Академический Документы

Профессиональный Документы

Культура Документы

3.20 Removal of Conveyor Belt With New Belt

Загружено:

vinodsnАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

3.20 Removal of Conveyor Belt With New Belt

Загружено:

vinodsnАвторское право:

Доступные форматы

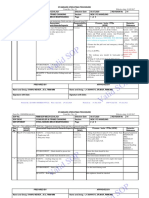

UNITED CEMENTS PVT. LTD. DOC NO.

UCPL-ME-SOP-020

DHUNIBESHI-9,NAUBISE, DHADING, NEPAL ISSUE NO.:01

INTEGRATED MANAGEMENT SYSTEM ISSUE DATE: 1st NOV. 2018

STANDARD OPERATING PROCEDURE REVISION NO: 00

MECHANICAL DEPARTMENT REVISION DATE:

TITLE:REMOVAL OF CONVEYOR BELT WITH PAGE 1 OF 2

NEW BELT

To facilitate Safe working procedure for Replacement of the Conveyor

Purpose

Belt

Scope Applicable in complete plant area

HOD -Head of Department

SI - Section In-charge

Abbreviations

LC - Line Clear (Power Cut-off)

SE/C - Shift Engineer/Coordinator

Respective Area In charge (Mech.) is responsible for operation of this

procedure.

Responsibility

HOD (mechanical) is responsible for providing the safety equipment

required during the designated work.

1.Operation

Lift the take up drum chain block of required capacity is to be

installed.

Lift the take up drum to make sufficient looseness of the

conveyor belt to carry out the splicing work.

Lock the chain block to arrest position of the take up Drum.

Cut the old belt and remove it away from the working area.

Tie up the new belt and roll it to position.

Position both end of the belt and tie up with Clamps.

Remove the toughing idlers to perform the work.

All the persons engaged in the work should use the PPE’s ..

Procedure Remove the damaged portion of the belt by cutting with sharp

knife with safety precaution.

Cutting of belt is done in 3-4 rounds to avoid heavy load on

the knife and its breakage on this account.

The splices holding tool should have proper gripping to avoid

slippage.

The person engaged in pulling the splices should take proper

care to avoid slippage.

After splicing the grinding is to be done to properly so that

jointing should be perfect.

Apply the jointing compound after checking it expiry date .

Hammer the joint and roll the roller to remove the traces of air

between the joint.

PREPARED BY: APPROVED BY:

DATE: DATE:

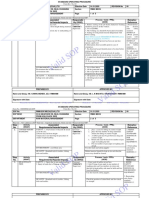

UNITED CEMENTS PVT. LTD. DOC NO. UCPL-ME-SOP-020

DHUNIBESHI-9,NAUBISE, DHADING, NEPAL ISSUE NO.:01

INTEGRATED MANAGEMENT SYSTEM ISSUE DATE: 1st NOV. 2018

STANDARD OPERATING PROCEDURE REVISION NO: 00

MECHANICAL DEPARTMENT REVISION DATE:

TITLE:REMOVAL OF CONVEYOR BELT WITH PAGE 2 OF 2

NEW BELT

Place plate / ply board on joint and place heavy material for

bonding.

After curing time as recommended by the supplier of jointing

compound remove all the clamps,

Release the take up pulley and remove the chain blocks.

Replace the toughing idlers in position and after checking of

the complete circuit clearance for the operation may be given.

2.Data & Record

Maintenance Register.

PREPARED BY: APPROVED BY:

DATE: DATE:

Вам также может понравиться

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshОт EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshОценок пока нет

- 621-CC#09 Idler and Frame ChangingДокумент4 страницы621-CC#09 Idler and Frame ChangingBuddy Hart100% (1)

- Iron Ore Dressing Plant Auditing - LectureДокумент7 страницIron Ore Dressing Plant Auditing - LectureravibelavadiОценок пока нет

- 10 MW TPP Coal TestingДокумент13 страниц10 MW TPP Coal TestingUmesh ShahОценок пока нет

- CC-8 Gear Box Oil Seal Changing SOPДокумент5 страницCC-8 Gear Box Oil Seal Changing SOPBuddy HartОценок пока нет

