Академический Документы

Профессиональный Документы

Культура Документы

2line Pavement-Revised - A

Загружено:

rolandtrojasАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

2line Pavement-Revised - A

Загружено:

rolandtrojasАвторское право:

Доступные форматы

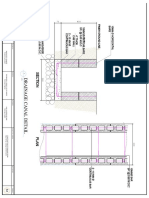

TYPICAL BAR LAYOUT FOR "T" THICK PAVEMENT

4500 4500 1500

MINIMUM

300

TABLE FOR SPACING OF TIE BARS (L=600mm)

SECTION 1

6 SLAB THICKNESS SPACING, S1 (mm)

6

LINE SHOWING TRANSVERSE CONSTRUCTION JOINT (mm)

6

12mm Ø 16mm Ø

6

Width as shown on the Plans

AT LOCATION OF WEAKENED PLANE JOINT

T/4

T/4

230 600 750

BAR SUPPORT LONGITUDINAL

JOINT LANE SHOWING TRANSVERSE CONSTRUCTION JOINT

240 600 750

( 6.70m. )

300

AT MIDDLE THIRD OF NORMAL JOINT INTERVAL POURED ASPHALT 250 600 750

SEAL 30 TO 50 PREMOLDED JT. FILLER

PENETRATION 260 500 750

PREMOLDED

SAWED GROOVE TYPE STRIP TYPE 270 500 750

400 400 400 400

280 500 750

Weakened Plane joint

F WEAKENED GROOVE DETAIL 290 500 750

With Dowel Bars

NOT TO SCALE 300 500 750

TRANSVERSE CONSTRUCTION JOINT SHALL BE PROVIDED

AT THE END OF ANY RUN WHERE LAYING OF CONCRETE 310 400 750

HAS BEEN STOPPED FOR THIRTY (30) MINUTES OR LONGER.

320 400 750

ALL TRANSVERSE CONSTRUCTION JOINTS SHOULD BE

330 400 750

BUTT JOINTS WITH DOWELS.

340 400 750

TYPICAL PLAN OF A TWO - LANE DOWELED PAVEMENT Based on AASHTO Guide for the Design of Pavement Structures 1993

NOT TO SCALE

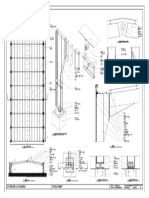

6mm RADIUS TIE BAR TABLE FOR SPACING OF DOWEL BARS ( L=600mm)

T/3

30-50 PENETRATION ASPHALT SEAL OR COLD APPLIED

SPACING FOR SPACING FOR SPACING FOR SPACING FOR

LIQUID RUBBER BASE SEALING COMPOUND SLAB DEPTH, (T)

T/3

25

PLAIN DOWEL BAR

T

36mmØ DOWEL BAR 32mmØ DOWEL BAR 28mmØ DOWEL BAR 25mmØ DOWEL BAR

3

75 (mm)

T/3

(mm) (mm) (mm) (mm)

METAL DOWEL CAP

25 280 300 250 190 150

FIXED SLIDING WITH Inside Dia. SAME AS

300 300 DOWEL BAR DIAMETER + 1.56mm 290 290 230 170 140

25mm PREMOLDED

EXPANSION FILLER

TO BE PLACED ON 300 270 210 160 130

EACH DOWELBAR ON

25 25 ALTERNATE END ( SEE 1L ). 310 250 200 150 120

B LONGITUDINAL CONSTRUCTION JOINT 320 230 190 140 110

( TO BE USED FOR ONE LANE CONSTRUCTION ) HALF OF THE BAR ON THE SIDE OF THE

METAL DOWEL CAP SHALL BE PAINTED 330 220 180 130 110

WITH RED LEAD AND THEN GREASED 340 200 170 130 100

DOWEL BARS (PLAIN BAR) Based on AASHTO Guide for the Design of Pavement Structures 1993

F RED LEAD AND GREASED OR

BITUMEN COATED

D DOWELLED EXPN. JOINT DETAIL 25

600

300 300

T/3

50 50

11

50 150 100 150 50

T/3

T=SLAB DEPTH

SAWED CUT DEPTH= T/4 16 mm Ø DRILLED HOLES SEE NOTE ABOVE 1. MATERIALS AND WORKMANSHIP SHALL CONFORM WITH THE "DPWH STANDARD

T/2

FILLED WITH EPOXY SPECIFICATIONS FOR HIGHWAYS,BRIDGES AND AIRPORTS,2013".

