Академический Документы

Профессиональный Документы

Культура Документы

W. Castles, JR: Filed Jan. 11, 1957

Загружено:

1550 оценок0% нашли этот документ полезным (0 голосов)

11 просмотров3 страницы066

Оригинальное название

Us 3066742

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документ066

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

11 просмотров3 страницыW. Castles, JR: Filed Jan. 11, 1957

Загружено:

155066

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

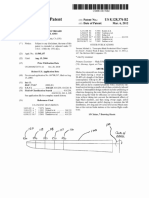

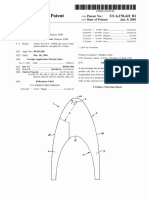

Dec. 4, 1962 W.

CASTLES, JR 3,066,742

ROTOR BLADE

Filed Jan. 11, 1957

33 31

INVENTOR.

//4 LTAA C4S7AAS, WA2.

" (2.9/k-it 477 OAAWAY

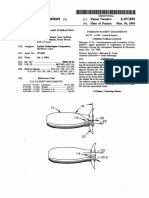

United States Patent Office 3,066,742

Patented Dec. 4, 1962

2

normal airfoil section modified in accordance with the

3,066,742 chord.

ROTOR BLADE

Walter Castles, Jr., Atlanta, Ga., assignor to Georgia For the purpose of definition herein, the "chord” is de

Tech Research Institute, Atlanta, Ga., a corporation of fined as the distance frcm the leading edge of the blade

Georgia airfoil to the trailing edge of the blade airfoil; the “thick

Fied Jara. 11, 1957, Ser. No. 633,655 ness' as hereinafter used, means the maximum distance

Claim. (C. 170-159) from the upper or one surface of the blade airfoil to the

This invention relates to rotor blades and is particularly lower or other surface of the blade airfoil; the term

concerned with the shape of air impeller blades such as "inverse taper' is a linear increase in airfoil chord with in

crease in the distance or radius from the hub at which that

may be appropriately used for high speed helicopters or chord is measured, and the “angularity” is defined as the

converta-planes. slope of the leading or trailing edge of the blade with re

It is well recognized that the top speed of helicopters Spect to the radial axis of the blade.

and in some instances that of converta-planes is limited Referring now more particularly to the drawings, that

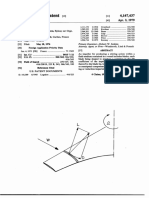

by the occurrence of blade tip stall of the rotating blade. form of the invention shown in FIGS. 1 and 2 discloses

The tip-stall speed limitation arises from the necessity the rotor blade conventionally mounted on the usual hub

to balance out to zero the net rolling moment acting upon i0 through a connector 1 having a lever 12 for con

the rotor. As a consequence of this limitation, it is well trolling the feathering of the blade by which its angularity

recognized that the top speed for helicopters and some is set. In this form of the invention the inboard portion

converta-planes is comparatively quite low with respect 20 of the blade is of uniform cross-section or chord as indi

to other forms of aircraft. This limitation is despite the cated at 13. At the outboard portion of the blade, the

fact that a great deal of excess power is available from chord increases in a substantially uniform inverse taper

the power plant. as shown at 14. In this form of the invention the chord

It is therefore among the objects of the present inven distribution is one in which the inboard chord c equals

tion to provide a novel and improved rotor blade for co and is essentially constant from the blade root to a

air impelling which will have an improved blade tip-stall radius which may be expressed as R, where x is of the

characteristic. order of about 0.5 to about 0.9, the optimum being 0.7

More particularly, it is among the objects of the present and R is the radius of the blade tip. The inverse taper

invention to provide an improved impeller blade shape by of the outboard portion 14 may be approximately de

which the blade tip-stall characteristics of the impeller 30 scribed, using the letter c for the chord, by the following

blades of helicopters and/or converta-planes may be im formula:

proved. -

Another object of the invention is to provide a novel c=e1+(8–1) (i-aca)(ac-ace) for aesars 1

blade shape, the chord distribution of which is such as to

materially increase the tip-stall limit top speed of a heli 35 where

copter or converta-plane. c=blade tip chord

It is also an object of the present invention to provide C

a blade of the type defined in which the chord distribu

tion is such as to provide an inverse taper for the out 40 C

board portion of the blade with respect to the inboard is from about 1.5 to about 3

blade chord.

