Академический Документы

Профессиональный Документы

Культура Документы

Clevis and Lug Design V0001

Загружено:

Ben FriskneyАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Clevis and Lug Design V0001

Загружено:

Ben FriskneyАвторское право:

Доступные форматы

Clevis and lug design V0001.xls has been downloaded from www.ExcelCalcs.

com

If you see #NAME errors you may need to download our XLC software

Ratings and user reviews for this workbook.

View other downloads in the same ExcelCalcs Repository folder.

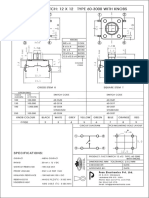

Purpose of calculation:

Determine stress levels in a clevis and pin assembly.

Calculation Reference

Peterson's Stress Concentration Factors

Additional Requirements

This calculation uses XLXtrFun Extra Functions for Microsoft® Excel

This is a free download from http://www.xlxtrfun.com

Clevis

H/2

Radius

Point A h

Problem input data

Pin diameter c

d= 130 mm d

Lug dimension

c= 120 mm

Joint width

H= 220 mm

Lug width

h= 60 mm

Maximum hole clearance

d= 0.15 mm Lug P

Axial Force P

P = 8E+05 N

H

Governing ratio's

R1 = 0.5455###

R2 = 0.4615###

R3 = 0.5909###

maximum % pin hole clearance

e = 0.12% ###

Stress Concentration at point A

Stress Concentration factor when pin clearance is 0.2%

Kt0.2 = ### From Lookup table derived from Peterson's chart 5.12

Stress Concentration factor when pin clearance is 100% (i.e single line contact)

Kt100 = ### From Lookup table derived from Peterson's chart 5.12

Interpolation factor (approximate)

f = ### From Lookup table derived from Peterson's chart 5.12

Actual Stress Concentration factor

K = ### ###

te

Note: no account is taken for surface finish and geometric imperfections which also

effect stress concentartions.

Nominal stress across at section AA

s = ### ###

nom

Maximum stress at point A

s = ### ###

max

1.2 Kt100 d/H = 0.4

7 Kt100 d/H = 0.5

Kt100 d/H = 0.6

1 Kt100 d/H = infinity

6 Kt0.2 d/H = 0.4

Kt0.2 d/H = 0.5

0.8

Kt0.2 d/H = 0.6

5 Kt0.2 d/H = infinity

Interpolation factor (f)

0.6

Stress Concentration (Kt)

4

0.4

3

0.2

2

0

0.1% 1.0% 10.0% 100.0%

1

-0.2

-0.4 0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

% pin hole clearance (e)

d/H

Вам также может понравиться

- Discrete Cosine Transform: Algorithms, Advantages, ApplicationsОт EverandDiscrete Cosine Transform: Algorithms, Advantages, ApplicationsОценок пока нет

- Stress Concentration Factors Chart 2.7, Page 87, (Ktu Vs Ktalfa)Документ4 страницыStress Concentration Factors Chart 2.7, Page 87, (Ktu Vs Ktalfa)Mehmet ErenОценок пока нет

- Diagramas de Interaccion AciДокумент48 страницDiagramas de Interaccion AciGeorge Henry Perez Cruz100% (1)

- Sesion 3 - Tabla Concentrador de EsfuerzosДокумент10 страницSesion 3 - Tabla Concentrador de EsfuerzosĞôřqûî ĀğūîřřêОценок пока нет

- Pipe Distributor Sizing Calculations - 07-08-2013Документ26 страницPipe Distributor Sizing Calculations - 07-08-2013pelotoОценок пока нет

- Unit3Документ291 страницаUnit3mongkol_1001Оценок пока нет

- Modulo IIIДокумент8 страницModulo IIIjose antonio manchaОценок пока нет

- Perhitungan Bronjong: 1. Data Perencanaan 1.1 DimensiДокумент5 страницPerhitungan Bronjong: 1. Data Perencanaan 1.1 DimensiMohamad Hartadi50% (2)

- sm1 061Документ3 страницыsm1 061Paulo Henrique D. FavarettoОценок пока нет

- Ideal Inherent Equal-Percentage Flow Characteristic:: Control Valve TrimsДокумент7 страницIdeal Inherent Equal-Percentage Flow Characteristic:: Control Valve TrimsAsthy FaridaОценок пока нет

- AC Steady-State Analysis: Sinusoidal Forcing Functions, Phasors, and ImpedanceДокумент14 страницAC Steady-State Analysis: Sinusoidal Forcing Functions, Phasors, and ImpedanceRami ReddyОценок пока нет

- CE325 - 08 Consolidation TheoryДокумент25 страницCE325 - 08 Consolidation TheoryRobert PrinceОценок пока нет

