Академический Документы

Профессиональный Документы

Культура Документы

Piston Air Compressor Functionality

Загружено:

Radhe kumawatОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Piston Air Compressor Functionality

Загружено:

Radhe kumawatАвторское право:

Доступные форматы

AIR COMPRESSOR

An air compressor is a device that converts power (using an electric motor, diesel or

gasoline engine, etc.) into potential energy stored in pressurized air (i.e., compressed air).

In today’s world of pneumatic operations, it’s hard to imagine a time when air compressors

were nonexistent in factories or workshops. The fact is, in the context of machine-age history,

air compressors are a relatively recent innovation.

The most significant benefit of the standard workshop air compressor is its compact and

relatively lightweight dimensions, which stand in contrast to centralized sources of power that

generally utilize large motors. Additionally, air compressors last longer, require less

maintenance, are easier to move from worksite to worksite and are far less noisy than old-

fashioned machinery.

Piston Air Compressor Functionality

So, How Do Air Compressors Work?

Air compression is essentially a twofold process in which the pressure of air rises while the

volume drops. In most cases, compression is accomplished with reciprocating piston

technology, which makes up the vast majority of compressors on the market.

Every compressor with a reciprocating piston has the following parts:

crankshaft cylinder piston

connecting rod valve head

Air compressors, for the most part, are powered by either gas or electric motors — it varies

by model. At one end of the cylinder are the inlet and discharge valves. Shaped like metal

flaps, the two valves appear at opposite sides of the cylinder’s top end. The inlet sucks air in

for the piston to compress. The compressed air is then released through the discharge valve.

In certain air compressor models, the pressure is produced with rotating impellers. However,

the models that are typically used by mechanics, construction workers and crafts people tend

to run on positive displacement, in which air is compressed within compartments that reduce

its space. Even though some of the smallest air compressors consist of merely a motor and

pump, the vast majority have air tanks. The purpose of the air tank is to store amounts of air

within specified ranges of pressure until it’s needed to perform work. In turn, the compressed

air is used to power the pneumatic tools connected to the unit supply lines. While all of this is

going on, the motor repeatedly starts and stops to keep the pressure at a desired

consistency.

What the piston effectively does with its back and forth movements is create a vacuum. As

the piston retracts, the space in front gets filled with air, which is sucked through the inlets

from the outside. When the piston extends, that same air is compressed and therefore given

the strength to push through the discharge valve — simultaneously holding the inlet shut —

and into the tank. As more air is sent into the tank, the pressure gains intensity.

Air Compressor Power Ratings : CFM

The amount of power being used by an active air compressor can be measured in terms of

horsepower. Still, other things need to be taken into consideration in order to determine how

much pressure a given machine can offer. The rate and volume by which a machine can offer

compression is measured in cubic feet per minute (cfm). However, the rate at which outside

air moves into the cylinder is impacted by the heat, humidity and wind of the surrounding

environment. Therefore, the atmosphere itself will play a part in the cfm of a given machine.

As a way of taking internal and external factors into consideration, manufacturers use

standard cubic feet per minute (scfm) to determine cfm in combination with outside pressure

and humidity. Another type of rating is known as displacement cfm, which determines the

efficiency of the compressor pump. This rating is drawn from a combination of motor rpm and

cylinder displacement.

In order to determine which kind of tools an air compressor will be able to support, it’s crucial

to look at a given machine’s cfm and psi ratings.

Pumps vs. Compressors: Two Instruments for Harnessing Air

A certain degree of confusion exists between the words “pump” and “compressor,” which are

often perceived as being synonymous with one another. Technically, there are crucial

distinctions between the two, the main differences being:

A pump takes liquids or gases and moves them between places.

A compressor takes a gas, squeezes the volume of that gas and then sends it

elsewhere.

Basically, a pump will work with any fluid, whether liquid or gas, whereas a compressor can

only do its function with gas because liquids are a lot harder to compress. In some cases, the

portion of a reciprocating air compressor that performs the compression function is called a

pump. However, pump and compressor functions overlap on pumps that have pressure

gauges that rise with each revolution. One example of this dual function is a tire pump, which

basically does both functions — moving air and creating a tighter air compartment — while

filling a tire with air. Still, since the purpose of a foot pump is to move outside air into an air-

tight space, the tool is not technically considered a compressor. After all, the purpose behind

a compressor is to put compressed air to use, such as when pneumatic tools are powered.