- FG-Spiral Classifier Operating ManualДокумент5 страницFG-Spiral Classifier Operating ManualRogelio Israel LedesmaОценок пока нет

- Is 9295 - 2002 - Steel Tubes For Idlers For Belt ConveyorsДокумент14 страницIs 9295 - 2002 - Steel Tubes For Idlers For Belt ConveyorsavijayakumarsamyОценок пока нет

- Commissioning Activities - Ball MillДокумент10 страницCommissioning Activities - Ball MillVijay Bhan100% (1)

- TROUBLESHOOTING OF Cement Plant Mechanical and Electrical EquipmentДокумент66 страницTROUBLESHOOTING OF Cement Plant Mechanical and Electrical EquipmentCorrosion FactoryОценок пока нет

- Belt Conveyor Idler LifeДокумент19 страницBelt Conveyor Idler LifehimanshumalОценок пока нет

- Rugged Single-Shaft Hammer Crusher for 2500mm MaterialsДокумент1 страницаRugged Single-Shaft Hammer Crusher for 2500mm MaterialspeymanОценок пока нет

- Ball Mill Liner ReplacementДокумент26 страницBall Mill Liner ReplacementParmeshwar Nath Tripathi100% (1)

- Vertical Roller Mill Repair: Enduring PerformanceДокумент12 страницVertical Roller Mill Repair: Enduring PerformanceSunny KumarОценок пока нет

- Iron Ore Pellet Is at IonДокумент19 страницIron Ore Pellet Is at Ionvivekojha14645100% (1)

- List of Activities To Be Carried Out Before The Kiln Light UpДокумент3 страницыList of Activities To Be Carried Out Before The Kiln Light UpVijay BhanОценок пока нет

- SCR#2 Bucket Bolt Tightening and Changing SOPДокумент4 страницыSCR#2 Bucket Bolt Tightening and Changing SOPBuddy HartОценок пока нет

- Ball Mill MaintainanceДокумент3 страницыBall Mill MaintainanceKritish ShettyОценок пока нет

- Final TSДокумент259 страницFinal TShareesh13hОценок пока нет

- 24 00 RP and BM Operation EДокумент9 страниц24 00 RP and BM Operation EDiego AlejandroОценок пока нет

- 4 MP AdsorptionДокумент54 страницы4 MP AdsorptionAdham ElbrawyОценок пока нет

- Attock Cement MaintenanceДокумент20 страницAttock Cement Maintenancedanialme089Оценок пока нет

- Tracking FDA 0105Документ21 страницаTracking FDA 0105최문섭Оценок пока нет

- SMP For Pinion Shaft Assembly Replacement of Ball MillДокумент2 страницыSMP For Pinion Shaft Assembly Replacement of Ball Millananthu.u100% (1)

- Coal NEW CHECKLIST Coal MillДокумент9 страницCoal NEW CHECKLIST Coal MillanilОценок пока нет

- Condition monitoring of raw mill sectionДокумент2 страницыCondition monitoring of raw mill sectionlaxman JoshiОценок пока нет

- Services For Bulk Material Handling Projects: Project Formulation Phase Project Engineering PhaseДокумент29 страницServices For Bulk Material Handling Projects: Project Formulation Phase Project Engineering PhasesrichmechОценок пока нет

- KILn Tyre FailureДокумент5 страницKILn Tyre FailureTarun AroraОценок пока нет

- Pellet PLNT ManualДокумент19 страницPellet PLNT ManualsubhankarprustyОценок пока нет

- Junior Engineer ResumeДокумент3 страницыJunior Engineer ResumeRam Babu RamzzОценок пока нет

- Report On Mill VibrationДокумент7 страницReport On Mill VibrationDebraj DattaОценок пока нет

- EXX-EME-STD-0008 - Wear Liners For Plate Work and ChutesДокумент22 страницыEXX-EME-STD-0008 - Wear Liners For Plate Work and Chutesjonodo89100% (1)

- Overhaul Procedure for Coal MillДокумент5 страницOverhaul Procedure for Coal MillJenal Tampubolon100% (1)

