Академический Документы

Профессиональный Документы

Культура Документы

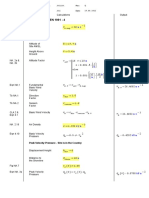

Capital Budgeting 1

Загружено:

Daniel DiaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Capital Budgeting 1

Загружено:

Daniel DiaАвторское право:

Доступные форматы

Customized Systems Nanostructures and Surface Analysis and Surface Science

and Solutions Thin Film Deposition Preparation Components Applications

Components for Surface Analysis

PHOIBOS 150 WAL

Hemispherical Energy Analyzer with Wide Angle Lens

State-of-the-art ARPES with 60° Acceptance Angle

Optimized Lens Geometry for Non-Destructive Depth Profiling

Large Kinetic and Pass Energy Range

High Energy and Angular Resolution

Complete System Concept for Samples up to 12”

PHOIBOS 150 WAL

Analyzer Wide Angle Lens

Hemispherical energy analyzers are used in photoemis- The design of the wide-angle deceleration lens uses an

sion spectroscopy for a wide variety of tasks, e. g. chemi- entrance mesh with high transparency and an optimized

cal analysis (ESCA), electronic structure determination electrode design. The mesh is shaped to produce an im-

(ARUPS), non-destructive depth profiling with angular age of the sample region that is analyzed at the aperture

resolved XPS (ARXPS), structure analysis (XPD), inves- with negligible spherical aberration. The mesh lens col-

tigation of buried interfaces and bulk properties using lects electrons emitted from the sample over a cone of

hard X-ray photoemission spectroscopy (HAXPES), and up to ±30°. The lens can be operated in different modes

in near ambient pressure conditions (NAP-PES). In all of for angular studies and high transmission. All lens modes

these applications, a larger acceptance angle is favora- can be set electronically. The standard working distance

ble for different reasons: of 27.75 mm and the ±40° conical shape of the front

It increases count rate by collecting more electrons, part of the lens provide optimum access to the sample

thereby improving the signal-to-noise ratio, espe- for all kinds of excitation sources. Trajectories within an

cially in notoriously low count rate environments like angular range of ±30° starting from different positions

HAXPES and/or NAP-PES. but with the same angle are focussed on the same loca-

It increases the observable volume in k-space, which tion on the analyzer plane.

is especially important when performing ARUPS at

low photon energies.

It enables angular resolved XPS for non-destructive

depth profiling without rotating the sample, which is

essential for large samples like 12“ Si wafers. Simulated electron trajectories at 300 eV kinetic energy for the

angular resolved mode at 30 eV pass energy and at 0.2 mm sample

spot size.

SPECS has developed a wide angle lens (WAL), which,

due to it’s modular design, can be used from UPS – XPS The PHOIBOS 150 WAL analyzer is a true 180° hemi-

– HAXPES, and from UHV to 25 mbar. Triggered by the spherical energy analyzer with 150 mm mean radius.

needs of semiconductor technology for non-destructive The analyzer, the lens system, and the detector are sur-

depth profiling, SPECS introduced the PHOIBOS 150 rounded by two layers of 2 mm thick μ-metal to screen

WAL onto the market in 2009 and carried on with its external magnetic fields down to an uncritical level. For

development. In combination with a monochromated ultimate performance, the analyzer and the lens system

small spot X-ray source, the PHOIBOS 150 WAL offers are constructed entirely from nonmagnetic materials in-

the solution for ARPES. side the μ-metal shielding.

Cross section of PHOIBOS 150 WAL showing simulated electron tra-

jectories with an angle span of ±30° and three different energies. The

image on the 2D-CCD detector shows the Ta 4f core level emission of

TaN/TaON for an angluar range of 20° to 80°. The TaN

component is only visible for small take off angles.

TaN sample PVD grown in TIMARIS

by Singulus NDT at IISB

Erlangen.

