Академический Документы

Профессиональный Документы

Культура Документы

Advanced Lithography

Загружено:

LIAKMAN0 оценок0% нашли этот документ полезным (0 голосов)

41 просмотров23 страницыNanomaterials

Lecture 3: Advanced Lithography

Department of Materials Science and Engineering, Northwestern University

Deep Ultra-Violet Lithography

Deep UV XeF XeCl KrF ArF F2 Excimer Laser Sources: 351 nm 308 nm 248 nm 193 nm 157 nm Fused silica / quartz optics

}

CaF optics difficult to grind and polish due to hygroscopic (water-absorbing) properties

Department of Materials Science and Engineering, Northwestern University

Phase Shifting Masks

Minimizes diffraction effects but complica

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документNanomaterials

Lecture 3: Advanced Lithography

Department of Materials Science and Engineering, Northwestern University

Deep Ultra-Violet Lithography

Deep UV XeF XeCl KrF ArF F2 Excimer Laser Sources: 351 nm 308 nm 248 nm 193 nm 157 nm Fused silica / quartz optics

}

CaF optics difficult to grind and polish due to hygroscopic (water-absorbing) properties

Department of Materials Science and Engineering, Northwestern University

Phase Shifting Masks

Minimizes diffraction effects but complica

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

41 просмотров23 страницыAdvanced Lithography

Загружено:

LIAKMANNanomaterials

Lecture 3: Advanced Lithography

Department of Materials Science and Engineering, Northwestern University

Deep Ultra-Violet Lithography

Deep UV XeF XeCl KrF ArF F2 Excimer Laser Sources: 351 nm 308 nm 248 nm 193 nm 157 nm Fused silica / quartz optics

}

CaF optics difficult to grind and polish due to hygroscopic (water-absorbing) properties

Department of Materials Science and Engineering, Northwestern University

Phase Shifting Masks

Minimizes diffraction effects but complica

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 23

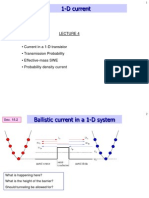

Nanomaterials

Lecture 3: Advanced Lithography

Department of Materials Science and Engineering, Northwestern University

Deep Ultra-Violet Lithography

Deep UV Æ Excimer Laser Sources:

XeF Æ 351 nm

XeCl Æ 308 nm Fused silica / quartz optics

KrF Æ 248 nm

ArF Æ 193 nm

F2 Æ 157 nm

} CaF optics Æ difficult to grind and polish due to

hygroscopic (water-absorbing) properties

Department of Materials Science and Engineering, Northwestern University

Phase Shifting Masks

Æ Minimizes diffraction effects but complicates mask making

R. Waser (ed.), Nanoelectronics and Information Technology, Chapter 9

Department of Materials Science and Engineering, Northwestern University

Influence of Substrate Reflections

Interference between incident and

reflected photon beams can lead to a

standing wave pattern in the resist.

Reflections can also occur at buried

interfaces, thus leading to a

dependence of linewidth on buried

layer thicknesses.

R. Waser (ed.), Nanoelectronics and Information Technology, Chapter 9

Department of Materials Science and Engineering, Northwestern University

Effect of Anti-Reflective Coatings

Without Anti-Reflective Coating

With Anti-Reflective Coating

R. Waser (ed.), Nanoelectronics and Information Technology, Chapter 9

Department of Materials Science and Engineering, Northwestern University

Extreme Ultra-violet Lithography

(a.k.a., soft x-ray lithography)

• Developed at Sandia National Laboratory in 1996

• EUV source based on a plasma created when a laser is focused

on a beam of Xe gas clusters expanding at supersonic speeds

• λ ~ 10 nm

NOTE: At short λ, optical materials are highly absorptive

Æ Reflective optics (e.g., Bragg reflectors)

Æ Thin, defect-free masks

e.g., at λ = 13 nm, reflector consists of 40 layer pairs of Mo and

Si with 7 nm periodicity per layer pair

Department of Materials Science and Engineering, Northwestern University

Extreme Ultra-violet Lithography

(cont.)

