Академический Документы

Профессиональный Документы

Культура Документы

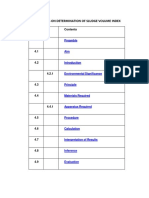

Aerated Grit Chamber - Characteristic Dimension Equation

Загружено:

Ray LimОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Aerated Grit Chamber - Characteristic Dimension Equation

Загружено:

Ray LimАвторское право:

Доступные форматы

Aerated Grit Chambers Hydraulic Design Equation

Jerzy M. Sawicki1

Abstract: The paper is devoted to the problem of dimensioning of aerated grit chambers. Existing hitherto methods of design of such

Downloaded from ascelibrary.org by SOUTHERN CALIFORNIA UNIVERSITY on 09/11/13. Copyright ASCE. For personal use only; all rights reserved.

objects are based on the very large experience of operation but they do not concern the important relation between the intensity of aeration

Q p and the discharge of transverse circulation Q c . For elimination of that fault four concepts 共initially suggested for air-lift pumps兲 of

explanation of the process were analyzed. Three of them were empirically verified and in effect the relation Q c (Q p ) was proposed. In the

next succession a simplified model of transverse circulation was suggested. Results of calculations led to the conclusion that the resultant

bottom velocity of the properly designed aerated grit chamber should not exceed the nonsilting velocity for those fractions which would

be removed in the chamber. Two practical examples of existent aerated grit chambers 共situated in Gdansk and Gdynia兲 were presented

below.

DOI: 10.1061/共ASCE兲0733-9372共2004兲130:9共1050兲

CE Database subject headings: Hydraulic design; Waste disposal; Sedimentation; Water circulation; Bubbles.

Introduction • Intensive transverse circulation can mix added chemicals with

wastewater. However, one can enumerate also the following

The aerated grit chamber is a specific kind of settling tank, serv- faults of aerated grit chambers.

ing for the selective separation of sand, ash, cullet, seeds, and • High capital costs 共aeration system兲.

other granular suspended particles 共commonly called ‘‘grit’’兲. • High operating costs 共growth of consumption of energy and

Such a device is equipped with an aeration system. Air bubbles, additional servicing personnel兲.

introduced along one side of the chamber, usually near its bottom, • Some volatile organic components and odors may be released

induce a transverse circulation, which combines with the longitu- from the wastewater.

There are many pieces of technical information which enable

dinal motion of the waste water and forms a characteristic spiral

dimensioning of aerated grit chambers. These recommendations

flow. The aeration system can be replaced by a set of hydraulic

usually have the form of design guidelines or simple physical and

nozzles. In such a case the transverse motion is induced by water-

mathematical expressions. However, among the said instructions

jets 关see, e.g., Brenner and Diskin 共1991兲兴. However, this kind of there are no reliable relations which express the functional depen-

solution is rather seldomly applied. The intensity of circulation dence between the discharge of the air Q p , introduced into the

should be high enough to keep the lighter, mainly organic, par- chamber, and the intensity of transverse circulation Q c , which is

ticles in suspension, but it should not disturb the sedimentation of a very important disadvantage of existing methods of design. An

the heavier grit elements. empirical relation between the induced transverse fluid flow rate

Practical experience 共e.g., Albrecht 1967; ASCE 1992兲 shows and the bottom velocity can be found in Brenner and Diskin

that aerated grit chambers provide some important advantages in 共1991兲. However, this expression was derived for the circulation

comparison with conventional solutions. The most important ben- induced by water-jets and hence cannot be applied for typical

efits are aerated grit chambers.

• Maintaining of the same efficiency of removal of grit for vari- The lack of the discussed relation is underlined in technical

able sewage discharge. handbooks 共e.g., ASCE 1992兲 because it creates an important

• Relatively low content of organic matter in the removed problem. If someone wants to design a new chamber or to adjust

sludge. an existing installation, one must be able to determine the change

• Preliminary aeration 共‘‘refreshing’’兲 of sewage. of the velocity field, due to the change of the air discharge.

• Low head loss 共much less than in conventional grit chambers, The main goal of this paper is to find a mathematical equation

which describes the qualitative relation between Q p and Q c .

where troublesome linear weirs are necessary for maintaining

of constant velocity兲.

Computational Scheme of the Aerated Grit Chamber

1

Professor, Technical Univ., Faculty of Hydro- and Environmental Generally, the perimeter of each chamber can have the shape of a

Engineering, ul. G. Narutowicza 11/12, 80-952 Gdańsk, Poland. polygon 共Fig. 1, solid line兲 or can be an oval 共Fig. 1, broken line兲.

Note. Associate Editor: A. Bruce De Vantier. Discussion open until

The smooth, curvilinear shape of this perimeter was justified by

February 1, 2005. Separate discussions must be submitted for individual

German investigators 共Pöpel and Hartman 1958兲 to minimize hy-

papers. To extend the closing date by one month, a written request must

be filed with the ASCE Managing Editor. The manuscript for this paper draulic disturbances of the wastewater velocity field. However,

was submitted for review and possible publication on April 2, 2001; construction of such oval grit chambers is more difficult and ex-

approved on June 10, 2003. This paper is part of the Journal of Envi- pensive. Besides, the oval cross section creates some difficulties

ronmental Engineering, Vol. 130, No. 9, September 1, 2004. ©ASCE, also during the chamber design, as its depth H and width B are

ISSN 0733-9372/2004/9-1050–1058/$18.00. changeable parameters: H⫽H(y) and B⫽B(z).

1050 / JOURNAL OF ENVIRONMENTAL ENGINEERING © ASCE / SEPTEMBER 2004

J. Environ. Eng. 2004.130:1050-1058.

Moreover, the organic matter content in the removed grit should

not exceed 10% 共percentage by weight兲.

According to the remarks stated above, it is logical to intro-

duce two critical free-sedimentation velocities: v s1 for particles of

diameter d 1 ⫽0.1 mm, and v s2 for d 2 ⫽0.2 mm. For typical grit

density p ⫽2,600 kg/m3 共Imhoff and Imhoff 1979兲 we have

v s1 ⫽0.007 m/s, v s2 ⫽0.023 m/s (1)

Methodology of Aerated Grit Chamber Design

Downloaded from ascelibrary.org by SOUTHERN CALIFORNIA UNIVERSITY on 09/11/13. Copyright ASCE. For personal use only; all rights reserved.

The aerated grit chamber can be dimensioned with the help of

exact methods or by means of compact technical procedures. The

methods of the first kind are based on equations of mathematical

physics 共differential ones as a rule兲, which describe the inner

structure of physical fields characteristic of the problem consid-

ered. The typical example of such an exact method, applied to

conventional desanders, can be found in an International Associa-

tion for Hydraulic Research journal paper 共Olsen and Skoglund

Fig. 1. Characteristic dimensions of aerated grit chamber cross 1995兲. However, procedures of this kind are very time-consuming

section 共that means expensive兲, so they should be used rather when com-

plex objects are designed that justify the additional cost of labor

and equipment. The simplified variant of an exact method will be

In this paper it was assumed that the computational shape of presented below.

the aerated grit chamber is determined by a schematic polygon The technical methods in turn are based on synthetic balance

共pentagon兲, shown in Fig. 1. Eventual ‘‘rounding’’ of this shape equations, combined with practical directions which express the

can be done individually by the designer. In the other case, the experience of engineers. We have the following geometrical and

technical version of the method proposed below could not be hydraulic formulas for aerated grit chambers:

applied and one should make use of its full, i.e., differential,

S⫽BH⫹Bh/2

variant 关see Eqs. 共32兲 and 共34兲, or even the more elaborated sug-

gestion, e.g., Olsen and Skoglund 共1995兲兴. 关 or equivalent relation S⫽S 共 B,H 兲 for more

