Академический Документы

Профессиональный Документы

Культура Документы

A Programmable Solution For Stepped Crane Columns

Загружено:

Mohamed Mostafa IbrahimОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

A Programmable Solution For Stepped Crane Columns

Загружено:

Mohamed Mostafa IbrahimАвторское право:

Доступные форматы

A Programmable Solution for Stepped

Crane Columns

WILLIAM E. MOORE, II

T h e basic equations for the solution of a stepped column

with a fixed base are easily derived, but the pinned top

equations are the only forms found in generally available

hterature such as the AISC book on Industrial Buildings.^

This paper presents the 10 basic equations required for a

general solution of the stepped crane column and de-

scribes the use of these equations with the generally

accepted Murray-Graham model of crane column action.^

The 10 equations are applicable to both bayonet and

double-shaft crane columns and by setting I2 equal to Ij Fig. 1. Column model without wind

(see Fig. 1) may be applied to single-shaft columns with a

bracketed crane girder. The equations also allow the

designer to locate the crane thrust at the proper location

instead of at the column step, a refinement which compli- H-KilM POfr^-T- OtS R.OO|=.

cates needlessly the solution for manual calculation but

which presents no problem to the computer.

L

The reader may use these equations, Anderson and

Woodward's iterative solution for the effective length of •Ro* iMi'o'itO Cfc«-c.-n»j

stepped columns^ and the procedures recommended in

AISE Technical Report No. 13^ to program a complete ^

crane column solution. The author's program solves AISC

Equations 1.6-la & lb or 1.6-2 using procedures and load ^H

combinations specified by the AISE, allowing a rapid

selection of an economical combination of wide-flange

sections. Fig. 2. Column model with wind

The assumptions for the Murray-Graham stepped col-

umn model are:

Base: Fixed the top of the column. R„ is the force required to

Top: A. No wm^.-A pin is assumed midway between the restore the deflection at the top of the column to

top and bottom chords or midway between the a given fraction R of the deflection for /?o=0. For

top chord and knee brace, permitting rotation a bent with two identical columns, the fraction

but no translation (see Fig. 1). R is obviously 0.5, but when two or more bays

B. With wind: A slider is assumed at the bottom share the lateral loads the fraction is not so

chord or at the knee brace, permitting transla- obvious. If /i, I2 and l^ (see Fig. 3) were the same

tion but no rotation (see Fig. 2). MQ is the for all columns:

moment required to maintain zero rotation at

_ / of column being designed

R

XI of all columns in bent

William E. Moore, II is president of Ferro Products Company,

Charleston, West Virginia. Since the / of an interior column is likely to be

more than double that of an exterior column.

SECOND QUARTER / 1986 55

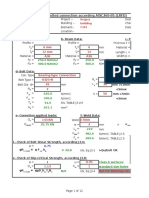

4. £/A.M2=M2£4 £4=fl«2 + % (4)

wOA.oS> ArfJto t^*.A.^-no>Jii>

^ ^ 1 _i_ * ^ _l_ ^ 2

5. Eh^oMo = Mo£5 £5 = y + <?i<?2 + ^ = ^6 (5)

Ko^^«.K•r5

6Ha.aC

c^ 6. £/2d^o™ = HoE^ E,= ^-^ + e,€2 + Y = '^^ ^^^

D2 jp2

D 7. £/2(t>oH, = / / , £ 7 -^7 = Y + €2^3 + - ^ (7)

?. Ehi>,^ =WE, £, = M + :^2 + M + ^ (8)

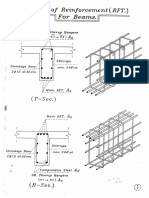

Fig. 3. Column geometry and sign convention 6 2 2 6

9. El2<^oM2=M2E, E, = £2 (9)

the use of /? of 0.3 for two identical bays and 0.2 10. El2<\>oMo=M,,E, £ o = / ^ i + ^2 (10)

for more than two bays seems reasonable. Exact

values of R may be determined after the initial

member selection, but such over refinement is

of dubious value in the opinion of the author. PROGRAM OUTLINE

The basic equations given below are for the deflection and 1. Enter column geometry (see Figs. 2 and 3)

rotation at the unrestrained top of the column for each of ^ 1 ? ^2y "^37 ^4^ "^5? ^ 0

five loading conditions: 2. Enter column loads (see Figs. 1 and 3)

