Академический Документы

Профессиональный Документы

Культура Документы

1E-Motors Inspection Checklist

Загружено:

Anonymous iiUUgwИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

1E-Motors Inspection Checklist

Загружено:

Anonymous iiUUgwАвторское право:

Доступные форматы

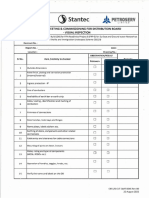

MOTOR INPECTION CHECKLIST Project No. Sequential Rev.

Page

Subject

(CONSTRUCTION) 017408-C-

QA

C1

1 of 1

5001

Date Report No.

Company : Tabreed

Project: TABREED COOLING PLANT –AL KIFAF (DM-04)

Mechanical, Piping, Electrical &

Instrumentation

Contractor: SNC Lavalin Sub-Contractor: TOLEDO REFER ITP NO.:

Plant Area / Bldg. No.:

Specification No.:

Tag / Part / System:

Drawing:

Materials / Equipment Description:

CHECKED BY

TOLEDO SLGC

NO. ITEMS TO BE CHECKED Signature Date Signature Date

1. Equipment tag correct

2. Material and equipment conform to specification

3. Cable number, size and voltage checked against drawing and specification

4. Motor nameplate rating verified against specification

5. Visually inspect for any damages

6. Location and orientation as per drawing

7. Motor approved for area classification

8. Verify that the insulation’s temperature class ratings conforms to the specification

9. Check for missing parts, frame and casting sound, clean and free of debris.

Shaft turns freely

10. Grounding conductors installed, connected, unit tested and results recorded

11. Megger motor and record results

12. Verify that power and control cables have been meggered before connection to motor

13. Cable glanded and terminated properly

14. Starters installed and checked

15. Local terminal panel installed and connected

16. Verify the installation and connection of emergency stop button

17. Motor is applied with enamel paint system

18. Make sure that all specific inspections and tests recommended by the manufacturer has

been performed

19. Labeling and identification have been completed

20. Check that all inspection activities are reported and recorded

Remarks:

Form No. 1E

Record Acc Prepared By (Toledo) Approved by(SLGC)

Name

Title Site QA/QC Engineer SLGC Quality Controller

Signature

Date

Вам также может понравиться

- Pre Energization Check List.Документ2 страницыPre Energization Check List.shenbagaraman100% (1)

- Visual Inspection Checklist For Electrical Safety: Portable Electrical Equipment Yes NoДокумент2 страницыVisual Inspection Checklist For Electrical Safety: Portable Electrical Equipment Yes NoAhmed Zahran100% (1)

- Inspection Item Color CodeДокумент3 страницыInspection Item Color CodePerwez21Оценок пока нет

- Electrica QC Check ListДокумент21 страницаElectrica QC Check Listmakana qc100% (1)

- Electrical Distribution Board Inspection ChecklistДокумент2 страницыElectrical Distribution Board Inspection ChecklistBoluwatife ElishaОценок пока нет

- Itr Ew 01a - EngДокумент2 страницыItr Ew 01a - Engwassim nasriОценок пока нет

- Switchgear Inspection Checklist: Section A - Customer DataДокумент1 страницаSwitchgear Inspection Checklist: Section A - Customer Data20082012Оценок пока нет

- Electric Motor Check SheetДокумент2 страницыElectric Motor Check SheetRsilvesterОценок пока нет

- PPM Checklist - Air Circuit Breaker (Acb)Документ1 страницаPPM Checklist - Air Circuit Breaker (Acb)Mohamed Firdaus Bin ZakariaОценок пока нет

- Form Motor Solo Run Interlock FuncДокумент1 страницаForm Motor Solo Run Interlock FuncImam HanafiОценок пока нет

- Checklist of HT Motor MaintenancexlsxДокумент2 страницыChecklist of HT Motor Maintenancexlsxersanjeeb_456Оценок пока нет

