engineering 2012 02Документ58 страницEngineering 2012 02triuneenergyОценок пока нет

- Kister - Troubleshoot Packing Maldistribution Upset Part 1, Temperature Surveys and Gamma ScansДокумент8 страницKister - Troubleshoot Packing Maldistribution Upset Part 1, Temperature Surveys and Gamma ScansgonzalezpcjОценок пока нет

- Tower Line Size Criteria PDFДокумент1 страницаTower Line Size Criteria PDFBurhanОценок пока нет

- Kettle TrouhleshootingДокумент8 страницKettle TrouhleshootingForcus onОценок пока нет

- So Many Tuning Rules, So Little Time: Control Talk ColumnsДокумент36 страницSo Many Tuning Rules, So Little Time: Control Talk ColumnsIvan BevandaОценок пока нет

- Gas Blowby - An Overview - ScienceDirect TopicsДокумент15 страницGas Blowby - An Overview - ScienceDirect TopicsWin Thi HaОценок пока нет

- Microreactors: W. Ehrfeld, V. Hessel, H. LöweДокумент20 страницMicroreactors: W. Ehrfeld, V. Hessel, H. LöweAnonymous Ksq1dyPRhОценок пока нет

- EI Regulator Station Handbook TDC UKДокумент32 страницыEI Regulator Station Handbook TDC UKupesddn2010Оценок пока нет

- Heat-Exchanger Bypass Control: William L. LuybenДокумент9 страницHeat-Exchanger Bypass Control: William L. LuybenYu Hui100% (1)

- SulzerДокумент3 страницыSulzerVladimir AleksandrovОценок пока нет

- H2O2 TechnologyДокумент3 страницыH2O2 TechnologyalijadoonОценок пока нет

- High Performance Trays PDFДокумент9 страницHigh Performance Trays PDFAlan ChewОценок пока нет

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7От EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Оценок пока нет

- Xu Distillation How To Push A Tower To Its Maximum Capacity PDFДокумент9 страницXu Distillation How To Push A Tower To Its Maximum Capacity PDFRajendraОценок пока нет

- 08b PDFДокумент38 страниц08b PDFProcess EngineerОценок пока нет

- Reboilers & VaporisersДокумент17 страницReboilers & VaporisersKamran MalikОценок пока нет

- Reciprocating Compressors in A Hydrogen Plant 2016Документ5 страницReciprocating Compressors in A Hydrogen Plant 2016Lucas SondreОценок пока нет

- 1 s2.0 S1226086X14001221 MainДокумент6 страниц1 s2.0 S1226086X14001221 MainJorge Rodriguez HerreraОценок пока нет

- ChemicalEngineering Chemical Engineering June 2023Документ56 страницChemicalEngineering Chemical Engineering June 2023Mauricio Huerta jaraОценок пока нет

- H P 2011 02 PDFДокумент97 страницH P 2011 02 PDFErvin WatzlawekОценок пока нет

- DWCДокумент10 страницDWCkennethmsorianoОценок пока нет

- Using Installed Gain To Improve Valve Selection and Valves & Specialty Metal Materials - CE - October 2010 PDFДокумент8 страницUsing Installed Gain To Improve Valve Selection and Valves & Specialty Metal Materials - CE - October 2010 PDFonizuka-t2263Оценок пока нет

- Control and Safeguarding of Fired Equipment Foster Wheeler Energy LTD Process Engineering GuidelineДокумент12 страницControl and Safeguarding of Fired Equipment Foster Wheeler Energy LTD Process Engineering GuidelineAugusto ManuelОценок пока нет

- Line Sizing CriteriaДокумент5 страницLine Sizing CriteriaBILAL ILYASОценок пока нет

- Aqueous Solubility of Inorganic Compounds at Various TemperaturesДокумент9 страницAqueous Solubility of Inorganic Compounds at Various TemperaturesterrorfordОценок пока нет