The aerated grit chamber is fully determined by the following

set of design parameters 共Fig. 1兲: length L, width B, depth H, complex cross sections兴 (2)

depth of the gutter h, volume V, cross section S, distance of the

bottom line from the left wall B L and from the right wall B R V⫽LS (3)

(B L ⫹B R ⫽B), submergence of the aeration system H A , width of

v ⫽Q/S (4)

the air-lift zone b B , height of the vertical baffle H B , height of the

gap above (H G ) and under the baffle (H D ), effective detention T R ⫽V/Q (5)

time T R , discharge of wastewater Q 共along the chamber兲, dis-

charge of the transverse circulation Q C , air supply Q P 共or Q P1 Technical directions, complementary to Eqs. 共2兲–共5兲, can be pre-

when related to the unit length兲, mean longitudinal velocity v, sented in the following juxtaposition 共Neighbor 1965; Imhoff and

free-sedimentation velocity for critical particles of suspension v si Imhoff 1979; ‘‘Design’’ 1992兲:

(i⫽1, . . . ,I c ). • Depth H⫽2.0– 5.0 m;

A very important element of the aerated grit chamber is the • Width B⫽(1 – 5)H 共typical: B⫽2H; formally one can assume

vertical baffle. According to practical recommendations 关see, e.g., that B/H⬎1, but when B/HⰇ1 the conditions of the transver-

Albrecht 共1967兲; ASCE 共1992兲兴, such a baffle improves the func- sal circulation worsen and this possibility is not suggested兲;

tioning of the chamber so much that it should appear in all de- • Length L⫽(2.5– 5.0)B;

signs. However, sewage treatment plants are very often equipped • Minimal detention time T R ⫽120– 300 s 共typical: 180 s兲;

with conventional aerated grit chambers without the baffle. Such • Air supply Q p1 ⫽0.0045– 0.0125 m3 /sm 共typical: 0.0075

conventional solutions will be also considered in this paper. m3/sm, higher intensities for broader and deeper chambers兲;

• Distance of aerators from the bottom H⫺H A ⫽0.6– 1.0 m;

• Width of the air-lift zone b B ⫽1.0 m;

Required Efficiency of Aerated Grit Chambers • Circumferential velocity 共about 150 mm under the waste water

free-surface兲

Surprisingly, in the available design literature one cannot find vB⫽0.60– 0.75 m/s

many precisely formulated requirements related to the expected • Mean velocity v ⫽0.20– 0.30 m/s.

efficiency of grit removal which should be achieved. Hence it is The number of relations and directions listed above is less than

reasonable to accept the classical concept 共Imhoff and Imhoff the number of unknown parameters of the desander that creates

1979兲, according to which the properly functioning aerated grit the necessary conditions of the elastic object design. However, as

chamber should remove was already mentioned, the design method outlined above does

• 100% of the coarse sand fraction (d⬎0.2 mm); and not contain any relation between two crucial parameters: Q p and

• 65–75% of the medium sand fraction (0.1⬍d⬍0.2 mm). Q c . Such a relation will be derived in the next section.

JOURNAL OF ENVIRONMENTAL ENGINEERING © ASCE / SEPTEMBER 2004 / 1051

J. Environ. Eng. 2004.130:1050-1058.

‘‘Experimental’’ Model

The physical analysis of the considered problem, jointly with re-

markable experimental support, presented in Hussain and Sped-

ding 共1976兲, led to the following relation 共definitions of symbols

are given in ‘‘Notation’’兲:

K 2 V A2.75 A1.5g K 1V A

N DX ⫽ A , m⫽ (11)

p 共 exp m⫺1 兲

H A1.5Q 1.5 H A Q p

Two coefficients K 1 and K 2 are of empirical character. In the

Downloaded from ascelibrary.org by SOUTHERN CALIFORNIA UNIVERSITY on 09/11/13. Copyright ASCE. For personal use only; all rights reserved.

Fig. 2. Scheme of 共a兲 transverse circulation and 共b兲 location of original paper it was stated that

measurement points K 1 ⫽1,050 kg/m2 s, K 2 ⫽133,313 kg/m1.25 s2.5 (12)

However, these parameters were determined for air-lift pumps, so

it seems impossible to adapt this method for grit chambers ana-

lyzed in this paper.

Connection between Discharge of Air and Intensity

of Circulation

‘‘Energetic’’ Model

Models Considered The startpoint of this concept was a statement 共Sawicki and

Pawłowska 1999兲 that the terminal velocity of the single air

The motion of the liquid, induced by the gas bubbles, is a very bubble rising in a perfect fluid ( v pi ) is higher than the same

important technical factor, not only for aerated grit chambers, but parameter for the viscous medium ( v pr ⬍ v pi ). It means that the

also for some other objects, as, for example, air-lift pumps or real terminal energy of a bubble E r differs from its perfect value

pneumatic baffles. E i , and the difference (E i ⫺E r ), multiplied by the number of

In the bibliography there are four concepts explaining the bubbles, equals the ‘‘gas–liquid’’ energy transfer. Making use of

mechanism of transfer of energy from bubbles into the liquid: this concept one obtains the evident formula

• ‘‘Hydrostatic’’ 共‘‘Pumpen’’ 1984兲;

• ‘‘Empirical’’ 共Hussain and Spedding 1976兲; N DE ⫽ A Q p A gH A / (13)

• ‘‘Energetic’’ 共Sawicki and Pawłowska 1999兲; where ⫽coefficient of virtual mass; for the spherical bubble

• ‘‘Dynamic’’ 共Sawicki and Pawlowska 1999兲. ⫽0.5 共Wijngaarden 1976兲.

Each concept describes in a different way the power output N D

which is passed from the air bubbles to the liquid. It is necessary

to underline that those concepts were elaborated for air-lift ‘‘Dynamic’’ Method

pumps, hence they must be adapted for conditions of aerated grit According to the idea used in this concept, the energy delivered to

chambers. the liquid by the air bubbles is equal to the local work performed

by each bubble against the drag force. That kind of explanation

‘‘Hydrostatic’’ Model leads to the relation

The basis of this method is formed by the assumption that the N DD ⫽3 A C D H A v 2p Q P /4d p (14)

column of height H A 共and of the volume of the air-lift zone V A ), In the broad range of dimensions of bubbles we can consider the

containing the gas–liquid mixture, can be considered as a homo- drag coefficient C D ⫽0.44; parameters v p and d p , see Eqs. 共8兲

geneous substance of mean density z 共Fig. 2兲 and 共9兲 共Soo 1966兲.

z ⫽ 关 共 V A ⫺V P 兲 ⫹ A V P 兴 /V A (6)

The total volume of the air bubbles V P , suspended in water at Intensity of Dissipation of Energy

each moment of time, can be calculated from the equality The relation Q C ⫽Q C (Q P ), so important for the proper designing

V P ⫽Q P T P ⫽Q P H A / v P (7) of aerated grit chambers, may be obtained from the evident equal-

ity between the input of power 共i.e., the power, delivered by the

where T P ⫽time of air-bubble upflow, and v P ⫽characteristic ve- air bubbles兲 and the consumption of power

locity of the bubble rising which can be calculated, for example,

from the classical relation 共Soo 1966兲

Power InputÄPower Output¿Dissipation

v P ⫽0.687冑gd p (8)

N D ⫽N U ⫹N V (15)

where d p ⫽effective diameter of a bubble

The function N U describes the output of power and must be

d p ⫽1.49关 Q 2P /g 共 ⫺ A 兲兴 0.2 (9) expressed by the different relations for the different systems. For

Provided that the air bubbles are subject to the isothermal air-lift pumps we have 共Hussain and Spedding 1976兲

expansion from the initial pressure p d ⫽p atm⫹ z gH A , up to the NU air-lift pumps⫽gQ W ⌬H (16)

terminal pressure p g ⫽p atm , one can obtain the following expres-

sion for the power input, according to the ‘‘hydrostatic’’ concept where Q W ⫽pump discharge; and ⌬H⫽elevation head. The dis-

( A ⫽efficiency of transfer of energy兲: sipation power N V in this case is usually neglected, although in a

more precise attitude it should be taken into account 共Sawicki and

N DH ⫽ A Q P p atm ln关 1⫹ z gH A /p atm兴 (10) Pawłowska 1999兲.