H i , Po, P2. W

1. Horizontal load or reaction at top of column To compute AISE load combinations, provide separate

2. Moment reaction at top of column variables for:

3. Crane thrust at any location on top shaft a. Live- and dead-load components of PQ

4. Moment at step due to difference between roof and b. Multiple and single crane values for P2 and H^

crane loads 3. Enter wind deflection reduction ratio R.

5. Uniform wind load 4. Enter or read properties of trial sections

The development of the 10 basic equations is routine by 5. Enter or compute D^, D2, h (see Fig. 3)

any classical method. Superposition of cantilever formulas 6. Compute Ho=W (€4 + ^5) (see Fig. 2)

as described in the Appendix was the method used by the M2 = P2D2-PoDi (see Figs. 1 and 3)

author. 7. A. No wind (see Figs. 1 and 3)

a. Compute €^ = € + ^ - € 2

BASIC EQUATIONS b. Compute E^, E2 and £4 using E q s . l , 2 and 4.

c. Set El2^= 0 and compute

1. El2h()H()-H^)Ex (1)

3 3 H,E2 + M2E,

Ro = (11)

E,

d. Compute loads and moments at Sects. 1, 2, 3, 4.

2. El2hoH^=H,E2 E2=£2i— + —+—+^i€3\ +

e. Solve AISC Eqs. 1.6 - l a & l b or 1.6-2

B. With wind (see Figs. 2 and 3)

(2) a. Compute €1 = € - €2

* 3 2 b. Compute, Ei through £0 using Eqs. 1 to 10.

c. Setting El2<\>o = 0

_ ^^\ I M^2j_ 3-tit2

3. £/28ow=V^^3 E: (3) {Ro + Ho)E, + H,Ej + WEs + M2E,

8 2 4 Mo = (12)

Eo

^1^2 I ^2

EI2^o = HoE^ + H^E2 + WE3 + M2E4 + Mo^s (13)

56 ENGINEERING JOURNAL / AMERICAN INSTITUTE OF STEEL CONSTRUCTION

d. Assuming Ro = 0 solve Eq. 12 for MQ and Eq. 13 APPENDIX: DERIVATION OF EQUATIONS

for EI2 Ao While the basic equations can be derived by several

e. Find RQ required for final deflection of REI2A0 methods, the superposition of cantilever beam deflections

and rotations permits the equations to be written directly,

REh^Q - HQE^ -H^E2 - WEs -M2E4 without intermediate calculations. The method is de-

Rn = scribed in Prof. J. P. Den Hartog's Strength of Materials^ as

EsEe

E, "The Myosotis Method." I know of no other text where

Eo this useful alternate to area-moment methods is described.

^HoEe + H,Ej + WEs + M2E,j [|^] The cantilever beam equations are:

(14)

Ei-

E,Ee

^0 J

i"^

f. Solve Eq. 12 forfinalMQ

Me

g. Compute loads and moments at critical sections EI 2EI

1, 2, 3 & 4 (see Fig. 3)

h. Compute the K-factors for top and bottom

shafts in accordance with Ref. 3.

i. Compute AISC Eqs. 1.6-la & lb or 1.6-2 for se-

lected load combinations (AISE Procedures,

Ref. 4, recommended).

i' 2EI

pe

3EI

j . If trial sections are incorrect, return to Step 4;

else print results.