Other objects, features and advantages of the present x=nondimensional radius

R

invention will be apparent from consideration of the fol R

lowing specification taken in conjunction with accom 45

panying drawings in which: 32=nondimensional radius at inboard end of inverse tip

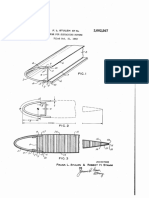

FIG. 1 is a top plan view of one form of blade carrying taper.

out the present inventive concept.

FIG. 2 is a side elevation of the blade of FIG. 1. In other words, x is the actual distance from the hub

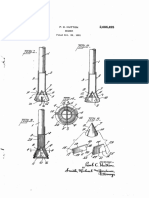

FIG. 3 is a modification of the blade embodying the to the chord c divided by the total distance from the hub

50 to the blade tip and x is the distance from the hub to

inventive principle disclosed in FIG. 1. the beginning of the inverse taper divided by the total

FIG. 4 is a side elevation of the blade in FIG. 3. distance from the hub to the blade tip.

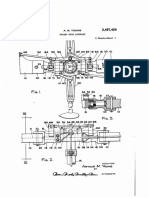

FIG. 5 is a top plan view of further modification of With such a blade it has been calculated that the fast

the blade embodying my inventive concept. Cessna CH-1 helicopter which presently has a tip-stall

FIG. 6 is a side elevation of the blade of FIG. 5. limit top speed of 122 m.p.h. although at such speed only

While the blade shape of the present invention may be approximately 70 percent of the power available is uti

widely varied as indicated by the three forms disclosed in lized, may by using the formula given in the NACA TN

the drawings, it may be generally stated that the principle 2656, by Walter Castles, Jr. and Noah C. New, July, 1952,

of the invention is concerned with the chord distribution published by National Advisory Committee for Aero

of the blade in such manner as to provide inverse out 60 nautics, have the following improved factors:

ward taper of the blade. Generally speaking, the blade 10 percent increase in the tip-stall limited top-speed

of the present invention has a substantially constant in where the rotor blades have the proportions x=0.70 and

board blade chord for over half of the blade length and

preferably in the order of 0.7 of such length and there

after the outboard portion of the blade is of greater width. 65

Preferably such extended width is by virtue of an inverse and;

taper of the outboard portion and preferably following 15 percent tip-stall speed increase where the blades

approximately the formula hereinafter set forth. It will have the proportions

be understood in connection with the following specifi

cation that the invention is not concerned with the internal O

structure of the rotor blade or with the material thereof.

a = 0.70 and 8-3

Co

The cross-sectional design may be presumed to follow the in comparing the above it is to be noted that these

3,086,742

3 4.

ratios are for the same hovering mean blade lift coef While the transverse configuration of the blade may

ficient; i.e. value of not be of critical value, it will be noted from the drawings

2ct in each instance the blade diminishes in thickness at the

bot3 extreme end of the outboard portion, the bevel producing

where 5 such diminishment being upwardly from the bottom with

the top surface of the blade being substantially in the

Cas parSR

T same plane throughout,

In considering the present invention it will, of course,

the rotor thrust coefficient, be understood that the formulae here presented are

O suggestive and that in the practice of the invention various

---

3-I, c. da

'1. 2. departures therefrom may be indicated in the light of

further experimentation and in view of specific circum

the nondimensional second moment of the blade area stances under which the impeller is to be used, thus it

about the blade root, and b-number of blades on rotor, will be understood that numerous changes, modifications

consequently the present form does not entail any ap and the full use of equivalents may be resorted to in

preciable sacrifice in hovering performance. For a fur the practice of my invention without departing from the

ther consideration of the mathematical analysis of the spirit or scope thereof as defined in the appended claim.

present subject matter, reference may be had to the pres claim:

ent inventor's article as co-author with Howard L. Dur A flexible air impeller blade particularly adapted for

ham in the October 1956 issue, vol. 1, No. 4 of the jour helicopters and the like, designed to increase the tip

nal of the American Helicopter Society. stall factor whereby speeds may be increased, having