1052 / JOURNAL OF ENVIRONMENTAL ENGINEERING © ASCE / SEPTEMBER 2004

J. Environ. Eng. 2004.130:1050-1058.

r⫽B/H (21)

we can obtain the following expression describing the power of

dissipation of energy 共for the aerated grit chamber兲:

N V ⫽n V V⫽2.56Q 3c 共 1⫹r 兲 2 共 1⫹r 2 兲共 r 4 ⫹3r 2 ⫹1 兲 / 共 L 2 H 2 r 5 兲

(22)

Experimental Verification of the Function N D (Chamber

with Baffle)

Downloaded from ascelibrary.org by SOUTHERN CALIFORNIA UNIVERSITY on 09/11/13. Copyright ASCE. For personal use only; all rights reserved.

For the purpose of selection of the best model of the process of

the delivery of power 共function N D ), the parameters of transverse

circulation were measured in the ‘‘old’’ aerated grit chamber in

Gdansk-‘‘East’’ sewage treatment plant, for Q⫽0. The shape of

this desander cross section is identical with the scheme in Fig. 1

Fig. 3. Assumed simplified scheme of transverse velocity field

for B⫽2.20 m, B L ⫽B R ⫽1.10 m, b B ⫽0.60 m, H⫽H A ⫽1.55 m,

h⫽1.10 m, H B ⫽1.00 m, H G ⫽0.27 m, H D ⫽0.35 m, and L

⫽21.0 m.

For aerated grit chambers the elevation head is practically Three various aeration systems 共adequate to the existing tech-

equal to zero 共the waste water free-surface is strongly foamed by nical possibilities兲 were investigated:

the outflowing air bubbles, but its mean level across the chamber • Ceramic diffusers ‘‘Brandol’’ 共12 units along the chamber兲,

is almost horizontal兲, so N U ⫽0 in this case. The main consump- AS1;

tion of power is connected with the dissipation of energy, due to • Perforated pipes of diameter 50 mm 共804 holes of diameter 2.5

the transverse circulation. According to the entropy balance equa- mm along the chamber兲, AS2; and

tion 共Landau and Lifshitz 1987兲, the intensity of the viscous dis- • Perforated pipes of diameter 50 mm 共300 holes of diameter 6.0

sipation 共related to the unit volume of the chamber兲 can be ex- mm along the chamber兲, AS3.

pressed as follows: The discharge of air was measured by means of an anemom-

n V ⫽ T 冋冉u y u z

z

⫹

y 冊 冉 冊 冉 冊

2

⫹

2 u y

3 y

2

⫹

2 u z

3 z

2 eter, installed just behind the compressor. The total amount of the

air was recalculated into the unit air supply:

Q pl ⫽Q p /L

冉 冊册

(23)

2 u y u z 2

⫹ ⫹ (17) The intensity of aeration was regulated from Q p1 min

3 y z ⫽0.0044 m3 /sm, up to Q p1 max⫽0.0107 m3 /sm 共attention: the air

It was taken into account in this relation that the transverse cir- discharge is related to the unit length of the chamber兲. For each

culation is two-dimensional 共Fig. 1兲 and turbulent. system, five different intensities were established.

In order to calculate the value of n V , described by Eq. 共17兲, The transverse circulation discharge was determined indi-

one should determine the velocity field of wastewater, or 共at least兲 rectly, the mean horizontal velocity was measured in the gap

define some model of this field. Such a model should be realistic above the baffle (u GB , in 10 points, see Fig. 2兲 and under the

and simple enough to be applied in engineering practice. baffle (u DB , in 20 points兲. Subsequently Q C was calculated from

After some considerations and analyses, it was assumed that the relation

the simplified field of velocity of the transverse circulation in the Q C ⫽ 共 u GB H G L⫹u DB H D L 兲 /2 (24)

aerated grit chamber can be described by the single, horizontal

vortex, presented in Fig. 3. Of course, such an attitude can be The velocity was measured by an electromechanical current

considered as an oversimplification, but owing to this we obtain a flow meter 共the propeller diameter⫽80 mm, made in Delft, Hol-

convenient algebraic formula, and in addition, such a model of land兲. This kind of equipment seems to be the most typical for the

the velocity field is quite similar to the measured velocity profiles considered case 关see, e.g., Brenner and Diskin 共1991兲兴. The mea-

共Fig. 5兲. Thus we can define the following estimations: surements were limited to these two regions only 共i.e., gaps above

冏 冏 冏 冏 冏 冏 冏 冏

and under the baffle兲 as the velocity field was so irregular that the

u y 2u H u z 2u V u y 4u H u z 4u V accuracy of measurements in the remaining parts of the real

⬇ ; ⬇ ; ⬇ ; ⬇

y B z H z H y B chamber was found to be too low.

(18)

u V ⬇2Q c / 共 BL 兲 ; u H ⬃2Q c / 共 HL 兲 ; BHL⫽V The obtained results are presented in Fig. 4 in the form of the

experimental points Q C (Q P ). Attention should be drawn to the

The coefficient of turbulent viscosity T 共its mean value for fact that this type of aeration system exerts rather poor influence

the whole chamber兲 can be computed according to the classical on the investigated function, although in the bibliography 共‘‘De-

Prandtl hypothesis sign’’ 1992兲 medium to coarse bubbles are recommended.

T ⫽0.5 2 l 2p 冉冏 冏 冏 冏冊

u y

z

⫹

u z

y

(19)

Experimentally determined points were compared with three

theoretical lines, which were obtained by means of the ‘‘hydro-

static’’ method 关Eq. 共10兲兴, ‘‘energetic’’ method 关Eq. 共13兲兴, and

where l P ⫽mean maximal distance from the wall ‘‘dynamic’’ method 关Eq. 共14兲兴, respectively. All three lines in Fig.

4 describe the idealized case, when the efficiency of the system is

l P ⫽ 共 H⫹B 兲 /4 (20)

maximal, i.e., when A ⫽1. The expected value of efficiency can

While substituting these approximated relations into Eq. 共17兲 be evaluated on the basis of experimental data for air-lift pumps

together with the auxiliary parameter when the coefficient A varies between A max⫽0.65 for minimal

JOURNAL OF ENVIRONMENTAL ENGINEERING © ASCE / SEPTEMBER 2004 / 1053

J. Environ. Eng. 2004.130:1050-1058.

Downloaded from ascelibrary.org by SOUTHERN CALIFORNIA UNIVERSITY on 09/11/13. Copyright ASCE. For personal use only; all rights reserved.