NOMENCLATURE w

Loads H we

6E1 SEI

HQ = Concentrated horizontal load at top of column, kips

Hi = Crane thrust, kips A

M2 = Moment at step, kip-in. Using Myosotis to write eq. 1:

= {P2) (crane eccentricity) - (PQ) (roof col. eccen-

tricity) (//o€i)€i ^0^2

Fo = Roof load 2EI. 3EIn

P2 = Crane load

W=Wind load, kips/in. ( ^ 0 ^ 1 ) ^ 2 _L ^ 0 ^ 2

• + • €1

EI2 2EI.

Reactions

HQ^I

Mo = Restoring moment at top of column, kip-in.

[3Eh

7?o = Restoring horizontal reaction at top of column, kips

Deflections

Which when summed, cleared and I substituted for A^

80 = Deflection at top of column, in. h

yields Eq. 1.

^OHO ^om^ ^0M2^ etc = deflection due to subscripted load,

in. The general case of a fixed base column with unknown

Ao = 28o with RQ = 0, in. translational and rotational restraint at the top has four

(t)o = Rotation at top of column, rad unknowns

^o//05 4>o//i5 4>0A/2 etc = rotation caused by subscripted

load (l)/?o (2) Mo (3) 80 (4)(|>,

And two conditions of equilibrium

Properties

(1)2F, = 0 (2)SM = 0

11 = Moment of inertia of top shaft, in"*

/2 = Moment of inertia of bottom shaft, in"^ The Murray-Graham wind model adds two boundary

conditions

h (1) 28o = a known amount (2) Scf^o = 0

SECOND QUARTER / 1986 57

Equations 1 to 10 are individual statements of equilibrium REFERENCES

which may be superimposed as: 1. Fisher, James M. and Donald R. Buettner Light and

Eq. 15: E^^o = (^o + Ro)Ei + H1E2 + WE^ + Heavy Industrial Buildings AISC, 1979, Chicago, III

M2E4 + MoEs 2. Murray, John J. and Thomas C. Graham Design of

Mill Buildings Proceedings ofAISC Engineering Con-

Eq. 16: E/2(t>o = {HQ + Ro)Ee + H^Ej + WEs + ference, 1959.

M2Eg + MQEQ 3. Anderson, John P. and James H. Woodward Calcula-

Equation 14 is the solution for RQ of Eqs. 15 and 16 with tion of Effective Lengths and Effective Slenderness

(t) = 0 and Eh^Q = REhl^Q. Ratios of Stepped Columns AISC Engineering Jour-

nal, 4th Qtr., 1974, New York, N.Y. (pp. 157).

Equation 13 is not one of the simultaneous equations for 4. Association of Iron and Steel Engineers AISE Tech-

solution, but is an intermediate step which forms the basis nical Report No. 13 August 1, 1979.

for the selection of the "known amount" of deflection, 5. Den Hartog, J. P. Strength of Materials McGraw-

REh^^. D Hill, 1949, New York, N.Y.

58 ENGINEERING JOURNAL / AMERICAN INSTITUTE OF STEEL CONSTRUCTION

Вам также может понравиться

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Crack Control in Concrete Masonry WallsДокумент4 страницыCrack Control in Concrete Masonry WallsMohamed Mostafa IbrahimОценок пока нет

- Crack Control in Concrete Masonry WallsДокумент4 страницыCrack Control in Concrete Masonry WallsMohamed Mostafa IbrahimОценок пока нет

- KDS 41 17 00 2019Документ75 страницKDS 41 17 00 2019Suso IglesiasОценок пока нет

- COMPARISON OF COMPOSITE BEAM DESIGNДокумент8 страницCOMPARISON OF COMPOSITE BEAM DESIGNMohamed Abo-ZaidОценок пока нет

- AISC Design Guide 33 Curved Member Design 2018Документ166 страницAISC Design Guide 33 Curved Member Design 2018saital92% (12)

- GBES Flash Cards LEED Green AssociateДокумент134 страницыGBES Flash Cards LEED Green AssociateMohamed Mostafa Ibrahim100% (2)

