Академический Документы

Профессиональный Документы

Культура Документы

General Notes PDF

Загружено:

sorowareОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

General Notes PDF

Загружено:

sorowareАвторское право:

Доступные форматы

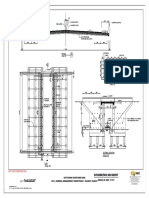

Purpose Post-Tensioning Steel Epoxy Joining of Precast Concrete

The standards shown on these sheets have been Post-Tensioning steel shall be 7-wire, 1/2 inch or Segments

developed to establish a limited number of 0.6 inch diameter strands, conforming to

When required by the Contract Drawings, epoxy

practical sections leading to uniformity and ASTM A416 (AASHTO M203), Grade 270. The maximum

joining of precast segments shall be in

simplicity of forming and production methods. internal tendon size used for balanced cantilever

accordance with the Recommended Contract

These standards are applicable to most construction under these standards shall not

Administration Guidelines for Design and

conditions of highway bridge loading and exceed 15-1/2 inch, or 12-0.6 inch diameter

Construction of Segmental Concrete Bridges,

usage within the approximate span limits Grade 270 low relaxation strands. Unless

March, 1995, American Segmental Bridge Institute,

indicated for the sections, and the design otherwise stated in the contract special

unless other requirements are specified in the

loads specified in these General Notes. provisions, other aspects of furnishing,

Contract Special Provisions.

installing and grouting of prestressing steel

shall be in accordance with the details shown on

Span Limits the plans, and the "Recommended Contract Temporary Post-Tensioning

The span limits shown on these sheets are Administration Guidelines for Design and

Temporary Post-tensioning required for

approximate only and are not mandatory at either Construction of Segmental Concrete Bridges",

construction of span-by-span, or

limit. The span limits shown contemplate the March, 1995, American Segmental Bridge Institute.

balanced cantilever bridges using these standard

use of concrete weighing 155 pcf (including segments shall be internal bars or tendons in

rebar) and concrete strength of not less than Reinforcing Steel top and bottom slabs unless specifically

5000 psi. It is intended that the segment depth detailed otherwise in the contract drawings.

All reinforcing steel shall conform to the

should generally increase in 300 mm increments

requirements of the AASHTO Standard

for each 6 M increase in span above the

minimum span of 30.5 M.

Specifications, and shall be ASTM A615, Camber Diagrams

Grade 60, or ASTM A706. When permitted welded

For span-by-span construction, a final, long

grillages shall be shop prepared. Field welding

Web Thickness of reinforcing steel will be permitted at the

term camber diagram which compensates for

deflections in accordance with the assumed

discretion of the engineer.

Web thickness for balanced cantilever material properties shall be provided by the

construction is based on use of 100% internal designer. For balanced cantilever construction,

tendons in top and bottom slabs (no draped Shop Drawing Requirements camber diagrams shall be prepared by the

internal or external tendons). The web Shop Drawing Requirements shall be in accordance contractor and reviewed by the designer.

thickness for balanced cantilever bridges with with the "Recommended Contract Administration

100% straight internal tendons may be reduced

for segments in the interior 60% of spans in

Guidelines for Design and Construction of Crown Roadway Cross Sections

Segmental Concrete Bridges" published by the

accordance with shear requirements and other American Segmental Bridge Institute, March, 1995, Crown roadways should be accomodated by rotating

provisions of the "AASHTO Guide Specifications unless other provisions are stated in the the cantilever wings downward and building up the

for Design and Construction of Segmental Contract Special Provisions. top slab between the webs. The shape of the inside

Concrete Bridges". Reductions in shear and web void shall remain unchanged.

thickness requirements for balanced cantilever

construction may also be achieved by use of

Fabrication, Formwork, Handling,

draped external tendons in the box cells in Storage, Shipment and Erection

conjunction with straight internal tendons.

