Академический Документы

Профессиональный Документы

Культура Документы

Ficha Tecnica Silicona70

Загружено:

leidy0529Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ficha Tecnica Silicona70

Загружено:

leidy0529Авторское право:

Доступные форматы

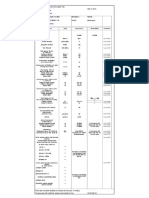

Ge Mao Rubber Industrial Co.

, Ltd

Ge Mao Rubber

LABORATORY Industrial Co., Ltd

REPORT

MATERIAL: SILICONE RUBBER E-07-C

COMPOUND: S7000AB Ge Mao Rubber Industrial Co., Ltd DATE:Jan/02/2014

SPEC.: ASTM D2000 M2GE705 A19 B37 EA14 EO16 EO36 F19

COLOR: RUST

Original Physical Properties Requirements Results

Hardness, (Shore A ) (ASTM D2240-05) 70±5 71

Tensile Strength, psi (MPa) (ASTM D412-06a) 725(min) 979(6.75)

Elongation, (%) (ASTM D412-06a) 150(min) 226

Ge Mao

Modulus at 100%,psi (MPa) (ASTM D412-06a) Rubber Industrial Co., Ltd 650(4.48)

Specific Gravity (g/cm³) 1.32

Ge Mao Rubber Industrial Co., Ltd

A19 Heat Age, 70 Hrs @225℃ (ASTM D573-04)

Hardness Change, pts +10(max) +2

Tensile Strength Change, % -25(max) -6

Elongation Change, % -30(max) -29

Weight Change, % -2.2

B37 Compression Set, 22 Hrs @ 175℃ (ASTM D395-03,Method B) 25%(plied)(max) 22.8

EA14 Water Resistance, 70Hrs@100℃ (ASTM D471-12a)

Hardness Change, pts. ±5 +1

Tensile Strength Change, % -6

Elongation Change, % -21

Volume Change, % ±5 +1.9

EO16 IRM901 Oil, 70 Hrs @ 150℃ (ASTMGe Mao Rubber

D471-12a) Ge Mao

Industrial

Rubber Industrial

Co., Ltd Co., Ltd

Hardness Change, pts. 0~-10 -2

Tensile Strength Change, % -30(max) +3

Elongation Change, % -30(max) -12

Volume Change, % 0~+15 +4.0

Ge

EO36 IRM903 Oil, 70 Hrs @ 150℃ (ASTMGeMao

MaoRubber

RubberIndustrial

D471-12a) IndustrialCo.,

Co.,Ltd

Ltd

Hardness Change, pts. -40(max) -17

Tensile Strength Change, % -17

Elongation Change, % -20

Volume Change, % +60(max) +35.6

F19 Low-Temperature Brittleness Point Test,3 min at-55 ℃ (ASTM D2137-11, Method A)

Sample type: T-50

Coolant : Isopropyl alcohol

Brittleness temperature to nearest 1℃ no crack pass

Ge Mao Rubber Industrial Co., Ltd

APPROVAL Dennis AUDIT Ru-Ling Liu REPORT Reachel

(Lab Manager) (Chemical Engineer) (Laboratory Specialist)

Вам также может понравиться

- Ficha Tecnica FKM 75Документ1 страницаFicha Tecnica FKM 75leidy0529Оценок пока нет

- Toparts Pte LTD: Laboratory ReportДокумент1 страницаToparts Pte LTD: Laboratory ReportkmulyadiОценок пока нет

- Datasheet V7500AA Viton 75 - Toparts - ApprovedДокумент1 страницаDatasheet V7500AA Viton 75 - Toparts - ApprovedBogdan CăpățînăОценок пока нет

- Premlene EPS HES B70 TDSДокумент1 страницаPremlene EPS HES B70 TDSKamran FarooqОценок пока нет

- EPDM - Test by Romac Inc PDFДокумент2 страницыEPDM - Test by Romac Inc PDFRajendra Kumar SharmaОценок пока нет

