Академический Документы

Профессиональный Документы

Культура Документы

Orthogonal Machining

Загружено:

mwasfy_1Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Orthogonal Machining

Загружено:

mwasfy_1Авторское право:

Доступные форматы

IE 337: Materials and Manufacturing Processes Lab # 3

Orthogonal Machining

Introduction:

Machining can be defined as the process of removing material from a workpiece in the form

of chips by a sharp cutting to leave the desired part shape. The predominant cutting action in

machining involves shear deformation of the work-piece to form a chip; as the chip is removed, a

new surface is exposed. A typical machining process is illustrated in Figure 3.1.

Figure 3.1. (a) Cross-sectional view of a typical machining process, and

(b) a cutting tool with positive rake angle.

A cutting tool has one or more sharp cutting edges and is made of a material harder than that

of work material. It usually achieves their motion relative to workpiece by rotating. The cutting edge

serves to separate a chip from the workpiece. There are two surfaces connected to the cutting edge:

the rake face and the flank. The rake face, which directs the flow of chips, is oriented at a certain

angle called the rake angle, α. The rake angle can be positive or negative. The flank of the tool

provides a clearance between the tool and the newly generated work surface, thus protecting the

surface from abrasion. The rake face and flank are shown in Figure 3.2.

Figure 3.2. A single-point tool showing rake face and flank.

The orthogonal Cutting Model

The machining process is a complex 3D operation. A simplified 2D model of machining is

available that neglects many of geometric complexities, yet describes the process quite well.

Orthogonal cutting uses a wedge-shaped tool in which the cutting edge is perpendicular to the cutting

direction. As the tool is forced into the material, the chip is formed by shear deformation along shear

1 January 14, 2010

IE 337: Materials and Manufacturing Processes Lab # 3

Orthogonal Machining

plane oriented at an angle φ (shear angle) with the surface of the workpiece. Along the shear plane,

plastic deformation of work material occurs.

The tool in orthogonal cutting has only two elements of geometry: (1) rake angle and (2)

clearance angle. The rake angle α determines the direction of chip flow as it is formed; and the

clearance angle provides a small clearance between tool flank and newly generated work surface.

During cutting, the cutting edge of the tool is positioned at a certain distance below the original work

surface. This corresponds to the chip thickness prior to chip formation, to. As the chip is formed along

the shear plane, its thickness increases to tc. The ratio of to to tc is called chip ratio thickness is called

the chip ratio, rc and is always less than 1.

𝑡𝑡0

𝑟𝑟𝑐𝑐 =

𝑡𝑡𝑐𝑐

The governing equations in a machining process are provided below:

Shear angle: Shear strain:

Force Relationships

Several forces act during the cutting process. A normalized force diagram is shown in Figure 3.3.

Figure 3.3. Forces in orthogonal cutting: (a) Forces acting on the chip, and (b) forces on the tool.

Merchant Equation: Cutting force:

𝐹𝐹𝑐𝑐 cos ∅−𝐹𝐹𝑡𝑡 sin ∅ 3∗𝐸𝐸∗𝐼𝐼∗𝛿𝛿

𝜏𝜏𝑠𝑠 = 𝐹𝐹𝑐𝑐 =

(𝑡𝑡 0 𝑤𝑤 /𝑠𝑠𝑠𝑠𝑠𝑠 ∅) 𝐿𝐿 3

Other related equations and related terms are:

MRR=(𝑡𝑡0 ∗ 𝑑𝑑)𝑉𝑉

2 January 14, 2010

IE 337: Materials and Manufacturing Processes Lab # 3

Orthogonal Machining

rc Chip thickness ratio w Width of work piece material (in)

φ Shear angle b Thickness of cutting tool (in)

α Tool rake angle d Width of cutting tool (in)

MRR Material Removal Rate (in3/min) E Modulus of Elasticity (Young’s Modulus)

I Moment of Inertia (in4) δ Deflection of tool (in)

Tool length (measured from tool Linear cutting speed of cutting tool relative to work