While the blade of FIGS. 1 and 2 is of uniform chord inboard and outboard portions and an airfoil section, the

through the inboard portion 13 thereof, it will be seen outboard portion having an inverse taper comprising

that the invention contemplates an inboard taper, if such approximately three tenths of the length of the blade

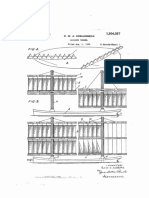

is desired, and thus in FIGS. 3 and 4 the inboard portion 25 and having a maximum chord ct approximately three

23, comprising approximately 70 percent of the blade times the chord of the base of the blade, chord c at any

length is of an outwardly increasing taper and thus radius r of said inverse taper conforming substantially

inversely tapered, as is the outboard terminal portion to the formula:

24. But such taper is considerably more mild than

that of the outboard portion 24; however, since the

inverse taper of the inboard portion 23 is not critical no

30 c=c1+(i-1) for acsacsl.

formula need be applied for this portion. Where

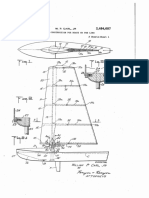

It will further be noted from FGS. 5 and 6 that the co-the blade chord at the base of the blade

enlargement of the outboard end 34 need not follow a c=the blade tip chord

uniform inverse taper. In this form of the blade the 35 R=the blade tip radius

inboard portion 33 is of uniform chord for approximately x=nondimensional radius

80 percent of the length of the blade while the outboard r

portion 34 is of a rounded or paddle like type of inverse R

enlargement.

As hereinbefore noted, the invention is not concerned 40 x=nondimensional radius at inboard end of inverse

with the material or internal structure of the blade; tip taper.

however, it is to be noted that in each instance the lead

ing edge of the blade, here shown as the upper edge, is References Cited in the file of this patent

closer to the axis of the blade than the opposed trailing 45

UNITED STATES PATENTS

edge, and it is proposed that the axis of the blade be

disposed approximately one quarter of the total chord 1,427,307 MaKenney ---------- - Aug. 29, 1922

of the base end of the blade from the leading edge. 1,692,081 De La Cierva ---------- Nov. 20, 1928

In that form of the invention shown in FIGS. 3 and 4, 1,855,660 Allen ------------------ Apr. 26, 1932

the chord of the outboard portion where it joins the 2,014,242 Weichwald ------------Sept. 10, 1935

tapered inboard portion 23 may be determined as approxi 50 2,070,657 Hafner ------'m a - ran m r - - - Feb. 16, 1937

mately 1.5 times the chord at the base of the blade; in 2,152,861 Bennett ---------------- Apr. 4, 1939

other words, the taper of the inboard portion from 2,532,371 Peterson ---------------- Dec. 5, 1950

the base to the outboard portion is about one-half the FOREIGN PATENTS

length of the chord at the inboard portion of the blade 229,375 Germany -------------- Dec. 14, 1910

while as suggested above the width of the extremity of 55 820,131 France ---------------- Nov. 4, 1937

the outboard portion of the blade is three times the

width of the chord at the base.

Вам также может понравиться

- Design Sheet For Armature of DC Generator (Complete)Документ11 страницDesign Sheet For Armature of DC Generator (Complete)Noykols GRncОценок пока нет

- Airscrews For The AeromodellerДокумент66 страницAirscrews For The AeromodellerRussell Hartill100% (4)

- Us 4431376Документ17 страницUs 4431376mihailmiОценок пока нет

- US3448518Документ4 страницыUS3448518liebersax8282Оценок пока нет

- Patente Aircraft With Rotative Wings Cierva 1928 Us1692081Документ3 страницыPatente Aircraft With Rotative Wings Cierva 1928 Us1692081Mariela TisseraОценок пока нет

- Patente Aspa Parsons Como Las Que Tengo de 1953 Us3002567Документ4 страницыPatente Aspa Parsons Como Las Que Tengo de 1953 Us3002567Mariela TisseraОценок пока нет

- EP0801230A2Документ12 страницEP0801230A2Navdeep SinghОценок пока нет

- April 2, 1963 R. T. Cella 3,083,933 Ski Glider: Filed April 28, 1960 2. Sheets-Sheet LДокумент4 страницыApril 2, 1963 R. T. Cella 3,083,933 Ski Glider: Filed April 28, 1960 2. Sheets-Sheet L63Оценок пока нет