- Portacabin Inspection ChecklistДокумент2 страницыPortacabin Inspection ChecklistApm FoumilОценок пока нет

- ChecklistДокумент14 страницChecklistInstrument SCIОценок пока нет

- Part Submission WarrantДокумент4 страницыPart Submission WarrantSam AnuОценок пока нет

- Installation - A - EarthmatДокумент11 страницInstallation - A - Earthmatpdky yadavОценок пока нет

- Elcb Checking Format-TДокумент1 страницаElcb Checking Format-TGyanendra Narayan NayakОценок пока нет

- Function Checks Is Not Applicable For This Panel: Switchgear Functional TestДокумент3 страницыFunction Checks Is Not Applicable For This Panel: Switchgear Functional Testeswaran005Оценок пока нет

- 26 1.itp ElectricalДокумент1 страница26 1.itp Electricalmee100% (1)

- Electrical Pump & Motor Inspection ChecklistДокумент1 страницаElectrical Pump & Motor Inspection ChecklistJIJESH GOKULDASОценок пока нет

- Service, Feeders, Standby Systems Required Lighting OutletsДокумент1 страницаService, Feeders, Standby Systems Required Lighting OutletsIvar NilastaОценок пока нет

- E14-B LV Switchboard and MCCДокумент3 страницыE14-B LV Switchboard and MCCAmyОценок пока нет

- Pre-Use Checklist For Welding MachinesДокумент2 страницыPre-Use Checklist For Welding MachinesNuno LopesОценок пока нет

- E&I QAP's - Submitted To Contractor HZAДокумент33 страницыE&I QAP's - Submitted To Contractor HZASuraj ShettyОценок пока нет

- Borang Pemeriksaan Air KompressorДокумент1 страницаBorang Pemeriksaan Air KompressorAndara Asifa YudianaОценок пока нет

- WMS INFINEON PROJECT TOWER (MSB, SSB AND DBs INSTALLATION) - REV-1Документ5 страницWMS INFINEON PROJECT TOWER (MSB, SSB AND DBs INSTALLATION) - REV-1tanaОценок пока нет

- Old LT Panel 400 AmpДокумент5 страницOld LT Panel 400 AmpAbhinav TewariОценок пока нет

- M/S Kapoor Enterprises Vendor Code: K635: Mechanized Rock Breaker ChecklistДокумент2 страницыM/S Kapoor Enterprises Vendor Code: K635: Mechanized Rock Breaker Checklistprojit basu100% (1)

- Generator Daily Inpection: Generator ID No: Period: MON TUE WED THU FRI SAT SUNДокумент2 страницыGenerator Daily Inpection: Generator ID No: Period: MON TUE WED THU FRI SAT SUNrnp2007123Оценок пока нет

- Stacker Preventive Maintenance Weekly: Clean and InspectДокумент1 страницаStacker Preventive Maintenance Weekly: Clean and InspectFabio Gonzalez100% (1)

- SOP-08 Thermocouple - DTC CalibrationДокумент9 страницSOP-08 Thermocouple - DTC CalibrationPandu BirumakovelaОценок пока нет

- DB ChecklistДокумент4 страницыDB ChecklistJabinОценок пока нет

- Motor Test FormДокумент1 страницаMotor Test FormArie Yantoe100% (1)

- Emergency Lights Inspection ChecklistДокумент7 страницEmergency Lights Inspection ChecklistDemmy Rose NugasОценок пока нет

- Checklist For Equipment Inspection Circular SawДокумент2 страницыChecklist For Equipment Inspection Circular SawUMMU AIMAN BINTI AYUBОценок пока нет

- 2640.011SWP - Excavations and TrenchesДокумент7 страниц2640.011SWP - Excavations and TrenchesHasanuddin HAMIDОценок пока нет

- Electrical Equipment Check ListДокумент3 страницыElectrical Equipment Check ListRania Saied100% (2)

