Академический Документы

Профессиональный Документы

Культура Документы

Gantry

Загружено:

Atul BansalИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Gantry

Загружено:

Atul BansalАвторское право:

Доступные форматы

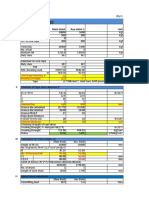

DESIGN OF GANTRY GIRDER as per IS 800:2007 (LSM)

Grade of Steel, Fe 250 MPa

ϒm0 1.1

ϒm1 1.1

Capacity of Crane 10.00 Ton

Crab Weight (Crane Capacity /5 aprox) 2.00 Ton

Factored Wheel Load, Wc 15.00 Ton 15.0 T 15.0 T

Wheel Base on Gantry Girder, c 3.0 m

Span of Gantry Girder, L 6.0 m 3.0m

Max Shear Condition, One Wheel on Bracket 22.50 Ton Max Shear

Condition 6.0m

Va= 28.8 T

Impact 25% 5.63 Ton

Self Weight of Gantry Girder 0.65 Ton

Max Shear on Bracket, V 28.77 Ton

15.0 T 15.0 T

Max Vertical Bending Moment Left End Right End 1.5 1.5

Dist. of First Wheel from 0.75 5.250

Dist. of second Wheel from 3.75 2.250 0.75 2.250

Reaction Due to Self Weight of Girder 0.32 Ton 0.32 Ton

Reaction Due to Wheel Load 18.75 Ton 11.25 Ton B.M. Condition 3.0 m 3.0 m

Total Reaction 19.07 Ton 11.57 Ton 0.75 0.75

Bending Moment 14.31 T-m 26.04 T-m

Max Bending Moment 26.04 T-m

Longitudinal Force on Girder, 5% of Individual Wheel Load 0.75 Ton

Reaction due to Longitudnal force 0.05 Ton

Longitudnal Moment Due to drag force 0.11 T-m

Impact 25% 6.51 T-m

Max Vertical Bending Moment, Mux 32.66 T-m

So, Zreq = 296910000 mm³

Lateral Force on Gantry Girder

10% of Surge load on Individual Wheel, (Factored) 0.45 Ton

Lateral Shear Force due to surge Load, Vy 0.68 Ton

Max Horizontal Bending Moment, Muy 0.76 T-m

So, Zreq = 6903409 mm³

Member for Gantry Girder

ISMC ISMB

ISMC 300 ISMB 450 Y

Moment of Inertia about X-Axis Ixx, cm 6362.80 30390.80

Moment of Inertia about Y-Axis Iyy, cm⁴ 310.80 834.60 CV

CV ISMC 300

Section Modulas about X-Axis ⁴

Zxx, cm³ 424.20 0.00 X X

Section Modulas about Y-Axis Zyy, cm³ 46.80 111.20 ISMB 450

Radious of Gyration about X-Axis Rxx, cm 11.81 18.15

Radious of Gyration about Y-Axis Ryy, cm 2.61 3.01

Center of Gravity (for Channel only) Cyy, cm 2.36 CV

Area A, cm² 45.64 92.27 Y

Depth of Section mm 300.00 450.00

Width of Flange mm 90.00 150.00

Thk of Flange mm 13.60 17.40

Thk of Web mm 7.60 9.40

Weight of Member kg/m 35.80 72.40

Calculation of Composite Section Property

Total Area of Gantry Girder 13791 mm²

Over all Depth of Section, D' 457.60 mm

Distance of Centroidal Axis form Tension Edge,ӯ 294.17 mm

h1 = ӯ -(D'/2) 69.17 mm

h2 = D' - ӯ - Cyy 139.83 mm

Dist. of Centroidal Axis from Comp. Edge (D'- ӯ-tch), h3 163.43 mm

Radius of Gyration for Comp. Sec. Kyy 72.24 mm

MOI of Full Comp. Section about X-Axis, Ixx 440399764 mm

MOI of Full Comp. Section about Y-Axis, Iyy 71974000 mm ⁴

MOI of Tension flange of Composite Sec about Y-Axis,Itf 4893750 mm ⁴

MOI of Compression flange of Composite Sec about Y-Axis,Icf 68521750 mm⁴

Section Modulas of Comp. Section about X-Axis Zzb 1497110 mm³⁴

Section Modulas of Comp. Section about X-Axis Zzt 2694673 mm³

Section Modulas of Comp. Section about Y-Axis Zyy 535400 mm³

Section Modulas of Comp. Section about Y-Axis Zcf 456812 mm³

Servicebility Deflection Due to Vertical wheel Load