Fabrication, formwork, handling, storage,

shipment and erection of precast segments shall

Precast Concrete be in accordance with the "Recommended Contract

Recommended minimum strength of concrete is Administration Guidelines for Design and

5000 psi. Concrete of greater compressive Construction of Segmental Concrete Bridges",

strength may be used, and may be required for March, 1995, American Segmental Bridge Institute, Wearing Surfaces

structural considerations, in which case unless other requirements are specified in the

limiting stresses will be based on the concrete For those regions in which deicing chemicals are

Contract Special Provisions. Angular

specifications for the actual project. used on roadways, a sacraficial wearing surface

intersections of formwork shall have a minimum

is recommeneded to protect the structural deck and

radius of 50 mm. Slab and box edges shall have

thereby enhance the life of the structure. In

Segment Lengths a minimum chamfer of 20 mm.

regions where deicing chemicals are not used, as-

Maximum Segment Length using these standards is cast riding surfaces without wearing surfaces may

3000 mm. In curved alignments, the segment length be used.

should be kept as close to the Maximum as possible.

AASHTO - PCI - ASBI FOR SPAN-BY-SPAN AND

GENERAL NOTES

SEGMENTAL BOX GIRDER STANDARDS BALANCED CANTILEVER CONSTRUCTION

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Neoprene Bearing Pad 749Документ6 страницNeoprene Bearing Pad 749sorowareОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Etabs DimentioningДокумент1 страницаEtabs DimentioningsorowareОценок пока нет

- L E L E E T P W: SPENCER MethodДокумент14 страницL E L E E T P W: SPENCER MethodsorowareОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Analysis of A Slip On A Long Natural SlopeДокумент4 страницыAnalysis of A Slip On A Long Natural SlopesorowareОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Analysis of A Slip On A Long Natural SlopeДокумент4 страницыAnalysis of A Slip On A Long Natural SlopesorowareОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Foundations in Oil and Gas IndustryДокумент64 страницыFoundations in Oil and Gas IndustryPower PowerОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Abutment Connecting BeamДокумент1 страницаAbutment Connecting BeamsorowareОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Pile LayoutДокумент1 страницаPile LayoutsorowareОценок пока нет

- Pile Layout RightДокумент1 страницаPile Layout RightsorowareОценок пока нет

- Semi Through BridgeДокумент1 страницаSemi Through BridgesorowareОценок пока нет

- Abutment Elevation Section C 10m SpanДокумент1 страницаAbutment Elevation Section C 10m SpansorowareОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Abutment HeadДокумент1 страницаAbutment HeadsorowareОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Abutment DetailsДокумент1 страницаAbutment DetailssorowareОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Abutment PlanДокумент1 страницаAbutment PlansorowareОценок пока нет

- Abutment Plan 10m SpanДокумент1 страницаAbutment Plan 10m SpansorowareОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Abutment Sectional Plan 10m SpanДокумент1 страницаAbutment Sectional Plan 10m SpansorowareОценок пока нет

- Abutment Elevation 10m SpanДокумент1 страницаAbutment Elevation 10m SpansorowareОценок пока нет

- Bearing PedestalДокумент1 страницаBearing PedestalsorowareОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- 4/3/2012 3:43:26 PM, DWG To PDF - pc3: Produced by An Autodesk Educational ProductДокумент1 страница4/3/2012 3:43:26 PM, DWG To PDF - pc3: Produced by An Autodesk Educational ProductsorowareОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Abutment SectionДокумент1 страницаAbutment SectionsorowareОценок пока нет

- Sheet PilingДокумент1 страницаSheet PilingRoger SugatanОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Bridge DrawingДокумент1 страницаBridge DrawingsorowareОценок пока нет

- Information Document: Not For ConstructionДокумент1 страницаInformation Document: Not For ConstructionsorowareОценок пока нет

- Guard RailДокумент1 страницаGuard RailsorowareОценок пока нет

- Information Document: Not For ConstructionДокумент1 страницаInformation Document: Not For ConstructionsorowareОценок пока нет

- PC GirderДокумент1 страницаPC GirdersorowareОценок пока нет

- Bridge LayoutДокумент1 страницаBridge LayoutsorowareОценок пока нет

- Bridge InterchangeДокумент1 страницаBridge InterchangesorowareОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Consumable and Welding of Modified 9 Cr-1M0 Steel PDFДокумент4 страницыConsumable and Welding of Modified 9 Cr-1M0 Steel PDFmahmoud_allam3Оценок пока нет

- Final Report NDT PDFДокумент8 страницFinal Report NDT PDFAbhay Shankar MishraОценок пока нет

- Sika Fibre: DescriptionДокумент2 страницыSika Fibre: DescriptionMarni Mohd JamilОценок пока нет