Fig. 4. Intensity of circulation Q C versus intensity of aeration Q P

共real object兲

Fig. 5. Measured and calculated velocity fields 关Eq. 共32兲兴

elevation head ⌬H and A min⫽0.37 for very high elevations

共‘‘Pumpen’’ 1984兲. Provided that the aerated grit chamber can be

treated as a kind of air-lift pump for which ⌬H⫽0, we can sus- By numerical integration of the measured profile of velocity

pect that for this case the object efficiency will reach 60–70%. along the vertical line y⫽B/2, from the bottom (z⫽0) up to the

Analyzing the set of theoretical curves in Fig. 4 we can state zero-velocity point (z⫽z 0 ), or from z⫽z 0 up to the free-surface

that the best coincidence with experimental points is described the z⫽H, the discharge of circulation was obtained

‘‘dynamic’’ method 关Eq. 共14兲兴. By computing the quotient of the

measured and calculated values of N D we obtain:

• For the ‘‘hydrostatic’’ model: A ⫽0.48;

Q C⫽

1

2 冉冕

0

z0

兩 u y 共 z 兲 兩 Ldz⫹ 冕

z0

H

兩 u y 共 z 兲 兩 Ldz 冊 (27)

• For the ‘‘energetic’’ model: A ⫽3.27 共physically impossible兲; The set of 10 experimental points Q C (Q P ) is shown in Fig. 6 and

and compared to Eqs. 共10兲, 共13兲, and 共14兲.

• For the ‘‘dynamic’’ model: A ⫽0.62. In the next succession the theoretical curves ‘‘intensity of cir-

Taking the above-mentioned evaluation into account, it was stated culation versus intensity of aeration’’ have been determined in the

that the best explanation of the function Q C (Q P ) was given by manner already described 共Fig. 4兲 for A ⫽0.62. As one can see,

the ‘‘dynamic’’ concept. Comparing Eqs. 共14兲 and 共22兲, we can again the best fit gives the ‘‘dynamic’’ method. The truth is that

record the level of coincidence would be better for slightly higher effi-

ciency, about 70%, but the main focus of this paper is not the

Q C ⫽0.74 A 关 L 2 H 2 r 5 H A v 2p Q p / 共 R r d p 兲兴 1/3 (25)

experimental determination of the efficiency of the chamber, but

where v p ⫽Eq. 共8兲, d p ⫽Eq. 共9兲 共or equivalent relations兲, r⫽Eq. the choice of the relation between Q P and Q C .

共21兲, A ⫽0.65, and It is quite important that the same conclusion 关i.e., Eq. 共14兲

gives the best evaluation of the power input兴 was drawn after

R r ⫽ 共 1⫹r 兲 2 共 1⫹r 2 兲共 r 4 ⫹3r 2 ⫹1 兲 (26)

investigations of the air-lift pumps 共Sawicki and Pawlowska

1999兲.

Experimental Verification of the Function N D

(Chamber without Baffle)

Measurements of the intensity of circulation for this case were

performed in a laboratory model of a chamber, also for Q⫽0. The

chamber had a rectangular shape of the following dimensions:

H⫽H A ⫽0.50 m, B⫽0.50 m, and L⫽1.50 m. For the aeration

system, a perforated pipe of diameter 20 mm was used 共100 holes

of diameter 1.5 mm兲. The geometrical scale of the model was not

so large as in the previous case 共the ‘‘old’’ aerated grit chamber in

Gdańsk兲, so it was possible to measure the horizontal components

of the velocity along three vertical lines by means of an electro-

mechanical current flow meter 共diameter of the propeller

⫽35 mm). An exemplary result of measurements, for the air sup-

ply Q P ⫽0.002 m3 /s, is shown in Fig. 5 共full line兲. Particular

attention should be paid to the sudden growth of velocity just

below the sewage free-surface. It is apparently the consequence

Fig. 6. Intensity of circulation Q C versus intensity of aeration Q P

of the low resistance of the air along the surface 共in contrast with

共laboratory model兲

the wall region, where the resistance of flow is much higher兲.

1054 / JOURNAL OF ENVIRONMENTAL ENGINEERING © ASCE / SEPTEMBER 2004

J. Environ. Eng. 2004.130:1050-1058.

Simplified Model of Kinematics of the Aerated Grit

Chamber

The relation Q C (Q P ), formulated above, enables us to determine

the velocity field in the chamber for different supplies of air. In

the most general form, this field is described by the Reynolds

equations 共for the turbulent flow兲. However, taking into account

demands of labor for computational procedures necessary for

solving such a general task 共even if a ready-made commercial

software were applied兲, it is apparent that the use of a simplified

Downloaded from ascelibrary.org by SOUTHERN CALIFORNIA UNIVERSITY on 09/11/13. Copyright ASCE. For personal use only; all rights reserved.

version 共or versions兲 of the general model is very expedient.

Characteristic features of the areated grit chambers are:

• Longitudinal component of the sewage velocity vector (u x )

does not depend on its transverse components (u y and u z ); this

statement can be justified by the fact that both the transverse

circulation and longitudinal flow can be induced in the aerated

grit chamber independently each from one another.

• Longitudinal velocity profile can be replaced by its average

value:

ux⬇ūx⫽v⫽Q/S⫽const (28) Fig. 7. Examples of trajectories of suspended particles 关Eq. 共34兲兴

• Using Eq. 共28兲 the continuity equation takes the form

uy uz

⫹ ⫽0 (29)

y z

according to which the stream-function can be introduced Motion of Suspended Particles

subject to the following definitions:

On having at our disposal an acceptable method of description of

uy⫽ , uz⫽⫺ (30) the transverse flow, we can determine the trajectories of indi-

z y

vidual grit particles. These trajectories are described by the fol-

• The air bubbles, rising upward induce in the chamber a vortex

lowing set of equations 共Soo 1966兲:

with a horizontal axis; the intensity of the vortex is practically

constant and equal to 关see Fig. 3 and Eq. 共18兲兴: dvA d 共 u⫺vA 兲 w 1 w 2 g

u z u y ⫽w 1 g⫹w 2 ⫹ 兩 u⫺vA 兩 共 u⫺vA 兲 (34)

共rot u兲 x ⫽ ⫺ ⫽⍀ x ⬇⫺8Q c 共 B 2 ⫹H 2 兲 / 共 LB 2 H 2 兲

dt df v 2s

y z

(31) drA

vA ⫽ (35)

共although the vorticity ⍀ x can be expressed also in a different dt

form兲.

w 1 ⫽ 共 p ⫺ 兲 /, w 2 ⫽/ p (36)

• Substituting Eq. 共30兲 into Eq. 共31兲 共or equivalent兲 one obtains

where vA ⫽particle velocity; rA ⫽radius vector of a particle trajec-

⌬⫽8Q c 共 B 2 ⫹H 2 兲 / 共 LB 2 H 2 兲 (32) tory; p ⫽density of a particle; g⫽gravity acceleration;

Thus, according to the above proposal, the transverse circula- vs⫽particle free-sedimentation velocity.

tion is described by means of the Poisson equation 共32兲. It is a The system given by Eqs. 共32兲–共36兲 is a set of relations, form-

relatively simple expression and can be solved numerically rela- ing the simplified model of the hydraulic characteristics of aerated

tively easily. As a convenient boundary condition of Dirichlet grit chambers. The quantitative analysis of behavior of each par-

form, the following obvious relation can be used suit 共⌫ perimeter ticle leads to the conclusion that two categories of trajectories can

of the chamber cross section兲: be expected during the motion of suspension in a chamber:

• Given by a closed loop; and

兩 ⌫ ⫽0 (33) • Given by an open line 共from the initial position, up to the

bottom of a chamber兲.