Limit is < L/750 8.00 mm

Vertical Δc = Wc L³[(3a/4L) - (a³/L³)]/ (6EI) 7.02 mm OK

a = (L - c)/2 1.5 m

Leteral Δc = Wc L³[(3a/4L) - (a³/L³)]/ (6EI) 1.35 mm OK

Calculation for Plastic Modulus

Plastic Neutral Axis, dp 242.77 mm

Dist. Of Plastic neutral axis from bottom of girder 467.77 mm

Dist. Of Plastic neutral axis from Top of girder -10.17 mm

Plastic Section Modulus Below Equal Axis, Σ Aӯ = 2151461 mm³

Plastic Section Modulus Above Equal Axis, Σ Aӯ = -217372 mm³

Section Modulus for section below Plastic NA Zpx = 1934089 mm³

Section modulus of top flange Zpy = 522766 mm³

Check for Plastic Section

b/t of the flange of I beam 4.0 PLASTIC SECTION

d/t of the web of I beam 44.2 PLASTIC SECTION

b/t of the flange of Channel 6.1 PLASTIC SECTION

Check for Moment Capacity

Local Moment Capacity Check

1.2 Zxb fy/1.1 = 40.83 T-m

Mdx = fy Zp/1.1 43.96 T-m

Value to be considered lesser of above two, Mdx 40.83 T-m

Mdy = fy Zpy/1.1 11.88 T-m

1.2 Zy fy/1.1 = 12.46 T-m

Value to be considered lesser of above two, Mdy 11.88 T-m

Combined Local Capacity Check,(Mux/Mdx)+(Muy/Mdy)<1 0.864 SAFE

Max Vertical Bending Moment, Mux 32.66 T-m

Max Horizontal Bending Moment, Muy 0.76 T-m

(Calculation Based on IS800: Cl 8.2.2)

Chaeck for Buckling Resistance, Mdx = βb Zp fbd 39.50 T-m SAFE

Mcr = 1454631127.16 N/mm

C1 = 1.132 TABLE 42

E 200000.0

MOI of Full Comp. Section about Y-Axis, Iyy 71974000 mm

Over all Depth of Section, D' 457.60 mm ⁴

KL 6000.00 mm

Radius of Gyration for Comp. Sec. Kyy 72.24 mm

Thickness of flange, tf 25.00 mm

For Plastic & Compact Section, βb 1.0 (IS800: Cl 8.2.2)

Imperfaction parameter, αLT 0.21 (IS800: Cl 8.2.2)

Non Dimensional Slenderness ratio, λLTX 0.58

Along X-direction, ØLTX = 0.5[1 + αLT (λLTX - 0.2) + λ²LTX] 0.706

Bending Stress Reduction Factor, χLTX 0.899 (IS800: Cl 8.2.2)

fbd = fy χLTX/ϒm0 204.24 MPa

Chaeck for Biaxial Bending, (Mux/Mdx)+(Muy/Mdy)<1 0.89 T-m SAFE

Mdy = 11.88 T-m

Mdx = 39.50 T-m

Max Vertical Bending Moment, Mux 32.66 T-m

Max Horizontal Bending Moment, Muy 0.76 T-m

Check For Shear Capacity

Max Shear on Bracket, V 28.77 Ton SAFE

Shear Capacity = Av fyw / (√3 X 1.1) 55.50 Ton NO REDUCTION IN

0.6 x Shear Capacity = 33.30 Ton MOMENT CAPACITY

Weld Design

Req. of Weld Q = V A ӯ /Iz 487 N/mm

Max Shear on Bracket, V 28.77 Ton

Area 4564 mm²

Dist. of Centroidal Axis from Comp. Edge (D'- ӯ-tch), h3 163.43 mm

MOI of Full Comp. Section about X-Axis, Ixx 440399764 mm

⁴

Design strength of Fillet Weld, fwd = fwn / ϒmw 96.2

For Site weld, ϒmw = 1.5

fwn = fu/√3 144.3

fu = 250.0

Lateral Shear Force due to surge Load, Vy 0.68 Ton SAFE

Lateral Shear Capacity Vny = Av fyw / (√3 x 1.1) 64.16 Ton

Av 4890 mm²

Web Buckling

Length of Bearing b1 150.00 mm OK

n1 232.60 mm

Web Slenderness λ = 2.5 d/t 139.7

Stress reduction Factor 0.768 Table 8; IS 800:2007

fcd 174.55 MPa

Buckling Resistance = (b1-n1)t fcd 62.77 Ton SAFE

Web Bearing

Req Minimum Stiff Bearing Rx/(t fyw/1.1)-n2 41.19 mm

n2 93.50 mm

Max. Shear on Bracket, V = Rx 28.77 Ton

Вам также может понравиться

- Thermal Physics Questions IB Question BankДокумент43 страницыThermal Physics Questions IB Question BankIBBhuvi Jain100% (1)

