Академический Документы

Профессиональный Документы

Культура Документы

Experience PDF

Загружено:

Anonymous AdofXEYAgE0 оценок0% нашли этот документ полезным (0 голосов)

9 просмотров8 страницОригинальное название

EXPERIENCE.pdf

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

9 просмотров8 страницExperience PDF

Загружено:

Anonymous AdofXEYAgEАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 8

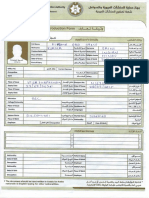

feecuewes ~ Seeris

43678

WELDER / WELDING OPERATOR QUALIFICATION TEST RECORD

FSL Job. No. SA10- 7187 i

Welder Name. Satya Rao Kara Date r |

Stamp No (Symbol) _6VU za Passport No

Using WPS No, ‘SAS 186/02 Rev.t_ Type Manual (gama no

Welding Process. GTAW Backing "None ___Nationaliy i

Base Material ‘APL GL Gr. Thickness: "0.218" _ GhenvGorvacto S.A. Saipom_

RECORD ACTUAL VALUES

VARIABLES ‘Used in Qualification Range Qualified

‘Welding Process GTAW = GTAW |

Base Metal: j

‘Specification ‘API SL Gr. B to APISL Gr. B Phin Pise, pos gpa imu PAs to same |

Classification Number Pt to Pt “Pith Pier, Poe grat thu PAB to Same — |

Joint ee a aE . oe |

Type of Joint (Bult, ap etc.) —_Butt All uf |

Type of Weld (Groove. Filet) “Single “V" Groove _ “Groove & Filiet ia |

Pipe or Plate Pipe Pipe a Plate \

‘Consumable Inserts None None

Backing No With or Without Backing |

Pipe Diameter “2 B NPS |

lor Metal:

Specification SFA 5.18

Classification ER 708-2

F-number F6

Deposited Weld Thickness _GTAW- 0.218"

Deposited Weld Thickness.

Welding Parameters:

Position

Welding Progression

Gas Backing

Current 1 Polarity (Root)

Current / Polarity (FillCap)

Tests Conducted

Visual Inspection t

Root Bene (

Face Bend {

Side Bere (

Filet Fracture {

Macro etch {

Rodiography t

Other Sa

“He cely Wal a Worst in Tis Vecord i cone nd Wake el coupons were prepared,

Seea rat dance wil in roqurements of ASME Sec. IK-2010"

Date 9 May 2011 ___ Date

canie ee Ce

Print Name:

ory rona on (98 04

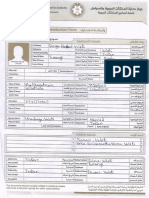

FSL Job No

39608

WELDER QUALIFICATION TEST RECORD.

Ciassification Number

Joint:

Type of Joint (Bult, lap ete.)

Type of Weld (Groove, Fillet)

SA09- 7303, i =

Welder Name “Satya Rao Karri Sa Date ~4a'sbptember 2010

Stamp No, (Symbol) “MCH- 028 3 PassportNo _H 6891089

Using WPS No ZMM- 03 Rov. 07 Type Igama No NIA

Welding Process. _GTAW + SMAW Backing Nationality, indian

Base Material ‘SA106 Gr. B ‘Thickness ClenvContracto: “ZN, AL MADAWI St

RECORD ACTUAL VALUES

VARIABLES Used in Qualification RANGE QUALIFIED

Base Metal:

Specification SA 106 Gr. B to Same

“Pito Pt

Cab ees eee

Groove & Fillet

Pipe or Plate Pipe ~ “Pipe & Plate Brier bi

Backing an ~ “With or Without 6:

Pipe Diameter NPS 2718" 0.0. & Above

Filler Metal:

Specification SFA 5.18 & SFA SFA 5.18 & SEA

Classification ER70S-2 & E7018 AILFG & F4 Nii

F-number FG FA Fé, Fi thru Fa kin

Deposited Weld Thickness _GTAW. “Up to 0.236" thickness.

Deposited Weld Thickness

Welding Parameters:

Position 6G

Welding Progression:

Gas Backing

Current / Polarity (Root)

Current / Polanty (Fil/Cap)

Up to 0.764" thickness.

All eee

Uphill

NA,

DCSP z

DERP

Results

“Uphill

NIA

DCSP

DORE

‘Tests Conducted

Visual Inspection

Root Bend

Face Bend

Side Bend

[ Satisfactory

{

[

[

Fillet Fracture [

[

[

[

Tensile

Radiography

Other

“We the undersigned) erty thratthreayommationsin this record is correct and that the test coupons were prepared

welded and tested infaccordance wif the refetnents of ASME DX2007 ©

:

Date [18 September 2010 =" Date = .

Signed, Signed: = 5

\g Inspector Contractor

Print Name: Aneesh T.

PrintName: 1 San Pedro |

[INN WLEDRM 03(98) Rev 04

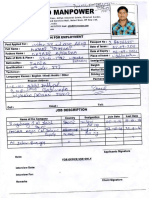

44588 | |

WELDER / WELDING OPERATOR QUALIFICATION TEST RECORD |

il

Me

F.S.L Job No, SA10-7187

IA ST

Weider Name “Satya Rao K ———— Inspection Date: _o4 July 2014 E

Stamp No. (Symbol); “BU. PassportNo. "NIA

(Sing WPS No: "SAS-2T6I08 Rev 0 Type — Manual — igama no. 2284174d26

‘Welding Process: GTAW Backing: “No Nationality: Indian

Base Materia SA 333 Gr. 6 Thickness: “O.218" _ cienvConmsco:. “SA SRS i

RECORD ACTUAL VALUES a.

