Академический Документы

Профессиональный Документы

Культура Документы

Shriram Shikshan Sanstha's Shriram Institute of Engineering & Technology (Polytechnic), Paniv Institute Code: 0994

Загружено:

Ajit KalasaitОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Shriram Shikshan Sanstha's Shriram Institute of Engineering & Technology (Polytechnic), Paniv Institute Code: 0994

Загружено:

Ajit KalasaitАвторское право:

Доступные форматы

Shriram Shikshan Sanstha’s

Shriram Institute of Engineering & Technology (Polytechnic), Paniv

Institute Code: 0994

A Project

Report On

“Human Powered Sugarcane Bud Cutter”

Submitted By,

Name Roll No.

Mr. Patil Jayant Sadanand 3003

Mr. Nikam Santosh Rakhamaji 3011

Mr. Barve Satyawan Vasant 3014

Mr. Koli Sourabh Rajendra 3050

Under The Guidance of

Mr. Shete Y.S.

S.I.E.T. (Poly), Paniv i

Department of Mechanical Engineering

Academic Year – 2018-19

Shriram Shikshan Sanstha’s

Shriram Institute of Engineering & Technology (Polytechnic), Paniv

CERTIFICATE

This is to certify that,

Name Roll No.

Mr. Kilmise Nagesh Vilas 3073

Mr. Tamboli Saddam Rashid 3108

Mr. Jagtap Pancham Uttam 3109

Mr. Jadhav Swapnil Rajendra 3119

Students of Third Year Mechanical Engineering have completed project entitled

“Electricity Generation In Speed Breaker

Mechanism”

In the partial fulfillment of Diploma in Mechanical Engineering of

Maharashtra State Board of Technical Education, Mumbai During

academic year 2018-19

Mr. Shinde R.R. External Examiner

(Project Guide) (MSBTE)

Mr. Lawand S. S. Mr. Khandare P. P.

(HOD Mech. Dept.) (Principal)

S.I.E.T. (Poly), Paniv ii

ACKNOWLEDGEMENT

The satisfaction and euphoria that accompanies the successful completion

of any task would be incomplete without the mention of people who make it possible.

Many are Responsible for the knowledge and experience we have gained our project

and throughout the course. Technical education has few constraints one among them is

project work, taken up in the final year, which an abstract evaluate of person’s

capability in becoming an engineer.

We would like to thank our guide Mr.Shinde R.R. and project coordinator

Mr.Sargar P.J. for his continuous guidance and polite encouragement that was

of prime important during the completion of this project. We would also like to thank

to Mr. Lawand S.S. (H.O.D. Mech.Engg. Dept)for his support.

We would also like to thank to honorable Principal Mr. Khandare P. P. and all

staff members who have been helping us throughout the completion of project.

Name Roll No.

Mr. Kilmise Nagesh Vilas 3073

Mr. Tamboli Saddam Rashid 3108

Mr. Jagtap Pancham Uttam 3109

Mr. Jadhav Swapnil Rajendra 3119

S.I.E.T. (Poly), Paniv 3

Abstract

Agriculture is the backbone of India. The need of agriculture product in India has risen due to

huge popularity, scarcity of labours in agriculture and increasing labour wages. In today’s

world there is a demand for Sugarcane and its byproducts. The major state growing sugarcanes

are Tamil Nadu, Andhra Pradesh, Maharashtra, Uttar Pradesh, now India is the 4th leading producer of

sugarcane in world. In today’s world, the entire requirements are being fulfilled through automatic

system. The demand for reducing the wastage of sugarcane .So the search of easy semiautomatic

method is completed by our project on the topic Design and Fabrication of semiautomatic

Sugarcane Bud Chipping Machine, which is used for producing Sugarcane Bud for the plantation

and growing sugarcane which is helpful to farmer that reduces the initial cost, and increase the yield of

production in sugarcane.. One alternative to reduce the mass and improve the quality of seed cane would

be to plant excised auxiliary buds of cane stalk, popularly known as bud chips. These bud chips

are less bulky, easily transportable and more economical seed material. The bud chip technology holds

great promise in rapid multiplication of new cane varieties.