- Procedures For Safe Working and Testing of Energized Electrical EquipmentДокумент25 страницProcedures For Safe Working and Testing of Energized Electrical EquipmentSelvn SubramanianОценок пока нет

- Motor Bump Test Record Sheet: Project: Motor Tag No Marker: Starter Type: Rating: EX CertificationДокумент6 страницMotor Bump Test Record Sheet: Project: Motor Tag No Marker: Starter Type: Rating: EX CertificationMuhammad AshfaqueОценок пока нет

- Check ListДокумент88 страницCheck ListRaafat SaadОценок пока нет

- MV Cable Hi-Pot Test ShetДокумент1 страницаMV Cable Hi-Pot Test ShetAhmad Dagamseh100% (1)

- Change Request FormДокумент4 страницыChange Request Formdnmule0% (1)

- Commissioning Service Department Commissioning Standard Test Formats Description: MVAJ101 - TRIP RELAYДокумент2 страницыCommissioning Service Department Commissioning Standard Test Formats Description: MVAJ101 - TRIP RELAYtajudeenОценок пока нет

- MQP of PanelДокумент1 страницаMQP of Panelrahulchitrakoot123Оценок пока нет

- 318-Welding Machine Inspection Report Monthly Rev 000Документ1 страница318-Welding Machine Inspection Report Monthly Rev 000francisОценок пока нет

- Lockout - Tagout (LOTO) Annual Inspection and Training Assessment Checklist Department: Shop: Location: EquipmentДокумент2 страницыLockout - Tagout (LOTO) Annual Inspection and Training Assessment Checklist Department: Shop: Location: EquipmentSayed Saad ShehataОценок пока нет

- Electrical Panel Board ChecklistДокумент2 страницыElectrical Panel Board Checklistkhrayzie bhoneОценок пока нет

- E 001B1 MotorДокумент2 страницыE 001B1 MotorBhihi RajaОценок пока нет

- Daily Checklist For DGДокумент2 страницыDaily Checklist For DG7Days Facility ManagementОценок пока нет

- QAP Plan Elect.Документ2 страницыQAP Plan Elect.insap_dineshОценок пока нет

- MS of 220 KV Switchyard EquipmentДокумент8 страницMS of 220 KV Switchyard EquipmentFareh KhanОценок пока нет

- 13 Fan Coil Unit: Location: - No.Документ1 страница13 Fan Coil Unit: Location: - No.JIJUОценок пока нет

- Safety Daily Site Checklist Mastoura co-SA-1-12Документ12 страницSafety Daily Site Checklist Mastoura co-SA-1-12LawrenceОценок пока нет

- HV Work Method Statement-2Документ2 страницыHV Work Method Statement-2martins7333% (3)

- ELCB Checklist: SR No. Elcb Make Locaion Elcb No Rating of Elcb Ok/Notok RemarksДокумент1 страницаELCB Checklist: SR No. Elcb Make Locaion Elcb No Rating of Elcb Ok/Notok Remarksparth prajapatiОценок пока нет

- JSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Документ11 страницJSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Jayson EscamillanОценок пока нет

- QC-143 R2 Distribution Panel ChecklistДокумент1 страницаQC-143 R2 Distribution Panel ChecklistCamilo Jorquera100% (1)

- HLG HSE SPI FM 016B r00 Crane Inspection ChecklistДокумент1 страницаHLG HSE SPI FM 016B r00 Crane Inspection ChecklistLemuel PetronioОценок пока нет

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportДокумент9 страницEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiОценок пока нет

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportДокумент9 страницEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiОценок пока нет

- PDFДокумент3 страницыPDFnate anantathatОценок пока нет

- Calculating Design Loads For Residential Structures: Pdhonline Course S199 (4 PDH)Документ34 страницыCalculating Design Loads For Residential Structures: Pdhonline Course S199 (4 PDH)Vincent De GuzmanОценок пока нет