- Building Control For Temp BuildingsДокумент31 страницаBuilding Control For Temp BuildingsLordM00nОценок пока нет

- SKM-04 MD Inclinaiso N AzimuthДокумент6 страницSKM-04 MD Inclinaiso N AzimuthAwalou MohamadОценок пока нет

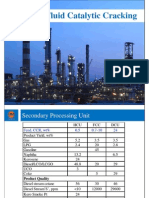

- V FCCДокумент38 страницV FCCpipe_boyОценок пока нет

- Villa Savoye Joseph BloomДокумент14 страницVilla Savoye Joseph BloomDinesh Ramamoorthy R100% (1)

- Chapter 15 (Acid and Bases)Документ46 страницChapter 15 (Acid and Bases)aliefyan4769Оценок пока нет

- OintmentДокумент12 страницOintmentErfaneh FNОценок пока нет

- Fundamentals of Stripe CoatingДокумент164 страницыFundamentals of Stripe Coatinganangwahjudi100% (1)

- Installation of Marble and Granite Tiles On FloorДокумент7 страницInstallation of Marble and Granite Tiles On FloorAleen Gamal Al-Dinji100% (2)

- Lab - Manual Bt-101 (Chemistry)Документ39 страницLab - Manual Bt-101 (Chemistry)Krishna MahajanОценок пока нет

- Clamps ColorДокумент19 страницClamps ColorGerson SuarezОценок пока нет

- Apavisa Catalogo General 16Документ438 страницApavisa Catalogo General 16ggestrudesОценок пока нет

- O&G MapДокумент2 страницыO&G MapTiffany DacinoОценок пока нет

- ASTM C1708 Self-Leveling Mortars Containing Hydraulic CementsДокумент8 страницASTM C1708 Self-Leveling Mortars Containing Hydraulic CementsIqbal KhanОценок пока нет

- Different Types of Wood JointДокумент2 страницыDifferent Types of Wood Joint[AP-STUDENT] Resty GarciaОценок пока нет

- ITERLENE PE-31 - F LC Rev 00-19 ENДокумент2 страницыITERLENE PE-31 - F LC Rev 00-19 ENRajkoОценок пока нет

- Cbse Sample Papers For Class 11 Chemistry Download PDFДокумент4 страницыCbse Sample Papers For Class 11 Chemistry Download PDFPIPARIYAОценок пока нет

- Aplikasi Beton Geopolimer: Djwantoro HardjitoДокумент23 страницыAplikasi Beton Geopolimer: Djwantoro HardjitoMa'rufОценок пока нет

- Chemistry QuizДокумент23 страницыChemistry QuizJoshuaОценок пока нет

- H.T BRAUTEK LITHIUM EP SeriesДокумент2 страницыH.T BRAUTEK LITHIUM EP SeriesALFREDO CANTOS CORNEJOОценок пока нет

- Analyzing Effects of Multi-Wall Carbon Nanotubes (MWCNT) & Polyethylene Glycol (PEG) On Performance of Water Base Mud (WBM) in Shale FormationДокумент19 страницAnalyzing Effects of Multi-Wall Carbon Nanotubes (MWCNT) & Polyethylene Glycol (PEG) On Performance of Water Base Mud (WBM) in Shale FormationMuhammad Rafly AndraОценок пока нет

- Beam - GBДокумент1 страницаBeam - GBJake CortezОценок пока нет

- Technical Data: Santicizer 160Документ1 страницаTechnical Data: Santicizer 160sriatul2006Оценок пока нет

- TMI Imperial Catalogue 2013Документ364 страницыTMI Imperial Catalogue 2013AZLAN ABDULLAIОценок пока нет

- Section 2: Water Analysis Section 2: Water Analysis Section 2: Water AnalysisДокумент84 страницыSection 2: Water Analysis Section 2: Water Analysis Section 2: Water AnalysisNasr RagehОценок пока нет

- MS Template 1419 AmendmentДокумент3 страницыMS Template 1419 AmendmentNurul AkmaОценок пока нет

- MDS Report Substances of Assemblies and Materials: 1. Company and Product NameДокумент3 страницыMDS Report Substances of Assemblies and Materials: 1. Company and Product NameMohamed HarisОценок пока нет

- Sol-Gel Process, PDFДокумент4 страницыSol-Gel Process, PDFMrRulesGtaОценок пока нет