G. D. Hutcheson, et al., Scientific American, 290, 76 (2004).

Department of Materials Science and Engineering, Northwestern University

Typical EUV Mask

R. Waser (ed.), Nanoelectronics and Information Technology, Chapter 9

Department of Materials Science and Engineering, Northwestern University

Depth of focus is less of an issue at short wavelengths

Æ high aspect ratio resist profiles are possible with EUV

G. Timp, Nanotechnology, Chapter 4

Department of Materials Science and Engineering, Northwestern University

Example of resist patterned with EUV lithography:

G. Timp, Nanotechnology, Chapter 4

Department of Materials Science and Engineering, Northwestern University

X-Ray Lithography

• λ = 1 nm BUT resolution = k(λg)1/2

where g = size of gap between mask and substrate

(tends to be 5 – 40 μm in production)

• Therefore, resolution = 0.07 – 0.2 μm for λ = 1 nm

• However, when contact printing is done in research

environments, 30 nm resolution is achievable

• High aspect ratios are achieved in developed resists

Department of Materials Science and Engineering, Northwestern University

Example of resist patterned with x-ray lithography:

R. Waser (ed.), Nanoelectronics and Information Technology, Chapter 9

Department of Materials Science and Engineering, Northwestern University

Established Advantages of

X-Ray Lithography

(1) Large depth of focus

(2) Excellent resist profiles (pillars of resist)

(3) Large process latitude

(4) Linewidth independent of substrate topography or type

(5) Relatively immune to low atomic weight contaminants

Department of Materials Science and Engineering, Northwestern University

Remaining Disadvantages of X-Ray Lithography

(1) 1X mask technology (gold on 1 – 2 μm thick silicon)

Æ Defects, aspect ratio, bending, and heating are problems

(2) Source cost and/or complexity

(3) Alignment/registration is nontrivial

To become a commercial success, x-ray lithography needs:

(A) A mask Æ distortion free, inspectable, repairable

(B) A resist Æ presently acceptable but could be improved

(C) An alignment/registration system

(D) An x-ray source Æ acceptable cost and throughput

Department of Materials Science and Engineering, Northwestern University

Ion Beam Lithography

• Typically, liquid metal (e.g., gallium) ions are used

• Ion projection lithography developed in the late 1970’s

• Advanced lithography group Æ consortium of industry,

government, and universities

• ALG-1000 Æ 20 μm by 20 μm fields at 3X reduction

using 150 keV hydrogen ions Æ 0.1 μm resolution

Department of Materials Science and Engineering, Northwestern University

Advantages of Ion Beam Lithography

(1) Less long range scattering than electrons

(2) Ion beams stay near initial trajectory

Æ no dose adjustment for different patterns or substrates

(3) Can directly write metal lines (focused ion beam)

Æ suitable for mask repair

Department of Materials Science and Engineering, Northwestern University

Disadvantages of Ion Beam Lithography

(1) Ions interact strongly with target causing:

(A) Ion mixing

(B) Amorphizing crystals

(C) Altered optical properties

(D) Implanted dopants

(E) Sputter etching

(2) Ions are highly absorbed (typically within 10 nm)

Æ Stencil type masks

Æ The center of a ring falls out unless sub-resolution

supports are used

Department of Materials Science and Engineering, Northwestern University

Electron Beam Lithography

• Very popular in research environments

• Used for mask making commercially

• λ = h/(2mE)1/2 Æ λ = 7.7 pm @ 25 keV

• Typically, EBL is direct write Æ serial (slow) process

• Projection EBL systems have been developed

Æ e.g., SCALPEL

(SCALPEL = Scattering with Angular Limitation

Projection Electron-beam Lithography)

Department of Materials Science and Engineering, Northwestern University

Advantages of Electron Beam Lithography

(1) High resolution Æ down to 5 nm

(2) Useful design tool Æ direct write allows for quick pattern

changes (no masks are needed)