- Air SeperatorДокумент45 страницAir Seperatorsameh ibrahemОценок пока нет

- Reverse Air Bag House PDFДокумент4 страницыReverse Air Bag House PDFRanga VamshiОценок пока нет

- Check List Rotary Packer: Packing Plant General StatusДокумент3 страницыCheck List Rotary Packer: Packing Plant General StatusTITUS YUSUF100% (1)

- Sop For Ls CrusherДокумент5 страницSop For Ls CrusherVinod Kumar VermaОценок пока нет

- SOP - Maintenance of Bag FilterДокумент22 страницыSOP - Maintenance of Bag FilterAkash SharmaОценок пока нет

- Hot Splicing of Rubber Conveyor Belts With Fabric PliesДокумент28 страницHot Splicing of Rubber Conveyor Belts With Fabric PliessivaОценок пока нет

- Foundations of Safe Bulk-Materials Handling: Section 1Документ73 страницыFoundations of Safe Bulk-Materials Handling: Section 1Nico JeriaОценок пока нет

- 45-Vibrating Screens PDFДокумент8 страниц45-Vibrating Screens PDFpraveenkumaurravutla100% (1)

- Conveyor Idler Standards ExplainedДокумент10 страницConveyor Idler Standards ExplainedObiwan1483100% (1)

- Grinding OKДокумент37 страницGrinding OKMGB EMBEDDED CAPASОценок пока нет

- Cement Kiln ReportДокумент22 страницыCement Kiln Reportamir100% (1)

- GET Wagon Tippler 2015Документ35 страницGET Wagon Tippler 2015Mukul VermaОценок пока нет

- Alumina PFR PDFДокумент309 страницAlumina PFR PDFMudit KediaОценок пока нет

- Iom DSM100-36Документ27 страницIom DSM100-36rogueatdoorОценок пока нет

- Care of Belting Rev 01Документ10 страницCare of Belting Rev 01jonodo89Оценок пока нет

- Managing Mill Maintenance - Roller Mill MaintenanceДокумент7 страницManaging Mill Maintenance - Roller Mill MaintenanceMilling and Grain magazine100% (1)

- Fluid Scr24r PremiumДокумент2 страницыFluid Scr24r Premiumvenka070% (1)

- Rubber Conveyor Belt SpecificationДокумент4 страницыRubber Conveyor Belt SpecificationPrashant MishraОценок пока нет

- Commissioning Guide LinesДокумент53 страницыCommissioning Guide LinesthurawinОценок пока нет

- Bench Marking For Coal PreparationДокумент10 страницBench Marking For Coal PreparationPritam PatnaikОценок пока нет

- Coal Drying Technology and Plant Design PDFДокумент12 страницCoal Drying Technology and Plant Design PDFImron MasfuriОценок пока нет

- RMS Installation Instructions 016-14-607v01Документ7 страницRMS Installation Instructions 016-14-607v01NileshgordeОценок пока нет

- Belt ConveyorДокумент55 страницBelt ConveyorKhalied Noynay100% (1)

- 19- Replacement of Horizontal Gear BoxДокумент7 страниц19- Replacement of Horizontal Gear BoxTanweer KhanОценок пока нет

- HYDRAULIC TONG SAFETY GUIDEДокумент39 страницHYDRAULIC TONG SAFETY GUIDEAlejandro ParradoОценок пока нет

- Bruc 1 081 001Документ6 страницBruc 1 081 001Adel AhmedОценок пока нет

- Lifting Procedure PDFДокумент25 страницLifting Procedure PDFAhmad Husnul MutaqinОценок пока нет

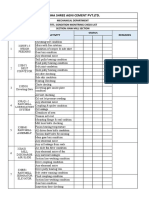

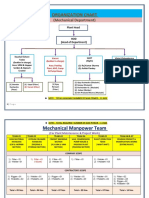

- ORGANIZATION CHARTДокумент3 страницыORGANIZATION CHARTvinodsn100% (1)

- Lime Stone Cleaning Station - Project Proposal-03Документ4 страницыLime Stone Cleaning Station - Project Proposal-03vinodsnОценок пока нет

- Balaji Cement Industries Pvt. Limited: Mechanical Work Progress ReportДокумент2 страницыBalaji Cement Industries Pvt. Limited: Mechanical Work Progress ReportvinodsnОценок пока нет