- Rectisol Wash Units: Acid Gas Removal For Polygeneration Concepts Downstream GasificationДокумент34 страницыRectisol Wash Units: Acid Gas Removal For Polygeneration Concepts Downstream Gasificationpippo2378793Оценок пока нет

- Vacuum Unit Pressure Control PTQ Revamps 2006Документ5 страницVacuum Unit Pressure Control PTQ Revamps 2006majope1966Оценок пока нет

- March 2014Документ76 страницMarch 2014jpsi6Оценок пока нет

- Ethylene Dichloride ManufacturerДокумент5 страницEthylene Dichloride Manufacturerbarus goldenОценок пока нет

- October 2013Документ68 страницOctober 2013jpsi6Оценок пока нет

- April 2014 - Chemical Engineering - P&ID DEvelopment PDFДокумент86 страницApril 2014 - Chemical Engineering - P&ID DEvelopment PDFRonak KapadiaОценок пока нет

- 14 Hot Oil Systems v3Документ14 страниц14 Hot Oil Systems v3sssss100% (1)

- DYNSIM Tutorial Reverse FlowДокумент50 страницDYNSIM Tutorial Reverse FlowsegunoyesОценок пока нет

- Desuperheater That Combines Proven Technologies For Better Operational EconomyДокумент4 страницыDesuperheater That Combines Proven Technologies For Better Operational Economyhappale2002Оценок пока нет

- Unit Processes Assignment: Made By:-Name:-E.Nithya CLASS:-B.TECH-2 ROLL NO:-U13CH039Документ39 страницUnit Processes Assignment: Made By:-Name:-E.Nithya CLASS:-B.TECH-2 ROLL NO:-U13CH039nityaОценок пока нет

- Gulfpub HP 201811Документ93 страницыGulfpub HP 201811avinashpatil2408Оценок пока нет

- Proper Piping For Vacuum SystemsДокумент5 страницProper Piping For Vacuum SystemsDowni Oader100% (1)

- For Exchanger Tube Rupture PDFДокумент3 страницыFor Exchanger Tube Rupture PDFNikhil DivateОценок пока нет

- Aspen Simulation Workbook Webinar FAQДокумент3 страницыAspen Simulation Workbook Webinar FAQluaweb123Оценок пока нет

- Orifice Plate Calculator Flow Rate Pressure DropДокумент3 страницыOrifice Plate Calculator Flow Rate Pressure Dropredroom31100% (1)

- IntroKGTowerV2 0 PDFДокумент14 страницIntroKGTowerV2 0 PDFrasyid93Оценок пока нет

- A D B C: Steam Ejector Hybrid Systems in The Chemical IndustryДокумент4 страницыA D B C: Steam Ejector Hybrid Systems in The Chemical IndustryAjiОценок пока нет

- Avoid Pressure-Relief System PitfallsДокумент8 страницAvoid Pressure-Relief System PitfallschublackОценок пока нет

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentОт EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentОценок пока нет

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationОт EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationОценок пока нет

- Handbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4От EverandHandbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Рейтинг: 5 из 5 звезд5/5 (1)

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979От EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonОценок пока нет

- Facts at Your Fingertips-201104-Hopper Inserts For Improved Solids FlowДокумент1 страницаFacts at Your Fingertips-201104-Hopper Inserts For Improved Solids Flowonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201012-Project Design Decision-Making Option ListsДокумент1 страницаFacts at Your Fingertips-201012-Project Design Decision-Making Option Listsonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201105-Pressure Measurement ConsiderationsДокумент1 страницаFacts at Your Fingertips-201105-Pressure Measurement Considerationsonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201103-Infrared Temperature MeasurementДокумент1 страницаFacts at Your Fingertips-201103-Infrared Temperature Measurementonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201010-MSMPR Crystallization EquipmentДокумент1 страницаFacts at Your Fingertips-201010-MSMPR Crystallization Equipmentonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201006-Fluid MechanicsДокумент1 страницаFacts at Your Fingertips-201006-Fluid Mechanicsonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201011-Viscosity MeasurementДокумент1 страницаFacts at Your Fingertips-201011-Viscosity Measurementonizuka-t2263Оценок пока нет