Disadvantages of Electron Beam Lithography

(1) Cost (up to $6 – 10 million for hardware)

(2) Direct write has low throughput Æ slow and expensive

Department of Materials Science and Engineering, Northwestern University

Projection Electron Beam Lithography

Department of Materials Science and Engineering, Northwestern University

Nanoimprint Lithography

Hot UV

embossing curing

R. Waser (ed.), Nanoelectronics and Information Technology, Chapter 9

Department of Materials Science and Engineering, Northwestern University

Nanoimprint Lithography Patterns

~20 nm pillars ~20 nm holes ~20 nm dots

P. R. Krauss, et al., Appl. Phys. Lett., 71, 3174 (1997).

Department of Materials Science and Engineering, Northwestern University

Other Lithographic Approaches

• Microcontact Printing

60 nm

• Nanosphere Lithography FIO

• Scanning Probe Lithographies

- Dip-pen Nanolithography

- Field Induced Oxidation

- Feedback Controlled Lithography

FCL

1 nm

• We will revisit these approaches

later in the course

Department of Materials Science and Engineering, Northwestern University

Вам также может понравиться

- Handbook of VLSI Microlithography: Principles, Technology and ApplicationsОт EverandHandbook of VLSI Microlithography: Principles, Technology and ApplicationsWilliam B. GlendinningРейтинг: 5 из 5 звезд5/5 (1)

- Impact of FLM Thickness in Laser Induced Periodic Structures On Amorphous Si FlmsДокумент8 страницImpact of FLM Thickness in Laser Induced Periodic Structures On Amorphous Si Flms趙睿中Оценок пока нет

- Extraordinary Optical Transmission in A Hybrid Plasmonic WaveguideДокумент8 страницExtraordinary Optical Transmission in A Hybrid Plasmonic WaveguideRami WahshehОценок пока нет

- Waveguides in COMSOLДокумент37 страницWaveguides in COMSOLAhmad Usman100% (3)

- July 14, 2005 10:3 WSPC/175-IJN 00313: Ion Beam Lithography and Nanofabrication: A ReviewДокумент18 страницJuly 14, 2005 10:3 WSPC/175-IJN 00313: Ion Beam Lithography and Nanofabrication: A Reviewmoviemac7Оценок пока нет

- Laser Interference Lithography for Fabricating Metal NanowiresДокумент15 страницLaser Interference Lithography for Fabricating Metal NanowiresJaya LohaniОценок пока нет

- Laser Nano-Manufacturing ReviewДокумент21 страницаLaser Nano-Manufacturing ReviewAntony Bazan100% (1)

- The BossДокумент9 страницThe BossXuan Phuong HuynhОценок пока нет

- Ijaiem 2014 04 26 057Документ5 страницIjaiem 2014 04 26 057International Journal of Application or Innovation in Engineering & ManagementОценок пока нет

- Epitaxial (Ba, SR) Tio Ferroelectric Thin Films For Integrated OpticsДокумент25 страницEpitaxial (Ba, SR) Tio Ferroelectric Thin Films For Integrated Opticsmsh-666Оценок пока нет

- LithographyДокумент17 страницLithographyRJ Singh100% (1)

- Vlsi6 LithographyДокумент21 страницаVlsi6 LithographyGaurav MehraОценок пока нет

- 32 Applsci 13 12352Документ12 страниц32 Applsci 13 12352sylwka.inoОценок пока нет

- Nanofabrication Lithography Generates Micro & Nano StructuresДокумент14 страницNanofabrication Lithography Generates Micro & Nano StructuresShahid AlamОценок пока нет

- Chap 7b Nanolithography Different TypesДокумент42 страницыChap 7b Nanolithography Different TypesmeetbalakumarОценок пока нет

- A Survey On Microstrip Patch Antenna Using MetamaterialДокумент6 страницA Survey On Microstrip Patch Antenna Using MetamaterialAlejandro-SBОценок пока нет

