Академический Документы

Профессиональный Документы

Культура Документы

TSTPP ABB 500 MW Steam Turbine

Загружено:

DenkaОригинальное название

Авторское право

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документTSTPP ABB 500 MW Steam Turbine

Загружено:

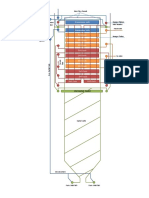

DenkaTALCHER 2 X 500 MW STEAM TURBINE

S. PARAMETER TALCHER

NO. (2 X 500 MW)

1. No. of Units 2

2. Turbine make/design ABB

3. Rated Capacity (MW) 500 MW

4. VWO Capacity (MW) 537

5. Rated Condenser Vacuum (MM of 77

Hg abs)

6. Rated CW Inlet Temp.0C 320C#1, 360C#2

7. Number of turbine cylinders 3

HP/IP/LP

8. Barring gear

a) Type Motorised

b) Speed (RPM) 11

c) Location On brg. No. 2

9. Critical Speeds (RPM) I II III

a) HP Rotor - - 2450

b) IP Rotor - - 2100

c) LP Rotor 1300 4250 -

d) Combined 700 2150 -

10. Operation Frequency Regime

a) Continuous Operation 47.5 - 53 Hz

b) Limited Operation range <47.5 for l0 secs ,>53.0 Hz width no time

continuous at a stretch & total delay

life time

11. Droop/Regulation

a) Standard droop % 6%

b) Droop ineffective range 47.5-52.5 Hz

C:\AJOB\GAURAV\RAO\TALCH-ST2.DOC::::IST PROOF PRINT :: 24.03.2000:::::1:::::::12

C:\AJOB\GAURAV\RAO\TALCH-ST2.DOC::::IIND PROOF PRINT :: 29.03.2000::1/11

TALCHER 2 X 500 MW STEAM TURBINE

S. PARAMETER TALCHER

NO. (2 X 500 MW)

12. Governing

a) Type Nozzle

b) Operation modes Combined EHC

c) Overspped tripping Speed i)+10% ii) 12% (mech. overspeed)

d) Dead band 47.5-52.5 Hz

e) Speed sensing device Inductive (works on principle of eddy

current)

13. Turbine type Impulse HP/IP/LP

14. HP

a) Type

b) No. of casings Split

c) No. of flows 2

d) Blade carrier/blade type Single

e) Inlet parameter -

i) Pressure (KG/cm2) 170

ii) Temperature 0C 537

iii) Wheel chamber pressure 140.4 (during PG test )

f) Exhaust Parameter

i) Pressure (KG/cm2) 46

iv) Temperature 0C 343

15. IP Casing

a) Type Split

b) No. of casings 2

c) No. of flows Double

d) Blade carrier/blade type -

e) Inlet parameter

i) Pressure (Kg/cm2) 40.57

C:\AJOB\GAURAV\RAO\TALCH-ST2.DOC::::IST PROOF PRINT :: 24.03.2000:::::2:::::::12

C:\AJOB\GAURAV\RAO\TALCH-ST2.DOC::::IIND PROOF PRINT :: 29.03.2000::2/11

TALCHER 2 X 500 MW STEAM TURBINE

S. PARAMETER TALCHER

NO. (2 X 500 MW)