11

RESIN / HARDER GROUT TIE BARS 2. CONSTRUCTION (CONTACT) JOINTS ARE FORMED WHEN CONCRETE ON ONE

T/3

SIDE OF THE JOINT IS POURED AHEAD AND ALLOWED TO SET BEFORE POURING

T/2

Te/2

ON THE OTHER SIDE, NO CONSTRUCTION JOINT SHALL BE PLACED WITHIN

1.50m FROM THE WEAKENED PLANE JOINT.

3. AT CONSTRUCTION JOINTS (LONGITUDINAL OR TRANSVERSE) CARE SHOULD BE

12mm Ø CHAIR ( BASKET ) METAL SIDE FORM (KEYED JOINT) TAKEN THAT NO CONCRETE FROM THE LAST SLAB PLACED OVERHANGS ANY

T

EXISTING PAVEMENT NEW PAVEMENT

12mm Ø Pin. L = 300mm FOR EVERY DOWEL BARS

PORTION OF THE FIRST SLAB.

FOR EVERY OTHER WHERE :

L DETAIL OF SIDE FORMS 4. TIE BARS SHOULD BE DEFORMED STEEL BARS,ALL DOWEL BARS SHALL BE

DOWEL BARS 20 300 300 Te = THICKNESS OF EXISTING PAVEMENT NOT TO SCALE SMOOTH ROUND STEEL BAR FREE FROM RUST AND OTHER DEFECTS ( REFER

T = THICKNESS OF NEW PAVEMENT TO CLAUSE 3; 1,3,12. THE STANDARD SPECIFICATION FOR ROADS AND BRIDGES 1995.).

5. TYPE OF WEAKENED PLANE JOINT TO BE USED SHALL BE AS SPECIFIED IN

THE PLANS AND ONLY ONE TYPE SHALL BE USED FOR THE WHOLE PROJECT.

CONTRACTION JOINT SECTION H CONSTRUCTION JOINT 6. MATERIAL FOR THE METAL SIDE FORM SHALL BE BRAND NEW SHEET METAL

C STEEL BASKET FOR SETTING DOWELS ( TO BE USED FOR WIDENING EXISTING

CONCRETE PAVEMENT )

GAUGE No.18 OF BLACK IRON FREE FROM RUST AND LINKS.

7. AT LEAST SIX (6) SUCCESSIVE DOWELLED BUTT JOINTS AT NORMAL JOINT

N T S METAL DOWEL CAP GAUGE No. 18 SPACING SHALL BE PROVIDED BEFORE OR AFTER AN EXPANSION JOINT.

TO BE PLACED ON EACH DOWEL

8. THE GROOVE OR CRACK ABOVE JOINTS (LONGITUDINAL OR TRANSVESE)SHALL

BAR ON ALTERNATE END

BE SEALED WITH 30-50 PENETRATION ASPHALT SEAL OR COLD APPLIED LIQUID

RUBBER COMPOUND AFTER THE CONCRETE HARDENS AND BEFORE OPENING

THE PAVEMENT TO TRAFFIC. PENETRATION ASPHALT SEAL ON CONCRETE

PAVEMENT , JOINTS SHALL BE POURED IN SUCH MANNER THAT SPILLING WILL

DOWEL BARS (PLAIN BARS) BE ELIMINATED / PREVENTED. THUS, PROVIDING A SMOOTH LEVELING / RIDING

PAINTED WITH RED LEAD CONST. JOINT TO BE KEEP EXISTING SURFACE.

6mm THEN GREASED

MOPPED W/ ASPHALT TIE BARS 9. ALL TRANSVERSE JOINTS,EXCEPT CONSTRUCTION JOINT SHALL BE CONTINOUS

T/4 FROM EDGE TO EDGE.

T/3

10. ALL LONGITUDINAL JOINTS SHALL MEET AT INTERSECTIONS WITH NO GAPS

T

OR OFFSET.