- United States Patent (19) : (21) Appl. No.: 927,123Документ7 страницUnited States Patent (19) : (21) Appl. No.: 927,123155Оценок пока нет

- United States PatentДокумент6 страницUnited States Patent155Оценок пока нет

- US4624203Документ11 страницUS4624203524Оценок пока нет

- Us3440963 PDFДокумент5 страницUs3440963 PDFtsegayОценок пока нет

- United States Patent (19) : JohnsonДокумент6 страницUnited States Patent (19) : JohnsongorgiОценок пока нет

- Dec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetДокумент6 страницDec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetEstebanPortilloОценок пока нет

- Us 4004514Документ3 страницыUs 4004514dgfsduuwioОценок пока нет

- US5186686Документ11 страницUS5186686雷黎明Оценок пока нет

- MVMK Mm. .: File?d Jan. 29, 1944Документ4 страницыMVMK Mm. .: File?d Jan. 29, 1944Syed Umair RizviОценок пока нет

- Filed Oct. 22, 1951: P. C. HuttonДокумент5 страницFiled Oct. 22, 1951: P. C. HuttonGalo YambayОценок пока нет

- US1908080Документ3 страницыUS1908080reichanОценок пока нет

- NC Maching Efficiency For Marine Propellers Kuo2002Документ7 страницNC Maching Efficiency For Marine Propellers Kuo2002장영훈Оценок пока нет

- United States Patent: SimpsonДокумент5 страницUnited States Patent: Simpsonاحمد عبدالكريمОценок пока нет

- Azul 27.2%: 1. SsanДокумент6 страницAzul 27.2%: 1. SsanjupaferbaОценок пока нет

- Developed Blade Area Drawings For Raked PDFДокумент7 страницDeveloped Blade Area Drawings For Raked PDFldigasОценок пока нет

- Design Precudure BP 4 BladedДокумент12 страницDesign Precudure BP 4 BladedToni PusicОценок пока нет

- Bell Helicopter Stabilizer BarДокумент6 страницBell Helicopter Stabilizer Barjorge paez100% (1)

- Rao 1961Документ10 страницRao 1961Sãröj ShâhОценок пока нет

- Unlted States Patent (191 1111 3,736,693: Koch 1451 June 5, 1973Документ4 страницыUnlted States Patent (191 1111 3,736,693: Koch 1451 June 5, 1973fgrt45Оценок пока нет

- US3981460Документ5 страницUS3981460MERIWON SURTAN JOHN / UPMОценок пока нет

- US4893426Документ7 страницUS4893426Jean DelaronciereОценок пока нет

- Buri CriteriaДокумент71 страницаBuri CriteriaolegmangОценок пока нет

- Us 5197855Документ6 страницUs 5197855John SmithОценок пока нет

- April 3, 1962 RAE 3,027,711: Securing Isentropic CompressionДокумент4 страницыApril 3, 1962 RAE 3,027,711: Securing Isentropic CompressionDinh LeОценок пока нет

- 1.1 Helicopter Design: Comp. & . Ath . TTH Appls Vol 12A. No. I. PP 85-10 . 1486Документ25 страниц1.1 Helicopter Design: Comp. & . Ath . TTH Appls Vol 12A. No. I. PP 85-10 . 1486Artur ZubovОценок пока нет

- US3889885Документ7 страницUS3889885Claudinei MayerОценок пока нет

- US8128376Документ11 страницUS8128376J clerio ClerioОценок пока нет

- Static Thrust of Airplane PropellersДокумент6 страницStatic Thrust of Airplane PropellersEwaОценок пока нет

- Diseño de Impulsores para Mezcla de SuspensionesДокумент9 страницDiseño de Impulsores para Mezcla de SuspensionesrwtoorresdОценок пока нет

- United States PatentДокумент7 страницUnited States Patentmohammad dehghanfarsiОценок пока нет

- United States PatentДокумент8 страницUnited States PatentMarcos ApablazaОценок пока нет

- Galvanometer Coil and Method of Making Same: A. D. RichardsonДокумент5 страницGalvanometer Coil and Method of Making Same: A. D. Richardsonmohamed hemdanОценок пока нет