- Pompa TankiДокумент25 страницPompa TankiEka SafitriОценок пока нет

- Turbulent Boundary Layer in A 3-Element High-Lift Wing: Coherent Structures IdentificationДокумент6 страницTurbulent Boundary Layer in A 3-Element High-Lift Wing: Coherent Structures IdentificationvetinenОценок пока нет

- Homework hmm2Документ2 страницыHomework hmm2Rawaa Ben BrahimОценок пока нет

- Hydraulic Calculations - Safe RainДокумент17 страницHydraulic Calculations - Safe RainmoisesОценок пока нет

- 화학공정계산 4판 솔루션 RicharДокумент244 страницы화학공정계산 4판 솔루션 Richar고영준Оценок пока нет

- Solving Laplace in PythonДокумент4 страницыSolving Laplace in PythonShyam ShankarОценок пока нет

- Slab Formwork CalculationДокумент13 страницSlab Formwork CalculationPrakash Singh RawalОценок пока нет

- Green-Cap (Electric Double Layer Capacitors) : Snap-In Terminal Type, Standard SeriesДокумент1 страницаGreen-Cap (Electric Double Layer Capacitors) : Snap-In Terminal Type, Standard SeriesGrey ParrotОценок пока нет

- Exam 10 1 2020Документ8 страницExam 10 1 2020Francisco MachadoОценок пока нет

- Wind Design CalculatorДокумент9 страницWind Design CalculatorMuhammad rifaiОценок пока нет

- Column Interaction Diagrams ACI Design HandbookДокумент48 страницColumn Interaction Diagrams ACI Design HandbookRekan100% (2)

- Intensity vs Angle Intensity vs cos (θ)Документ3 страницыIntensity vs Angle Intensity vs cos (θ)Sophia ChenОценок пока нет

- Fractional Crystallization 1) ModelДокумент9 страницFractional Crystallization 1) ModelOmni SthaОценок пока нет

- Columns Interaction DiagramsДокумент96 страницColumns Interaction DiagramsHadeel AL-Rasheed100% (2)

- Lecture 4: PID of A Spring Mass Damper SystemДокумент6 страницLecture 4: PID of A Spring Mass Damper SystemAditya AdОценок пока нет

- Interaction Diagram Circular Column1Документ10 страницInteraction Diagram Circular Column1Diego DíazОценок пока нет

- Concentration Factors KTДокумент7 страницConcentration Factors KTYogesh RameshОценок пока нет

- Inter Acci OnДокумент12 страницInter Acci OnMaria Alejandra Bastidas MicoltaОценок пока нет

- Ejercicio RetadorДокумент10 страницEjercicio RetadoringenieromantencionОценок пока нет

- Derived SCMДокумент6 страницDerived SCMkeroroeОценок пока нет

- Convolution Properties: B (N) B (N) A (N)Документ11 страницConvolution Properties: B (N) B (N) A (N)Darshana MakavitaОценок пока нет

- Sil Ptat Tugasdantutorial 011Документ8 страницSil Ptat Tugasdantutorial 011irgieОценок пока нет

- Nominal Load-Moment Strength Interaction Diagram PDFДокумент96 страницNominal Load-Moment Strength Interaction Diagram PDFBhavin ShahОценок пока нет

- Interaction Aci ImprimirДокумент96 страницInteraction Aci ImprimirBhavin ShahОценок пока нет

- Column Design ChartДокумент5 страницColumn Design ChartGabriel100% (2)

- Exer 5Документ3 страницыExer 5prr.paragОценок пока нет

- Hydrodynamic Pressure Calculation For Sump: Bending Moment Diagram Hoop Tension DiagramДокумент8 страницHydrodynamic Pressure Calculation For Sump: Bending Moment Diagram Hoop Tension Diagramepe civilОценок пока нет

- M-PSK System Performance in Multi-Channel Environments With MATLAB Simulink ModelsДокумент9 страницM-PSK System Performance in Multi-Channel Environments With MATLAB Simulink ModelsJoel AlvinagortaОценок пока нет

- Agitator Power Requirement and Mixing Intensity CalculationДокумент26 страницAgitator Power Requirement and Mixing Intensity CalculationChemical Engineering100% (2)

- Fer GraficoДокумент4 страницыFer GraficoJorsh FarroñanОценок пока нет

- Unit Operations Lecture 9Документ14 страницUnit Operations Lecture 9mompopli007Оценок пока нет

- Hydraulic Calculations Safe RainДокумент17 страницHydraulic Calculations Safe RainAnabel BejaranoОценок пока нет