- XringДокумент2 страницыXringJoão Pedro Marin De GodoiОценок пока нет

- Survey No:33/3A1B, 11th Main Road, Sidco Industrial Estate, Thirumudivakkam, Chennai - 600044Документ4 страницыSurvey No:33/3A1B, 11th Main Road, Sidco Industrial Estate, Thirumudivakkam, Chennai - 600044Tumbin DilseОценок пока нет

- PTFE HZ-2 HoerbigerДокумент2 страницыPTFE HZ-2 HoerbigerТатьяна ВасильеваОценок пока нет

- Astm D4462-90Документ2 страницыAstm D4462-90Priyadarshini KrishnaswamyОценок пока нет

- Viton O Rings CommercialДокумент1 страницаViton O Rings CommercialErhanОценок пока нет

- Marco Material Datasheet B1083 PDFДокумент2 страницыMarco Material Datasheet B1083 PDFAlaa SaadОценок пока нет

- N7047BДокумент1 страницаN7047B蔡JoОценок пока нет

- PTFE HY538 HoerbigerДокумент1 страницаPTFE HY538 HoerbigerТатьяна ВасильеваОценок пока нет

- PTFE HZ-1 HoerbigerДокумент1 страницаPTFE HZ-1 HoerbigerТатьяна ВасильеваОценок пока нет

- Marco Material Datasheet N1000 PDFДокумент2 страницыMarco Material Datasheet N1000 PDFAlaa SaadОценок пока нет

- Request A Quote: O-Ring Compound A80 Data SheetДокумент3 страницыRequest A Quote: O-Ring Compound A80 Data SheetScarlet BlancoОценок пока нет

- Roop Polymers LTD (Unit Iii) : Laboratory Results On SlabsДокумент1 страницаRoop Polymers LTD (Unit Iii) : Laboratory Results On SlabsLALIT SHARMAОценок пока нет

- Ab 139Документ1 страницаAb 139entesharat.tarasht3Оценок пока нет

- 8 Wear Testing - ASTM G65Документ25 страниц8 Wear Testing - ASTM G65yamenОценок пока нет

- Request A Quote: O-Ring Compound HNBR70 Data SheetДокумент2 страницыRequest A Quote: O-Ring Compound HNBR70 Data SheetDadangОценок пока нет

- Physical Properties Elastomeric Bearing MSTДокумент4 страницыPhysical Properties Elastomeric Bearing MSTBudhi KurniawanОценок пока нет

- EPDM 70 Specifications PDFДокумент1 страницаEPDM 70 Specifications PDFfirebolt_hari2006Оценок пока нет

- O Ring Data SheetДокумент3 страницыO Ring Data Sheetandri putrantoОценок пока нет

- PTFE HY79 HoerbigerДокумент1 страницаPTFE HY79 HoerbigerТатьяна ВасильеваОценок пока нет

- PTFE HY54 HoerbigerДокумент1 страницаPTFE HY54 HoerbigerТатьяна ВасильеваОценок пока нет

- Grade: St900 DM311: Polypropylene CompoundДокумент1 страницаGrade: St900 DM311: Polypropylene Compoundhugo santiago chavez godoyОценок пока нет

- Marco Material Datasheet M1002Документ2 страницыMarco Material Datasheet M1002Chang MikeОценок пока нет

- Tasnee 1925ASДокумент1 страницаTasnee 1925ASpolymeianОценок пока нет

- Braskem Braskem PE GP100ORXP Pead GAS PE100Документ2 страницыBraskem Braskem PE GP100ORXP Pead GAS PE100weimar solizОценок пока нет

- Viton Material - Dopont PDFДокумент1 страницаViton Material - Dopont PDFKamlesh DalavadiОценок пока нет

- Marco Material Datasheet V1000Документ2 страницыMarco Material Datasheet V1000FinОценок пока нет

- Poron 4701-30 Very SoftДокумент2 страницыPoron 4701-30 Very SoftItzelMalagonVeraОценок пока нет