- Glauert, H. - The Theory of The Autogyro (1927)Документ26 страницGlauert, H. - The Theory of The Autogyro (1927)Mariela TisseraОценок пока нет

- US2099314Документ3 страницыUS2099314Jhonnatan E Avendaño Florez100% (1)

- Performance of A Low Cost Cross Wind AxiДокумент8 страницPerformance of A Low Cost Cross Wind AxiBoka AlzupidiОценок пока нет

- Jain. 1U, 1939. T.'4 Harris ': MW Gßz/:ÁwДокумент4 страницыJain. 1U, 1939. T.'4 Harris ': MW Gßz/:Áwmoch rizki darmawanОценок пока нет

- United States Patent: (54) SailboatДокумент5 страницUnited States Patent: (54) Sailboat155Оценок пока нет

- Us4540334 PDFДокумент9 страницUs4540334 PDFJigar SutharОценок пока нет

- Us 3688484Документ4 страницыUs 3688484James LindonОценок пока нет

- United States Patent (19) : Peyman 45 Date of Patent: Aug. 15, 1989Документ7 страницUnited States Patent (19) : Peyman 45 Date of Patent: Aug. 15, 1989155Оценок пока нет

- Nov. 21, 1961 C, H, Burnside 3,009,385: Method of Loading A Rocket Motor With Solid PropellantДокумент7 страницNov. 21, 1961 C, H, Burnside 3,009,385: Method of Loading A Rocket Motor With Solid PropellantSeenu CnuОценок пока нет

- US3841371-metal InsertДокумент5 страницUS3841371-metal InsertgauravОценок пока нет

- Computerized: Method Design DiameterДокумент10 страницComputerized: Method Design DiameterPavan KishoreОценок пока нет

- United States Patent (10) Patent No.: US 6,170,421 B1: Ross (45) Date of Patent: Jan. 9, 2001Документ8 страницUnited States Patent (10) Patent No.: US 6,170,421 B1: Ross (45) Date of Patent: Jan. 9, 2001155Оценок пока нет

- Computerized Method For Design of Propeller BladeДокумент10 страницComputerized Method For Design of Propeller BladePavan KishoreОценок пока нет

- Hydrofoil - US5297938Документ8 страницHydrofoil - US5297938rwtoorresdОценок пока нет

- Worn Gearing - Ralph e Flanders Book No. 1Документ49 страницWorn Gearing - Ralph e Flanders Book No. 1Rocio Mtz100% (1)

- United States Patent (19) : WalkerДокумент8 страницUnited States Patent (19) : Walker155Оценок пока нет

- March I I, 192©: 1 2 ." O-Io O-2Q 0 - 1020Документ1 страницаMarch I I, 192©: 1 2 ." O-Io O-2Q 0 - 1020Mark Evan SalutinОценок пока нет

- Aeroelastic Stability For Straight and Swept-Tip Rotor BladesДокумент17 страницAeroelastic Stability For Straight and Swept-Tip Rotor BladesGökhan ÖzlüОценок пока нет

- EP0746495B1Документ9 страницEP0746495B1155Оценок пока нет

- C. W. A. Koelkebeck: 6 Sheets-Sheet LДокумент10 страницC. W. A. Koelkebeck: 6 Sheets-Sheet L155Оценок пока нет

- United States Patent (19) : Peyman 45 Date of Patent: Aug. 15, 1989Документ7 страницUnited States Patent (19) : Peyman 45 Date of Patent: Aug. 15, 1989155Оценок пока нет

- United States Patent (19) : VicardДокумент4 страницыUnited States Patent (19) : Vicard155100% (1)

- United States Patent (19) : (76) Inventor: John Guthrie, Suite 1401-555-13th ST.Документ10 страницUnited States Patent (19) : (76) Inventor: John Guthrie, Suite 1401-555-13th ST.155Оценок пока нет

- Fied Feb. 5, 1967: 2. Sheets-Sheet LДокумент5 страницFied Feb. 5, 1967: 2. Sheets-Sheet L155Оценок пока нет