Section view of Mini air compressor :

Viair 40040 400C Air Compressor

This unit is in the mid price range but includes a lot of high-end

materials to complete the package. Features include a 150 PSI MAX, a 2.54

CFM free flow at 0 PSI, an oil-less design, and easy mounting. The system is

not intended for beginners and is designed to be mounted on the vehicle for

use in an on-board air system or air suspension system, with the ability to also

power air horns. Despite some loss of versatility in overall use, this is still a

very durable air compressor. It includes permanent magnetic motors, brush

DC, and mounting hardware with vibration isolators. The wiring is freeze

resistant and accessories also include a remote mount air filter assembly, air

line for remote mounting air filter, and heavy duty terminals. The entire system

is loaded with features from top to bottom so you will definitely get your

money’s worth.

Despite all these added features, it clocks in well under 10 pounds, which is a

testament to its portability. This isn’t your normal air compressor and relies on

an on-board air system to be used. This is more for an intermediate to advanced

user, even with the manual included. Its uses are also limited as is its

functionality. For the brave beginner, there are numerous help documents and

videos online, and to be honest, after using it a couple of times, it’s no different

than a regular run-of-the-mill air compressor. There’s a 1-year limited warranty

attached, but the high quality parts most likely won’t need to be replaced

anytime soon. This is an awesome option for those that have the means to use it.

Вам также может понравиться

- U3 Reciprocating Air Compressor: TitleДокумент14 страницU3 Reciprocating Air Compressor: TitleShahir Afif Islam0% (1)

- How It Works Air CompressorДокумент5 страницHow It Works Air CompressorJohn Mathew TanОценок пока нет

- Years Ago, It Was Common For ShopsДокумент6 страницYears Ago, It Was Common For Shopskumar avnijОценок пока нет

- Livelo Adrian - ME Lab 2 - Activity#3Документ11 страницLivelo Adrian - ME Lab 2 - Activity#3Adrian LiveloОценок пока нет

- Air Compressor Script AUX MACHДокумент5 страницAir Compressor Script AUX MACHRalph Jay M. TaladroОценок пока нет

- How Air Compressor WorksДокумент3 страницыHow Air Compressor WorksPinak ParkhiОценок пока нет

- Test of An Air Compressor ME LAB 2Документ27 страницTest of An Air Compressor ME LAB 2nibin venugopal0% (1)

- Study of Air CompressorДокумент8 страницStudy of Air Compressorali0% (1)

- Three Axis Pnumatic Modern TrailДокумент7 страницThree Axis Pnumatic Modern Trailsuraj dhulannavarОценок пока нет

- Pneumatic JackДокумент5 страницPneumatic JackSandeep ChauahnОценок пока нет

- Compressed Air Energy Efficiency PDFДокумент95 страницCompressed Air Energy Efficiency PDFYASSERHENDY80100% (2)

- Introduction To CompressorsДокумент30 страницIntroduction To CompressorsSriram SuryaОценок пока нет

- Centrifugal Air Compressor BasicsДокумент7 страницCentrifugal Air Compressor BasicsCésarОценок пока нет

- Marine Gas Turbine PDFДокумент14 страницMarine Gas Turbine PDFSaint JoaquinОценок пока нет

- Fabrication of Pneumatic Paper Cup MakinДокумент28 страницFabrication of Pneumatic Paper Cup MakinPatel NikhilОценок пока нет

- Compressed Air PlantДокумент24 страницыCompressed Air Plantliezaebot100% (4)

- The Basics of Air Compressor On A ShipДокумент4 страницыThe Basics of Air Compressor On A ShipBhuvan JhaОценок пока нет

- Amte 130Документ30 страницAmte 130Jan Patrick VelosoОценок пока нет

- Your Essential Guide To Rotary Screw CompressorsДокумент5 страницYour Essential Guide To Rotary Screw CompressorstechbiomedОценок пока нет

- Research Paper On Scroll CompressorДокумент5 страницResearch Paper On Scroll Compressorgatewivojez3100% (1)

- CompressorДокумент10 страницCompressorVina SulistyaОценок пока нет

- ME Lab 2 Module No. 3 PDFДокумент36 страницME Lab 2 Module No. 3 PDFIsmaeli KielОценок пока нет

- ME Laboratory 2: Test of An Air CompressorДокумент12 страницME Laboratory 2: Test of An Air CompressorRenzo M. JognoОценок пока нет

- 10.pneumatic Lifting TableДокумент58 страниц10.pneumatic Lifting TableWORLD360Оценок пока нет

- Aircraft Gas Turbine EngineДокумент11 страницAircraft Gas Turbine Engineখালিদহাসান100% (1)

- Centrifugal Compressors RecentДокумент34 страницыCentrifugal Compressors RecentMOAB FIFA mobileОценок пока нет