ii) Temperature 0C 537

f) Exhaust Parameter

i) Pressure (Kg/cm2) 6.47

ii) Temperature 0C 276.8

16. LP Casing

a) Type Split

b) No. of casings 2

c) No. of flows Double

d) Blade carrier/blade type -

e) Inlet parameter

i) Pressure (Kg/cm2) 6.147

0

ii) Temperature C 276.8

f) Exhaust Parameter

i) Pressure (Kg/cm2) 0.121

ii) Temperature 0C 49.3

17. Bearing Pedestals Type

a) HP front Fixed

b) Between HP/IP Sliding

c) Between IP/LP Fixed

d) LP-1&LP-2 (if applicable) Not applicable

e) Between LP & Generator Fixed

18. Bearing Type/Size (mm x mm dia)

I. HP front 157 x 200

II. Between HP & IP 260 x 315

III. Between IP & LP 371 x 525

IV. Between LP & Gen. 421 x 475

V. Between Gen. & Exciter 371 x 425 (Bet gen & Exc.)

VI. Exciter Rear 211 x 250 (Exc rear)

C:\AJOB\GAURAV\RAO\TALCH-ST2.DOC::::IST PROOF PRINT :: 24.03.2000:::::3:::::::12

C:\AJOB\GAURAV\RAO\TALCH-ST2.DOC::::IIND PROOF PRINT :: 29.03.2000::3/11

TALCHER 2 X 500 MW STEAM TURBINE

S. PARAMETER TALCHER

NO. (2 X 500 MW)

19. Bearing Seating Type

a) Bearing no. 1

b) Bearing no. 2 NA

c) Bearing no. 3

d) Bearing no. 4

20. Turbine rotors

a) HP rotor

i) Type Disc. Type

ii) Weight 10.60 tonnes

iii) Length (coupling to 5500 mm

coupling)

b) IP rotor

Disc. type

i) Type

20.00 tonne

ii) Weight

4667mm

iii) Length (coupling to coupling)

c) LP rotor

Disc

i) Type

53.7 tonnes

ii) Weight

6462

iii)Length (coupling to coupling)

21. HP stage blading

a) No. of blades /Stage No. NA

b) Shroud type/section All integral

c) Root type/section All dove Tail

22. IP stage blading

a) No. of blades / stage NA

b) Shroud type/section All Integral shroud

c) Root type/section All dove. Tail

C:\AJOB\GAURAV\RAO\TALCH-ST2.DOC::::IST PROOF PRINT :: 24.03.2000:::::4:::::::12

C:\AJOB\GAURAV\RAO\TALCH-ST2.DOC::::IIND PROOF PRINT :: 29.03.2000::4/11

TALCHER 2 X 500 MW STEAM TURBINE

S. PARAMETER TALCHER

NO. (2 X 500 MW)

23. LP stage blading

a) No. of blades / stage NA

b) Shroud type/section All integral except last 2 stages which are

Free standing.

All dove tail except last 2 stages which are

c) Root type/section FIR TREE type.

24. Stop & Control Valves

a) Type Combined/Separate In HPT-Separate, In IPT-Combined

b) Location : Mounted on turbine Mounted on Turbine

away from turbine

c) Number of valves

i) HP i) 2 nos S/V & 4 nos. S/V

ii) IP ii) 2 nos. combine SV & CV

d) Actuating servomotor

Common/dedicated to each

valve

i) HP Dedicated to each valve

ii) IP

e) Pilot/Relief valves-Yes/No Yes

(Integral)

f) Valve

HPCV - 49.0 mm HPSV - 83.3 mm

Travel (m.m)

IPCV – 172.0 mm IPSV – 153.7 mm

g) Facility for individual valve

Auto

testing manual automatic/not

available

25. Couplings Type

i) HP/IP Rigid

ii) IP/LP Rigid

iii) LP/Gen Rigid

iv) HP/MOP Rigid

C:\AJOB\GAURAV\RAO\TALCH-ST2.DOC::::IST PROOF PRINT :: 24.03.2000:::::5:::::::12

C:\AJOB\GAURAV\RAO\TALCH-ST2.DOC::::IIND PROOF PRINT :: 29.03.2000::5/11

TALCHER 2 X 500 MW STEAM TURBINE

S. PARAMETER TALCHER

NO. (2 X 500 MW)

26. Turbovisory

a) Total expn. At HP front

27.90 mm

b) Expansion at IP pedestal

11.70 mm

c) Differential expn limits

+ 8.31 mm to – 0.52 mm

HP

+ 13.95 mm to – 1.48 mm

IP

+ 16.00 mm to – 4.0 mm

LP

+ 0.8 mm

d) Axial shift trip valve (Limit)

27. Automatic Turbine Run up System

(ATRS)

Incorporated / not incorporated

Incorporated

28. Automatic testing

of protection devices (ATT)

a) Incorporated / not incorporated Incorporated

b) If incorporated testing envisaged

- Overspeed at operating speed Yes

- Axial shift/high thrust wear Yes

- Stop valves Yes

- Vacuum protection Yes

- Any other protection Lube oil pr. & MOT Level low protection

29. Design heat rate (Kcal/Kwhr) Heat Rate At rated conditions

Make up % Conds. Vac.