In today’s world, the entire requirements are being fulfilled through automatic system. The

demand for reducing the wastage of sugarcane .So the search of automatic system is completed by our

project. One alternative to reduce the mass and improve the quality of seed cane would be to

plant excised axillary buds of cane stalk, popularly known as bud chips. These bud chips are less bulky,

easily transportable and more economical seed material. The bud chip technology holds great promise in

rapid multiplication of new cane varieties. The problem of establishment and initial growth could

be addressed by application of appropriate plant growth regulators and essential nutrients.

Sugarcane is a major crop in the field of agriculture in India. As per survey, sugar

output dropped to about 2.2 million tons in fiscal year 2016. As per the ministry of agriculture the

production rate from 2014-2015 to fiscal year 2016 has decreased tremendously. Percentage wise it varies

10-15% of overall production in India. India produces 11 to 12 % of sugarcane in the world. Sugar,

jiggery etc. are the by products made from sugarcane. A part of sugarcane production is used for the

plantation of sugarcane and rest of sugarcane is used for the various purposes. The part of

sugarcane used for plantation of sugarcane is known as ‘bud’ or ‘eye of sugarcane’.

S.I.E.T. (Poly), Paniv 4

INDEX

Sr. No. Title Page No.

1 Abstract

2 Introduction

3 Literarure Survey

4 Key Words, Need &Aim

5 Design And Development

6 Performance Analysis

7 Photographs & Cost Analysis

8 Advantages

9 Disadvantages

10 Conclusions

11 Referanc

S.I.E.T. (Poly), Paniv 5

LIST OF FIGURES

Sr. No. Fig. No. Fig. Name Page No.

1 1.1 Sugar cane, seed cane and seed setts

2 1.2 Fabrication of Sugarcane Bud Cutter

3 1.3 Sugarcane Bud Cutter

4 1.4 Sugarcane Bud Cutter

5 1.5 Sugarcane Bud Cutter

6 1.6 Sugarcane Bud

7 1.7 Sugarcane Cut

8 3.1.1 Setup

9 3.1.2 Rack & Pinion

10 3.1.3 Bud Collecting Box

11 3.1.4 Cutter

12 3.1.5 Welding on Cutter

13 3.2.1 Bud Collecting Box

S.I.E.T. (Poly), Paniv 6

LIST OF TABLES

Sr. No. Tables Page No.

1 Calculation

2 Cost Expenditure

Merits & Limitations

3

S.I.E.T. (Poly), Paniv vii

Вам также может понравиться

- Certificate: Portfolio For Self Dircted Learning For Major Project WorkДокумент22 страницыCertificate: Portfolio For Self Dircted Learning For Major Project WorkRaja ManeОценок пока нет

- "Financial Analysis": Summer Internship Report ONДокумент92 страницы"Financial Analysis": Summer Internship Report ONxorqofqtwhsmr3850Оценок пока нет

- Construction of Resedential BuildingsДокумент38 страницConstruction of Resedential BuildingsSurendra BhaduОценок пока нет

- Project ReportДокумент49 страницProject ReportSanket KhuleОценок пока нет

- Mega Project ReportДокумент40 страницMega Project ReportChaitanyaОценок пока нет

- Group 13Документ43 страницыGroup 13Devendra Pratap SinghОценок пока нет

- Design and Fabrication of Automatic Seed Sowing MachineДокумент31 страницаDesign and Fabrication of Automatic Seed Sowing MachineSakthiVelMОценок пока нет

- Final Intership Report - Shivam PhadatareДокумент51 страницаFinal Intership Report - Shivam PhadatareNishantОценок пока нет

- Certificate & ContaintsДокумент8 страницCertificate & ContaintsmanikantaОценок пока нет