- Chapter V - PneumaticsДокумент20 страницChapter V - PneumaticsMc Kevin Jade MadambaОценок пока нет

- Chapter No 3 Air CompressorsДокумент59 страницChapter No 3 Air CompressorsAchmad Denny DarmawanОценок пока нет

- Компрессор 2Документ7 страницКомпрессор 2momoyomotaОценок пока нет

- Air Compressors: Chapter No: 3Документ59 страницAir Compressors: Chapter No: 3Eric CookОценок пока нет

- I. Identify System Around That Consist Compressor in The SystemДокумент2 страницыI. Identify System Around That Consist Compressor in The Systemzul hilmiОценок пока нет

- 4d GP One (Inlet&Comp)Документ16 страниц4d GP One (Inlet&Comp)BookMaggotОценок пока нет

- Compressors and Compressed Air SystemsДокумент24 страницыCompressors and Compressed Air SystemsjimmyshaОценок пока нет

- Compressed Air SystemДокумент29 страницCompressed Air SystemPrathmesh GujaratiОценок пока нет

- Case Study Compressed AirДокумент8 страницCase Study Compressed AirDinia Saleh100% (1)

- Thermodynamics-2 ECP Work SampleДокумент5 страницThermodynamics-2 ECP Work SampleMuhammad IbrahimОценок пока нет

- Compressors and Compressed Air SystemsДокумент24 страницыCompressors and Compressed Air SystemsVinay PanditОценок пока нет

- Centrifugal CompressorДокумент19 страницCentrifugal CompressorMOAB FIFA mobileОценок пока нет

- A Mini-Project Report Course Code: 17AE4DCAP-I: "Model of Air-Compressor Using A Syringe"Документ9 страницA Mini-Project Report Course Code: 17AE4DCAP-I: "Model of Air-Compressor Using A Syringe"Shreya Giri0% (1)

- Fluid Machineries SW - 4Документ9 страницFluid Machineries SW - 4Napoleon Russell QueОценок пока нет

- Compressor NotesДокумент4 страницыCompressor NotesMuhammad Shahir100% (1)

- Compressor and Classification of Compressor Operation Industrial UsesДокумент3 страницыCompressor and Classification of Compressor Operation Industrial UsesMark StrifeОценок пока нет

- Compressor and Classification of Compressor Operation Industrial UsesДокумент4 страницыCompressor and Classification of Compressor Operation Industrial UsesMark StrifeОценок пока нет

- Compressed Air Supply: Training NotesДокумент22 страницыCompressed Air Supply: Training NotesardianalimОценок пока нет

- Air Compressor TermsДокумент9 страницAir Compressor TermsUniversal CollabОценок пока нет

- MEEC 301 PPT WEEK 13 Perform Maintenance and Repair, Such As DismantlingДокумент29 страницMEEC 301 PPT WEEK 13 Perform Maintenance and Repair, Such As DismantlingMariel PernitoОценок пока нет

- Pedal Operated Water Pumping SystemДокумент33 страницыPedal Operated Water Pumping Systemchristin9193% (15)

- Gte Components LastДокумент41 страницаGte Components LastTw Carlo BeltranОценок пока нет

- Compressors: Operating Principle of CompressorДокумент12 страницCompressors: Operating Principle of CompressorNikka Briones DomingoОценок пока нет

- Pneumatic JackДокумент35 страницPneumatic JackVignesh viki100% (1)

- Turbine Construction (D ENG 18 0047 AE)Документ7 страницTurbine Construction (D ENG 18 0047 AE)Nidushan NethsaraОценок пока нет

- Air CompressorsДокумент59 страницAir Compressorsommech2020Оценок пока нет

- Gas Turbine Parts: Fast Basic Guide About Components: What Is A Gas Turbine? Where Is It Used?Документ6 страницGas Turbine Parts: Fast Basic Guide About Components: What Is A Gas Turbine? Where Is It Used?Lion Tiger100% (1)

- Compressed AirДокумент14 страницCompressed Airkstan112233100% (2)

- Oral and Practical Review: Reflections on the Part 147 CourseОт EverandOral and Practical Review: Reflections on the Part 147 CourseОценок пока нет

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideОт EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideРейтинг: 4 из 5 звезд4/5 (8)

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesОт EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesРейтинг: 5 из 5 звезд5/5 (1)

- Lecture 19 Code Standards and ReviewДокумент27 страницLecture 19 Code Standards and ReviewAdhil Ashik vОценок пока нет