- Prepared by Guided by K.S.Vaghosi Prof. G.D.Karadkar M.E.Part - Ii (Production) Roll No - 139 Mech. DepttДокумент42 страницыPrepared by Guided by K.S.Vaghosi Prof. G.D.Karadkar M.E.Part - Ii (Production) Roll No - 139 Mech. DepttKetan VaghosiОценок пока нет

- Chita Photography Tin ResistanceДокумент19 страницChita Photography Tin ResistanceGdadbhhОценок пока нет

- Highly Sensitive UV Sensors Based On SMR OscillatorsДокумент8 страницHighly Sensitive UV Sensors Based On SMR OscillatorsMinaОценок пока нет

- Nanolithography - DefinitionДокумент15 страницNanolithography - DefinitionDesamsetti Kranthi KiranОценок пока нет

- (2016) (Malinauskas Et Al) Ultrafast Laser Processing of Materials - From Science To IndustryДокумент14 страниц(2016) (Malinauskas Et Al) Ultrafast Laser Processing of Materials - From Science To IndustryRenkuReОценок пока нет

- Biological and Chemical Sensors Based On Graphene MaterialsДокумент25 страницBiological and Chemical Sensors Based On Graphene MaterialsFA MahyariОценок пока нет

- Electron Beam Lithography Resolution and MaterialsДокумент36 страницElectron Beam Lithography Resolution and MaterialsMuraleetharan BoopathiОценок пока нет

- Interferometric LithographyДокумент18 страницInterferometric Lithographyp6tzk7Оценок пока нет

- Uwb Fractal Antenna ThesisДокумент5 страницUwb Fractal Antenna Thesisafcmunxna100% (2)

- Effects of Co Laser Conditioning of The Antire Ection Y O /sio Coatings at 351 NMДокумент8 страницEffects of Co Laser Conditioning of The Antire Ection Y O /sio Coatings at 351 NMRamin ShojaОценок пока нет

- Status and Prospects For Metallic and Plasmonic Nano-Lasers (Invited)Документ9 страницStatus and Prospects For Metallic and Plasmonic Nano-Lasers (Invited)abdoОценок пока нет

- Design and Analysis of Ultra-Miniaturized Meandering Photonic Crystals Delay LinesДокумент10 страницDesign and Analysis of Ultra-Miniaturized Meandering Photonic Crystals Delay LinesKhải NguyễnОценок пока нет

- Ijaiem 2014 04 26 057Документ5 страницIjaiem 2014 04 26 057International Journal of Application or Innovation in Engineering & ManagementОценок пока нет

- Electron Beam LithographyДокумент11 страницElectron Beam LithographySaqib ZargarОценок пока нет

- Study Some Structural and Optical Properties of Copper Nano FilmДокумент6 страницStudy Some Structural and Optical Properties of Copper Nano FilmInternational Journal of Application or Innovation in Engineering & ManagementОценок пока нет

- André 2 - A Plasma Lens For Magnetron SputteringДокумент2 страницыAndré 2 - A Plasma Lens For Magnetron SputteringRamani ChandranОценок пока нет

- 10.1515_nanoph-2022-0445Документ7 страниц10.1515_nanoph-2022-0445Ailen CamaraОценок пока нет

- Maskless LithographyДокумент8 страницMaskless Lithographymarci_elgОценок пока нет

- Electron Beam LithographyДокумент14 страницElectron Beam LithographyAmey RanjekarОценок пока нет

- Formation of Copper Lines Using Femtosecond LaserДокумент5 страницFormation of Copper Lines Using Femtosecond LaserSundry 1000Оценок пока нет

- Electron-beam lithography resolution and throughputДокумент10 страницElectron-beam lithography resolution and throughputgОценок пока нет

- Research Paper On LaserДокумент5 страницResearch Paper On Laserafnhekkghifrbm100% (1)

- Gain Enhancement in Microstrip Patch Antennas Using Metallic RingsДокумент8 страницGain Enhancement in Microstrip Patch Antennas Using Metallic RingsAJER JOURNALОценок пока нет