T/3

T

FIRST SLAB

11. ALL DIMENSIONS ARE IN MILLIMETERS UNLESS OTHERWISE SPECIFIED.

EXISTING 1L METAL DOWEL CAP DETAIL

T/3

PAVEMENT NEW PAVEMENT 12. AVOID STOPPAGE OF FORMWORKS ALONG CURVES.

NOT TO SCALE

300 300

BUTT TRANSVERSE CONSTRUCTION

E OR CONTACT JOINT

N T S

I LONGITUDINAL CONST'N. JT.

( TO BE USED FOR CONNECTIONS WITH EXISTING

CONCRETE PAVEMENT AND NEW PAVEMENT )

REPUBLIC OF THE PHILIPPINES

DEPARTMENT OF PUBLIC WORKS AND HIGHWAYS CAD: MARCIAL D. ORIOL

ENGINEERING ASSISTANT

STANDARD PORTLAND CEMENT

BUREAU OF DESIGN AS - SHOWN CONCRETE PAVEMENT JOINTS

DESIGN: PETER JAMES T. ESQUIBIL /

PAOLO CARLO M. SALVADOR

STD 02

HIGHWAYS DIVISION DANILO L. BALISI DANTE B. POTANTE GILBERTO S. REYES RAUL C. ASIS PCCP-2 03

( DOWELLED ) ENGINEER II

CHIEF- HIGHWAYS DIV.,B.O.D. DIRECTOR IV , B.O.D. ASSISTANT SECRETARY UNDERSECRETARY

BONIFACIO DRIVE, PORT AREA, MANILA CHECKED: ROMEO C. RAAGAS

ENGINEER IV

Вам также может понравиться

- PROJECT PROPOSAL - Drainage ConstructionДокумент5 страницPROJECT PROPOSAL - Drainage Constructionrolandtrojas97% (143)

- Sample of A Project Proposal - Livelihood Starter KitДокумент3 страницыSample of A Project Proposal - Livelihood Starter Kitrolandtrojas90% (119)

- Sample of A Project Proposal - Water System ProjectДокумент4 страницыSample of A Project Proposal - Water System Projectrolandtrojas93% (225)

- Project Proposal-2016 BuB-DOLE Livelihood or Kabuhayan ProgramДокумент8 страницProject Proposal-2016 BuB-DOLE Livelihood or Kabuhayan Programrolandtrojas85% (60)

- Standard Barangay Health Station (BHS)Документ11 страницStandard Barangay Health Station (BHS)rolandtrojas100% (5)

- Kto12 Grade 7 Math q1 To q4Документ261 страницаKto12 Grade 7 Math q1 To q4rolandtrojas86% (240)

- Project Proposal - Sea WallДокумент5 страницProject Proposal - Sea Wallrolandtrojas96% (25)

- Sample of A Project Proposal - Provision of Farm Inputs (Production of Palay, Corn, Mongo, Peanut and Camote)Документ13 страницSample of A Project Proposal - Provision of Farm Inputs (Production of Palay, Corn, Mongo, Peanut and Camote)rolandtrojas93% (182)

- 2015 DPWH Cost Estimation ManualДокумент250 страниц2015 DPWH Cost Estimation Manualrolandtrojas100% (8)

- Bioethanol From CornДокумент13 страницBioethanol From Cornpricett100% (1)

- Structural Plan MD Rock Concrete Mix Corporation: Motorpool Building As-Built Plan As ShownДокумент1 страницаStructural Plan MD Rock Concrete Mix Corporation: Motorpool Building As-Built Plan As ShownPaulineAnnLambitoUlanОценок пока нет

- Establishment of Fish Aggregating Device - Detailed ProposalДокумент10 страницEstablishment of Fish Aggregating Device - Detailed Proposalrolandtrojas92% (13)

- Typical Roadway SectionДокумент1 страницаTypical Roadway Sectionjc aremero100% (1)

- Construction Master Specs Guide to CSI FormatДокумент2 страницыConstruction Master Specs Guide to CSI FormatMark Roger II HuberitОценок пока нет