2 Innovation in Surface Spectroscopy and Microscopy Systems

PHOIBOS 150 WAL

Power Supply HSA 3500 plus Modes of Operation

The HSA 3500 plus is a versatile high voltage power sup- Range Application Min. Step Width Ripple

ply. The modular design of the unit allows independent 0 ... ±3500 V AES and XPS 7 meV 1 mV

setting of all voltages via high-precision 24-bit digital- 0 ... ±1500 V XPS 3 meV 0.5 mV

to-analog converters with an overall maximum settle 0 ... ±400 V UPS 0.8 mV 0.25 mV

time of 3 ms. Each module is equipped with a micro- 0 ... -100 V UPS 0.125 mV 0.25 mV

controller allowing independent setting of all voltages,

including diagnosis and error localization. The complete

electronic package is contained in a single 19” standard Detectors

rack housing with removable cables. The power supply The analyzer with its modular detector concept can be

can be operated in FAT (Fixed Analyzer Transmission) or equipped with different detectors according to the cus-

FRR (Fixed Retarding Ratio) mode. Both pass energy and tomer’s needs. The 2D detector system (CCD or delay-

retarding ratio can be continuously adjusted to fine-tune line detector) uses both the energy and angular resolu-

resolution and intensity. tion for Angle Dependent XPS measurements without

tilting the sample. The CCD system features a 12-bit dig-

With an energy span of ±3500 eV, the power supply of ital CCD camera with high dynamic range. The detector

the PHOIBOS analyzer provides a wider energy range design is especially optimized for the detection of low

than most other instruments and gives access to the kinetic energy electrons. A 3D (one time and two lateral

high kinetic energy lines. For ultra high energy resolution dimensions) delay-line detector system can be installed.

applications the unit can be operated in a 400 V bipolar The design combines high count rates with extremely

range and a 100 V unipolar range with extremely low high temporal resolution in one device.

ripple. Step widths down to 0.125 mV are possible.

HSA 3500 plus power supply for the PHOIBOS analyzer. 2D-CCD detector

These ranges guarantee extraordinary stability and low-

noise, allowing ultra high resolution measurements. The

power supply provides the fast and reliable CAN Bus

interface and an internal microprocessor for fast and re-

liable processing and remote control. The temperature

stability of the analyzer voltage modules are better than

1.5 ppm of the voltage span per °C.

3D-DLD detector

Innovation in Surface Spectroscopy and Microscopy Systems 3

PHOIBOS 150 WAL

Performance Results

The angular acceptance and angular resolution of a

hemispherical analyzer is usually tested during setup,

where a slit array between the sample and the lens en-

trance is used to create a regular angular emission pat-

tern. The slits of the array are oriented perpendicular to

the entrance slit of the analyzer and create a line pattern

on the detector. The width of the lines includes the con-

tribution from the finite slit width and the finite width

of the spot size amongst the angular resolution of the

analyzer. Therefore, small spot excitation sources like a

focussed electron source are used in such test measure-

ments.

The PHOIBOS 150 WAL allows angular dependent meas-

urements in two different modes: snapshot mode and

sweep mode. In snapshot mode all voltages are kept

fixed and the width of the energy window on the detec-

tor is determined by the pass energy. In sweep mode the

analyzer is swept over kinetic energy with a step width

smaller than the energy window on the detector. In this XPS spectra taken from polycrystalline Ag using a micro-FOCUS 500

monochromatic X-ray source. X-ray power is 47 W and spot size on

mode the data can be taken either with full resolution the sample is about 200 μm.

of the camera, or with a predefined number of angular

channels.

Angular resolved sweep from 150 eV to 1500 eV kinetic energy with

30 eV pass energy. Angular acceptance is 60° and number of angular

channels is 120. Distance between two lines is 5°.

The PHOIBOS 150 WAL is able to operate in a range of

retarding ratio R = Ekin/Epass of at least 4 < R < 50 with

the full angle acceptance range of ±30 degrees. A large

available range in retarding ratio is of particular impor-

tance when using an X-ray source with fixed excitation

energy, i.e. Al Kα.