- United States Patent (19) : Menegus (11) 4,047,493Документ18 страницUnited States Patent (19) : Menegus (11) 4,047,493155Оценок пока нет

- United States Patent: (54) SailboatДокумент5 страницUnited States Patent: (54) Sailboat155Оценок пока нет

- July 17, 1951 W. W. Wels-Coates 2,561,253: Filed Dec. 4, 1946 10 Sheets-Sheet LДокумент16 страницJuly 17, 1951 W. W. Wels-Coates 2,561,253: Filed Dec. 4, 1946 10 Sheets-Sheet L155Оценок пока нет

- Us 2484687Документ7 страницUs 2484687155Оценок пока нет

- United States Patent (19) : WalkerДокумент8 страницUnited States Patent (19) : Walker155Оценок пока нет

- United States Patent (19) : Menegus (11) 4,047,493Документ18 страницUnited States Patent (19) : Menegus (11) 4,047,493155Оценок пока нет

- United States Patent 19 11 Patent Number: 5,775,249: Samuel 45) Date of Patent: Jul. 7, 1998Документ19 страницUnited States Patent 19 11 Patent Number: 5,775,249: Samuel 45) Date of Patent: Jul. 7, 1998155Оценок пока нет

- United States PatentДокумент6 страницUnited States Patent155Оценок пока нет

- United States Patent (19) : (21) Appl. No.: 927,123Документ7 страницUnited States Patent (19) : (21) Appl. No.: 927,123155Оценок пока нет

- United States Patent (19) 11 Patent Number: 5,992,793: Perry Et Al. (45) Date of Patent: Nov.30, 1999Документ8 страницUnited States Patent (19) 11 Patent Number: 5,992,793: Perry Et Al. (45) Date of Patent: Nov.30, 1999155Оценок пока нет

- United States Patent (19) 11 Patent Number: 5,474,257: Fisher Et Al. (45. Date of Patent: Dec. 12, 1995Документ11 страницUnited States Patent (19) 11 Patent Number: 5,474,257: Fisher Et Al. (45. Date of Patent: Dec. 12, 1995155Оценок пока нет

- United States PatentДокумент13 страницUnited States Patent155Оценок пока нет

- EP2404820A1Документ18 страницEP2404820A1155Оценок пока нет

- United States Design Patent (10) Patent No.:: USD639,239 SДокумент9 страницUnited States Design Patent (10) Patent No.:: USD639,239 S155Оценок пока нет

- United States Design Patent (10) Patent No .:: US D807, 823 SДокумент9 страницUnited States Design Patent (10) Patent No .:: US D807, 823 S155Оценок пока нет

- United States Patent (10) Patent No.: US 6,578,798 B1: Ave., #129, Anaheim, CA (US) 92801 S A 2: RegДокумент24 страницыUnited States Patent (10) Patent No.: US 6,578,798 B1: Ave., #129, Anaheim, CA (US) 92801 S A 2: Reg155Оценок пока нет

- United States Design Patent (10) Patent No.: US D478,598 SДокумент5 страницUnited States Design Patent (10) Patent No.: US D478,598 S155Оценок пока нет

- United States Patent 19 11 Patent Number: 5,697,468: Russell, Jr. Et Al. (45) Date of Patent: Dec. 16, 1997Документ8 страницUnited States Patent 19 11 Patent Number: 5,697,468: Russell, Jr. Et Al. (45) Date of Patent: Dec. 16, 1997155Оценок пока нет

- Us 5253828Документ12 страницUs 5253828155Оценок пока нет

- United States Patent: (10) Patent No.: US 6,168,383 B1Документ17 страницUnited States Patent: (10) Patent No.: US 6,168,383 B1155Оценок пока нет

- Us 5253828Документ12 страницUs 5253828155Оценок пока нет

- United States PatentДокумент18 страницUnited States Patent155Оценок пока нет

- United States Patent (10) Patent No.: US 6,471,157 B1: Streett Et Al. (45) Date of Patent: Oct. 29, 2002Документ8 страницUnited States Patent (10) Patent No.: US 6,471,157 B1: Streett Et Al. (45) Date of Patent: Oct. 29, 2002155Оценок пока нет

- Intervention Grade 7 - Second Quarter 3Документ1 страницаIntervention Grade 7 - Second Quarter 3Monsanto JomarОценок пока нет