- BEAM SCHEDULE (C21:Fy414) (LEVEL: 2m)Документ1 страницаBEAM SCHEDULE (C21:Fy414) (LEVEL: 2m)janrayC13Оценок пока нет

- Appendix 1 BДокумент28 страницAppendix 1 BRikky ZuluetaОценок пока нет

- Tanginl SeawallДокумент12 страницTanginl SeawallKing LemuelОценок пока нет

- Outline of Topics: Resultant Moments. These Are The Stress Resultants (Also Called Membrane ForcesДокумент16 страницOutline of Topics: Resultant Moments. These Are The Stress Resultants (Also Called Membrane ForcesJosiah FloresОценок пока нет

- Reviewer Material Quality Control and Hydrology Division (Promotional Exam)Документ99 страницReviewer Material Quality Control and Hydrology Division (Promotional Exam)Pat Hadji AliОценок пока нет

- Detailed Engineering Design For Evacuation CenterДокумент292 страницыDetailed Engineering Design For Evacuation Centerrolandtrojas33% (3)

- Maintenance & Trouble Shooting of Voith CouplingДокумент20 страницMaintenance & Trouble Shooting of Voith Couplingsen_subhasis_58100% (1)

- Colorado Passenger Tramway Safety Board Adam Lee Accident ReportДокумент28 страницColorado Passenger Tramway Safety Board Adam Lee Accident ReportMichael_Lee_RobertsОценок пока нет

- Annual traffic growth rates by region Philippines 2003-2026Документ1 страницаAnnual traffic growth rates by region Philippines 2003-2026Angelo KaragdagОценок пока нет

- AASHTO - Rigid Pavement DesignДокумент83 страницыAASHTO - Rigid Pavement DesignBenedict OgbaghaОценок пока нет

- Beam DesignДокумент21 страницаBeam DesignKent XyrellОценок пока нет

- Two Way Slab Design 2Документ8 страницTwo Way Slab Design 2ZuzarОценок пока нет

- NSCP2001-UBC97 Static Earthquake PDFДокумент9 страницNSCP2001-UBC97 Static Earthquake PDFMichael Dixon100% (1)

- REVISED PERT/CPM TIME-SCALED NETWORK DIAGRAM FOR MARCOS BRIDGE REHABILITATION PHASE IIДокумент1 страницаREVISED PERT/CPM TIME-SCALED NETWORK DIAGRAM FOR MARCOS BRIDGE REHABILITATION PHASE IIThortheGreayОценок пока нет

- Chart For Steel Beams PDFДокумент2 страницыChart For Steel Beams PDFDan Aragon RetotaОценок пока нет

- RSSA Assesses Functionality and Sustainability of Roads, Bridges and Flood Control ProjectsДокумент2 страницыRSSA Assesses Functionality and Sustainability of Roads, Bridges and Flood Control ProjectsRichard MendezОценок пока нет

- Flood Resilience, Planning and Management in San Juan Accfa in Cabanatuan CityДокумент2 страницыFlood Resilience, Planning and Management in San Juan Accfa in Cabanatuan CityJulie Ann Sta. AnaОценок пока нет

- 02 PDFДокумент319 страниц02 PDFHarot StyleshОценок пока нет

- Effect of Gravity and Centrifugal ForcesДокумент21 страницаEffect of Gravity and Centrifugal ForcesCharisse RiveraОценок пока нет

- DO 037 s2016 PDFДокумент13 страницDO 037 s2016 PDFKaren Balisacan Segundo RuizОценок пока нет

- Design of Tie Beam (TB)Документ3 страницыDesign of Tie Beam (TB)Khael Angelo Zheus JaclaОценок пока нет

- Sampling Aggregates Lab ManualДокумент8 страницSampling Aggregates Lab ManualJoshua CalaОценок пока нет

- STAAD - Pro & STAAD Advanced Concrete: Design of Two-Storey Reinforced-Concrete ResidentialДокумент47 страницSTAAD - Pro & STAAD Advanced Concrete: Design of Two-Storey Reinforced-Concrete ResidentialKaye Kathlene BasubasОценок пока нет

- Typical Roadway Section DetailsДокумент3 страницыTypical Roadway Section DetailsNoel Jr Reyes100% (1)