- 07au MidtermДокумент17 страниц07au MidtermEman AsemОценок пока нет

- Lec7 Density PDFДокумент9 страницLec7 Density PDFimranОценок пока нет

- SSE Shear Design - EC2v1 - 07 - G1 - 20211027 - 2233 - 53Документ4 страницыSSE Shear Design - EC2v1 - 07 - G1 - 20211027 - 2233 - 53SES DESIGNОценок пока нет

- Steel Pipe: C S U A Max S MaxДокумент4 страницыSteel Pipe: C S U A Max S Maxankkeshmundra1Оценок пока нет

- Sudhanshu 17026 Prac - 4Документ8 страницSudhanshu 17026 Prac - 4Yash SharmaОценок пока нет

- Chapter IV Piled Raft CapacityДокумент28 страницChapter IV Piled Raft CapacityVinod kumarОценок пока нет

- Barra Diámetro Peso Área Perímetro Num. Pulg. Cms. KG/M cm2 CmsДокумент16 страницBarra Diámetro Peso Área Perímetro Num. Pulg. Cms. KG/M cm2 CmsiandelaguiОценок пока нет

- Interaction Diagram For Columns NewДокумент2 страницыInteraction Diagram For Columns NewBunkun1550% (2)

- Sheet Mid 000Документ20 страницSheet Mid 000kareemshdefat00Оценок пока нет

- Calculo AgitadorДокумент25 страницCalculo AgitadorJuan MendozaОценок пока нет

- Parametros CompresibilidadДокумент1 страницаParametros CompresibilidadCarlos MartinezОценок пока нет

- Pressure Drop Calculation: SR. No. Parameter Value UnitДокумент1 страницаPressure Drop Calculation: SR. No. Parameter Value UnitSushil WadiyeОценок пока нет

- Falih Hibatullah - PR 2Документ1 страницаFalih Hibatullah - PR 2Falih HibatullahОценок пока нет

- Consider a reservoir with the following data 0.17 1 1 80,000 ft 40,000 ft 10,000 STB/D Viscosity data: μ = 1.05 cp μ = 2.5+ 36 12 Fractional flow dataДокумент3 страницыConsider a reservoir with the following data 0.17 1 1 80,000 ft 40,000 ft 10,000 STB/D Viscosity data: μ = 1.05 cp μ = 2.5+ 36 12 Fractional flow dataVictor Pugliese ManotasОценок пока нет

- G.A.A.A. Ucss: Plano de Planta Portico PrimarioДокумент91 страницаG.A.A.A. Ucss: Plano de Planta Portico PrimarioDan ContrerasОценок пока нет

- PDF Instruction In-Flight Adjustable IvoProp Ultralight Model.Документ5 страницPDF Instruction In-Flight Adjustable IvoProp Ultralight Model.Ben FriskneyОценок пока нет

- FlightManual MTOsport 5-2 ENGДокумент122 страницыFlightManual MTOsport 5-2 ENGBen FriskneyОценок пока нет

- IVO AG-SB-2017-05-B-EN IVO-prop Gearbox OverhaulДокумент7 страницIVO AG-SB-2017-05-B-EN IVO-prop Gearbox OverhaulBen FriskneyОценок пока нет

- Maintenance Manual: Poplar Farm Prolley Moor Wentnor Bishops Castle Sy9 5ejДокумент43 страницыMaintenance Manual: Poplar Farm Prolley Moor Wentnor Bishops Castle Sy9 5ejBen FriskneyОценок пока нет

- Funke Transponder ADSB ConversionДокумент9 страницFunke Transponder ADSB ConversionBen FriskneyОценок пока нет

- IT Client Interview SheetДокумент4 страницыIT Client Interview SheetBen FriskneyОценок пока нет

- MTOsport Maintenance Manual - UK PDFДокумент101 страницаMTOsport Maintenance Manual - UK PDFBen FriskneyОценок пока нет

- Poh MT 6.1 en PDFДокумент136 страницPoh MT 6.1 en PDFBen FriskneyОценок пока нет

- Mtosport Maintenance PDFДокумент191 страницаMtosport Maintenance PDFBen FriskneyОценок пока нет

- Design To NZS3603 TimberДокумент3 страницыDesign To NZS3603 TimberBen FriskneyОценок пока нет

- Safety Lines 75Документ7 страницSafety Lines 75Ben FriskneyОценок пока нет

- Novakey Fittings 2014Документ4 страницыNovakey Fittings 2014Ben FriskneyОценок пока нет

- Design of Lifting and Tailing LugsNetsc001Документ30 страницDesign of Lifting and Tailing LugsNetsc001Tshilidzi Irene Netselo100% (1)

- Cable Cosby Safety Factor 380Документ1 страницаCable Cosby Safety Factor 380Ben FriskneyОценок пока нет

- Proof Load Lifting Equipment Components and Certify For UseДокумент4 страницыProof Load Lifting Equipment Components and Certify For UseBen FriskneyОценок пока нет