- 13 1611Документ8 страниц13 1611teguh andriantoОценок пока нет

- Hydrocyclones For Particle Size SeparationДокумент7 страницHydrocyclones For Particle Size SeparationJean DejardinОценок пока нет

- Excel program analyzes end plate moment connectionsДокумент27 страницExcel program analyzes end plate moment connectionscengizОценок пока нет

- Faraday CupsДокумент10 страницFaraday CupsAshish SharmaОценок пока нет

- Fillet Weld Strength Calculation Example For Welded Connection Subjected To BendingДокумент6 страницFillet Weld Strength Calculation Example For Welded Connection Subjected To BendingpipestressОценок пока нет

- Effective Lengthsof Uniformand Stepped Crane ColumnsДокумент9 страницEffective Lengthsof Uniformand Stepped Crane ColumnspruebaОценок пока нет

- BEAMCOL9Документ10 страницBEAMCOL9Richard FallegaОценок пока нет

- ASTM .A497.1979Документ8 страницASTM .A497.1979Rommel UparelaОценок пока нет

- Limit States Design of Crane Runway GirdersДокумент7 страницLimit States Design of Crane Runway GirdersRatna YanuarОценок пока нет

- C - Energy Audit InstrumentationДокумент19 страницC - Energy Audit InstrumentationghonamyОценок пока нет

- Defrosting:: The Evaporators Are As FollowsДокумент4 страницыDefrosting:: The Evaporators Are As FollowsAnnexe RuetОценок пока нет

- ACI 313R-97: Reported by ACI Committee 313Документ20 страницACI 313R-97: Reported by ACI Committee 313DIDIER ANGEL LOPEZ RINCONОценок пока нет

- ANSI Testing Standards RacksДокумент126 страницANSI Testing Standards RacksmloredoОценок пока нет

- Steel Design Flowcharts: Read Chapter 2 of Aisc For General InformationДокумент70 страницSteel Design Flowcharts: Read Chapter 2 of Aisc For General InformationNathaniela LoretoОценок пока нет

- Step ColДокумент21 страницаStep ColamachmouchiОценок пока нет

- AISC360-05 LRFD Shear Bolted Connection CheckДокумент12 страницAISC360-05 LRFD Shear Bolted Connection CheckMario FeghaliОценок пока нет

- "Stepcol" - Stepped Column Analysis: Program DescriptionДокумент6 страниц"Stepcol" - Stepped Column Analysis: Program DescriptionRicardo VázquezОценок пока нет

- Sheet Pile 1Документ13 страницSheet Pile 1belacewОценок пока нет

- AISC 360-10 Example 001Документ7 страницAISC 360-10 Example 001Bùi Văn HợpОценок пока нет

- UNIT 4 Raman Spectroscopy 12309Документ24 страницыUNIT 4 Raman Spectroscopy 12309NathanianОценок пока нет

- Practical design of stepped columnsДокумент12 страницPractical design of stepped columnstaosyeОценок пока нет

- Stepped Columns - A Simplified Design MethodДокумент23 страницыStepped Columns - A Simplified Design MethodwrayroОценок пока нет

- Aisc Asd-01 Example 001Документ5 страницAisc Asd-01 Example 001Bùi Văn HợpОценок пока нет

- MonorailДокумент14 страницMonorailZain AndabloОценок пока нет

- CMAA Most Asked Action AlertsДокумент27 страницCMAA Most Asked Action Alertstggjr100% (1)

- Design of Self Balanced Lifting TackleДокумент56 страницDesign of Self Balanced Lifting TackleDhanuОценок пока нет

- Uniform and Temperature LoadingДокумент2 страницыUniform and Temperature LoadingWessam NourОценок пока нет

- POS CAL TP No10 Vb2 C200x80x7 - 5 CVR Bolt R0 20180731Документ26 страницPOS CAL TP No10 Vb2 C200x80x7 - 5 CVR Bolt R0 20180731Nguyễn Duy QuangОценок пока нет