- Textbook For CMT (Asphalt, Wood, & Steel)Документ15 страницTextbook For CMT (Asphalt, Wood, & Steel)vincelordОценок пока нет

- 1.1 Basic Code Requirements From NSCP (2015)Документ20 страниц1.1 Basic Code Requirements From NSCP (2015)Joshua Cala100% (1)

- fdt-104 EmbankmentДокумент1 страницаfdt-104 EmbankmentGenevieve GayosoОценок пока нет

- Helical spring stress and elongation calculationsДокумент4 страницыHelical spring stress and elongation calculationsMavrix AgustinОценок пока нет

- Soil Mechanics HW TemplateДокумент3 страницыSoil Mechanics HW TemplateAmarilis RamosОценок пока нет

- ESWL FlexibleДокумент25 страницESWL FlexibleFiras BarrajОценок пока нет

- DPWH Issues New Road Construction Cost Estimation ManualДокумент1 страницаDPWH Issues New Road Construction Cost Estimation ManualIan JamesОценок пока нет

- Intro 2nd EditionДокумент594 страницыIntro 2nd EditionDDIОценок пока нет

- Proposed new pool and spa at residential propertyДокумент3 страницыProposed new pool and spa at residential propertyJohn Carlo RoselloОценок пока нет

- Ns 18 Steel DesignДокумент49 страницNs 18 Steel DesignKrm ChariОценок пока нет

- Bidding DocumentsДокумент60 страницBidding Documentspaul vincent marianoОценок пока нет

- DESCRIPTION: ITEM 405-Structural ConcreteДокумент11 страницDESCRIPTION: ITEM 405-Structural ConcreteKioОценок пока нет

- Origin - Destination Survey: Definition, Objective and MethodologyДокумент25 страницOrigin - Destination Survey: Definition, Objective and MethodologyAbhishek SharmaОценок пока нет

- Module 1 Quiz Solution PDFДокумент4 страницыModule 1 Quiz Solution PDFBanana QОценок пока нет

- Gumapos Bridge widening as-built planДокумент37 страницGumapos Bridge widening as-built planKen GabrielОценок пока нет

- DPWH Bridge OverviewДокумент7 страницDPWH Bridge OverviewTina Rosales100% (1)

- Calculating Section Properties of Built-Up Steel BeamsДокумент5 страницCalculating Section Properties of Built-Up Steel BeamsNavneet RaiОценок пока нет

- Bar Cutting List TemplateДокумент4 страницыBar Cutting List TemplateWrec SerranoОценок пока нет

- Elements of Roads and Highways by Max Fajardo 2nd EditionДокумент2 страницыElements of Roads and Highways by Max Fajardo 2nd Editionjohnnoe delosreyes0% (1)

- CamScanner Scanned DocumentДокумент1 025 страницCamScanner Scanned DocumentAnna Jeilica Lanuza Destura100% (1)

- 02 - DILG - Salintubig - Components of Water Supply SystemДокумент43 страницы02 - DILG - Salintubig - Components of Water Supply SystemTarhata KalimОценок пока нет

- CHB 125mmДокумент2 страницыCHB 125mmKatrina NanoОценок пока нет

- Reinforced Concrete Design (RCD) Working Stress Design NotesДокумент30 страницReinforced Concrete Design (RCD) Working Stress Design Noteslemi celemenОценок пока нет

- Sample House Construction Cost Estimate PhilippinesДокумент7 страницSample House Construction Cost Estimate PhilippinesJebong A. MarquezОценок пока нет

- Wind Load Analysis NSCP 2015Документ30 страницWind Load Analysis NSCP 2015Abhe MangampoОценок пока нет

- Lighting & Power Layout Vicinity Map: Chedule of LoadsДокумент1 страницаLighting & Power Layout Vicinity Map: Chedule of Loadsjohndean urbanozoОценок пока нет

- BrgyBantayanon Calatrava NegrosOccidental DDDДокумент31 страницаBrgyBantayanon Calatrava NegrosOccidental DDDNoel PagalingОценок пока нет

- Schedule of Minimum Test Requirements for Earthworks and Pavement ConstructionДокумент23 страницыSchedule of Minimum Test Requirements for Earthworks and Pavement ConstructionApple CurimatmatОценок пока нет