- ES8067-TS0231-V575-FKM75 Bisphenol Cured - ApprovedДокумент2 страницыES8067-TS0231-V575-FKM75 Bisphenol Cured - ApprovedBogdan CăpățînăОценок пока нет

- Marco Material Datasheet V1005Документ2 страницыMarco Material Datasheet V1005Bib GmzОценок пока нет

- Ifg 5500Документ1 страницаIfg 5500Amir100% (1)

- Elastron TPE DatasheetДокумент2 страницыElastron TPE DatasheetMateria by Purple AvenueОценок пока нет

- PORON 4701-50 Firm - Supported MaterialsДокумент2 страницыPORON 4701-50 Firm - Supported MaterialsLayeeq AhmedОценок пока нет

- AP101-R3-04 (Rev 02) Miami F1 PMB SpecificationДокумент1 страницаAP101-R3-04 (Rev 02) Miami F1 PMB SpecificationGarrick ChongОценок пока нет

- Versaflex OM1060-1Документ2 страницыVersaflex OM1060-1Javier RuizОценок пока нет

- E300 70 Technical ReportДокумент1 страницаE300 70 Technical ReportDavid Lay IIОценок пока нет

- V75mso Viton CompoundДокумент1 страницаV75mso Viton CompoundRuben HernandezОценок пока нет

- Polygomma EPDM Roofing Membrane CatalogueДокумент4 страницыPolygomma EPDM Roofing Membrane Cataloguepolygomma Industries Pvt. LtdОценок пока нет

- PTFE HY122 HoerbigerДокумент1 страницаPTFE HY122 HoerbigerТатьяна ВасильеваОценок пока нет

- Jna 33Документ1 страницаJna 33jaskaran singhОценок пока нет

- HSN/HNBR O-RingsДокумент2 страницыHSN/HNBR O-RingsPriyadarshini KrishnaswamyОценок пока нет

- Deesa Pipe Gasket Catal - 230310 - 121140Документ10 страницDeesa Pipe Gasket Catal - 230310 - 121140Pietro MachadoОценок пока нет

- Ss fs70Документ4 страницыSs fs70M J VoraОценок пока нет

- PTFE HY29 HoerbigerДокумент1 страницаPTFE HY29 HoerbigerТатьяна ВасильеваОценок пока нет

- Marco Material Datasheet E1097Документ3 страницыMarco Material Datasheet E1097phoenixenggworkОценок пока нет

- Material: Natural Rubber (NR) : Max Spare Code: NR 70Документ1 страницаMaterial: Natural Rubber (NR) : Max Spare Code: NR 70Bagus OktiОценок пока нет

- Soft Natural Rubber Lining: Technical Data SheetДокумент2 страницыSoft Natural Rubber Lining: Technical Data SheetArmanda SiryogiawanОценок пока нет

- A PDFДокумент4 страницыA PDFVerenice CentenoОценок пока нет

- HNBR207 TypicalPropsДокумент2 страницыHNBR207 TypicalPropsdinesh panchalОценок пока нет

- PTFE HY22 HoerbigerДокумент1 страницаPTFE HY22 HoerbigerТатьяна ВасильеваОценок пока нет

- PORON 4790-92-25041 P Extra SoftSlow ReboundSupportedДокумент2 страницыPORON 4790-92-25041 P Extra SoftSlow ReboundSupportedkarpagsОценок пока нет

- Tasnee LD 4025as Polyethylene: DescriptionДокумент2 страницыTasnee LD 4025as Polyethylene: Descriptiontrần hải namОценок пока нет

- Chapter 3 Miscellaneous Items: Quality Control Manual On Concrete and Steel Bridge StructuresДокумент33 страницыChapter 3 Miscellaneous Items: Quality Control Manual On Concrete and Steel Bridge StructuresMae Ann GonzalesОценок пока нет

- RTV Silicone Selector Guide EuropeДокумент32 страницыRTV Silicone Selector Guide EuropeReginaldoОценок пока нет