- Stepped Columns A Simplified Design MethodДокумент8 страницStepped Columns A Simplified Design Methoddaniel.j.mccarthy100% (1)

- Problem 1-015 PDFДокумент3 страницыProblem 1-015 PDFOscar SanchezОценок пока нет

- Two-span continuous box girder designДокумент20 страницTwo-span continuous box girder designMuhammad ImranОценок пока нет

- Project Ref: BD-Demo Project Title: DemoДокумент44 страницыProject Ref: BD-Demo Project Title: DemoarvindОценок пока нет

- 0488a0vvgc001 06Документ73 страницы0488a0vvgc001 06AlienshowОценок пока нет

- Din 4024Документ13 страницDin 4024Muhammad HassanОценок пока нет

- IS 14817 (Part 2) 2004 - MECHANICAL VIBRATION - EVALUATION OF MACHINE VIBRATION - PART 2 LARGE LAДокумент11 страницIS 14817 (Part 2) 2004 - MECHANICAL VIBRATION - EVALUATION OF MACHINE VIBRATION - PART 2 LARGE LAAbinashBeheraОценок пока нет

- STAADДокумент15 страницSTAADBaladad HaroldОценок пока нет

- Beam Deflections and Stresses During Lifting PDFДокумент10 страницBeam Deflections and Stresses During Lifting PDFManoj KumarОценок пока нет

- STAADPro V8i Verification ManualДокумент176 страницSTAADPro V8i Verification ManualjasimabdОценок пока нет

- Buckling Fatigue AnalysisДокумент55 страницBuckling Fatigue AnalysisHarshit Garg100% (2)

- 15.lattice (Cage) Beam Design and Finite Element Analysis of Gantry CraneДокумент3 страницы15.lattice (Cage) Beam Design and Finite Element Analysis of Gantry CraneravirajОценок пока нет

- Member Stability CheckДокумент3 страницыMember Stability CheckdamindaОценок пока нет

- Consistent determination of flexural and lateral buckling resistanceДокумент106 страницConsistent determination of flexural and lateral buckling resistanceAnonymous hprsT3WlPОценок пока нет

- How To Apply Horizontal Moving LoadsДокумент2 страницыHow To Apply Horizontal Moving LoadsRojan MathewОценок пока нет

- Tables for Allowable Axial Loads in Equal Single Angles in CompressionДокумент4 страницыTables for Allowable Axial Loads in Equal Single Angles in CompressionMikeОценок пока нет

- Wheel Calculation IDEA Analyzes Wheel Material OptionsДокумент35 страницWheel Calculation IDEA Analyzes Wheel Material Optionsbambang satryojatiОценок пока нет

- Example 45° Cone Method for Concrete Anchor DesignДокумент3 страницыExample 45° Cone Method for Concrete Anchor Designundf25Оценок пока нет

- Bottom LugДокумент7 страницBottom LugAjiri IvoviОценок пока нет

- Strength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsДокумент6 страницStrength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsValdemir ColaresОценок пока нет

- Example: Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in BendingДокумент10 страницExample: Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in BendingVarga ZoranОценок пока нет

- Bending Under Seated ConnectionsДокумент5 страницBending Under Seated ConnectionsSaeedОценок пока нет

- Shear Lug DesignДокумент19 страницShear Lug DesignariyaОценок пока нет

- 1542168570tieu Ban Ket Cau Cong Nghe Xay Dung 3 PDFДокумент62 страницы1542168570tieu Ban Ket Cau Cong Nghe Xay Dung 3 PDFI'm LuongОценок пока нет

- Design in Reinforced Concrete To BS 8110 1Документ14 страницDesign in Reinforced Concrete To BS 8110 1Anish KumarОценок пока нет

- Chapter8 - Design Theory & Procedure PDFДокумент407 страницChapter8 - Design Theory & Procedure PDFJunwhan KimОценок пока нет

- Risa Base Plate ExampleДокумент2 страницыRisa Base Plate ExampleFandy SipataОценок пока нет