L V

fixture to tip of dial indicator) (in) piece (in/min)

Fc Cutting force (lbf) hpc Cutting horsepower (hp)

R Resultant force hpu Specific (Unit) horsepower (hp/in3/min)

tc Chip thickness (in) γ Shear strain

τs

to Undeformed chip thickness (in) Shear Stress (psi)

Objective:

1. Understand the basic mechanics of chip formation.

2. Study the effect of rake angle, material system and the depth of cut on the process.

Equipment & Materials:

1. Vertical milling machine

2. Tool deflection gauge

3. Cutting tools with different rake angles (10°, 20°, 30°)

4. Workpiece: 6061 Aluminum, Brass

5. Dial calipers, protractor

Procedure:

1. Mount the aluminum work piece in the vise and the 10° cutting tool in the fixture. (The

rake angle is α in the calculation section).

2. Measure the distance from the bottom of the tool fixture to the point where the dial

indicator touches the tool. (This is the length L in the calculation section).

3. Adjust the X-axis feed rate (fr) to 4 inches per minute using the settings on the feed motor.

4. Turn on the CCD camera and monitor. With the cutting tool resting on the work piece,

adjust the camera so that the work piece fills approximately the bottom third of the screen

and the cutting tool appears on the right side of the screen. (*Note, focus the camera on

the work piece material, only a visible outline of the tool is needed).

5. Touch off on the top of the work piece then set the depth of cut to .003”. (This is to in the

calculation section).

6. Feed the tool into the work piece. Take an average reading from the tool deflection dial

indicator. Using a protractor, measure the shear angle on the screen. (These are δ and φ in

the calculations).

7. Collect the chip and measure the thickness with the dial calipers. (This is tc in the

calculations).

8. Repeat steps 1-7 at a depth of .006”.

9. Repeat steps 1-8 for the 20° rake angle tool.

10. Repeat steps 1-8 for the 30° rake angle tool.

11. Repeat steps 1-10 for brass.

3 January 14, 2010

IE 337: Materials and Manufacturing Processes Lab # 3

Orthogonal Machining

Lab Deliverables:

1. Prepare a report detailing the lab activity, observations, results and difficulties faced

(follow the lab report instructions).

2. Compare calculated shear angle with the values obtained in lab. Explain your findings.

3. Calculate cutting forces based on:

a. Deflection of the tool

b. Specific energy of the material

c. Shear strength of the material

How do they compare? Which of these you think are most representative of the actual

cutting force?

4. Describe the different types of chips formed for each experiment? How does chip type

affect the cutting forces?

5. What is the relationship between the shear angle and cutting force? Shear strain and

cutting force? Do these relationships make sense?

6. Why is the shear angle important in machining?

7. What factors control the shear angle in cutting?

8. How does the un-deformed chip thickness (depth of cut), tool rake angle, and work

piece material influence:

a) cutting force,

b) shear angle, and

c) chip type

References:

1. M.P. Groover, “Fundamentals of modern manufacturing,” 3rd edition, (2007).

2. F. Jones, H. Ryffel, E. Oberg, C. McCauley, and R. Heald, “Machinary’s handbook,” 26th

edition, Industrial Press, (2000).

3. You can see the chip formation for different conditions at

http://machine-tools.netfirms.com/Assets/FlashMovies/chip-formation-animation-2.htm

http://machine-tools.netfirms.com/Assets/FlashMovies/chip-formation-no-rake-angle.htm

4 January 14, 2010

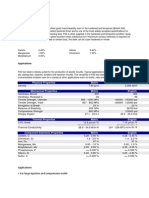

Orthogonal Machining Experiment Data Sheet

Aluminum

Rake Depth of Tool Shear Chip Chip

Angle cut Deflection Angle Thickness Type

.003”

10°

.006”

.003”

20°

.006”

.003”

30°

.006”

Brass

Rake Depth of Tool Shear Chip Chip

Angle cut Deflection Angle Thickness Type

.003”

10°

.006”

.003”

20°

.006”

.003”

30°

.006”