- Unit-5 Radiography: AdvantagesДокумент23 страницыUnit-5 Radiography: AdvantagescandypranavОценок пока нет

- Optical Fiber CommunicationsДокумент49 страницOptical Fiber CommunicationsShebОценок пока нет

- Subha 2020Документ10 страницSubha 2020abdallahmussa199603Оценок пока нет

- Laser Ablation ThesisДокумент8 страницLaser Ablation Thesisdianamezasaltlakecity100% (2)

- Plasmonic Lenses With Long Focal Lengths PDFДокумент4 страницыPlasmonic Lenses With Long Focal Lengths PDFgОценок пока нет

- Structural Morphological and Mechanical Properties of Laser Irradiated Copper Using Continuous Wave Diode LaserДокумент8 страницStructural Morphological and Mechanical Properties of Laser Irradiated Copper Using Continuous Wave Diode LaserAngie QuirozОценок пока нет

- Analysis of Semiconductors by Double-Crystal X-Ray DiffractometryДокумент8 страницAnalysis of Semiconductors by Double-Crystal X-Ray DiffractometryChun Yu YangОценок пока нет

- High-Resolution Ink-Jet Printing For Nanowire Transistors and Next Generation Flexible ElectronicsДокумент1 страницаHigh-Resolution Ink-Jet Printing For Nanowire Transistors and Next Generation Flexible ElectronicsNational Physical LaboratoryОценок пока нет

- 1-S2.0-S0264127523004161-Main PiezoДокумент12 страниц1-S2.0-S0264127523004161-Main Piezozmaxprom5Оценок пока нет

- 1 s2.0 S1359028614000631 MainДокумент10 страниц1 s2.0 S1359028614000631 MainOm PrakashОценок пока нет

- Sistec Notes Attenuation in Optical FiberДокумент22 страницыSistec Notes Attenuation in Optical Fibermanishsoni30Оценок пока нет

- Project On Optical Fiber: in Partial Fulfilment of The Course PH49006: EM & OPTICS Lab BДокумент35 страницProject On Optical Fiber: in Partial Fulfilment of The Course PH49006: EM & OPTICS Lab BDurgesh JoshiОценок пока нет

- Laser Cutting Parameters' Effect on HAZДокумент6 страницLaser Cutting Parameters' Effect on HAZHarshad PatelОценок пока нет

- Components and System Design For Optical Fiber CommunicationДокумент22 страницыComponents and System Design For Optical Fiber CommunicationmofiwОценок пока нет

- Components and System Design For Optical Fiber CommunicationДокумент22 страницыComponents and System Design For Optical Fiber CommunicationAnkur ChauhanОценок пока нет

- Research Article: Strategies For Fabricating Nanogap Single-Crystal Organic TransistorsДокумент7 страницResearch Article: Strategies For Fabricating Nanogap Single-Crystal Organic TransistorsandrewtomsonОценок пока нет

- Intro To RadiographyДокумент37 страницIntro To RadiographySaleemSahabОценок пока нет

- Review Paper On MetamaterialsДокумент8 страницReview Paper On MetamaterialsVivek PatelОценок пока нет

- App Nanosci VikasДокумент16 страницApp Nanosci VikasrashiОценок пока нет

- 8652 17.noiseДокумент14 страниц8652 17.noiseMuhammad Maiz GhauriОценок пока нет

- 8657 22.HJ CellsДокумент15 страниц8657 22.HJ CellsMuhammad Maiz GhauriОценок пока нет

- 8655 20.photovoltageДокумент9 страниц8655 20.photovoltageMuhammad Maiz GhauriОценок пока нет

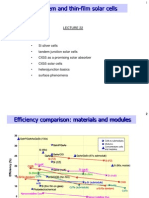

- Cell Types: Si, Tandem JunctionДокумент12 страницCell Types: Si, Tandem JunctionMuhammad Maiz GhauriОценок пока нет

- 8654 19.photocurrentДокумент11 страниц8654 19.photocurrentMuhammad Maiz GhauriОценок пока нет