At 100% load 1988.1 0% 77 mmHg

At 80% load 2006.4 0% 77 mmHg

At 60% load 2047.1 0% 77 mmHg

30. Extraction : Extr. Heater Pr. Temp. Flow

No. TerminalKg/CM2 C T/hr

C:\AJOB\GAURAV\RAO\TALCH-ST2.DOC::::IST PROOF PRINT :: 24.03.2000:::::6:::::::12

C:\AJOB\GAURAV\RAO\TALCH-ST2.DOC::::IIND PROOF PRINT :: 29.03.2000::6/11

TALCHER 2 X 500 MW STEAM TURBINE

S. PARAMETER TALCHER

NO. (2 X 500 MW)

Location – Turbine & Stage No.

a) H.P. Turbine Stage - - - - -

b) H.P. Exhaust 6 HPH-6A 44.67 342.6 108.6

& 6B

c) I.P. Turbine (5th stage towards 5 HPH-5A 25.83 470.6 109.26

HPT) & 5B

d) I.P. Turbine Stage 4 Dear. + 9.826 337.7 160.6

(13th stage towards LPT) TDBFP 89.76

+70.85)

e) L.P. Turbine (Ist stage) x 2 3 LPH-3 3.596 221.4 8.802

f) L.P. Turbine (3rd stage) x 2 2 LPH-2 1.366 120.2 56.696

g) L.P. Turbine (4th stage) x 2 1 LPH-1 0.573 81.5 62.534

31. Extractions NRV No. of NRV’s type

1 No valve Make

2 1 swing CHK V/V (Pneumatic)

1 swing CHK V/V (Mech.)

3 1 swing CHK V/V (Pneumatic) -

1 swing CHK V/V (Mech.)

4 4 swing CHK V/V (Pneumatic) -

5 2 swing CHK V/V (Pneumatic) -

6 2 swing CHK V/V (Pneumatic) -

CRH Line 2 swing CHK V/V (Pneumatic) -

32. HP Bypass

Type ARS-100 Actuator ASM – 160 – 11

Size Flow area – 42.44 CM2, seat dia –100 mm

Sulzer

C:\AJOB\GAURAV\RAO\TALCH-ST2.DOC::::IST PROOF PRINT :: 24.03.2000:::::7:::::::12

C:\AJOB\GAURAV\RAO\TALCH-ST2.DOC::::IIND PROOF PRINT :: 29.03.2000::7/11

TALCHER 2 X 500 MW STEAM TURBINE

S. PARAMETER TALCHER

NO. (2 X 500 MW)

Make 270.4 tonnes/hr per valve

Capacity (Rated % flow) No

Jacking Cooling Provided

Downstream Parameter 33 Kg/cm2

i) Pr 3100C

ii) Temperature

33. Oil System

33.1 Main Oil Tank (Lube Oil)

i) Tank Capacity (m3) 40

ii) Oil requirement for NWL (m3) 40

iii) Type of strainer Basket

iii) Size of strainer -

32.2 Oil vapour exhauster

i) No. & Location 2 nos. on MOT

33.3 Centrifuge

i) Type & make WHPX 40 g/Alpha Laval

ii) Capacity (Ltrs/hr) 8000 ltr/hr

33.4 Oil Cooler

i) Nos. & standby 2 (1 standby)

ii) Type of Tubes arrangement U- Tubes

iii) Material of tubes Admirality Brass

C:\AJOB\GAURAV\RAO\TALCH-ST2.DOC::::IST PROOF PRINT :: 24.03.2000:::::8:::::::12

C:\AJOB\GAURAV\RAO\TALCH-ST2.DOC::::IIND PROOF PRINT :: 29.03.2000::8/11

TALCHER 2 X 500 MW STEAM TURBINE

S. PARAMETER TALCHER

NO. (2 X 500 MW)