- Ce Laws, Contracts and SpecificationsДокумент20 страницCe Laws, Contracts and SpecificationsMIKE ARTHUR DAVIDОценок пока нет

- Project: Mabini Pier (Conveyor Support) Location: Mabini, Batangas OwnerДокумент1 страницаProject: Mabini Pier (Conveyor Support) Location: Mabini, Batangas OwnerjologscresenciaОценок пока нет

- CPM Cost Crashig-3Документ17 страницCPM Cost Crashig-3John Rennekien Mateo0% (1)

- S1 - BoringДокумент1 страницаS1 - BoringNonoy Justiniane-Giray JrОценок пока нет

- BENDING SCHEDULEДокумент1 страницаBENDING SCHEDULERichard AkelaОценок пока нет

- Plate 1 Portal FrmaesДокумент1 страницаPlate 1 Portal FrmaesMAHAK GUPTAОценок пока нет

- SHOP MATERIALS BILL OF MATERIALSДокумент1 страницаSHOP MATERIALS BILL OF MATERIALSDeborah Jasmine Saldarriaga CrisantoОценок пока нет

- Revised Foundation For 315 Mva Transformer 28 10 09 Model PDFДокумент1 страницаRevised Foundation For 315 Mva Transformer 28 10 09 Model PDFepe civilОценок пока нет

- Climate Change in The PhilippinesДокумент91 страницаClimate Change in The PhilippinesAnonymous PlAzpcuOEОценок пока нет

- 02 AM Road DrainageДокумент67 страниц02 AM Road Drainagerolandtrojas100% (1)

- Overview Staad Dilg Ded2018 WslopezДокумент128 страницOverview Staad Dilg Ded2018 Wslopezrolandtrojas100% (1)

- 2line Pavement-Revised - BДокумент1 страница2line Pavement-Revised - Balex abestadoОценок пока нет

- 2line Pavement-Revised - AДокумент1 страница2line Pavement-Revised - Arolandtrojas100% (2)

- STNDRD Kilometer Post & Maintainance Marker Post - PДокумент1 страницаSTNDRD Kilometer Post & Maintainance Marker Post - Palex abestadoОценок пока нет

- Sample Computation-Excavate and TransportДокумент4 страницыSample Computation-Excavate and Transportrolandtrojas100% (1)

- Engineering Surveys LectureДокумент80 страницEngineering Surveys LecturerolandtrojasОценок пока нет

- Math Learner Module k-12 Grade 8Документ112 страницMath Learner Module k-12 Grade 8Joseph Ryan Prolles67% (39)

- Project Proposal-2016 BuB-Reintegration Program For OFWsДокумент5 страницProject Proposal-2016 BuB-Reintegration Program For OFWsrolandtrojas100% (2)

- Narrative Project Status Report - DKSK ProjectДокумент5 страницNarrative Project Status Report - DKSK ProjectrolandtrojasОценок пока нет

- Sacahon Beach and Nagngangang Buaya: A Historic CoastlineДокумент3 страницыSacahon Beach and Nagngangang Buaya: A Historic CoastlinerolandtrojasОценок пока нет

- MSDS 42935Документ3 страницыMSDS 42935EliasОценок пока нет

- DIN EN 10213 - 2008 - Fundidos em AçoДокумент29 страницDIN EN 10213 - 2008 - Fundidos em AçoLeonardo MartinsОценок пока нет

- Conventional Smoke DetectorДокумент1 страницаConventional Smoke DetectorThan Htike AungОценок пока нет

- TUGAS BAHASA INGGRIS Cahaya Karisma Wilani Faturrachman Rengga Wisnu Resza Bunga Nisa POLITEKNIK NEGERI JAKARTA JURUSAN KONSTRUKSI BANGUNAN SIPILДокумент4 страницыTUGAS BAHASA INGGRIS Cahaya Karisma Wilani Faturrachman Rengga Wisnu Resza Bunga Nisa POLITEKNIK NEGERI JAKARTA JURUSAN KONSTRUKSI BANGUNAN SIPILFaturrachman Nanu Rengga WisnuОценок пока нет