- 8650 15.fmaxДокумент11 страниц8650 15.fmaxMuhammad Maiz GhauriОценок пока нет

- 2-port device parameters and power gainsДокумент7 страниц2-port device parameters and power gainsMuhammad Maiz GhauriОценок пока нет

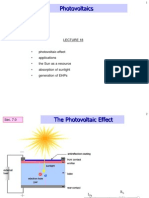

- 8653 18.photovoltaicsДокумент12 страниц8653 18.photovoltaicsMuhammad Maiz GhauriОценок пока нет

- 8649 - 14.comparing F - TДокумент10 страниц8649 - 14.comparing F - TMuhammad Maiz GhauriОценок пока нет

- Hydrodynamic Equations Lecture NotesДокумент7 страницHydrodynamic Equations Lecture NotesMuhammad Maiz GhauriОценок пока нет

- F, A High-Frequency Figure-Of-Merit: T T T TДокумент10 страницF, A High-Frequency Figure-Of-Merit: T T T TMuhammad Maiz GhauriОценок пока нет

- 8647 12.small-Signal ModelДокумент8 страниц8647 12.small-Signal ModelMuhammad Maiz GhauriОценок пока нет

- 8646 11.transistor CapacitanceДокумент6 страниц8646 11.transistor CapacitanceMuhammad Maiz GhauriОценок пока нет

- 8645 10.capacitanceДокумент11 страниц8645 10.capacitanceMuhammad Maiz GhauriОценок пока нет

- 8644 9.device Equation SetДокумент6 страниц8644 9.device Equation SetMuhammad Maiz GhauriОценок пока нет

- 8642 7.bteДокумент7 страниц8642 7.bteMuhammad Maiz GhauriОценок пока нет

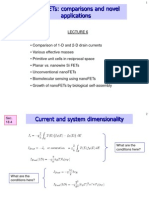

- Nanofets: Comparisons and Novel ApplicationsДокумент12 страницNanofets: Comparisons and Novel ApplicationsMuhammad Maiz GhauriОценок пока нет

- 8636 1.introductionДокумент9 страниц8636 1.introductionMuhammad Maiz GhauriОценок пока нет

- NanoFETs: The Roadmap and Short Channel EffectsДокумент11 страницNanoFETs: The Roadmap and Short Channel EffectsMuhammad Maiz GhauriОценок пока нет

- Transport, Density of States and CurrentДокумент6 страницTransport, Density of States and CurrentMuhammad Maiz GhauriОценок пока нет

- 8639 4.1-D CurrentДокумент6 страниц8639 4.1-D CurrentMuhammad Maiz GhauriОценок пока нет

- 8637 - 2. Band Structure, Band Diagram, Effective MassДокумент8 страниц8637 - 2. Band Structure, Band Diagram, Effective MassMuhammad Maiz GhauriОценок пока нет

- UBC Course Slides for InstructorsДокумент1 страницаUBC Course Slides for InstructorsMuhammad Maiz GhauriОценок пока нет

- Heat loss and fluid temperature calculation for buried insulated and non-insulated oil pipelinesДокумент34 страницыHeat loss and fluid temperature calculation for buried insulated and non-insulated oil pipelinesselisenОценок пока нет

- Chapter 7 PDFДокумент36 страницChapter 7 PDFRbtl BañosОценок пока нет

- Ellc Rmnbemae Llce Bmmneera Lecl Mebmaren Lcel Nbmemaer: Cell MembraneДокумент9 страницEllc Rmnbemae Llce Bmmneera Lecl Mebmaren Lcel Nbmemaer: Cell MembraneAlvin PaboresОценок пока нет

- BDA30603 Tutorial 4Документ7 страницBDA30603 Tutorial 4Firdaus JannahОценок пока нет

- Electron Spin Resonance (Esr) SpectrosДокумент18 страницElectron Spin Resonance (Esr) SpectrosIndarto Al-kimia100% (1)