33.5 Main oil pump

i) Speed 1410 rpm

ii) Coupling arrangement Gear coupling

iii) Discharge Pr. 4.0 Kg/cm2

iv) Flow / capacity 2200 ltr/minute

v) No. & type of bearing -

33.6 Auxiliary Oil Pump

i ) Numbers Two (AC Driven)

ii) Make Allweiler (NSS-8-200)

iii) Speed 3000 rpm

iv) Discharge Pressure 4.0 Kg/cm2

v) Rated flow 1980 lit/min

vi) Mounting location Top of main oil tank

vii) Type of mounting (V/H) Vertical

viii) Motor make & rating 24.2 KW

33.7 Emergency oil pump (DC)

a) Make Allweiler

b) Speed (RPM) 1500

c) Discharge PR (ata) 1.3 kg/cm2

d) Rated flow (dm3/Sec) 1020 lit/min

e) Mounting location On Top of MOT

f) Mounting arrangement (V/H) Vertical

g) Motor, make, rating 3.8 KW

33.8 Jacking Oil Pump

a) No. of pumps AC/DC 2 a.c and 1 d.c. each for bearing 3, 4 & 5

C:\AJOB\GAURAV\RAO\TALCH-ST2.DOC::::IST PROOF PRINT :: 24.03.2000:::::9:::::::12

C:\AJOB\GAURAV\RAO\TALCH-ST2.DOC::::IIND PROOF PRINT :: 29.03.2000::9/11

TALCHER 2 X 500 MW STEAM TURBINE

S. PARAMETER TALCHER

NO. (2 X 500 MW)

b) Type of pump/make Q34-010R BDZ

c) Discharge pressure Maximum pr. 250 kg/cm2

d) Speed rpm 1450 rpm

e) Capacity 1.5 lit/min.

f) Motor make, rating, frame size 8.7 KW

34. Fire Resistant Fluid System Yes

34.1 Type & make of fluid (Unit wise if Fyrquel EHC/Shell HTGD 690, 149

different)

34.2 Tank Details

a) Tank capacity 6000 litres

b) Fluid requirement for NWL First filling 6900 lits

c) No. of strainer Two

d) Strainer size

e) Heater nos. Nil

f) Type of heaters Nil

34.5 FRF Pumps

a) Numbers Two

b) Make & Type Aliweiler SNDAT 1300-42

c) Rated flow 876 lit/min

d) Rated pressure 40 Kg/cm2

e) Speed 1500 rpm

f) Motor

i) Make -

ii) Rating 81KW

iii) Frame size -

34.6 FRF Regenerative System

a) Type of system Fuller’s earth Rotring,

b) Details of filter Attha pulgus clay

C:\AJOB\GAURAV\RAO\TALCH-ST2.DOC::::IST PROOF PRINT :: 24.03.2000:::::10:::::::12

C:\AJOB\GAURAV\RAO\TALCH-ST2.DOC::::IIND PROOF PRINT :: 29.03.2000::10/11

TALCHER 2 X 500 MW STEAM TURBINE

S. PARAMETER TALCHER

NO. (2 X 500 MW)

Earth filter -

Fine mesh filter -

c) Type Rotring fine filter

d) Filter size -

C:\AJOB\GAURAV\RAO\TALCH-ST2.DOC::::IST PROOF PRINT :: 24.03.2000:::::11:::::::12

C:\AJOB\GAURAV\RAO\TALCH-ST2.DOC::::IIND PROOF PRINT :: 29.03.2000::11/11

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Husqvarna 235Документ33 страницыHusqvarna 235Joaquin Quinteros RissoОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Cat C 6.4 Fuel SystemДокумент13 страницCat C 6.4 Fuel Systemali83% (6)