Snapshot taken at 1500 eV with 30 eV

pass energy. Energy window width

is 2.5 eV. The measured FWHM

of the lines is 0.49°.

Correcting the measured line

width against the contribution Angle integrated UPS spectra taken from polycrystalline Ag using

of the slit aperture (0.4°) the a non-focussed UVS 10/35 gas-discharge lamp. Spectra are excited

angular resolution is smaller with He I in a spot of about 1 mm. The work function of the sample is

than 0.3°. determined to 4.3 eV.

4 Innovation in Surface Spectroscopy and Microscopy Systems

PHOIBOS 150 WAL

Small Spot Photon Source

High resolution photoemission measurements demand

not only the highest performance electron spectro-

meter, but also photon sources with high flux den-

sity. Especially for angular resolved measurements the

photon source spot size should be well below 1 mm, be-

cause otherwise the angular resolution is limited by the

spot size broadening.

SPECS offers high performance small spot photon sourc-

es for the UV and X-ray region. In combination with the UVLS + TMM 304 monochromator with ETC

PHOIBOS 150 WAL they offer unsurpassed performance

for wide angle photoemission measurments with high Microfocus X-ray Source and Monochromator

angular resolution. The UV sources can be equipped ei- The micro-FOCUS 500 consists of a X-ray monochroma-

ther directly or via a TMM monochromator with an el- tor with 500 mm Rowland circle diameter and an XRMF

lipsoidal focussing capillary producing a high intensity microfocus X-ray source. The X-ray source provides Al Kα

photon spot with about 500 μm FWHM. radiation in a spot smaller than 200 μm on the sample.

Small Spot UV Sources and Monochromators

The UVS 300 generates a high density plasma by guid-

ing the electrons extracted from a hot cathode filament

along the lines of a strongly inhomogeneous magnetic

field towards a small discharge region (duo-plasmatron

principle). The intense vacuum ultraviolet radiation is

transferred from the cathode side by a capillary.

The UVLS is a filamentless microwave plasma-based UV

light source. The plasma is created directly in the quartz

output capillary leading to excellent coupling of the Micro-FOCUS 500

generated UV to the chamber or monochromator. This

design provides long term plasma stability making the

source suitable for use even with heavier gases like Ar

and Xe.

The design of TMM 302 monochromator consists of a

toroidal mirror in combination with a plane grating

and a plane mirror. This superior design provides high

transmission combined with the advantage of produc-

ing a polarized light source with a degree of polarization

of 90%. The TMM 304 monochromator uses a unique

cassette-based optical design to maximize the photon

flux at specific user-selectable wavelengths.

Innovation in Surface Spectroscopy and Microscopy Systems 5

PHOIBOS 150 WAL

12” In-situ ARXPS Depth Profiling System

The PHOIBOS 150 WAL and the micro-FOCUS 500

can be integrated in compact analysis systems

for ADXPS. One application of ADXPS is the

non-destructive depth profiling of layered

materials. The image below shows such a

system, which is connected to a 12” wafer

handler.

Software SpecsLab2

SpecsLab2 is the user friendly data acquisition software Data analysis starts with the decomposition of the spec-

package which accompanies the PHOIBOS analyzer se- tral data in chemical components using standard peak

ries. It enables data acquisition using a wide variety of fitting routines. The peak fitting result for a specific an-

operational modes. Some important features are: gle can easily be propagated to other angles.

Angle integrated or angular resolved measurements

Lateral resolved measurements The expected angle profile of the photoemission inten-

2D-measurements in sweep or snapshot mode sities is simulated within the sample simulator module.

Batch processing of spectra Extensive databases for the physical properties of ele-

Ion source remote control for automated depth ments and compounds are already included. Photoemis-

profiling sion anisotropy and elastic scattering are taken into ac-

Manipulator and monochromator remote control count.