- Formato MultimodalДокумент1 страницаFormato MultimodalcelsoОценок пока нет

- Kootenay Lake Pennywise April 26, 2016Документ48 страницKootenay Lake Pennywise April 26, 2016Pennywise PublishingОценок пока нет

- Rapp 2011 TEREOS GBДокумент58 страницRapp 2011 TEREOS GBNeda PazaninОценок пока нет

- (Problem Books in Mathematics) Antonio Caminha Muniz Neto - An Excursion Through Elementary Mathematics, Volume III - Discrete Mathematics and Polynomial Algebra (2018, Springer)Документ647 страниц(Problem Books in Mathematics) Antonio Caminha Muniz Neto - An Excursion Through Elementary Mathematics, Volume III - Discrete Mathematics and Polynomial Algebra (2018, Springer)Anonymous iH6noeaX7100% (2)

- Glossary of Blasting TermsДокумент13 страницGlossary of Blasting TermsNitesh JainОценок пока нет

- Ppap - 2556 PDFДокумент7 страницPpap - 2556 PDFMohamed ElmakkyОценок пока нет

- ABBindustrialdrives Modules en RevBДокумент2 страницыABBindustrialdrives Modules en RevBMaitry ShahОценок пока нет

- SL Generator Ultrasunete RincoДокумент2 страницыSL Generator Ultrasunete RincoDariaОценок пока нет

- OBOE GougerДокумент2 страницыOBOE GougerCarlos GaldámezОценок пока нет

- Caroline Coady: EducationДокумент3 страницыCaroline Coady: Educationapi-491896852Оценок пока нет

- JMC MSDS Puraspec 1173 (GB)Документ10 страницJMC MSDS Puraspec 1173 (GB)Benny Samsul B.Оценок пока нет

- Thermodynamics WorksheetДокумент5 страницThermodynamics WorksheetMalcolmJustMalcolmОценок пока нет

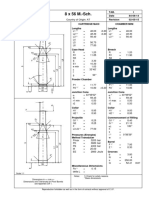

- 8 X 56 M.-SCH.: Country of Origin: ATДокумент1 страница8 X 56 M.-SCH.: Country of Origin: ATMohammed SirelkhatimОценок пока нет

- 1Документ2 страницы1TrầnLanОценок пока нет

- Investment Analysis and Portfolio Management: Frank K. Reilly & Keith C. BrownДокумент113 страницInvestment Analysis and Portfolio Management: Frank K. Reilly & Keith C. BrownWhy you want to knowОценок пока нет

- Chronic Renal FailureДокумент54 страницыChronic Renal FailureAkia Cayasan BayaОценок пока нет

- 5 Ways To Foster A Global Mindset in Your CompanyДокумент5 страниц5 Ways To Foster A Global Mindset in Your CompanyGurmeet Singh KapoorОценок пока нет

- Fashion DatasetДокумент2 644 страницыFashion DatasetBhawesh DeepakОценок пока нет

- Chemical & Ionic Equilibrium Question PaperДокумент7 страницChemical & Ionic Equilibrium Question PapermisostudyОценок пока нет

- Department of Education: Raiseplus Weekly Plan For Blended LearningДокумент3 страницыDepartment of Education: Raiseplus Weekly Plan For Blended LearningMARILYN CONSIGNAОценок пока нет

- Final SEC Judgment As To Defendant Michael Brauser 3.6.20Документ14 страницFinal SEC Judgment As To Defendant Michael Brauser 3.6.20Teri BuhlОценок пока нет

- UAP Grading Policy Numeric Grade Letter Grade Grade PointДокумент2 страницыUAP Grading Policy Numeric Grade Letter Grade Grade Pointshahnewaz.eeeОценок пока нет

- OB and Attendance PolicyДокумент2 страницыOB and Attendance PolicyAshna MeiОценок пока нет

- Chapter 13 Current Liabilities Test Bank Versi 2Документ72 страницыChapter 13 Current Liabilities Test Bank Versi 2Slamet Tri PrastyoОценок пока нет

- Session 10. Value Proposition.Документ69 страницSession 10. Value Proposition.Bibhu R. TuladharОценок пока нет

- Quotation - 1Документ4 страницыQuotation - 1haszirul ameerОценок пока нет

- Driver Drowsiness Detection System Using Raspberry PiДокумент7 страницDriver Drowsiness Detection System Using Raspberry PiIJRASETPublicationsОценок пока нет

- Bichelle HarrisonДокумент2 страницыBichelle HarrisonShahbaz KhanОценок пока нет

- PathologyДокумент31 страницаPathologyStudy Usmle100% (1)