- Prodinfo Antox-75-E Eng FinalДокумент2 страницыProdinfo Antox-75-E Eng FinalKumar RamanОценок пока нет

- SEPCO 12 Productos de Fibra de VidrioДокумент3 страницыSEPCO 12 Productos de Fibra de VidrioVictor Flores ResendizОценок пока нет

- ConversationДокумент2 страницыConversationHiggilty PiggiltyОценок пока нет

- The Periodic Table of ElementsДокумент39 страницThe Periodic Table of ElementsSamKris Guerrero Malasaga100% (1)

- Thermodynamics For EngineersДокумент620 страницThermodynamics For Engineersgsuresh40100% (8)

- Techstuff 3.09Документ117 страницTechstuff 3.09Hazairin As-Shiddiq RahmanОценок пока нет

- Experiment 6Документ6 страницExperiment 6Sobana Kanthi33% (3)

- Msds Icr 122 LSFДокумент12 страницMsds Icr 122 LSFWisnu AbaraiОценок пока нет

- Onion Cell Structure Under MicroscopeДокумент2 страницыOnion Cell Structure Under MicroscopeAnirudh100% (1)

- 85 TPH CFBC Boiler Operation and Maintenance ManualДокумент152 страницы85 TPH CFBC Boiler Operation and Maintenance ManualAamirMalik100% (1)

- Laboratory Exercise 4Документ3 страницыLaboratory Exercise 4dennise reyesОценок пока нет

- Zhang, Xiangwu - Fundamentals of Fiber Science-DeStech Publications (2014)Документ431 страницаZhang, Xiangwu - Fundamentals of Fiber Science-DeStech Publications (2014)Fawad hameed100% (1)

- CarbonicAnhydrases Manuscript withDOIДокумент11 страницCarbonicAnhydrases Manuscript withDOIFadhil MiftahulОценок пока нет

- Science - Form 4 - Chapter 5Документ12 страницScience - Form 4 - Chapter 5Marcia PattersonОценок пока нет

- 1976-Morito - Transition From External To Internal Oxidation in Fe-Si Alloy As A Function of Oxygen Potential of The Ambient AtmosphereДокумент4 страницы1976-Morito - Transition From External To Internal Oxidation in Fe-Si Alloy As A Function of Oxygen Potential of The Ambient AtmosphereDavid Hernández EscobarОценок пока нет

- Nuclear Power: Pros, Cons and FutureДокумент4 страницыNuclear Power: Pros, Cons and FutureSamarthОценок пока нет

- LP2 SCI-12 MICROBIO LABORATORY-fINALДокумент21 страницаLP2 SCI-12 MICROBIO LABORATORY-fINALJOHNERROL CARCELLARОценок пока нет

- IGCSE Periodic Table v2Документ1 страницаIGCSE Periodic Table v2Umar ElèvénОценок пока нет

- Nanotechnology Applications and Its Importance in Various FieldsДокумент24 страницыNanotechnology Applications and Its Importance in Various FieldsSuresh ShahОценок пока нет

- An Updated Review On IPQC Tests For Sterile and Non Sterile ProductsДокумент12 страницAn Updated Review On IPQC Tests For Sterile and Non Sterile ProductsJvnОценок пока нет

- Dhuime Et Al. 2012 - ScienceДокумент4 страницыDhuime Et Al. 2012 - ScienceLady Johana Buritica CortesОценок пока нет

- Monsal Enzymic Hydrolysis New Developments and Lessons LearntДокумент23 страницыMonsal Enzymic Hydrolysis New Developments and Lessons LearntAnonymous MVHQ97KEoPОценок пока нет

- Waste Water TreatmentДокумент3 страницыWaste Water TreatmentSana Saleem100% (1)

- A3 Classification of Elements and Periodicity in Properties MinДокумент1 страницаA3 Classification of Elements and Periodicity in Properties MinKarthikeyan LakshmananОценок пока нет

- Molecular Biology IB ReviewerДокумент28 страницMolecular Biology IB ReviewerCeline Garin ColadaОценок пока нет