- Design of Crane Runway Beam (10 Tons)Документ5 страницDesign of Crane Runway Beam (10 Tons)maris_sasec100% (1)

- Design of Box CulvertДокумент4 страницыDesign of Box CulvertPriodeep ChowdhuryОценок пока нет

- Purlin & Sagrod Design (NSCP 2015)Документ7 страницPurlin & Sagrod Design (NSCP 2015)Glaizel Morcilla0% (1)

- Design of Superstructure - 25mДокумент243 страницыDesign of Superstructure - 25mmrinal kayal0% (1)

- Ergonomics For The BlindДокумент8 страницErgonomics For The BlindShruthi PandulaОценок пока нет

- Retaining Wall Design TemplateДокумент18 страницRetaining Wall Design TemplateReuben James BangaoilОценок пока нет

- Final Stress SummДокумент3 страницыFinal Stress SummSharyn PolleyОценок пока нет

- Design Calculation For Column 750Kn, 140Knm, 20Knm Parameter Unit Column Segment Oa Db1 AbДокумент30 страницDesign Calculation For Column 750Kn, 140Knm, 20Knm Parameter Unit Column Segment Oa Db1 AbJanaka KarunarathnaОценок пока нет

- RC Design For STPДокумент14 страницRC Design For STPafiqОценок пока нет

- Himesh PSD21140Документ3 страницыHimesh PSD21140Himesh PanchalОценок пока нет

- Sub STR 2Документ8 страницSub STR 2Poshan DhunganaОценок пока нет

- Design of Box CulvertДокумент6 страницDesign of Box CulvertAasif ShaikОценок пока нет

- Bending Moment Calculation - Anticreep Center, One Cantilever, Tangent TrackДокумент7 страницBending Moment Calculation - Anticreep Center, One Cantilever, Tangent TrackAnkit AgarwalОценок пока нет

- Box CulvertДокумент6 страницBox CulvertanufabdesignsОценок пока нет

- TestДокумент2 страницыTestSharyn PolleyОценок пока нет

- Load Calculation: Item Description Contributing Width Contributing Height Aero Dynamic Drag CoefficientДокумент12 страницLoad Calculation: Item Description Contributing Width Contributing Height Aero Dynamic Drag CoefficientGaneshPerumalОценок пока нет

- Structural Design of 3t Jib CraneДокумент2 страницыStructural Design of 3t Jib Cranedebasish bhowmickОценок пока нет

- 6 - Abutment - A2 BargarhДокумент197 страниц6 - Abutment - A2 BargarhBINAY KUMARОценок пока нет

- Resume Calculation Analysis MOTO 23m - Urban Area - R.0 - 28072022Документ15 страницResume Calculation Analysis MOTO 23m - Urban Area - R.0 - 28072022mochganafiaОценок пока нет

- Beam CalculationДокумент49 страницBeam CalculationRobin Charles SamuelОценок пока нет

- Structural Design of Single Cell Box Culvert Vijayanagaram: Input DataДокумент6 страницStructural Design of Single Cell Box Culvert Vijayanagaram: Input Datakiran raghukiranОценок пока нет

- GratingДокумент4 страницыGratingrammohan100% (1)

- Lower Column LiftingДокумент1 страницаLower Column LiftingSrikanth EjumandlaОценок пока нет

- Cold Formed Sections DesignДокумент17 страницCold Formed Sections DesignSourabh Das100% (1)

- Monorail Structural AnalysisДокумент5 страницMonorail Structural AnalysisSherwin PonsОценок пока нет

- Structural MembersДокумент33 страницыStructural MembersALZHAMMER MANUPACОценок пока нет

- Tripper Belt Conveyor CalculationДокумент5 страницTripper Belt Conveyor Calculationbashok20Оценок пока нет

- Design of Gantry ShedsДокумент4 страницыDesign of Gantry ShedsJulian TremontОценок пока нет

- ROB Pier DesignДокумент18 страницROB Pier DesignTransportation Dept. SatyaVaniОценок пока нет

- Class A LoadingДокумент120 страницClass A LoadingAakash RastogiОценок пока нет

- Etabs 2016 16.2.1 License # 143Lqux7Krx7Jml: T Ctied Cspiral Vns Vs Vjoint 0Документ1 страницаEtabs 2016 16.2.1 License # 143Lqux7Krx7Jml: T Ctied Cspiral Vns Vs Vjoint 0galatiansОценок пока нет