In order to verify the simplified model of the transverse circu- A series of 64 calculations were carried out 共for four different

lation in the aerated grit chamber, Eq. 共32兲 was solved with use of parameters of particle, four different intensities of circulation, and

the boundary condition 共33兲 and Eq. 共25兲. The results of calcula- four different initial positions兲. Two example trajectories are

tions were compared with profiles of the measured velocity, de- shown in Fig. 7. The number of parameters influencing the mo-

termined previously. As can be seen in Fig. 5, where the exem- tion of particle is high enough, so it is very advisable to formulate

plary effects of calculations were juxtaposed with the some compact conditions, which could guarantee the removal of

experimental lines, the level of conformity is quite good. Only the coarse grit particles with maintenance of the lighter 共organic兲

just below the sewage free-surface, the difference is noticeable particles in suspension.

since it is a consequence of the negligible flow resistance in this Such a condition can be derived if we realize that the chamber

part of the desander cross section 共i.e., negligible in comparison cross section can be divided into two parts: one with ‘‘ascending

with the flow resistance along the rigid wall of the chamber兲. flow’’ 共near the aeration system兲 and the second with ‘‘descending

However, that effect is of local character, and thus it was assumed flow’’ 共near the opposite wall兲. In the second part each particle

finally that the model given by Eq. 共32兲 can be generally ac- always moves downwards, whereas in the ‘‘ascending’’ zone such

cepted. a particle can move upwards only when the driving force is large

JOURNAL OF ENVIRONMENTAL ENGINEERING © ASCE / SEPTEMBER 2004 / 1055

J. Environ. Eng. 2004.130:1050-1058.

Table 1. Characteristic Parameters of Analyzed Grit Chambers

Gdansk STP Gdynia STP

Parameter Inflow Outflow Chamber Inflow Outflow Chamber

Mean concentration 共mg/L兲:

d⬎0.1 mm 33.42 5.43 53.11 10.86

d⬎0.2 mm 14.85 0.82 37.84 6.74

0.1⬍d⬍0.2 mm 18.57 4.61 15.27 4.12

Mean reduction 共%兲:

d⬎0.1 mm

Downloaded from ascelibrary.org by SOUTHERN CALIFORNIA UNIVERSITY on 09/11/13. Copyright ASCE. For personal use only; all rights reserved.

d⬎0.2 mm 83.8 79.6

0.1⬍d⬍0.2 mm 94.5 82.2

75.2 73.1

Organic matter in 5.7 11.3

the removed

grit 共%兲:

Discharge of 1.328 1.898

circulation 共m3/s兲

Mean horizontal 0.063 0.039

velocity 共m/s兲

Maximal 0.126 0.078

velocituy 共m/s兲

Maximal bottom 0.152 0.108

Fig. 8. Aerated grit chamber ‘‘E’’ 共Gdańsk-‘‘East’’兲 cross section velocity 共m/s兲

enough. Especially important is the bottom part of the ‘‘ascend- The shape of the second investigated object 共Gdynia STP兲 is

ing’’ zone, where the flow is mainly horizontal, with the resultant shown in Fig. 9. The chamber of this sand trap was divided into

velocity two parts: aerated and conventional. The baffle, which divides the

chamber, has a completely different character than the solution

u B ⫽ 冑u 2HM ⫹ v 2 (37) recommended for the aerated desanders, as its upper edge juts out

Each particle which should remain in the suspension must cross of the sewage free-surface and the contents of the chamber cannot

this bottom region, so the velocity u B should be higher than the circulate around it. The basis of that decision is unknown, as the

nonsilting velocity for smaller particles (d⬍0.1 mm for desand- designer has not explained it in the desander design.

ers兲, but should be less than the proper value for bigger particles The object is characterized by the following parameters: Q

(d⬎0.2 mm). Accepting the characteristic nonsilting velocities, ⫽0.94 m3 /s 共for one chamber; number of chambers: 2兲, L

according to the classical investigations of Telford 共Watson and ⫽21.5 m, Q P1 ⫽0.0019 m3 /sm 共344 holes of diameter 3.0 mm in

Burnett 1995兲, we can record the 50 mm pipe兲.

0.076 m/s⬍u B ⬍0.150 m/s (38)

The latter expression is a condition in demand which supple-

ments other prescriptions also presented in this paper, which must

be fulfilled in the properly designed aerated grit chamber.

Discussion of the Method Proposed

All considerations presented above were discussed on the basis of

data, obtained during the operation of two real aerated grit cham-

bers, in Gdansk-‘‘East’’ sewage treatment plant 共STP兲 共a ‘‘new’’

one this time兲 and that of Gdynia STP.

The schematic cross section of the first object is shown in Fig.

8. Its main parameters were equal to Q⫽0.52 m3 /s 共for one

chamber; number of chambers: 6兲, L⫽16.0 m, Q p1

⫽0.0028 m3 /sm 共perforated pipes of diameter 50 mm with 1,280

holes of 3.0 mm兲.

The efficiency of that chamber was determined six times from

1998 to 1999 during the first period of its operation. The sewage

samples of the volume 0.15 m3 were taken 12 times a day 共in each

series of measurements兲 and analyzed in the laboratory, according

to the typical standards. The mean concentrations of sand, ob-

Fig. 9. Aerated grit chamber ‘‘D’’ 共Gdynia兲 cross section

tained during these investigations, are presented in Table 1.

1056 / JOURNAL OF ENVIRONMENTAL ENGINEERING © ASCE / SEPTEMBER 2004

J. Environ. Eng. 2004.130:1050-1058.

Investigations of efficiency of the chamber 共carried out in the Conclusions

identical way with those described previously兲 gave the results

presented in Table 1. The method of design of aerated grit chambers results from many

On comparing dimensions and characteristics of both objects years of technical experience. However, each set of prescriptions,

described above with the technical prescriptions, one can see that which creates the particular version of this method, is laden with

the geometrical parameters of the desanders on the whole were a very essential fault, viz. the lack of relation between the air

chosen properly. Some discrepancies appear during the analysis supply Q P and the transverse circulation discharge Q C .

of kinematic variables. Mean velocities are less than recom- In the technical bibliography one can find practically four con-

mended values, as for the object in Gdansk v E ⫽0.085 m/s cepts, explaining the relation Q C (Q P ), but each of them was

elaborated for the air-lift pumps. In this paper three of those con-

⬍0.20 m/s, and at the second plant v D ⫽0.074 m/s⬍0.20 m/s.

Downloaded from ascelibrary.org by SOUTHERN CALIFORNIA UNIVERSITY on 09/11/13. Copyright ASCE. For personal use only; all rights reserved.

cepts were analyzed, after having adapted to the conditions of

The functioning aeration intensities also lie below the prescribed

aerated grit chambers and subject to the empirical verification. It

range 0.0045–0.0125 m3/sm 共as Q P1 ⫽0.0028 m3 /sm and Q P2

was stated in the conclusion that the best fitting of experimental

⫽0.0019 m3 /sm). and theoretical relation between Q P and Q C is rendered by the

In order to assess these discrepancies in the light of the rela- ‘‘dynamic’’ method 关Eqs. 共14兲 and 共25兲兴.

tion Q C (Q P ), proposed in this paper, the following parameters The resultant function Q C (Q P ) allows the determination of the

were calculated for both investigated objects: velocity field in a chamber. In this paper, two attitudes were con-

• Intensity of transverse circulation 关Eq. 共25兲兴; sidered: a ‘‘structural’’ model, based on a simplified model of the

• Mean horizontal velocity 关Eq. 共18兲兴; transverse circulation 关Eq. 共32兲兴 and a ‘‘technical’’ one, reduced to

• Maximal circumferential velocity; and the compact prescriptions given by Eq. 共38兲.