- Course Overviews MYP Mathematics, UWC Thailand 2022-2023: Processes SolutionsДокумент9 страницCourse Overviews MYP Mathematics, UWC Thailand 2022-2023: Processes Solutionslulusutbk9Оценок пока нет

- Week 23 Maths (Lead) - ReflectionsДокумент35 страницWeek 23 Maths (Lead) - Reflectionseshaal junaidОценок пока нет

- Math5 Q3 SIM5 Solid-Figures v5Документ16 страницMath5 Q3 SIM5 Solid-Figures v5Jane Marie Albios TevesОценок пока нет

- Sample Lesson PlanДокумент5 страницSample Lesson Planapi-284302752Оценок пока нет

- Whole Group Lesson Plan RevisedДокумент6 страницWhole Group Lesson Plan Revisedapi-458954188Оценок пока нет

- GR 4 Paltimum HelpДокумент48 страницGR 4 Paltimum HelpRoxanneОценок пока нет

- Metropolitan Opera HouseДокумент47 страницMetropolitan Opera HouseMichael Hart0% (1)

- Caie Igcse Maths 0580 Theory v2Документ16 страницCaie Igcse Maths 0580 Theory v2Melis Doğu BayazıtОценок пока нет

- Geometry G7 Lesson Iii-Day 7Документ9 страницGeometry G7 Lesson Iii-Day 7ROSEMARIE SANTOSОценок пока нет

- Concept Formation and Categorization of ComplexДокумент4 страницыConcept Formation and Categorization of ComplexJohn Paul De La FuenteОценок пока нет

- SymmetryДокумент43 страницыSymmetryDeepa Kapadia0% (1)

- ISSFD24 Paper S10-3 BradleyДокумент20 страницISSFD24 Paper S10-3 BradleyfasОценок пока нет

- Mathematics in The Modern World - ModuleДокумент147 страницMathematics in The Modern World - ModuleRichard BacharОценок пока нет

- Elf Project Lesson Plan Dec 4Документ4 страницыElf Project Lesson Plan Dec 4api-491037759Оценок пока нет

- Math 6 q3 w1 FinalДокумент9 страницMath 6 q3 w1 Finaljose fadrilanОценок пока нет

- 23Документ20 страниц23enrmeОценок пока нет

- Calefato (2004) - The Clothed BodyДокумент175 страницCalefato (2004) - The Clothed BodyGeorgiana Bedivan100% (1)

- Adela Elementary School Four Angeli A. Lim English October 29, 2021 FirstДокумент8 страницAdela Elementary School Four Angeli A. Lim English October 29, 2021 FirstangeliОценок пока нет

- VGD Las Week 2.1 Final PDFДокумент17 страницVGD Las Week 2.1 Final PDFJudy Ann Quisay RamirezОценок пока нет

- Lesson 1 - Portrait DrawingДокумент26 страницLesson 1 - Portrait DrawingNerissa VillarojasОценок пока нет

- ProE Surfacing - Module 1Документ52 страницыProE Surfacing - Module 1inthemoney8100% (1)

- 5 Freshman CempakaДокумент20 страниц5 Freshman CempakamxmenОценок пока нет

- Revit Reinforcement ManualДокумент102 страницыRevit Reinforcement ManualamadofirstОценок пока нет

- Year 4 Maths Test - Symmetry - QuestionsДокумент6 страницYear 4 Maths Test - Symmetry - QuestionsMoodjair IkanОценок пока нет

- CS2401 2 MarksДокумент2 страницыCS2401 2 MarksShanmugapriyaVinodkumarОценок пока нет

- PrelimДокумент4 страницыPrelimPatleen Monica MicuaОценок пока нет

- t2 M 4150 Year 4 Maths Revision Booklet - Ver - 4Документ24 страницыt2 M 4150 Year 4 Maths Revision Booklet - Ver - 4thuyb26080% (1)

- Chapter 2 PDFДокумент36 страницChapter 2 PDFSpaykuОценок пока нет

- Mathematics 5 - Q3 - W4 DLLДокумент6 страницMathematics 5 - Q3 - W4 DLLISRAEL VENIEGASОценок пока нет