- WeldДокумент7 страницWeldMuhammad Akbar Faereza NugrahaОценок пока нет

- Discussion - Yield Line Analysis of Bolted Hanging ConnectionsДокумент1 страницаDiscussion - Yield Line Analysis of Bolted Hanging ConnectionsRob TamaccioОценок пока нет

- Eurocode 4: Design of Composite Steel and Concrete StructuresДокумент19 страницEurocode 4: Design of Composite Steel and Concrete StructuresGautam BudhОценок пока нет

- Load Capacities of Threaded Hanger Rods Are Indicated in The Table BelowДокумент1 страницаLoad Capacities of Threaded Hanger Rods Are Indicated in The Table Belownt_long76Оценок пока нет

- Proposed Design Criteria For Stiffened Seated Connections To Column WebsДокумент25 страницProposed Design Criteria For Stiffened Seated Connections To Column WebsBùi Văn HợpОценок пока нет

- MonorailДокумент14 страницMonorailAnand.5Оценок пока нет

- Some Important Prestressed Silos and Reservoirs in ScandinaviaДокумент17 страницSome Important Prestressed Silos and Reservoirs in ScandinaviaRolando RojasОценок пока нет

- L-21T .2/WRE Date: 08/12/2014: Section-AДокумент20 страницL-21T .2/WRE Date: 08/12/2014: Section-AMuradОценок пока нет

- Va UserДокумент180 страницVa UserMohamed Mostafa IbrahimОценок пока нет

- DG 15 ErrataДокумент6 страницDG 15 ErrataMohamed Mostafa IbrahimОценок пока нет

- Dry Bulk Storage Tank SpecificationДокумент7 страницDry Bulk Storage Tank SpecificationMohamed Mostafa IbrahimОценок пока нет

- Δ 1.5 cm E 220000 kg.cm L 750 cm I 540000 cm4 M= 19.008 m.tДокумент1 страницаΔ 1.5 cm E 220000 kg.cm L 750 cm I 540000 cm4 M= 19.008 m.tMohamed Mostafa IbrahimОценок пока нет

- Introduction of The Bauhaus Research School: Dr. Franziska Matthes / Meeta WolffДокумент14 страницIntroduction of The Bauhaus Research School: Dr. Franziska Matthes / Meeta WolffMohamed Mostafa IbrahimОценок пока нет

- 01 - Introduction For Reinforced Concrete DesignДокумент10 страниц01 - Introduction For Reinforced Concrete DesignHany Seif-Aldien NasserОценок пока нет

- BeamsДокумент23 страницыBeamsMahmoud AboalrobОценок пока нет

- Steel Beam Column ECPДокумент9 страницSteel Beam Column ECPMohamed Mostafa IbrahimОценок пока нет

- 60 AutoCAD Tips in 60 Minutes FinalДокумент21 страница60 AutoCAD Tips in 60 Minutes FinalslajicaОценок пока нет

- 024Документ13 страниц024Emad Elhussieny100% (2)

- If You Are Viewing This in Google Docs, Press "Edit Online" To Modify The SpreadsheetДокумент1 страницаIf You Are Viewing This in Google Docs, Press "Edit Online" To Modify The SpreadsheetMohamed Mostafa IbrahimОценок пока нет

- Limcon BrochureДокумент16 страницLimcon BrochureMohamed Mostafa IbrahimОценок пока нет

- Limcon BrochureДокумент16 страницLimcon BrochureMohamed Mostafa IbrahimОценок пока нет

- Design Functions 2005 DistДокумент55 страницDesign Functions 2005 DistMohamed Mostafa IbrahimОценок пока нет

- Tek 05-05aДокумент4 страницыTek 05-05aMohamed Mostafa IbrahimОценок пока нет

- Release Notes Sap 2000 V 1801Документ12 страницRelease Notes Sap 2000 V 1801Mohamed Mostafa IbrahimОценок пока нет

- R.C. Shop DrawingsДокумент1 страницаR.C. Shop DrawingsMohamed Mostafa IbrahimОценок пока нет