Tool width Material width

10° Aluminum

20° Brass

30°

Вам также может понравиться

- Metal Cutting TheoryДокумент8 страницMetal Cutting TheorySheetal SoniОценок пока нет

- May 2015Документ20 страницMay 2015ManojKumar MОценок пока нет

- Theory of Metal MachiningДокумент42 страницыTheory of Metal MachiningAbdulla AlattawiОценок пока нет

- Lecture-2.Conventional Machining - 2018 PDFДокумент80 страницLecture-2.Conventional Machining - 2018 PDFSaumya ShahОценок пока нет

- MACHINING THEORY FORCES AND CHIP FORMATIONДокумент63 страницыMACHINING THEORY FORCES AND CHIP FORMATIONThiran Boy LingamОценок пока нет

- Fundamentals of CuttingДокумент56 страницFundamentals of CuttingTrevor WarnerОценок пока нет

- Metal Cutting OperationsДокумент6 страницMetal Cutting OperationsNikhil SinghОценок пока нет

- Chapter Three: FUNDAMENTALS OF CUTTING PROCESS: The Common Feature Is The Use of A Cutting Tool To FormДокумент12 страницChapter Three: FUNDAMENTALS OF CUTTING PROCESS: The Common Feature Is The Use of A Cutting Tool To FormkidusОценок пока нет

- Fundamentals of Material Removal ProcessesДокумент48 страницFundamentals of Material Removal ProcessesJeff HardyОценок пока нет

- Theory of Metal Machining ProcessesДокумент111 страницTheory of Metal Machining ProcessesYuvraaj Singh100% (1)

- Fundamentals of Machining MetalsДокумент1 страницаFundamentals of Machining Metalstomica06031969Оценок пока нет

- Metal Cutting Forces and Chip FormationДокумент38 страницMetal Cutting Forces and Chip FormationcrazynupОценок пока нет

- 307 - Experimental - Analysis 1.denemeДокумент26 страниц307 - Experimental - Analysis 1.denemekaanfidan2002Оценок пока нет

- 5 MachiningДокумент84 страницы5 MachiningVisan NaiduОценок пока нет

- Metal Cutting Meaning, History and Principles MetallurgyДокумент21 страницаMetal Cutting Meaning, History and Principles MetallurgyJackson SichingaОценок пока нет

- Theory of Metal Cutting FundamentalsДокумент24 страницыTheory of Metal Cutting FundamentalsSreehari ViswanathanОценок пока нет

- CH-1 MachiningДокумент29 страницCH-1 MachiningAbreham DerejeОценок пока нет

- Theory of Metal Cutting: Submitted To MR. GURPREET SINGH Submitted byДокумент39 страницTheory of Metal Cutting: Submitted To MR. GURPREET SINGH Submitted byamitОценок пока нет

- Unit - 1.PrintOUTДокумент46 страницUnit - 1.PrintOUTvlucknowОценок пока нет

- Machining Processes GuideДокумент21 страницаMachining Processes GuideVenkat Reddy YanamiОценок пока нет

- Notes on Production Engineering IДокумент46 страницNotes on Production Engineering IpopsuvuydaОценок пока нет

- CNC Machine Tool LimitationsДокумент22 страницыCNC Machine Tool LimitationsSARAVANA KUMARОценок пока нет

- Metal Cutting 2Документ39 страницMetal Cutting 2Naman DaveОценок пока нет

- Ch2 MachiningДокумент134 страницыCh2 MachiningSaifAdamz'sОценок пока нет

- Mechanics of Metal Cutting: Tool EngineeringДокумент26 страницMechanics of Metal Cutting: Tool EngineeringChen WANYINGОценок пока нет

- Material ProcessingДокумент8 страницMaterial ProcessingioanapanaitОценок пока нет

- Mak307lab2 15.30 221501070Документ23 страницыMak307lab2 15.30 221501070kaanfidan2002Оценок пока нет