- Catálogo de Obturadores SAMMIДокумент28 страницCatálogo de Obturadores SAMMIunwedeporaiОценок пока нет

- Catalogue Stationclass Surge Arresters enДокумент76 страницCatalogue Stationclass Surge Arresters enkra_amОценок пока нет

- Biotech: VenairДокумент38 страницBiotech: VenairSalvador CorralОценок пока нет

- More or Less Silicone WackerДокумент25 страницMore or Less Silicone WackerAndrea GrajalesОценок пока нет

- What Is Silicone Conformal Coating For PCBДокумент19 страницWhat Is Silicone Conformal Coating For PCBjackОценок пока нет

- HazmatДокумент9 страницHazmategarciachОценок пока нет

- Product Information DOW CORNING 1430Документ2 страницыProduct Information DOW CORNING 1430Валентин СелищевОценок пока нет

- TDS Byk-037 enДокумент2 страницыTDS Byk-037 enwtwilightwОценок пока нет

- Catalog From Homey SealantДокумент16 страницCatalog From Homey SealantKelly WuОценок пока нет

- Oil Grea: Oils / Greases / LubricantsДокумент36 страницOil Grea: Oils / Greases / LubricantsJ. Carlos Alvarez C.Оценок пока нет

- DynatexДокумент2 страницыDynatexFaizal JamalОценок пока нет

- 2023 Ebook Silicone School 1Документ45 страниц2023 Ebook Silicone School 1gpОценок пока нет

- Lubriplate V-61Документ2 страницыLubriplate V-61ellen_girard2318Оценок пока нет

- Chem ThirdДокумент8 страницChem ThirdIpshita RanjanaОценок пока нет

- 20 PlysilДокумент1 страница20 PlysilJuan AdrianzenОценок пока нет

- SILASTIC™ HV 1551-55P Liquid Silicone Rubber: Features & BenefitsДокумент3 страницыSILASTIC™ HV 1551-55P Liquid Silicone Rubber: Features & Benefitsabdulbaset alselwiОценок пока нет

- Ardex WPM 2000EPДокумент12 страницArdex WPM 2000EPHarsa VardhanОценок пока нет

- Operation Manual: Manufacturer and Designer of Marine Aids To Navigation EquipmentДокумент27 страницOperation Manual: Manufacturer and Designer of Marine Aids To Navigation EquipmentBhavin DoshiОценок пока нет

- A Brief Presentation On Shoe-Sole MakingДокумент15 страницA Brief Presentation On Shoe-Sole MakingTahmidОценок пока нет

- X-17 Manual Jofra PDFДокумент124 страницыX-17 Manual Jofra PDFBlanca Y. Ramirez CruzОценок пока нет

- Varflex Varglas240Документ2 страницыVarflex Varglas240gk_rajpal640Оценок пока нет

- Materials For Oxygen ServicesДокумент4 страницыMaterials For Oxygen Services陳0鴻Оценок пока нет

- BT Design-Guide-2014 PDFДокумент15 страницBT Design-Guide-2014 PDFSamik MukherjeeОценок пока нет

- Final Research-Group 5Документ60 страницFinal Research-Group 5Michael John Lloyd LuzadaОценок пока нет

- AMI CatalogueДокумент17 страницAMI Cataloguesam_saqqiОценок пока нет

- Loctite 5699™: Technical Data SheetДокумент3 страницыLoctite 5699™: Technical Data Sheetbarathi thangarajОценок пока нет

- Threebond1212 PDFДокумент3 страницыThreebond1212 PDFDeepak JainОценок пока нет

- Achieving Emolliency and Sensory Effects by Sophisticated Cascading of Volatile Silicone OligomersДокумент5 страницAchieving Emolliency and Sensory Effects by Sophisticated Cascading of Volatile Silicone OligomersCharles OlsenОценок пока нет

- Service Manual: GuideДокумент29 страницService Manual: GuideRSX SОценок пока нет