- Controlling membrane foulingДокумент1 страницаControlling membrane foulingonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201101-Hansen Solubility Parameters (HSP)Документ1 страницаFacts at Your Fingertips-201101-Hansen Solubility Parameters (HSP)onizuka-t2263Оценок пока нет

- CHE Facts 0410Документ1 страницаCHE Facts 0410gwinnruОценок пока нет

- Facts at Your Fingertips-201102-Control Valve Position SensorsДокумент1 страницаFacts at Your Fingertips-201102-Control Valve Position Sensorsonizuka-t2263Оценок пока нет

- Heat Transfer Fluids: System FiltrationДокумент1 страницаHeat Transfer Fluids: System Filtrationonizuka-t2263Оценок пока нет

- Steam Tracer Lines and Traps GuideДокумент1 страницаSteam Tracer Lines and Traps Guideonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201005-Burner Operating Characteristics PDFДокумент1 страницаFacts at Your Fingertips-201005-Burner Operating Characteristics PDFonizuka-t2263Оценок пока нет

- Steam Tracer Lines and Traps GuideДокумент1 страницаSteam Tracer Lines and Traps Guideonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201005-Burner Operating Characteristics PDFДокумент1 страницаFacts at Your Fingertips-201005-Burner Operating Characteristics PDFonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201007-Conservation Economics Carbon Pricing ImpactsДокумент1 страницаFacts at Your Fingertips-201007-Conservation Economics Carbon Pricing Impactsonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201002-Positive Displacement PumpsДокумент1 страницаFacts at Your Fingertips-201002-Positive Displacement Pumpsonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201002-Positive Displacement PumpsДокумент1 страницаFacts at Your Fingertips-201002-Positive Displacement Pumpsonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-201001-Low-Pressure MeasurementДокумент1 страницаFacts at Your Fingertips-201001-Low-Pressure Measurementonizuka-t2263Оценок пока нет

- CHE Facts 0410Документ1 страницаCHE Facts 0410gwinnruОценок пока нет

- Facts at Your Fingertips-201001-Low-Pressure MeasurementДокумент1 страницаFacts at Your Fingertips-201001-Low-Pressure Measurementonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-200909-Heat Transfer System Design IIДокумент1 страницаFacts at Your Fingertips-200909-Heat Transfer System Design IIonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-200912-Creating Installed Gain GraphsДокумент1 страницаFacts at Your Fingertips-200912-Creating Installed Gain Graphsonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-200910-Chemical Resistance of ThermoplasticsДокумент1 страницаFacts at Your Fingertips-200910-Chemical Resistance of Thermoplasticsonizuka-t2263Оценок пока нет

- Adsorption PDFДокумент1 страницаAdsorption PDFrasik.kiraneОценок пока нет

- Facts at Your Fingertips-200907-Flowmeter SelectionДокумент2 страницыFacts at Your Fingertips-200907-Flowmeter Selectiononizuka-t2263Оценок пока нет

- Above and Underground Storage Tanks PDFДокумент1 страницаAbove and Underground Storage Tanks PDFrasik.kiraneОценок пока нет

- Specialty metals guide corrosion resistance and propertiesДокумент1 страницаSpecialty metals guide corrosion resistance and propertiesonizuka-t2263Оценок пока нет

- Facts at Your Fingertips-200905-Choosing A Control SystemДокумент1 страницаFacts at Your Fingertips-200905-Choosing A Control Systemonizuka-t2263Оценок пока нет

- Borang KWLДокумент2 страницыBorang KWLjp siaОценок пока нет

- Spitfire: Precise Card Model 1/48Документ4 страницыSpitfire: Precise Card Model 1/48Wil NelsonОценок пока нет

- Instruction Manual - SGF36 To 362kVДокумент116 страницInstruction Manual - SGF36 To 362kVrpshvjuОценок пока нет