Remote control of the software via TCP/IP interface

During reconstruction the expected concentration profile

SpecsProfiler is varied under the control of a global optimization al-

The SpecsProfiler software is designed to extract the gorithm (Simulated Annealing or Genetic Optimization).

depth profile information from angular resolved data. The extraction process can be stabilized by different

The expected angular profile is simulated and compared regularization techniques such as Maximum Entropy or

to the measured profile. The depth profile is reconstruct- Tikhonov-Phillips regularization. SpecsProfiler has prov-

ed using global optimization routines. en this leading technique in an interlaboratory study of

the Versailles Project on Advanced Materials and Stand-

ards (VAMAS).

6 Innovation in Surface Spectroscopy and Microscopy Systems

PHOIBOS 150 WAL

Step 1: Peak fitting of core level spectra.

Step 2: Sample simulator module.

Step 3: Resulting angle and depth profile.

Data courtesy of ANNA (European Integrated Activity of Excellence an Networking for Nano and Micros-Electronics Analysis).

Innovation in Surface Spectroscopy and Microscopy Systems 7

PHOIBOS 150 WAL

Technical Data

PHOIBOS 150 WAL Power Supply HSA 3500 plus

Acceptance Angle 60° Voltage Ranges 100 V, 400 V, 1500 V, 3500 V

(Angular Resolved Mode)

DAC Resolution 24 bit

Angular Resolution < 0.5° (200 µm spot size)

Voltage Setting Accurancy 20 bit

Maximum Tilt Angle 50°

Voltage Ripple and Noise < 250 µV @ 400 V

Kinetic Energy Range 5 - 3500 eV

Warmup Time 30 min

Pass Energy Range 1 - 200 eV

Weight Approx. 15 kg

Energy Resolution

XPS mode <520 meV @ 60 kcps Size 45 cm (W) x 32 cm (H) x 50 cm (D)

(Ag 3d5/2,

Al Kα 47 W, 200 µm spot)

UPS mode <107 meV @ 10 kcps

(Ag Fermi Edge,

He I, 1 mm spot)

Ultimate <2.5 meV

Working Distance 27.75 mm

Entrance Slits 8

Maximum Bakeout Temperature 180 °C

Mounting Flange DN 150 CF

Shielding Double µ-metal

Weight ca. 100 kg

Technical alterations reserved. The information in this document is provided with greatest Other product and company names mentioned herein are trademarks or trade names of their

care but SPECS does not assume any liability arising from the application or use of the respective companies.

information or product described here. SPECS is a registered trademarks of SPECS GmbH. Printed in July 2010

SPECS Surface Nano Analysis GmbH

Your Local Representative:

Voltastrasse 5

13355 Berlin

Germany

Tel. +49 30 46 78 24-0

Fax +49 30 46 42 08-3

Email support@specs.com

Web www.specs.com ISO 9001 Certificate

Innovation in Surface Spectroscopy and Microscopy Systems

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- David Stewart - H. Gene Blocker - James Petrik - Fundamentals of Philosophy-Pearson (2012)Документ542 страницыDavid Stewart - H. Gene Blocker - James Petrik - Fundamentals of Philosophy-Pearson (2012)angela dizonОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- E6-165-13 - ASME STRESS CLASSIFICATION in Pressure Vessels and PipingДокумент20 страницE6-165-13 - ASME STRESS CLASSIFICATION in Pressure Vessels and PipingLuis Ortiz100% (3)

- Assing 4Документ2 страницыAssing 4KazaValiShaikОценок пока нет

- Design Precast Boundary WallДокумент70 страницDesign Precast Boundary WallGajendra Bisht100% (2)

- Country Disaster Expenditures NotesssДокумент7 страницCountry Disaster Expenditures NotesssDaniel DiaОценок пока нет

- Ako Ay PinoyДокумент4 страницыAko Ay PinoyDaniel DiaОценок пока нет

- What Is LeadershipДокумент3 страницыWhat Is LeadershipDaniel DiaОценок пока нет