VARIABLES Used in Qualification Range Qualified

Weisig Brosess raw craw |

Bate Netal: any sae i

‘Specification SA 333 Gr. 6 10 $A.333 Gr. 6 tu PSE, P06 PEt ths P40 to Some

Classification Number Pi to Pi “Ein Pier, poe perma rest some

Joint: a

Type of Joint (Butt, Lap. etc) _ Butt Al eee:

T¥Pe of Weld (Groove, Filet) ~ Singia "W" Groove ———— —__~ “Groave & Fillet a

Pipe or Plate Pipe Pipe & Plate

Consumabie inserts None = Sia ge

Backing None i

Pipe Diameter 2° ONS —_ 1" 0.D. and over

Filler Metal:

Spectication SFA 5.48 SFA 5.18 an

Classification ER 708.3 —__ “F6 classification

F-Number FG a FG "

DePosited Weld Thickness“ GTAW- 0218" Thickness up to 0.456" a

Deposited Weld Thickness. “NIA NA tf

Welding Parameters:

Position 6c agora

Welding Progression Opi emer aeaeer erases Aeon i

Gas Backing NA, = NA. |

Current / Polarity (Root) DCsP. __ Seo Sea rca ti |

cre Postty (Fics) Dts a ~ “esr |

Tests Conducted: Description (Number, Type, ste Results:

Visual inspection [x _ Satisfactory

Tensile rap epee

Root Bend tay

Face Bend i

Fillet Fracture (aa)

Macro-Etch a =

Radiography (X] “ESC RT Report No, 138773 Satisfactory =

Other(s) ier ii

Tee Sat tat ihe ornath WIS vecorg emp reci and thal is al GGUS oS Prepared, welded and

Tested in accordande

Date:

Signed:

Print Name:

NOT Wi FORM 03 (98) 8

with the requirementssSER

ogi July 2084

«PME Section IX 20

Date:

10 Edition.”

40 JUL 201

Вам также может понравиться

- Kurma Rao Saini - Introduction Form040Документ2 страницыKurma Rao Saini - Introduction Form040Anonymous AdofXEYAgEОценок пока нет

- Kurma Rao Saini - Qualification Certificate044Документ10 страницKurma Rao Saini - Qualification Certificate044Anonymous AdofXEYAgEОценок пока нет

- CVДокумент2 страницыCVAnonymous AdofXEYAgEОценок пока нет

- Resume PDFДокумент4 страницыResume PDFAnonymous AdofXEYAgEОценок пока нет

- Kurma Rao Saini - CVДокумент1 страницаKurma Rao Saini - CVAnonymous AdofXEYAgEОценок пока нет

- JD PDFДокумент1 страницаJD PDFAnonymous AdofXEYAgEОценок пока нет

- JD FormДокумент1 страницаJD FormAnonymous AdofXEYAgEОценок пока нет

- Kurma Rao Saini - CVДокумент1 страницаKurma Rao Saini - CVAnonymous AdofXEYAgEОценок пока нет

- JD FormДокумент1 страницаJD FormAnonymous AdofXEYAgEОценок пока нет

- ExperienceДокумент19 страницExperienceAnonymous AdofXEYAgEОценок пока нет

- Vantakula Rambabu-Resume PDFДокумент1 страницаVantakula Rambabu-Resume PDFAnonymous AdofXEYAgEОценок пока нет

- Vantakula Rambabu-Experience CertificatesДокумент10 страницVantakula Rambabu-Experience CertificatesAnonymous AdofXEYAgEОценок пока нет

- Education PDFДокумент4 страницыEducation PDFAnonymous AdofXEYAgEОценок пока нет

- Intro Form PDFДокумент2 страницыIntro Form PDFAnonymous AdofXEYAgEОценок пока нет

- CVДокумент1 страницаCVAnonymous AdofXEYAgEОценок пока нет

- Intro FormДокумент2 страницыIntro FormAnonymous AdofXEYAgEОценок пока нет

- JD FormДокумент1 страницаJD FormAnonymous AdofXEYAgEОценок пока нет

- CV PDFДокумент1 страницаCV PDFAnonymous AdofXEYAgEОценок пока нет

- Mohammad Mukhtar Ali-CvДокумент15 страницMohammad Mukhtar Ali-CvAnonymous AdofXEYAgEОценок пока нет

- Receipt Report IE-2485530Документ1 страницаReceipt Report IE-2485530Anonymous AdofXEYAgEОценок пока нет

- Chand Masih h6045205 CVДокумент18 страницChand Masih h6045205 CVAnonymous AdofXEYAgEОценок пока нет

- Receipt IE 2485532Документ1 страницаReceipt IE 2485532Anonymous AdofXEYAgEОценок пока нет

- JD Form PDFДокумент1 страницаJD Form PDFAnonymous AdofXEYAgEОценок пока нет

- Kali Mukesh Reddy r7688643 CVДокумент44 страницыKali Mukesh Reddy r7688643 CVAnonymous AdofXEYAgEОценок пока нет

- Pravin Kumar Singh k8222245 CVДокумент33 страницыPravin Kumar Singh k8222245 CVAnonymous AdofXEYAgEОценок пока нет

- CVДокумент1 страницаCVAnonymous AdofXEYAgEОценок пока нет

- Pandi Devaraju Reddy p6303778 CVДокумент36 страницPandi Devaraju Reddy p6303778 CVAnonymous AdofXEYAgEОценок пока нет

- CV PDFДокумент2 страницыCV PDFAnonymous AdofXEYAgEОценок пока нет

- CV PDFДокумент1 страницаCV PDFAnonymous AdofXEYAgEОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)