- Industrial TourДокумент25 страницIndustrial TourAmit BairwaОценок пока нет

- Final Year Project (Main) PDFДокумент50 страницFinal Year Project (Main) PDFPradeep JoraОценок пока нет

- Curriculum Vitae: Academic QualificationsДокумент3 страницыCurriculum Vitae: Academic QualificationswongsosoegaliОценок пока нет

- Project Based Learning: Predicting Bitcoin Prices Using Deep LearningДокумент8 страницProject Based Learning: Predicting Bitcoin Prices Using Deep LearningSuraj BahadurОценок пока нет

- Foundryman CTS NSQF-4Документ45 страницFoundryman CTS NSQF-4Bijoy Z KiskuОценок пока нет

- Project Report Ms02Документ26 страницProject Report Ms02Hemant YadavОценок пока нет

- Detailed Estimation of G+1 BuildingДокумент56 страницDetailed Estimation of G+1 BuildingPratik KulkarniОценок пока нет

- Aug 2013Документ164 страницыAug 2013Sreekumar RajendrababuОценок пока нет

- Shriramshikshansanstha'S Shriraminstituteofengineering&Technology (Polytechnic), Paniv Institutecode:0994Документ4 страницыShriramshikshansanstha'S Shriraminstituteofengineering&Technology (Polytechnic), Paniv Institutecode:0994Ajit KalasaitОценок пока нет

- Chennai - 600 025Документ86 страницChennai - 600 025Dr.Maran KaliyamoorthyОценок пока нет

- Design and Optimization of Six-Axis Pick and Place RobotДокумент6 страницDesign and Optimization of Six-Axis Pick and Place RobothsdsdhОценок пока нет

- Project Report On Rope Making Machine From Waste Plastic BottlesДокумент69 страницProject Report On Rope Making Machine From Waste Plastic BottlesPradnesh Mokal67% (3)

- "Bench Voice Part Drawing and Assembly": A Micro-Project Report OnДокумент12 страниц"Bench Voice Part Drawing and Assembly": A Micro-Project Report OnRaviraj PatilОценок пока нет

- A Project Report On: TMT Bar Bending MachineДокумент47 страницA Project Report On: TMT Bar Bending MachinePrajay BhavsarОценок пока нет

- A Study On Flow of Information in Different Department Using SAP R/3 ECC 6.0Документ52 страницыA Study On Flow of Information in Different Department Using SAP R/3 ECC 6.0Shrinivas RathodОценок пока нет

- Ajp 1Документ15 страницAjp 1Yuva Neta Ashish PandeyОценок пока нет

- 360 Degree Rotating Vehicle: Submitted byДокумент39 страниц360 Degree Rotating Vehicle: Submitted byShubham RawatОценок пока нет

- Final Project Report 2.0Документ15 страницFinal Project Report 2.0Akash SiboОценок пока нет

- A Study On Technical Analysis As An Indicator For Investment Decision-MakingДокумент69 страницA Study On Technical Analysis As An Indicator For Investment Decision-MakingSantosh....Оценок пока нет

- New Final Major Project Exam ReportДокумент21 страницаNew Final Major Project Exam ReportAruna ParekhОценок пока нет

- Visvesvaraya Technological University,: "Design and Fabrication of AdjustableДокумент35 страницVisvesvaraya Technological University,: "Design and Fabrication of AdjustableAvinash HadpadОценок пока нет

- "Mobile Operated Multifunctional Agriculture Robot": A Project Stage-I Report OnДокумент19 страниц"Mobile Operated Multifunctional Agriculture Robot": A Project Stage-I Report Onsmartxdigital marketОценок пока нет

- 2020-21-Ce-Planning, Analysis, Design and Estimation of A Residential Building-6Документ46 страниц2020-21-Ce-Planning, Analysis, Design and Estimation of A Residential Building-6venkatesh gidijalaОценок пока нет

- Design and Fabricartion of Hydraulic Bench Vice: Submitted byДокумент7 страницDesign and Fabricartion of Hydraulic Bench Vice: Submitted by2ME302 JEEVANANTHAM SОценок пока нет