- Lime Stone Cleaning Station - Project Proposal-03Документ4 страницыLime Stone Cleaning Station - Project Proposal-03vinodsnОценок пока нет

- Transmital of Assly. Drgs. of Equipments of Coal Crusher & Storage Sec. & Coal Mill Sec.Документ2 страницыTransmital of Assly. Drgs. of Equipments of Coal Crusher & Storage Sec. & Coal Mill Sec.vinodsnОценок пока нет

- Offer Letter-Manpower Supply & Project WorkДокумент10 страницOffer Letter-Manpower Supply & Project WorkvinodsnОценок пока нет

- Nov 15 Daily MeetingДокумент2 страницыNov 15 Daily MeetingvinodsnОценок пока нет

- Coal Crushing Sec. Drg. List Fo ErectionДокумент1 страницаCoal Crushing Sec. Drg. List Fo ErectionvinodsnОценок пока нет

- Equip. Name:-RAW MILL Equip. TAG No. 300 RM-1Документ1 страницаEquip. Name:-RAW MILL Equip. TAG No. 300 RM-1vinodsnОценок пока нет

- Balaji Cement Industries Pvt. Limited: Mechanical Work Progress ReportДокумент1 страницаBalaji Cement Industries Pvt. Limited: Mechanical Work Progress ReportvinodsnОценок пока нет

- Pending Job of CPWДокумент2 страницыPending Job of CPWvinodsnОценок пока нет

- Daily Stoppage ReportДокумент2 страницыDaily Stoppage ReportvinodsnОценок пока нет

- Org ChartДокумент1 страницаOrg ChartvinodsnОценок пока нет

- Sop For Ls CrusherДокумент5 страницSop For Ls CrusherVinod Kumar VermaОценок пока нет

- Belt Conveyor Operation & Cleaning SOPДокумент2 страницыBelt Conveyor Operation & Cleaning SOPvinodsn100% (2)

- Operation & Maintenance of Cement Ball MillДокумент7 страницOperation & Maintenance of Cement Ball MillvinodsnОценок пока нет

- HR CircularДокумент4 страницыHR CircularvinodsnОценок пока нет

- Sop For Cleaning & HousekeepingДокумент4 страницыSop For Cleaning & HousekeepingvinodsnОценок пока нет

- Sop For Bag FilterДокумент5 страницSop For Bag FiltervinodsnОценок пока нет

- Sop Welding & Gas CuttingДокумент9 страницSop Welding & Gas CuttingvinodsnОценок пока нет

- Sop For Safe Working at HeightДокумент6 страницSop For Safe Working at HeightvinodsnОценок пока нет

- Costing Details E & I (2074-75)Документ8 страницCosting Details E & I (2074-75)vinodsnОценок пока нет

- HR CircularДокумент2 страницыHR CircularvinodsnОценок пока нет

- Sop Working at High Noise AreaДокумент5 страницSop Working at High Noise AreavinodsnОценок пока нет

- Safe Lifting Guide for Chain Pulley Blocks & SlingsДокумент5 страницSafe Lifting Guide for Chain Pulley Blocks & SlingsvinodsnОценок пока нет

- Sop Ls CrusherДокумент2 страницыSop Ls Crushervinodsn100% (1)

- 1-SOP For Raw Mill StartДокумент2 страницы1-SOP For Raw Mill Startvinodsn100% (2)

- Gist of Man Power in Grinding Unit: United Cements Pvt. Limited Naubise-4, Dhading, NepalДокумент1 страницаGist of Man Power in Grinding Unit: United Cements Pvt. Limited Naubise-4, Dhading, NepalvinodsnОценок пока нет

- Sukh Raj Sigh ResignationДокумент1 страницаSukh Raj Sigh ResignationvinodsnОценок пока нет

- X-RAY CENTER 100x100 Dual ViewДокумент2 страницыX-RAY CENTER 100x100 Dual ViewALEX FERNANDO BELTRAN GUTIERREZОценок пока нет

- Design of Pneumatic Conveying SystemДокумент6 страницDesign of Pneumatic Conveying SystemIJIRSTОценок пока нет