- Aluminium SectionsДокумент208 страницAluminium SectionsBen FriskneyОценок пока нет

- Neutralizing Amines Volume 10 Issue3Документ3 страницыNeutralizing Amines Volume 10 Issue3Waleed Emara100% (1)

- Hfe Sony Audio 1984 enДокумент60 страницHfe Sony Audio 1984 enaleksandar71Оценок пока нет

- Tact Micro Switch 12X12Документ1 страницаTact Micro Switch 12X12Solin CozОценок пока нет

- Case Study 1Документ2 страницыCase Study 1Tushar NepaleОценок пока нет

- 7805Документ2 страницы7805pandiОценок пока нет

- The Physics of Bowling BallsДокумент34 страницыThe Physics of Bowling Ballskhisham20005389100% (2)

- The Effect of Sustainable Human Resource ManagemenДокумент9 страницThe Effect of Sustainable Human Resource ManagemenFabio_WB_QueirozОценок пока нет

- Manufacture of Portland CementДокумент3 страницыManufacture of Portland Cementlaura kayОценок пока нет

- Growth and Yield Perpormance of Pechay FinalДокумент25 страницGrowth and Yield Perpormance of Pechay FinalJaimeh Annabelle100% (2)

- UGRD-ECE6205-Signals-Spectra-and-Signal-Processing-legit-not-quizess MidALLДокумент19 страницUGRD-ECE6205-Signals-Spectra-and-Signal-Processing-legit-not-quizess MidALLJitlee Papa100% (3)

- KOCOM Data SheetДокумент3 страницыKOCOM Data SheetcgdemoyaОценок пока нет

- Finite Element Analysis Using MATLAB ANSYS 16 HrsДокумент2 страницыFinite Element Analysis Using MATLAB ANSYS 16 HrsMOHIT PANTОценок пока нет

- Example 3 (Science-Based)Документ75 страницExample 3 (Science-Based)poppygibson1111Оценок пока нет

- BS 01916-3-2009Документ34 страницыBS 01916-3-2009pacoОценок пока нет

- Calculating IPv4 Subnets - ANSWER - KEYДокумент8 страницCalculating IPv4 Subnets - ANSWER - KEYPaul John QuirosОценок пока нет

- Padhle Akshay Maths 33 DaysДокумент263 страницыPadhle Akshay Maths 33 DaysShamik BhattacharjeeОценок пока нет

- Oasismontaj TutorialnewДокумент297 страницOasismontaj TutorialnewArmando Cesar Landa FerrelОценок пока нет

- Unit I. Bascis of Manufacturing ProcessesДокумент30 страницUnit I. Bascis of Manufacturing Processes070 ARITRITA BRAHMA ECEОценок пока нет

- Note CHP 2-Material Science 281 Uitm Em110Документ74 страницыNote CHP 2-Material Science 281 Uitm Em110bino_rye100% (1)

- Updated Fish Load CalculationДокумент3 страницыUpdated Fish Load CalculationMikhail Roy Dela CruzОценок пока нет

- Oracle Database: Performance Tuning Guide 12c Release 1 (12.1)Документ340 страницOracle Database: Performance Tuning Guide 12c Release 1 (12.1)sanjayid1980Оценок пока нет

- April 6, 2020: Laboratory Assignment: TrematodesДокумент9 страницApril 6, 2020: Laboratory Assignment: Trematodesthe someoneОценок пока нет

- SPSS Smart Viewer Evaluation Copy Step-by-Step Evaluation GuideДокумент4 страницыSPSS Smart Viewer Evaluation Copy Step-by-Step Evaluation GuideRoxy RoxaОценок пока нет

- Complexity, Liking and FamiliarityДокумент12 страницComplexity, Liking and FamiliarityAjaОценок пока нет

- Technical Data Sheet - Steel Cord FR GradeДокумент2 страницыTechnical Data Sheet - Steel Cord FR Gradeamol1321Оценок пока нет

- Electrostatics - 1: Charges and ChargingДокумент90 страницElectrostatics - 1: Charges and ChargingCat123Оценок пока нет

- Datos JeanДокумент8 страницDatos JeanJean Carlo GuarenasОценок пока нет

- Guia 4. Mov Aparente SolДокумент4 страницыGuia 4. Mov Aparente SolAlexa ContrerasОценок пока нет

- Advances in High-Performance CoolingДокумент15 страницAdvances in High-Performance Coolingygrao100% (1)

- Technical Information and Variances.: Spec/Feature Vst-Se VST-Mini CommentsДокумент1 страницаTechnical Information and Variances.: Spec/Feature Vst-Se VST-Mini CommentsAhmadОценок пока нет