- Production EnggДокумент41 страницаProduction EnggRinne UchihaОценок пока нет

- Merchant's Circle NotsДокумент5 страницMerchant's Circle NotsSaravanan MathiОценок пока нет

- Fundamentals of Metal Cutting and Machining Processes: Lecture 6-7Документ150 страницFundamentals of Metal Cutting and Machining Processes: Lecture 6-7Sibu SibuОценок пока нет

- 2nd Btech MECH 2021-22 MCMT Ses-K4 PDFДокумент14 страниц2nd Btech MECH 2021-22 MCMT Ses-K4 PDFGopi TОценок пока нет

- Metal Cutting Theory and MechanismДокумент75 страницMetal Cutting Theory and Mechanismnishantdubey1183Оценок пока нет

- MCT D ManualДокумент25 страницMCT D ManualAmit KumarОценок пока нет

- CIRP Annals - Manufacturing Technology: T. O Zel, Y. Karpat, A. SrivastavaДокумент4 страницыCIRP Annals - Manufacturing Technology: T. O Zel, Y. Karpat, A. SrivastavarajeshОценок пока нет

- Ipe 332Документ19 страницIpe 332S. M. Hasibur RahmanОценок пока нет

- Mechanics of Metal Cutting ExplainedДокумент23 страницыMechanics of Metal Cutting ExplainedzombieОценок пока нет

- PT All MergedДокумент429 страницPT All MergedArihant ShijuОценок пока нет

- Modeling and Simulation of Turning OperationДокумент8 страницModeling and Simulation of Turning OperationtabrezОценок пока нет

- Machine Tools: Aditya College of Engineering - MadanapalleДокумент32 страницыMachine Tools: Aditya College of Engineering - MadanapalleAmara Sanjeevaiah GandhiОценок пока нет

- Deber 1Документ15 страницDeber 1jmgavilanes0% (1)

- CIMT Important Lathe Machine QuestionsДокумент11 страницCIMT Important Lathe Machine QuestionsChandu ReddyОценок пока нет

- Question Bank For Machining and MetrologyДокумент7 страницQuestion Bank For Machining and MetrologyAbhisheak DineshОценок пока нет

- U1Metal Cutting & Tool DesignДокумент62 страницыU1Metal Cutting & Tool DesignVansh puriОценок пока нет

- Chip Geometry Modelling of 2-Dimension Ultrasonic Vibration Assisted Machining (2D UVAM) On Micromilling Machine With End MillДокумент7 страницChip Geometry Modelling of 2-Dimension Ultrasonic Vibration Assisted Machining (2D UVAM) On Micromilling Machine With End MillMuhammad Taqiy Nur FurqonОценок пока нет

- Metal Machining and Automation (ME 3201Документ19 страницMetal Machining and Automation (ME 3201kasam santhosh prathikОценок пока нет

- Manufacturing Technology - Ii (Me1253 Unit - IДокумент26 страницManufacturing Technology - Ii (Me1253 Unit - IRameez FaroukОценок пока нет

- 4-Machining Fundamentals Ams May01 13Документ87 страниц4-Machining Fundamentals Ams May01 13mjdaleneziОценок пока нет

- Manufacturing TechnologyДокумент41 страницаManufacturing Technologysharmashn50% (2)

- ch21 Fundamentals of MachiningДокумент25 страницch21 Fundamentals of MachiningBaatar Zorigt100% (1)

- CH 2 Metal Cutting ToolsДокумент19 страницCH 2 Metal Cutting ToolsAlex AdmasОценок пока нет

- Metal Removal ProcessesДокумент61 страницаMetal Removal ProcessesBinyam HabtamuОценок пока нет

- Ch-1 Basics of Metal Cutt PDFДокумент106 страницCh-1 Basics of Metal Cutt PDFAnkit AmbaniОценок пока нет

- Experiment No.1 PDFДокумент7 страницExperiment No.1 PDFGest Account 08Оценок пока нет

- Prod Tech-I - Unit 2 (A) - Metal CuttingДокумент24 страницыProd Tech-I - Unit 2 (A) - Metal CuttingNimish Raman MitalОценок пока нет