- Turbofan Engine ReportДокумент20 страницTurbofan Engine Reportkashuprakash78% (9)

- Downloaded From Manuals Search EngineДокумент55 страницDownloaded From Manuals Search EngineTDHofstetterОценок пока нет

- The Electronically Controlled ME EngineДокумент10 страницThe Electronically Controlled ME EngineKamal WanniarachchiОценок пока нет

- Operating Instructions For MAN Marine Diesel Engines - D2876 LE 301Документ40 страницOperating Instructions For MAN Marine Diesel Engines - D2876 LE 301nicusebp100% (3)

- Service Manual - Stihl FS94 KM94 SP92 SP92TДокумент94 страницыService Manual - Stihl FS94 KM94 SP92 SP92TMichael100% (1)

- Training Manual: EASA Part-66 72 Level 3Документ16 страницTraining Manual: EASA Part-66 72 Level 3Luis Enrique La Font FrancoОценок пока нет

- S2E-S6E2 Operation ManualДокумент34 страницыS2E-S6E2 Operation ManualJOHON SANCHEZОценок пока нет

- Power Plant QuestionsДокумент20 страницPower Plant QuestionsDenkaОценок пока нет

- Auxiliary Power Unit (Apu) Systems ReviewДокумент5 страницAuxiliary Power Unit (Apu) Systems Reviewromixrayzen100% (1)

- Linde forklift-HD12 20T-03-Service-TrainingДокумент238 страницLinde forklift-HD12 20T-03-Service-TrainingchinhОценок пока нет

- 2X500 MW Neyveli New Thermal Power Project (NNTPP) Neyveli, Tamilnadu, IndiaДокумент6 страниц2X500 MW Neyveli New Thermal Power Project (NNTPP) Neyveli, Tamilnadu, IndiaDenkaОценок пока нет

- ATPL Nhom4 BDHKДокумент114 страницATPL Nhom4 BDHKVăn Thành NguyễnОценок пока нет

- PRICE LIST MTRT by MODEL 2022Документ32 страницыPRICE LIST MTRT by MODEL 2022Lastrella Rue100% (1)

- 4.0L EngineДокумент347 страниц4.0L EngineCapssa Oscar100% (2)

- NTPCVBR1Документ91 страницаNTPCVBR1DenkaОценок пока нет

- Thajudeen ResumeДокумент2 страницыThajudeen ResumeDenkaОценок пока нет

- TSTPP Turbine InterlocksДокумент39 страницTSTPP Turbine InterlocksDenkaОценок пока нет

- TSTPP Turbine Protection InterlockДокумент7 страницTSTPP Turbine Protection InterlockDenkaОценок пока нет

- MSG For UДокумент18 страницMSG For UDenkaОценок пока нет

- 1 Construction SafetyДокумент26 страниц1 Construction SafetyDenkaОценок пока нет

- Introduction About Thermal Power Station 010807Документ2 страницыIntroduction About Thermal Power Station 010807DenkaОценок пока нет

- Hanger System - Heating Surfaces 1.48760/00 213-0009: Zugehörige Zeichnungen / Relevant DrawingsДокумент1 страницаHanger System - Heating Surfaces 1.48760/00 213-0009: Zugehörige Zeichnungen / Relevant DrawingsDenkaОценок пока нет

- Index To Volumes: I. Operation & Maintenance Manual - BoilerДокумент2 страницыIndex To Volumes: I. Operation & Maintenance Manual - BoilerDenkaОценок пока нет

- 007PDF 0 17 809 00566 2 0Документ1 страница007PDF 0 17 809 00566 2 0DenkaОценок пока нет

- 001PDF 1 42 010 02377 0 0Документ1 страница001PDF 1 42 010 02377 0 0DenkaОценок пока нет

- Bharat Heavy Electricals Limited: Remark Designation Drawing NoДокумент1 страницаBharat Heavy Electricals Limited: Remark Designation Drawing NoDenkaОценок пока нет