• Maximal bottom resultant velocity 关Eq. 共37兲兴. The structural model was solved together with the equation of

The obtained results are shown in Table 1. As can be seen trajectory of a particle. The computed velocity field showed

there, the condition expressed by Eq. 共38兲 in both cases is prac- proper conformity with the results of measurements, so this

tically fulfilled, whereas in the chamber ‘‘E’’ the velocity u B model can be suggested as a useful tool in technical practice.

slightly surmounts the upper value recommended. The mean ef- The proposal formulated in this paper was compared with

ficiencies of the considered objects are similar to each other 共83.8 technical situations, two examples of the real aerated grit cham-

bers 共‘‘E’’ in Gdansk and ‘‘D’’ in Gdynia兲. Generally this com-

and 79.3%, respectively兲 and generally they can be accepted, al-

parison led to the conclusions that both the bibliographic prescrip-

though one can suspect that the upper value G1 E

⫽94.5% is un-

tions and the new relation presented above are consistent with the

derrated, as u B ⫽0.152 m/s⬍0.150 m/s 关Eq. 共38兲兴. In such an

E

courses of real processes. But on the other hand, these new rela-

event, the efficiency of the desander ‘‘E’’ could be improved by tions should also be tested on additional data, independent from

diminishing the air supply. But on the other hand, such a conclu- the considerations presented above.

sion would be in contradiction with the bibliographic recommen-

dations, according to which v B ⫽0.60– 0.75 m/s. However, in the

face of considerations presented in this paper, such a high value Acknowledgments

of the circumferential velocity could be obtained for very high

aeration intensities. One can suspect that this discrepancy can be The writer is anxious to express his gratitude for the PEWIK-

explained on the grounds of the rise of local velocity, near the GDYNIA and the BUDIMEX-GDAŃSK for the financial support

free-surface 共Fig. 5兲. It is possible that the bibliographic prescrip- of this study.

tion given by ASCE 共1992兲 was related to the horizontal compo-

nent of the free-surface velocity, which is about three times higher

than the calculated one. In such a case the theoretical velocities Notation

关Eq. 共42兲兴 could be accepted.

In the Gdynia desander ‘‘D’’ the circumferential velocity still The following symbols are used in this paper:

lies in the prescribed range 关Eq. 共38兲兴, but the total efficiency of B ⫽ grit chamber width;

that object is apparently less than the first one. However, it is b B ⫽ width of air-lift zone;

probably the consequence of the fact that this desander only C D ⫽ drag coefficient;

partly works as an aerated device, and partly as a conventional d ⫽ diameter of suspended particle;

one 共Fig. 9兲. There are no technical possibilities to distinguish the d p ⫽ air bubble diameter;

E i ,E r ⫽ air bubble kinetic energy in ideal and real fluid,

influence of one part from another, so the efficiency GD ⫽73.1%

respectively;

must be related to the total result.

g ⫽ gravity acceleration;

It is interesting to compare the organic matter contents in the

H ⫽ grit chamber depth;

grit, removed from both desanders; for the object ‘‘E’’ this value H A ⫽ submergence of aeration system;

is quite low, less than the demanded 10%, whereas for the object H B ⫽ height of baffle;

‘‘D’’ it amounts to 11.3%, so it is slightly too high. This differ- H D ⫽ height of lower gap;

ence can also be correlated with the intensity of aeration, the H G ⫽ height of upper gap;

circumferential velocity of the desander ‘‘D’’ is lower than that in h ⫽ depth of gutter;

desander ‘‘E,’’ so the grit removed from ‘‘D’’ contains more or- K 1 ,K 2 ⫽ empirical constants;

ganic particles 共so much that part of this object was not aerated兲. L ⫽ grit chamber length;

It means that the supply of air in the object ‘‘D’’ should be in- l p ⫽ Prandtl’s mixing length;

creased 共it unfortunately could not be realized during the investi- m ⫽ coefficient;

gations without previous reconstruction of the object兲. N D ⫽ power input;

JOURNAL OF ENVIRONMENTAL ENGINEERING © ASCE / SEPTEMBER 2004 / 1057

J. Environ. Eng. 2004.130:1050-1058.

NU ⫽ power output; A ⫽ air density;

NV ⫽ power of energy dissipation; p ⫽ grit density;

nV ⫽ energy dissipation per unit volume; z ⫽ air–sewage mixture density;

p atm ⫽ atmospheric pressure; ⫽ von Karman constant; and

pd ⫽ bottom pressure; ⫽ stream function.

Q ⫽ discharge of waste water;

QC ⫽ transversal circulation discharge;

QP ⫽ air supply; References

Q P1 ⫽ air supply per unit length;

Albrecht, A. E. 共1967兲. ‘‘Aerated grit operation, design and chamber.’’

Rr ⫽ coefficient; Water Sewage Works, 114共9兲, 331–335.

Downloaded from ascelibrary.org by SOUTHERN CALIFORNIA UNIVERSITY on 09/11/13. Copyright ASCE. For personal use only; all rights reserved.

r ⫽ coefficient; Brenner, A., and Diskin, M. H. 共1991兲. ‘‘Model study of jet-circulated grit

rA ⫽ radius vector of suspended particle trajectory; chamber.’’ J. Environ. Eng., 117共6兲, 782–787.

S ⫽ chamber cross section; ‘‘Design of municipal wastewater treatment.’’ 共1992兲. ASCE manual and

TP ⫽ time of air bubble upflow; report on Engineering Practice No. 76, Vol. 1, Brattleboro, Vt.

TR ⫽ detention time; Hussain, I. A., and Spedding, R. L. 共1976兲. ‘‘The theory of the gas lift

u ⫽ sewage velocity; pump.’’ Int. J. Multiphase Flow, 7共3兲, 83– 87.

uB ⫽ resultant bottom velocity; Imhoff, K., and Imhoff, K. R. 共1979兲. Taschenbuch der stadtentwasse-

V ⫽ grit chamber cubature; rung, R. Oldenbourg Verlag, Munich 共in German兲.

Landau, L. D., and Lifshitz, E. M. 共1987兲. Fluid mechanics, Pergamon,

VA ⫽ air-lift zone volume;

Elmsford, N.Y.

VP ⫽ total volume of suspended air bubbles;

Neighbor, J. 共1965兲. ‘‘Design and operation criteria for aerated grit cham-

vA ⫽ suspended particle velocity; bers.’’ Water Sewage Works, 117共12兲, 37– 45.

v ⫽ mean longitudinal velocity; Olsen, N. R. B., and Skoglund, M. 共1995兲. ‘‘Three-dimensional numerical

vB ⫽ circumferential velocity; modeling of water and sediment flow in a sand trap.’’ J. Hydraul.

vP ⫽ air bubble velocity; Res., 32共6兲, 833– 844.

vS ⫽ free-sedimentation velocity of suspended particle; Pöpel, F., and Hartman, H. 共1958兲. ‘‘Der neue beluftete sandfang auf der

wi ⫽ parameter; biologischen reinigungsanlage der stadt heilbron.’’ Das Gas und

x,y,z ⫽ Cartesian coordinates; Wasserfach, 22 共in German兲.

⫽ virtual mass coefficient; Pumpen. technisches handbuch. 共1984兲. VEB Verlag-Technik, Berlin 共in

⌫ ⫽ perimeter of grit chamber cross section; German兲.