- Metal CuttingДокумент45 страницMetal CuttingVarun SinghОценок пока нет

- IPE-4102-Machine Tool SessionalДокумент29 страницIPE-4102-Machine Tool SessionalNafiz AlamОценок пока нет

- Manual of Engineering Drawing: British and International StandardsОт EverandManual of Engineering Drawing: British and International StandardsРейтинг: 3.5 из 5 звезд3.5/5 (4)

- Prompting Science and Engineering Students in Practical TrigonometryОт EverandPrompting Science and Engineering Students in Practical TrigonometryОценок пока нет

- AeenmcalДокумент2 страницыAeenmcalManideep AnanthulaОценок пока нет

- The Management of Everyday LifeДокумент23 страницыThe Management of Everyday LifeManideep AnanthulaОценок пока нет

- Railway Recruitment Board Examination Question Paper 2006Документ13 страницRailway Recruitment Board Examination Question Paper 2006Manideep AnanthulaОценок пока нет

- How To Manage Big, Powerful Clients - ProfitablyДокумент50 страницHow To Manage Big, Powerful Clients - ProfitablyManideep AnanthulaОценок пока нет

- How To Manage Big, Powerful Clients - ProfitablyДокумент50 страницHow To Manage Big, Powerful Clients - ProfitablyManideep AnanthulaОценок пока нет

- Geography Bit BankДокумент129 страницGeography Bit Banksuresh0% (1)

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 11apr TW RuralДокумент16 страниц11apr TW RuralManideep AnanthulaОценок пока нет

- IDPCДокумент68 страницIDPCRaja SubramanianОценок пока нет

- SAIL Placement Sample Paper 2Документ6 страницSAIL Placement Sample Paper 2Janiel JawaharОценок пока нет

- Fling 9 X 7 W 2Документ1 страницаFling 9 X 7 W 2Manideep AnanthulaОценок пока нет

- Banking Awareness Quick Reference Guide - Gr8AmbitionZДокумент11 страницBanking Awareness Quick Reference Guide - Gr8AmbitionZArif SheikhОценок пока нет

- Overviews: MillingДокумент12 страницOverviews: MillingManideep AnanthulaОценок пока нет

- Sail 2010 PaperДокумент3 страницыSail 2010 PaperChristopher WoodОценок пока нет

- Motivation TheoriesДокумент22 страницыMotivation TheoriesslixsterОценок пока нет

- AI SI P20 Steels PDFДокумент2 страницыAI SI P20 Steels PDFManideep AnanthulaОценок пока нет

- Drilling 2Документ12 страницDrilling 2Manideep AnanthulaОценок пока нет

- From Organisational Structure To Organisational Behaviour FormalisationДокумент21 страницаFrom Organisational Structure To Organisational Behaviour FormalisationManideep AnanthulaОценок пока нет

- Argumentation PDFДокумент3 страницыArgumentation PDFManideep AnanthulaОценок пока нет

- Mechanics of Chip FormationДокумент10 страницMechanics of Chip FormationManideep AnanthulaОценок пока нет

- Critical Reasoning: Cat 2002/Gmat/Other Mba ExamsДокумент4 страницыCritical Reasoning: Cat 2002/Gmat/Other Mba ExamssrujanbejavadaОценок пока нет

- Lab Manual PDFДокумент37 страницLab Manual PDFManideep AnanthulaОценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- ME364 Cutting MechanicsДокумент4 страницыME364 Cutting Mechanicslamia97Оценок пока нет

- Cost Concepts&cost SheetДокумент32 страницыCost Concepts&cost SheetManideep Ananthula0% (1)

- Cutting Tool PDFДокумент9 страницCutting Tool PDFManideep AnanthulaОценок пока нет

- Soa 373398 September 2013 PDFДокумент2 страницыSoa 373398 September 2013 PDFManideep AnanthulaОценок пока нет

- Attribution Theory PDFДокумент12 страницAttribution Theory PDFManideep AnanthulaОценок пока нет