- "Abakada Ina": by Eddie GarciaДокумент2 страницы"Abakada Ina": by Eddie GarciaDaniel DiaОценок пока нет

- Disaster Risk Building ResilienceДокумент39 страницDisaster Risk Building ResilienceAlexandra PassuelloОценок пока нет

- Country Disaster Expenditures Note PDFДокумент12 страницCountry Disaster Expenditures Note PDFDaniel DiaОценок пока нет

- TreeplantingДокумент8 страницTreeplantingDaniel DiaОценок пока нет

- Title PageДокумент1 страницаTitle PageDaniel DiaОценок пока нет

- Monetary Policy Is Generally The Process by Which The Central BankДокумент1 страницаMonetary Policy Is Generally The Process by Which The Central BankDaniel DiaОценок пока нет

- The Effectiveness of Pre-Disaster Planning and Post-Disaster AidДокумент29 страницThe Effectiveness of Pre-Disaster Planning and Post-Disaster AidDaniel DiaОценок пока нет

- Matrices NotesДокумент13 страницMatrices Notesps3266_753186479Оценок пока нет

- Matrices NotesДокумент13 страницMatrices Notesps3266_753186479Оценок пока нет

- Country Disaster Expenditures Note PDFДокумент12 страницCountry Disaster Expenditures Note PDFDaniel DiaОценок пока нет

- TreeplantingДокумент8 страницTreeplantingDaniel DiaОценок пока нет

- Preface: Dalubhasaan NG Lunsod NG San Pablo National Training Service ProgramДокумент37 страницPreface: Dalubhasaan NG Lunsod NG San Pablo National Training Service ProgramDaniel DiaОценок пока нет

- QUESTIONSДокумент1 страницаQUESTIONSDaniel DiaОценок пока нет

- Quiz Entrep 3 Opportunity SeekingДокумент1 страницаQuiz Entrep 3 Opportunity SeekingDaniel DiaОценок пока нет

- Group 8 QuizДокумент1 страницаGroup 8 QuizDaniel DiaОценок пока нет

- Norielyn Resume W PicДокумент2 страницыNorielyn Resume W PicDaniel DiaОценок пока нет

- English 4 AДокумент4 страницыEnglish 4 ADaniel DiaОценок пока нет

- DLC Day Proposal LetterДокумент1 страницаDLC Day Proposal LetterDaniel DiaОценок пока нет

- Norielyn Resume W PicДокумент2 страницыNorielyn Resume W PicDaniel DiaОценок пока нет

- For Sir OrillazaДокумент3 страницыFor Sir OrillazaDaniel DiaОценок пока нет

- Automated Scheduling SystemДокумент2 страницыAutomated Scheduling SystemDaniel DiaОценок пока нет

- Action PlanДокумент2 страницыAction PlanDaniel DiaОценок пока нет

- Answer Sheet To Quiz Entrep 3 Opportunity SeekingДокумент1 страницаAnswer Sheet To Quiz Entrep 3 Opportunity SeekingDaniel DiaОценок пока нет

- Family PlanningДокумент1 страницаFamily PlanningDaniel DiaОценок пока нет

- Dlc-Day Excuse LetterДокумент2 страницыDlc-Day Excuse LetterDaniel DiaОценок пока нет

- DLC Day InvitationДокумент2 страницыDLC Day InvitationDaniel DiaОценок пока нет

- Answer Sheet For Quiz GE 108 EthicsДокумент1 страницаAnswer Sheet For Quiz GE 108 EthicsDaniel DiaОценок пока нет

- Chapter 4 ThermochemistryДокумент6 страницChapter 4 ThermochemistryMadihah RamlyОценок пока нет

- CF 23Документ25 страницCF 23赵子杰Оценок пока нет

- Chemical Engineering ThermodynamicsДокумент35 страницChemical Engineering ThermodynamicsErik WeeksОценок пока нет