- Manual - Moses DecoderДокумент359 страницManual - Moses DecoderErwinGuntoroОценок пока нет

- MGB Form No. 13-1AДокумент1 страницаMGB Form No. 13-1ACarlo Frances CaballeroОценок пока нет

- Quakeguard Earthquake Early Warning System: January 17, 1994Документ2 страницыQuakeguard Earthquake Early Warning System: January 17, 1994runkirОценок пока нет

- 35c42c0c 3 PDFДокумент70 страниц35c42c0c 3 PDFpicottОценок пока нет

- Ovation Guitar Price History 1971-2004Документ14 страницOvation Guitar Price History 1971-2004flatfenderОценок пока нет

- Solution To Exercise 4.2Документ2 страницыSolution To Exercise 4.2priyankaОценок пока нет

- HoffmanДокумент148 страницHoffmanAnonymous 7xHNgoKE6eОценок пока нет

- Introduction To Ic EngineДокумент57 страницIntroduction To Ic EnginejhpandiОценок пока нет

- VCCS Project Charter Template 1 4Документ7 страницVCCS Project Charter Template 1 4João CarvalhoОценок пока нет

- Assessment of Hygiene Promotion in Madagascar - 2009Документ66 страницAssessment of Hygiene Promotion in Madagascar - 2009HayZara MadagascarОценок пока нет

- CH 11Документ50 страницCH 11Donna Mae HernandezОценок пока нет

- Iec 60601-2-49 (2001) (INDIA)Документ48 страницIec 60601-2-49 (2001) (INDIA)estebanОценок пока нет

- Dae 3Rd Year Online Classes Links Mechanical Technology: Subject Name Google Classroom CodeДокумент3 страницыDae 3Rd Year Online Classes Links Mechanical Technology: Subject Name Google Classroom CodemahmadwasiОценок пока нет

- Activity Based BudgetingДокумент13 страницActivity Based BudgetingAlvin Adrian67% (3)

- Mentorpaper 102908Документ79 страницMentorpaper 102908rohan357Оценок пока нет

- Craftsman c459 52833 Snow Blower 56Документ56 страницCraftsman c459 52833 Snow Blower 56Rick HenbidОценок пока нет

- N68C-GS FXДокумент54 страницыN68C-GS FXFrancisco AmpueroОценок пока нет

- Anh Minh's Brochure (SUMO)Документ2 страницыAnh Minh's Brochure (SUMO)Truong Anh MinhОценок пока нет

- Design and Development of Sensor Based Traffic Light SystemДокумент5 страницDesign and Development of Sensor Based Traffic Light SystemAyan BiswasОценок пока нет

- Mems, Piezoelectric Sensing & ActuationДокумент36 страницMems, Piezoelectric Sensing & ActuationNagabhushanaОценок пока нет

- Technical Evalution SheetДокумент2 страницыTechnical Evalution Sheetappalaraju gompaОценок пока нет

- CNC Machining Vocabulary Terms ExplainedДокумент2 страницыCNC Machining Vocabulary Terms ExplainedPeggopoulouОценок пока нет

- Difference Between A Computer Science & Information Technology DegreeДокумент7 страницDifference Between A Computer Science & Information Technology DegreeOvidiu Costinel DanciuОценок пока нет

- Cement and Concrete Research: D.K. Panesar, B. ShindmanДокумент13 страницCement and Concrete Research: D.K. Panesar, B. ShindmankanomasiОценок пока нет

- Continuous Sampling PlanДокумент2 страницыContinuous Sampling PlanAnonymous wA6NGuyklDОценок пока нет

- How To Prepare The SarДокумент107 страницHow To Prepare The Sargoldencomet100% (1)

- Signals & Systems For Dummies Cheat Sheet - For DummiesДокумент8 страницSignals & Systems For Dummies Cheat Sheet - For DummiesAbdallah E. AbdallahОценок пока нет