- Miniproject ReportДокумент27 страницMiniproject Reportsahith sabbisettiОценок пока нет

- Project 8 SemДокумент22 страницыProject 8 SemAkshesh PrajapatiОценок пока нет

- First ReportДокумент16 страницFirst ReportMCT 30 KAVI MANI LОценок пока нет

- Project ThesisДокумент55 страницProject Thesispratik giradkarОценок пока нет

- CTS WELDER (FABRICATION and FITTING) - NSQF PDFДокумент45 страницCTS WELDER (FABRICATION and FITTING) - NSQF PDFOnur oskay SaatçiОценок пока нет

- Minor Project FormatДокумент11 страницMinor Project FormatRajat MalviyaОценок пока нет

- ATS-Boiler Attendant-NSQF-5Документ44 страницыATS-Boiler Attendant-NSQF-5Pankaj ChopraОценок пока нет

- A Project Report ON: "Commodity Markets" AT CD Equisearch PVT LTDДокумент8 страницA Project Report ON: "Commodity Markets" AT CD Equisearch PVT LTDSaggam RaviОценок пока нет

- Seminar Report by SanjayДокумент26 страницSeminar Report by SanjayBharat PanwarОценок пока нет

- 360degree FlexibleДокумент21 страница360degree Flexiblechiru103mtech71% (7)

- A Project Report On: TMT Bar Bending MachineДокумент46 страницA Project Report On: TMT Bar Bending MachinePrajay BhavsarОценок пока нет

- Chapter-3-Interurban Multilane Highways - Self StudyДокумент41 страницаChapter-3-Interurban Multilane Highways - Self StudykrishanОценок пока нет

- 117700592001Документ91 страница117700592001khushbu GajjarОценок пока нет

- Nigam Mohanty 119Mn0774: Study of Variation of Diesel Particulate Matter in Various Urban Traffic Points in RourkelaДокумент33 страницыNigam Mohanty 119Mn0774: Study of Variation of Diesel Particulate Matter in Various Urban Traffic Points in Rourkelasudhanshu shekher mohantyОценок пока нет

- Sop DocuДокумент7 страницSop DocuChetan RajОценок пока нет

- Design of Semi Automatic Seed Sowing MachineДокумент53 страницыDesign of Semi Automatic Seed Sowing MachineMuralianandh SubramanianОценок пока нет

- Dibyajyoti Suryaprakash PandaДокумент27 страницDibyajyoti Suryaprakash PandaKkpandaОценок пока нет

- SEMINAR REPORT RCC RoadДокумент25 страницSEMINAR REPORT RCC RoadAkshay GhorpadeОценок пока нет

- Saw 4DДокумент33 страницыSaw 4DSai Ganadhi100% (1)

- 360 Drilling MachineДокумент37 страниц360 Drilling MachineVasu Salapu75% (4)

- 2022-23-CE ANALYSIS AND DESIGN OF RESIDENTIAL BUILDING (G+8) BY USING ETABS, SAP2000 AND Staad Pro SOFTWAR-4Документ32 страницы2022-23-CE ANALYSIS AND DESIGN OF RESIDENTIAL BUILDING (G+8) BY USING ETABS, SAP2000 AND Staad Pro SOFTWAR-4Charan MacharlaОценок пока нет

- Proforma Project Work & InstructionsДокумент10 страницProforma Project Work & Instructionssaibalajiyadav4Оценок пока нет

- 2059 Cksvim-Nikita SipДокумент80 страниц2059 Cksvim-Nikita SipJui ChandwadkarОценок пока нет

- Machine Learning in the Oil and Gas Industry: Including Geosciences, Reservoir Engineering, and Production Engineering with PythonОт EverandMachine Learning in the Oil and Gas Industry: Including Geosciences, Reservoir Engineering, and Production Engineering with PythonОценок пока нет