- Dunlop Cement Based Adhesives - SDS10024Документ4 страницыDunlop Cement Based Adhesives - SDS10024Dominic LeeОценок пока нет

- Carbon Dioxide in RespirationДокумент1 страницаCarbon Dioxide in Respirationlolay01Оценок пока нет

- Billing No. 4 Accomplishement ReportДокумент1 страницаBilling No. 4 Accomplishement ReportGOB ConstructionОценок пока нет

- MWD Log Quality & StandardsДокумент168 страницMWD Log Quality & StandardsHamed Sadeghi100% (1)

- Engineering Drawing Solution All Year First Part Ioe NotesДокумент31 страницаEngineering Drawing Solution All Year First Part Ioe Notesई. सन्तोष शर्माОценок пока нет

- Coiled Tubing For Downhole ProcessДокумент10 страницCoiled Tubing For Downhole ProcessCristian BarbuceanuОценок пока нет

- Acetylated Castor Oil - Preparation and Thermal DecompositionДокумент7 страницAcetylated Castor Oil - Preparation and Thermal DecompositionPee Hai NingОценок пока нет

- Understanding Japanese Management PracticesДокумент16 страницUnderstanding Japanese Management PracticesBusiness Expert Press100% (3)

- 864 Wiring Schematic: S/N 518913001-14999 S/N 516812001-14999 S/N 517512001-14999 (Printed March 2001) V-0072Документ6 страниц864 Wiring Schematic: S/N 518913001-14999 S/N 516812001-14999 S/N 517512001-14999 (Printed March 2001) V-0072Ataa AssaadОценок пока нет

- Assessment 1 - Questioning - Written Assessment: Satisfactory or Not YetsatisfactoryДокумент38 страницAssessment 1 - Questioning - Written Assessment: Satisfactory or Not YetsatisfactoryAbhishek Kumar0% (1)

- Electrical Power Transmission & DistributionДокумент18 страницElectrical Power Transmission & DistributionMd Saif KhanОценок пока нет

- SPE143315-Ultrasound Logging Techniques For The Inspection of Sand Control Screen IntegrityДокумент18 страницSPE143315-Ultrasound Logging Techniques For The Inspection of Sand Control Screen IntegrityYovaraj KarunakaranОценок пока нет

- f094 PDFДокумент4 страницыf094 PDFAnshuman SinghОценок пока нет

- Eco Web Server III Instruction Manual - OperatingДокумент0 страницEco Web Server III Instruction Manual - OperatingAndrew MaverickОценок пока нет

- RC F18 Super Hornet - Manual v2.0Документ13 страницRC F18 Super Hornet - Manual v2.0Darren-Edward O'NeillОценок пока нет

- 21 - Al Ghubaiba Bus Station To Al Quoz, Clinical Pathology Dubai Bus Service TimetableДокумент26 страниц21 - Al Ghubaiba Bus Station To Al Quoz, Clinical Pathology Dubai Bus Service TimetableDubai Q&A100% (3)

- Operating Procedure ERLDCДокумент154 страницыOperating Procedure ERLDCbramhanand vermaОценок пока нет

- Monopoly - Indian Railways: - Anand Dube - Darshna Chande - Karan Sobti - Sriaditya Kasula - Vinay ChaudhariДокумент52 страницыMonopoly - Indian Railways: - Anand Dube - Darshna Chande - Karan Sobti - Sriaditya Kasula - Vinay ChaudhariKristamRajuОценок пока нет

- PM IS - 12818 June2021Документ10 страницPM IS - 12818 June2021Mahendra AhirwarОценок пока нет

- Tetra Cardboard Packer 70 - CopyДокумент808 страницTetra Cardboard Packer 70 - CopyOmar AlneasОценок пока нет

- Project-BOQ - (Excluding VUP, LVUP)Документ127 страницProject-BOQ - (Excluding VUP, LVUP)Shivendra KumarОценок пока нет

- Vol 4 Div G ODS Part 1 of 2-Pages-18-55Документ38 страницVol 4 Div G ODS Part 1 of 2-Pages-18-55debapriyoОценок пока нет

- WT Lab ManualДокумент44 страницыWT Lab ManualVenkatanagasudheer Thummapudi100% (1)