Sawicki, J. M., and Pawtowska, A. 共1999兲. ‘‘Energy balance for air lift

⌬H ⫽ elevation head;

pumps.’’ Arch. Hydro-Eng. Env. Mech., 46共4兲, 63–72.

A ⫽ aeration system efficiency; Soo, L. 共1966兲. Fluid dynamics of multiphase systems, Blaisdale, London.

G ⫽ grit removal efficiency; van Wijngaarden, L. 共1976兲. ‘‘Hydrodynamic interaction between gas

o ⫽ organic matter contents in removed grit; bubles and liquid.’’ J. Fluid Mech., 77共4兲, 27– 44.

T ⫽ dynamic coefficient of turbulent viscosity; Watson, I., and Burnett, A. D. 共1995兲. Hydrology. An environmental ap-

⫽ waste water density; proach, Lewis, Boca Raton, Fla.

1058 / JOURNAL OF ENVIRONMENTAL ENGINEERING © ASCE / SEPTEMBER 2004

J. Environ. Eng. 2004.130:1050-1058.

Вам также может понравиться

- Group 1 - Section 01G - Separation Project PDFДокумент46 страницGroup 1 - Section 01G - Separation Project PDFHatta AimanОценок пока нет

- Secondary TreatmentДокумент14 страницSecondary TreatmentNasirОценок пока нет

- EE Notes FULLДокумент56 страницEE Notes FULLAnonymous Q4MsQAОценок пока нет

- Treatment of Pre-Treated Textile Wastewater Using Moving Bed Bio-Film ReactorДокумент8 страницTreatment of Pre-Treated Textile Wastewater Using Moving Bed Bio-Film ReactorIna SitaОценок пока нет

- Sewage FacilitiesДокумент31 страницаSewage FacilitiesNataliaKОценок пока нет

- Manual On The Causes and Contril of Activated SludgeДокумент21 страницаManual On The Causes and Contril of Activated SludgeRiianti WidiiОценок пока нет

- Nijhuis Water ConservationДокумент2 страницыNijhuis Water ConservationDaniel PérezОценок пока нет

- Landfill LeachateДокумент7 страницLandfill LeachateChristian Mihai GОценок пока нет

- Combined & Separate Sewer SystemsДокумент9 страницCombined & Separate Sewer SystemsKhairylle JuanОценок пока нет

- Thesis Title No.3Документ4 страницыThesis Title No.3Ejay EmpleoОценок пока нет

- Performance Evaluation of A Central WastewaterДокумент155 страницPerformance Evaluation of A Central WastewaterWayne HamiltonОценок пока нет

- Final Final Expt 3 - Part 1Документ6 страницFinal Final Expt 3 - Part 1Florecita CabañogОценок пока нет

- DWG Chapter 15 Treatment Processes Disinfection Jun19Документ84 страницыDWG Chapter 15 Treatment Processes Disinfection Jun19Alberto MeneghinОценок пока нет

- TC Owtu 502 PDFДокумент288 страницTC Owtu 502 PDFRon100% (1)

- Sludge PollutantsДокумент273 страницыSludge PollutantsRod LondonОценок пока нет

- Chemical Water TreatmentДокумент12 страницChemical Water TreatmentEderango JackОценок пока нет

- CPI BrochureДокумент2 страницыCPI Brochuremashonk okОценок пока нет

- Environmental Engineering (EN) - 20.03.18 PDFДокумент240 страницEnvironmental Engineering (EN) - 20.03.18 PDFRaj VermaОценок пока нет

- WWTP Mardan 1st PhaseДокумент41 страницаWWTP Mardan 1st Phasemohammad armaghan100% (1)

- Rotating Biological ContactorsДокумент18 страницRotating Biological Contactorsjjiménez_142046Оценок пока нет

- Purification of Brackish Water Using Hybrid CDI-EDI TechnologyДокумент30 страницPurification of Brackish Water Using Hybrid CDI-EDI TechnologyamtОценок пока нет

- Pulsator - P ER 003 EN 1603 - v2 PDFДокумент2 страницыPulsator - P ER 003 EN 1603 - v2 PDFpjrapanutОценок пока нет

- Edr 2 ElarmoДокумент15 страницEdr 2 ElarmoArfel Marie FuentesОценок пока нет

- Sand Filtration PDFДокумент2 страницыSand Filtration PDFBernadette Tumacder MaganaОценок пока нет

- Module 1 - WastewaterДокумент35 страницModule 1 - WastewaterPamela MendozaОценок пока нет

- Membrane ProcessesДокумент35 страницMembrane ProcessesArie Ikhwan SaputraОценок пока нет

- Mini Project ReportДокумент5 страницMini Project ReportSaj BhaiОценок пока нет

- Journal of Water Process Engineering: SciencedirectДокумент8 страницJournal of Water Process Engineering: SciencedirectOmar GameelОценок пока нет

- Wastewater Treatment Methods Physical Unit Operations Chemical Unit Operations Biological Unit OperationsДокумент34 страницыWastewater Treatment Methods Physical Unit Operations Chemical Unit Operations Biological Unit OperationsNumanОценок пока нет

- Treatment and Reuse of Wastewater From Beverage IndustryДокумент7 страницTreatment and Reuse of Wastewater From Beverage IndustryChaeyoung YooОценок пока нет

- V3i4 Ijertv3is040786 PDFДокумент5 страницV3i4 Ijertv3is040786 PDFsarikagОценок пока нет

- Foaming in Wastewater Treatment PlantДокумент8 страницFoaming in Wastewater Treatment PlantGeorge MarkasОценок пока нет

- Design of Arraba Waste Water Treatment Plant: Prepared By: Waleed Rahhal Hamed Daghles Saleh Abdel-RhmanДокумент47 страницDesign of Arraba Waste Water Treatment Plant: Prepared By: Waleed Rahhal Hamed Daghles Saleh Abdel-RhmanMOHAMMED ABBAS NAJI MAALAОценок пока нет

- Wastewater Technology Fact Sheet: Screening and Grit RemovalДокумент11 страницWastewater Technology Fact Sheet: Screening and Grit RemovalGayan Indunil JayasundaraОценок пока нет

- 22 - Some BOD ProblemsДокумент25 страниц22 - Some BOD ProblemsRoger Jayson MercadoОценок пока нет

- Recomended Design Criteria Manual - Wastewater Collection and Treatment FacilitiesДокумент139 страницRecomended Design Criteria Manual - Wastewater Collection and Treatment FacilitiesCarlos VegaОценок пока нет

- Yanbu WWTW Process Group PresentationДокумент52 страницыYanbu WWTW Process Group Presentationyxp2237Оценок пока нет

- D399DДокумент5 страницD399DHilarie Jonathan100% (1)

- CAP 15 - 3 Design of Water Resource Recovery Facilities, Sixth Edition Nitrogen-Removal-Sidestream-Process-DesignДокумент4 страницыCAP 15 - 3 Design of Water Resource Recovery Facilities, Sixth Edition Nitrogen-Removal-Sidestream-Process-DesignNICOLAS SANCHEZ GOMEZОценок пока нет

- Svi 5Документ5 страницSvi 5Kapil GhongadeОценок пока нет

- Lecture 5 - FiltrationДокумент90 страницLecture 5 - FiltrationChuah Chong YangОценок пока нет

- Surface Water Treatment Operations Plan TemplateДокумент8 страницSurface Water Treatment Operations Plan TemplateSkid RowОценок пока нет

- Process Engineer Water and Wastewater or Design Manager Water AnДокумент4 страницыProcess Engineer Water and Wastewater or Design Manager Water Anapi-78891068Оценок пока нет