- THE RELATIONSHIP OF TALENT MANAGEMENT AND JOB PERFORMANCE OF LOCAL EMPLOYEES MEDIATED BY ENGAGEMENT AND SATISFACTIONОт EverandTHE RELATIONSHIP OF TALENT MANAGEMENT AND JOB PERFORMANCE OF LOCAL EMPLOYEES MEDIATED BY ENGAGEMENT AND SATISFACTIONОценок пока нет

- Low Cost, Portable Briquetting Machine - Rural Use: Project Reference No.: 39S - Be - 1791Документ39 страницLow Cost, Portable Briquetting Machine - Rural Use: Project Reference No.: 39S - Be - 1791Ajit KalasaitОценок пока нет

- Report Ss of Forced Convective Heat TransferДокумент38 страницReport Ss of Forced Convective Heat TransferAjit KalasaitОценок пока нет

- 01 - Title Page PDFДокумент1 страница01 - Title Page PDFAjit KalasaitОценок пока нет

- Forced ConvectionДокумент11 страницForced Convectionjarek3aОценок пока нет

- Report Ss of Forced Convective Heat TransferДокумент6 страницReport Ss of Forced Convective Heat TransferAjit KalasaitОценок пока нет

- Shriramshikshansanstha'S Shriraminstituteofengineering&Technology (Polytechnic), Paniv Institutecode:0994Документ4 страницыShriramshikshansanstha'S Shriraminstituteofengineering&Technology (Polytechnic), Paniv Institutecode:0994Ajit KalasaitОценок пока нет

- Hydrobiological Study of Gangoti Tank Gangoti, Dist. Satara (M.S), India.Документ9 страницHydrobiological Study of Gangoti Tank Gangoti, Dist. Satara (M.S), India.Ajit KalasaitОценок пока нет

- Impact Jet PDFДокумент98 страницImpact Jet PDFAjit KalasaitОценок пока нет

- Calibration System For Thermocouple Testing: January 2009Документ19 страницCalibration System For Thermocouple Testing: January 2009Ajit KalasaitОценок пока нет

- 3997 11971 1 PBДокумент21 страница3997 11971 1 PBAjit KalasaitОценок пока нет

- Impact of Jet: July 2018Документ3 страницыImpact of Jet: July 2018Ajit KalasaitОценок пока нет

- Repo ErtДокумент36 страницRepo ErtAjit KalasaitОценок пока нет

- Milling MachineДокумент13 страницMilling MachineprashanthОценок пока нет

- Automatic Pneumatic HammerДокумент3 страницыAutomatic Pneumatic HammerIyappan40% (5)

- Design and Fabrication of Automatic Dishwasher Machine: January 2017Документ7 страницDesign and Fabrication of Automatic Dishwasher Machine: January 2017Ajit KalasaitОценок пока нет

- Investigation of Peel Resistance of Adhesives Materials Are ViewДокумент11 страницInvestigation of Peel Resistance of Adhesives Materials Are ViewAjit KalasaitОценок пока нет

- 11Документ6 страниц11Ajit KalasaitОценок пока нет

- 11Документ6 страниц11Ajit KalasaitОценок пока нет

- Design and Development of Pneumatic Punching MachineДокумент5 страницDesign and Development of Pneumatic Punching MachineAjit KalasaitОценок пока нет

- Design of Post Hole Digger Machine IJERTV3IS030320Документ5 страницDesign of Post Hole Digger Machine IJERTV3IS030320Ajit KalasaitОценок пока нет

- Control Valve For Irrigation PurposeДокумент38 страницControl Valve For Irrigation PurposeAjit KalasaitОценок пока нет

- Veg BrandsДокумент4 страницыVeg Brandssauvagya2Оценок пока нет

- Jura Regalia: 1. Regalian DoctrineДокумент10 страницJura Regalia: 1. Regalian DoctrineBryne BoishОценок пока нет