- Lalit Resume-2023-LatestДокумент2 страницыLalit Resume-2023-LatestDrew LadlowОценок пока нет

- Thesis Chapter IiiДокумент6 страницThesis Chapter IiiJohn Rafael AtienzaОценок пока нет

- Guide to Packaging for Small Parcel ShipmentsДокумент14 страницGuide to Packaging for Small Parcel Shipmentsrafael_figueroaОценок пока нет

- Inclined Belt Conveyors For Underground Mass Mining OperationsДокумент6 страницInclined Belt Conveyors For Underground Mass Mining OperationsIsmaelОценок пока нет

- 09-Ash Handling PlantДокумент26 страниц09-Ash Handling PlantKumar Ganesh100% (2)

- A Quick Look at Pneumatic Conveying System BasicsДокумент3 страницыA Quick Look at Pneumatic Conveying System BasicsParmasamy Subramani100% (1)

- 01-06225-226 Manual Mezc ScottДокумент26 страниц01-06225-226 Manual Mezc ScottLaura MalagarrigaОценок пока нет

- Sandvik Brandedtechspecqa450-Lr PDFДокумент2 страницыSandvik Brandedtechspecqa450-Lr PDFjulvОценок пока нет

- VIND - 4 January 2011 - Mynbou: Items AvailableДокумент54 страницыVIND - 4 January 2011 - Mynbou: Items Availablequockhanh152Оценок пока нет

- Work Flow For MSW Biomining (Kes)Документ6 страницWork Flow For MSW Biomining (Kes)girish krishnegowdaОценок пока нет

- Brochure Mechanical Ship Unloaders Portalino Portalink EN 001 PDFДокумент8 страницBrochure Mechanical Ship Unloaders Portalino Portalink EN 001 PDFdony ramdhaniОценок пока нет

- Conveyor system XL chains guideДокумент18 страницConveyor system XL chains guideGirishОценок пока нет

- Imager - Drypix7000 - E08Документ1 324 страницыImager - Drypix7000 - E08Nassima BELIL80% (5)

- SSM Resume NewДокумент3 страницыSSM Resume NewMastram HatheshОценок пока нет

- CIP-300 Conveyor: Car Inspection Portal 300KvДокумент2 страницыCIP-300 Conveyor: Car Inspection Portal 300Kvlinus200Оценок пока нет

- Habachain Engineering Guide: Habasit - Solutions in MotionДокумент74 страницыHabachain Engineering Guide: Habasit - Solutions in Motionphong viОценок пока нет

- Loop Laying HeadДокумент21 страницаLoop Laying HeadHarsha Reddy100% (4)

- DGSM Cir WRT MMRДокумент72 страницыDGSM Cir WRT MMRUttam SharmaОценок пока нет

- DRYPIX 6000 / FM-DL 100 Service Manual Preventive Maintenance (PM) (DRYPIX 6000)Документ24 страницыDRYPIX 6000 / FM-DL 100 Service Manual Preventive Maintenance (PM) (DRYPIX 6000)PaolaGrillo100% (2)

- Chain Conveyor Design Calculation for 400 TPH Drag ConveyorДокумент3 страницыChain Conveyor Design Calculation for 400 TPH Drag Conveyorsudip giriОценок пока нет

- Martin: Drag ConveyorДокумент12 страницMartin: Drag ConveyorMhd. FadelОценок пока нет

- ITC 120N #0516 Check MinutesДокумент24 страницыITC 120N #0516 Check MinutesARMANDO ROJO100% (1)

- Datasheet - Baggage Scanner & Metal Detector For Tournament TentДокумент4 страницыDatasheet - Baggage Scanner & Metal Detector For Tournament Tentmichael esoОценок пока нет

- Risk Assessment Plan TemplateДокумент5 страницRisk Assessment Plan Templatechristine isabel mendozaОценок пока нет

- Icarus Reference Guide V7.3.2Документ966 страницIcarus Reference Guide V7.3.2alan_yaobin8409Оценок пока нет

- Telestack Radial Telescopics Brochure 2017Документ16 страницTelestack Radial Telescopics Brochure 2017Alok MehtaОценок пока нет