- More Accurate Localized Wire Rope Testing Based On Hall Sensor ArrayДокумент2 страницыMore Accurate Localized Wire Rope Testing Based On Hall Sensor ArrayNesanОценок пока нет

- How Do I Compute Li and Drag?: Comsol Blog Comsol BlogДокумент10 страницHow Do I Compute Li and Drag?: Comsol Blog Comsol Blogadrian_63Оценок пока нет

- Axially and Eccentrically Loaded ColumnsДокумент13 страницAxially and Eccentrically Loaded ColumnsRefisa JiruОценок пока нет

- Content ServerДокумент21 страницаContent ServerÁngelCarlosGarcíaОценок пока нет

- Module 5 - BEJAR - ScriptДокумент7 страницModule 5 - BEJAR - Scriptrobejr2013Оценок пока нет

- DVPPS01-02 Instruction TseДокумент2 страницыDVPPS01-02 Instruction TseAndrés AracenaОценок пока нет

- Unit h556 01 Modelling Physics Sample Assessment MaterialsДокумент48 страницUnit h556 01 Modelling Physics Sample Assessment MaterialsY4NISMTОценок пока нет

- Shimizu, S. (2020) - Formulating Rationally Via Statistical Thermodynamics. Curr. Opin. Colloid Interface Sci. 48, 53-64Документ12 страницShimizu, S. (2020) - Formulating Rationally Via Statistical Thermodynamics. Curr. Opin. Colloid Interface Sci. 48, 53-64marco_ravelo_10Оценок пока нет

- Grade 9 Science UP 4Документ30 страницGrade 9 Science UP 4MR. BEST100% (1)

- Victrex PEEK 450FE20: Conditions Test Method Units Typical ValueДокумент2 страницыVictrex PEEK 450FE20: Conditions Test Method Units Typical ValueRohan KulkarniОценок пока нет

- Banerji Et Al-2000-Earthquake Engineering & Structural DynamicsДокумент16 страницBanerji Et Al-2000-Earthquake Engineering & Structural DynamicsDhirendra Kumar PandeyОценок пока нет

- Equilibrium in 3D Lecture Note 1Документ4 страницыEquilibrium in 3D Lecture Note 1venkatarao HanumanthuОценок пока нет

- Module11 Chemistry BitsДокумент5 страницModule11 Chemistry BitsPalОценок пока нет

- Astm d5946-04 Medicion Tratamiento CoronaДокумент6 страницAstm d5946-04 Medicion Tratamiento CoronaKattia Jhoana Martinez Sanjinez100% (1)

- PhET Blackbody SpectrumДокумент2 страницыPhET Blackbody SpectrumdsofewnОценок пока нет

- MH CET 2024 Sample PaperДокумент135 страницMH CET 2024 Sample PaperRishi ShahОценок пока нет

- Wind Loads Is en 1991-1-4Документ1 страницаWind Loads Is en 1991-1-4David O'MearaОценок пока нет

- Magnetic Field of Helmholtz Coils and Magnetic Moment - Group 4 - 24,25 Sept 2012Документ45 страницMagnetic Field of Helmholtz Coils and Magnetic Moment - Group 4 - 24,25 Sept 2012Anais ColibabaОценок пока нет

- Physics Division: Phys 141 Syllabus, PGДокумент7 страницPhysics Division: Phys 141 Syllabus, PGJun YoutubeОценок пока нет

- Seismaic Behaviour of Isloated BridgesДокумент41 страницаSeismaic Behaviour of Isloated Bridgespraveenpv7100% (1)

- Modul 11 - Response Spectrum AnalysisДокумент66 страницModul 11 - Response Spectrum AnalysisDYNОценок пока нет

- The First Century of Chemical EngineeringДокумент6 страницThe First Century of Chemical EngineeringFredericoОценок пока нет

- Chapter 10 Relative Equilibrium On FluidsДокумент42 страницыChapter 10 Relative Equilibrium On FluidsJubillee Magsino0% (1)