- 4BEAMCOL9 SteelBeamandColumnAnalysisДокумент7 страниц4BEAMCOL9 SteelBeamandColumnAnalysises2345Оценок пока нет

- Masonry Design Method ChoicesДокумент12 страницMasonry Design Method ChoicesDjordje LadjinovicОценок пока нет

- CUSAT Old Syllabus-Mechanical EngineeringДокумент61 страницаCUSAT Old Syllabus-Mechanical Engineeringpramodkb_cusatОценок пока нет

- Final Exam "Intro To Optics": Problems & SolutionsДокумент7 страницFinal Exam "Intro To Optics": Problems & SolutionsDavid SalahОценок пока нет

- Dwarf Mast Foundation Design - 11.05.20Документ8 страницDwarf Mast Foundation Design - 11.05.20SM ConsultantsОценок пока нет

- Impact of Dust, Foliage on Millimeter Wave SignalsДокумент18 страницImpact of Dust, Foliage on Millimeter Wave SignalsrainydaesОценок пока нет

- Temperature Control & VentilationДокумент30 страницTemperature Control & VentilationAssasia HydeОценок пока нет

- 9.1 Multiple-Choice and Bimodal QuestionsДокумент18 страниц9.1 Multiple-Choice and Bimodal QuestionsQuốc Thắng NguyễnОценок пока нет

- Evaporacion y EvapotranspiracionДокумент50 страницEvaporacion y EvapotranspiracionRaul Cordova Alvarado100% (1)

- Adiabatic CoolingДокумент28 страницAdiabatic Coolingcefa84Оценок пока нет

- CV Highlights Mechanical EngineerДокумент7 страницCV Highlights Mechanical EngineerE.s. BinbillahОценок пока нет

- Lecture 16 17Документ32 страницыLecture 16 17Md. Rafiqul IslamОценок пока нет

- Product Information F737 OberonДокумент2 страницыProduct Information F737 OberonCosmic TitusОценок пока нет

- Discussed QuestionsДокумент7 страницDiscussed Questionsnafish sams souravОценок пока нет

- Electro ChemistryДокумент5 страницElectro ChemistrySush ReddyОценок пока нет

- Regional Training of Teachers on Circular Motion and Newton's LawsДокумент4 страницыRegional Training of Teachers on Circular Motion and Newton's LawsROXANNE MONDIDOОценок пока нет

- Soal GeotekДокумент12 страницSoal GeotekNurafni Nugroho PutriОценок пока нет

- LR Soot Blow PDFДокумент35 страницLR Soot Blow PDFvtbk100% (1)

- Linear AccelerationДокумент45 страницLinear AccelerationEarl averzosaОценок пока нет

- Surfaces in Precision Engineering, Microengineering and NanotechnologyДокумент17 страницSurfaces in Precision Engineering, Microengineering and NanotechnologyAdnan TorlakovićОценок пока нет

- P&I Diagram Ri-Fliessbild: MWM Beijing / Voith Paper 1329360 Tem Evo, Akr / Nox 500 T 4513Документ1 страницаP&I Diagram Ri-Fliessbild: MWM Beijing / Voith Paper 1329360 Tem Evo, Akr / Nox 500 T 4513周庆卓Оценок пока нет

- CH3 MergerДокумент45 страницCH3 MergerRuthОценок пока нет

- Small Crack Under Cyclic and Static LoadingДокумент8 страницSmall Crack Under Cyclic and Static LoadingNebiyu Samuel NebaОценок пока нет

- RPC Ultra High Strength ConcreteДокумент19 страницRPC Ultra High Strength ConcreteSivaramakrishnaNalluriОценок пока нет

- Order of ReactionДокумент11 страницOrder of ReactionBadar RizwanОценок пока нет

- ĐỀ THI THỬ SỐ 23Документ10 страницĐỀ THI THỬ SỐ 23Hải Anh Lê ThịОценок пока нет