- Appendix - I (See Paragraph - 6) Form - 1Документ11 страницAppendix - I (See Paragraph - 6) Form - 1Vishnu PatidarОценок пока нет

- Butterfly Valve CatalogueДокумент6 страницButterfly Valve CatalogueromeshmoreyОценок пока нет

- Kitchen AssignmentДокумент39 страницKitchen AssignmentKhiZra ShahZadОценок пока нет

- Ceg461 - Tutorial 4b - ConsolidationДокумент5 страницCeg461 - Tutorial 4b - ConsolidationdzikrydsОценок пока нет

- Wall Panel SystemДокумент27 страницWall Panel SystemLiezel GasparОценок пока нет

- P-QAC-PLN-910-39451-Rev BДокумент23 страницыP-QAC-PLN-910-39451-Rev BAslaouiОценок пока нет

- AL Alpha Essentials WebДокумент182 страницыAL Alpha Essentials WebVo Hong KietОценок пока нет

- Exam Set 05Документ2 страницыExam Set 05allovidОценок пока нет

- ButalejaДокумент4 страницыButalejaSamuel WagemaОценок пока нет

- IB-80000B Nonsegregated-Phase Bus: 600V To 38kV, 1200A To 4000AДокумент17 страницIB-80000B Nonsegregated-Phase Bus: 600V To 38kV, 1200A To 4000Adestro57Оценок пока нет

- Installation Module: Xarios RangeДокумент20 страницInstallation Module: Xarios Rangefaza1111Оценок пока нет

- Alfacrimp - Part Numbering SystemДокумент1 страницаAlfacrimp - Part Numbering Systemphankhoa83-1Оценок пока нет

- Product Catlogue Final 2015Документ8 страницProduct Catlogue Final 2015khadeerabk7925Оценок пока нет

- Single Handle Pull-Out Kitchen Faucet PFXC5150: Parts BreakdownДокумент1 страницаSingle Handle Pull-Out Kitchen Faucet PFXC5150: Parts BreakdownCraig SmithОценок пока нет

- Dry Stone WallДокумент77 страницDry Stone Wallmokaficekhaver100% (3)

- FACP Power Supply QCDD 2022Документ2 страницыFACP Power Supply QCDD 2022ashraf saidОценок пока нет

- Vibration PPV EstimationДокумент8 страницVibration PPV EstimationJensen TanОценок пока нет

- STRATCO Slats DIY Guide PDFДокумент2 страницыSTRATCO Slats DIY Guide PDF112160rbcОценок пока нет

- OILES CorporationДокумент24 страницыOILES CorporationNiranjan KumarОценок пока нет

- Cementing PresentationДокумент34 страницыCementing PresentationKarwan Dilmany100% (3)

- KSCST Project ReportДокумент10 страницKSCST Project ReportGururaj TavildarОценок пока нет

- Elmo 2bh1 Gas Ring Vacuum PumpsДокумент11 страницElmo 2bh1 Gas Ring Vacuum PumpsAlberto Costilla GarciaОценок пока нет

- System 300 Modular Plants: Terex Minerals Processing Systems System 300Документ2 страницыSystem 300 Modular Plants: Terex Minerals Processing Systems System 300gambit galihОценок пока нет

- Tubular Conveyor GalleryДокумент10 страницTubular Conveyor GallerySudarshan Kamble100% (1)

- Differences Between Astm A706 and A615Документ4 страницыDifferences Between Astm A706 and A615Nouman MohsinОценок пока нет

- Stiffness Modifiers For RC BuilindingДокумент8 страницStiffness Modifiers For RC BuilindingDipak BorsaikiaОценок пока нет

- RRLДокумент4 страницыRRLRalph Lauren RodriguezОценок пока нет

- The Alumiguard Sheet Piling Is Used ForДокумент2 страницыThe Alumiguard Sheet Piling Is Used ForVitor José RodriguesОценок пока нет

- Site PlanningДокумент69 страницSite PlanningSAKET TYAGI100% (1)