- ParisarStd 4Документ162 страницыParisarStd 4Potdar_AmolОценок пока нет

- Fresh Ready-Mixed Concrete Waste in Construction Projects: A Planning ApproachДокумент8 страницFresh Ready-Mixed Concrete Waste in Construction Projects: A Planning ApproachFuadОценок пока нет

- Descriptive WritingДокумент6 страницDescriptive WritingJingky MarzanPurisima Lumauig SallicopОценок пока нет

- List of Protected Areas of The PhilippinesДокумент26 страницList of Protected Areas of The PhilippinesAly JebranОценок пока нет

- Euclidean ZoningДокумент1 страницаEuclidean Zoningneda1388Оценок пока нет

- Aggie Trends February 2013 IssueДокумент12 страницAggie Trends February 2013 IssueDepartment of Agriculture PublicationОценок пока нет

- Environmental Science WorksheetДокумент1 страницаEnvironmental Science WorksheetFrederickPaigeIIIОценок пока нет

- Polje BonacciДокумент11 страницPolje BonacciToni TursićОценок пока нет

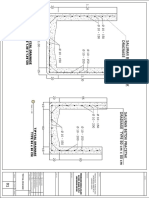

- Typical DrainaseДокумент1 страницаTypical Drainasesugii97Оценок пока нет

- Ravindra Bhan PDFДокумент21 страницаRavindra Bhan PDFMonalisa PandaОценок пока нет

- Eco FriendlyДокумент49 страницEco FriendlyVktoria HalenОценок пока нет

- Agra Law Reviewer IbДокумент7 страницAgra Law Reviewer Ibalex trincheraОценок пока нет

- Nicollet Mall Redesign PresentationДокумент125 страницNicollet Mall Redesign Presentationbpjohnson81Оценок пока нет

- Implements For Intercultural Operations - Hoes, Long Handled Weeders, Cultivators, and Rotary TillersДокумент56 страницImplements For Intercultural Operations - Hoes, Long Handled Weeders, Cultivators, and Rotary Tillerserkiruthiraj33% (3)

- Beach Nourishment Operations in Wales and Likely Future Requirements in An Era of Sea Level Rise and Climate Change 2010-CCW Science Report No 928Документ146 страницBeach Nourishment Operations in Wales and Likely Future Requirements in An Era of Sea Level Rise and Climate Change 2010-CCW Science Report No 928quocthanghueОценок пока нет

- Bonsai Society of Dallas: Message From The PresidentДокумент4 страницыBonsai Society of Dallas: Message From The PresidentAnimeshNandyОценок пока нет

- DENR Guidebook For CRMPДокумент180 страницDENR Guidebook For CRMPRichard BalaisОценок пока нет

- ApprovedvendorList Civil 22082019Документ61 страницаApprovedvendorList Civil 22082019T SenОценок пока нет

- Test MCQ'sДокумент9 страницTest MCQ'sMuhammad KashifОценок пока нет

- Purok 1 Purok 2 Purok 3: Bariw, Malinao, AlbayДокумент1 страницаPurok 1 Purok 2 Purok 3: Bariw, Malinao, Albayiricamae ciervoОценок пока нет

- Comprehensive Water Resources Management in Sri Lanka: P.S.M. MuthukudaДокумент3 страницыComprehensive Water Resources Management in Sri Lanka: P.S.M. MuthukudathisulaОценок пока нет

- 8º Ano InglêsДокумент5 страниц8º Ano InglêsCristianeGonçalves44% (9)

- Forage Seed Production 1Документ16 страницForage Seed Production 1abraha gebruОценок пока нет

- Interpretation Nadeem SirДокумент2 страницыInterpretation Nadeem SirDENZYL D'COUTHOОценок пока нет

- Summative 4.1Документ1 страницаSummative 4.1Shuwb Ne PheshОценок пока нет

- BiodiversityДокумент66 страницBiodiversityRahul ChaudharyОценок пока нет

- Diversity of Soil Fauna and Ecosystem FunctionДокумент14 страницDiversity of Soil Fauna and Ecosystem Functiontariqulmasud12Оценок пока нет