- Introduction To Activated Sludge Study Guide: Wisconsin Department of Natural Resources Wastewater Operator CertificationДокумент33 страницыIntroduction To Activated Sludge Study Guide: Wisconsin Department of Natural Resources Wastewater Operator CertificationAgus WitonoОценок пока нет

- Water EngineeringДокумент10 страницWater EngineeringdandewjangerОценок пока нет

- Liu Yi-Design and Construction of Biogas Digester 2017Документ74 страницыLiu Yi-Design and Construction of Biogas Digester 2017Stanley Wishmore MukuraОценок пока нет

- Waste Water TreatmentДокумент3 страницыWaste Water TreatmentSana Saleem100% (1)

- MBR Vs SBR Vs Conventional Treatment PDFДокумент9 страницMBR Vs SBR Vs Conventional Treatment PDFadalcayde2514Оценок пока нет

- Effect of Silica On The Properties of Cellulose Acetatepolyethylene Glycol Membranes For Reverse OsmosisДокумент15 страницEffect of Silica On The Properties of Cellulose Acetatepolyethylene Glycol Membranes For Reverse OsmosisPendi Adi MertaОценок пока нет

- ENVI Trickling FiltersДокумент23 страницыENVI Trickling FiltersbaBy daBy AnNetTeОценок пока нет

- Modelling Wastewater Treatment Plant - How Far Shall We Go With Sophisticated ModelДокумент11 страницModelling Wastewater Treatment Plant - How Far Shall We Go With Sophisticated ModelSong Nguyen NguyenОценок пока нет

- 1 s2.0 S2468519421001774 MainДокумент21 страница1 s2.0 S2468519421001774 Mainwinsyt35Оценок пока нет

- Notes Grit RemovalДокумент16 страницNotes Grit RemovalrojanmathewОценок пока нет

- Lamella Clarifier Leopold TexlerДокумент4 страницыLamella Clarifier Leopold TexlerAntony ThanosОценок пока нет

- Project Report PDFДокумент26 страницProject Report PDFcaloycaloy2Оценок пока нет

- Assignment 01 BKF1313Документ2 страницыAssignment 01 BKF1313Ray LimОценок пока нет

- Individual Assignment 1Документ2 страницыIndividual Assignment 1Ray LimОценок пока нет

- SPEAKING Test 1 (Individual) - NewДокумент2 страницыSPEAKING Test 1 (Individual) - NewRay LimОценок пока нет

- Production of 120000 MTA Oleochemical Fatty Acids From Sunflower OilsДокумент93 страницыProduction of 120000 MTA Oleochemical Fatty Acids From Sunflower OilsRay LimОценок пока нет

- Chapter 5Документ37 страницChapter 5Ray LimОценок пока нет

- Individual Assignment 2016 PDFДокумент2 страницыIndividual Assignment 2016 PDFRay LimОценок пока нет

- Understanding BatteriesДокумент258 страницUnderstanding Batteriesramprabhakarj100% (8)

- Midterm Exam Fall 2012Документ5 страницMidterm Exam Fall 2012Asanka RodrigoОценок пока нет

- Feasibility Study Part-I Thermal Hydraulic Analysis of Leu Target For 99mo Production in Tajoura ReactorДокумент8 страницFeasibility Study Part-I Thermal Hydraulic Analysis of Leu Target For 99mo Production in Tajoura Reactorbsebsu7901Оценок пока нет

- Assignment FluidДокумент11 страницAssignment Fluidadam ishakОценок пока нет

- TLE10 Electronics Q1 Wk7 Mathematical - Analysis of Parallel CircuitДокумент12 страницTLE10 Electronics Q1 Wk7 Mathematical - Analysis of Parallel Circuitismael delosreyesОценок пока нет

- Ashby - Biomaterials PDFДокумент26 страницAshby - Biomaterials PDFPao FrancavillaОценок пока нет

- Cracks in Buildings PDFДокумент50 страницCracks in Buildings PDFSanjay ShelarОценок пока нет

- Deformation of A Ring and A Square FrameДокумент5 страницDeformation of A Ring and A Square FrameMansoob BukhariОценок пока нет

- Chapter 1 BC SC Probe 8Документ36 страницChapter 1 BC SC Probe 8api-265180883Оценок пока нет

- 2 & 3 Wheeler Lab ManualДокумент36 страниц2 & 3 Wheeler Lab ManualKarthi100% (1)

- C 14Документ26 страницC 14pfylОценок пока нет

- (Guedes - Soares-Joško - Parunov) - Advanced Ship Design For Pollution Prevention-2010Документ303 страницы(Guedes - Soares-Joško - Parunov) - Advanced Ship Design For Pollution Prevention-2010Wee WeeОценок пока нет

- A Kinetic Model of The Peirce-Smith Converter: Part I. Model Formulation and ValidationДокумент11 страницA Kinetic Model of The Peirce-Smith Converter: Part I. Model Formulation and ValidationJaime MoralesОценок пока нет

- Lx400 PDFДокумент3 страницыLx400 PDFbalab2311Оценок пока нет

- Ortho TRX LineДокумент16 страницOrtho TRX LineAliOucharОценок пока нет

- Fundamentals of Digital Image Processing - A Practical Approach With Examples in Matlab Chris Solomon, Toby BreckonДокумент3 страницыFundamentals of Digital Image Processing - A Practical Approach With Examples in Matlab Chris Solomon, Toby Breckonశ్రీనివాస బాబ్జి జోస్యులОценок пока нет

- What Is Multivariable Calculus (MVC) ?Документ6 страницWhat Is Multivariable Calculus (MVC) ?Muhammad ArshadОценок пока нет

- Lesson Plan Solar SystemДокумент4 страницыLesson Plan Solar SystemAnneValdezAcostaОценок пока нет

- 1 s2.0 S0267726121000427 MainДокумент14 страниц1 s2.0 S0267726121000427 MainMarco Castro MayorОценок пока нет

- Radiation Dose Limits: Appendix BДокумент6 страницRadiation Dose Limits: Appendix BVaradha RajanОценок пока нет

- Projectile MotionДокумент6 страницProjectile MotionArseniojakejr FloresОценок пока нет

- Chapter 1 - Introduction To GeologyДокумент76 страницChapter 1 - Introduction To GeologyZulaikha KamalОценок пока нет

- LG mds712Документ71 страницаLG mds712Usman GoodОценок пока нет

- Rajprol Nn40-E1Документ1 страницаRajprol Nn40-E1Israel CarhuasОценок пока нет

- IS 3370 (Part 3) 1967 R 1999Документ14 страницIS 3370 (Part 3) 1967 R 1999Nayag Singh100% (1)

- Okjop, E9Uweeiowuweuhjqwhjwqhhwqjdhjwjkxjasljxlassj A Short-Circuit Design Forces in Power Lines and SubstationsДокумент28 страницOkjop, E9Uweeiowuweuhjqwhjwqhhwqjdhjwjkxjasljxlassj A Short-Circuit Design Forces in Power Lines and Substationsamit77999Оценок пока нет

- Rabia7 Base 28.02 EmbedДокумент7 страницRabia7 Base 28.02 EmbedvengadОценок пока нет

- 8DOF KinematicsДокумент6 страниц8DOF KinematicsmarbonfОценок пока нет

- MAG8000 Manual PDFДокумент137 страницMAG8000 Manual PDFHanks EpphОценок пока нет

- Solid Dispersion PolymorphismДокумент37 страницSolid Dispersion PolymorphismAmey KamtheОценок пока нет