- AssemblyДокумент1 страницаAssemblyDenkaОценок пока нет

- Bharat Heavy Electricals Limited: Neyveli Lignite Corporation Limited (NLC LTD)Документ1 страницаBharat Heavy Electricals Limited: Neyveli Lignite Corporation Limited (NLC LTD)DenkaОценок пока нет

- Superheater 1 06HAH10 AC001 ST-Row 3/4 ST-Row 2/5 ST-Row 1/6Документ1 страницаSuperheater 1 06HAH10 AC001 ST-Row 3/4 ST-Row 2/5 ST-Row 1/6DenkaОценок пока нет

- Bharat Heavy Electricals Limited: Neyveli Lignite Corporation Limited (NLC LTD)Документ1 страницаBharat Heavy Electricals Limited: Neyveli Lignite Corporation Limited (NLC LTD)DenkaОценок пока нет

- 007PDF 0 17 809 00566 2 0Документ1 страница007PDF 0 17 809 00566 2 0DenkaОценок пока нет

- Electromatic Relief Valve TYPE 1525 VX: Bharat Heavy Electricals Limited TiruchirapalliДокумент31 страницаElectromatic Relief Valve TYPE 1525 VX: Bharat Heavy Electricals Limited TiruchirapalliDenkaОценок пока нет

- Economizer Coils: Non Flow PanelsДокумент1 страницаEconomizer Coils: Non Flow PanelsDenkaОценок пока нет

- 002PDF 0 00 056 11072 5 0Документ1 страница002PDF 0 00 056 11072 5 0DenkaОценок пока нет

- Schlumberger CPS-361Документ1 страницаSchlumberger CPS-361Игорь ШиренинОценок пока нет

- Soal Airframe FixДокумент8 страницSoal Airframe FixMonita DiazsОценок пока нет

- Petrol Engines-Diesel EnginesДокумент10 страницPetrol Engines-Diesel EnginesAli Mohamed KhalilОценок пока нет

- CWI Product Information Bulletin - Natural Gas Engine Oils - April 2018Документ2 страницыCWI Product Information Bulletin - Natural Gas Engine Oils - April 2018roger gonzales hoyosОценок пока нет

- 3600 ME A&I Control System - Lekm8468Документ32 страницы3600 ME A&I Control System - Lekm8468Kuswanto MarineОценок пока нет

- Operation and Maintenance of Electronically Controlled Engines - Man B & W Me-C"Документ2 страницыOperation and Maintenance of Electronically Controlled Engines - Man B & W Me-C"GianОценок пока нет

- UL Certificate of Compliance DP DQ DR DS DT - Sflb.ashxДокумент3 страницыUL Certificate of Compliance DP DQ DR DS DT - Sflb.ashxEduardo CondeОценок пока нет

- I ST Sem 2018-19Документ30 страницI ST Sem 2018-19Venkata Subbaiah Mamilla CОценок пока нет

- Wankel Engine MainДокумент23 страницыWankel Engine MainAbhay MauryaОценок пока нет

- 2AZ-FE Ignition PDFДокумент8 страниц2AZ-FE Ignition PDFnelson prietoОценок пока нет

- Technical Parameter - toyota-2GR-FE CatolocgueДокумент74 страницыTechnical Parameter - toyota-2GR-FE CatolocgueTânn DuyyОценок пока нет

- How To: Index The Spark Plugs On A Ficht / Direct Injection OutboardДокумент4 страницыHow To: Index The Spark Plugs On A Ficht / Direct Injection OutboardrfffffОценок пока нет

- s2125 Service ManualДокумент222 страницыs2125 Service ManualJomesОценок пока нет

- 32 Urai Pressure Performance Curve PDFДокумент1 страница32 Urai Pressure Performance Curve PDFvasco scoterОценок пока нет

- C9 Valve SpecДокумент7 страницC9 Valve SpecWa TokeОценок пока нет

- Katalog O&k RH6.5Документ1 384 страницыKatalog O&k RH6.5Arek ZerebeckiОценок пока нет