- 10MT Gantry DesignДокумент7 страниц10MT Gantry Designvinit soodОценок пока нет

- Geometry of MS Pipe Staging For PSC GirderДокумент5 страницGeometry of MS Pipe Staging For PSC Girderqs.saidurrahmanОценок пока нет

- BK 4 (CC 51400)Документ9 страницBK 4 (CC 51400)hasan arifОценок пока нет

- Himesh PanchalДокумент12 страницHimesh PanchalHimesh PanchalОценок пока нет

- (From Is 875-Part 3) : Pxl/AwДокумент2 страницы(From Is 875-Part 3) : Pxl/AwSantosh BapuОценок пока нет

- Proracun OsoviniceДокумент9 страницProracun OsoviniceThe bossОценок пока нет

- Well-Design 202Документ4 страницыWell-Design 202Amit Kumar PaulОценок пока нет

- JK42HS40 1004acДокумент1 страницаJK42HS40 1004acjuanОценок пока нет

- Superstructure Sketch: Fig. Superstructure Dimensions (All Dimensions Are in MM)Документ14 страницSuperstructure Sketch: Fig. Superstructure Dimensions (All Dimensions Are in MM)Himal KafleОценок пока нет

- Design of PurlinsДокумент4 страницыDesign of PurlinsNicole PerezОценок пока нет

- Planning Criteria Location Petrol Filling StationДокумент2 страницыPlanning Criteria Location Petrol Filling StationobanizeОценок пока нет

- Load Data and EOT Crane Load-20TДокумент6 страницLoad Data and EOT Crane Load-20TKiran KumarОценок пока нет

- QY20B Brand New PDFДокумент3 страницыQY20B Brand New PDFDavid GomezОценок пока нет

- Given: 3. Purlins DesignДокумент3 страницыGiven: 3. Purlins DesignJake CortezОценок пока нет

- Design of R.C.C. Retaining WallДокумент5 страницDesign of R.C.C. Retaining WallAmit KushwahaОценок пока нет

- Cable Slickline UHT CarbonДокумент1 страницаCable Slickline UHT CarbonRafael EspinosaОценок пока нет

- Design Test Setup Arrangement For Initial Vertical Pile Load Test A Design of Main Beam Condition 1 - After Loading ConditionДокумент33 страницыDesign Test Setup Arrangement For Initial Vertical Pile Load Test A Design of Main Beam Condition 1 - After Loading ConditionSantosh ZunjarОценок пока нет

- 20 5T PDFДокумент3 страницы20 5T PDFMUBASHSHIR HELALОценок пока нет

- Conveyor Design Summary: Copper Ore 1800 1800 30 15 100 MM 4860 Tonnes/hr 3 M/s 1800 8 MM 281 4 MMДокумент20 страницConveyor Design Summary: Copper Ore 1800 1800 30 15 100 MM 4860 Tonnes/hr 3 M/s 1800 8 MM 281 4 MMiman zareieОценок пока нет

- ZTC250H431 27CSzxFDGHAWERS4GSZDTQ78JHYY英文技术规格书Документ17 страницZTC250H431 27CSzxFDGHAWERS4GSZDTQ78JHYY英文技术规格书RajОценок пока нет

- G 3 EccДокумент8 страницG 3 EcckuttyОценок пока нет

- Torque & Drag Report TC-34Документ26 страницTorque & Drag Report TC-34Ferney BohorquezОценок пока нет

- General Material: 1000 1,00 440 - 18 Katkı 1500 20,0Документ2 страницыGeneral Material: 1000 1,00 440 - 18 Katkı 1500 20,0hasan arifОценок пока нет

- Trunnion 6 TonДокумент3 страницыTrunnion 6 TonEngr Khurram Jaan RamayОценок пока нет

- 4 Bar Linkage Calculator v3.0: Vehicle Specifications: Suspension Geometry: Geometry SummaryДокумент16 страниц4 Bar Linkage Calculator v3.0: Vehicle Specifications: Suspension Geometry: Geometry SummaryWagner MenezesОценок пока нет

- 99.450 2.500 95.775 0.270 90.260 Anticlockwise Moment +ve: SL - No. 1Документ2 страницы99.450 2.500 95.775 0.270 90.260 Anticlockwise Moment +ve: SL - No. 1Anonymous wosn1lyОценок пока нет

- General Material: 1000 1,00 440 - 18 Katkı 1500 20,0Документ2 страницыGeneral Material: 1000 1,00 440 - 18 Katkı 1500 20,0hasan arifОценок пока нет

- Design of Gantry GirdersДокумент2 страницыDesign of Gantry Girdersvikas WaghmareОценок пока нет

- Transportador FernandaoДокумент9 страницTransportador Fernandaobraviross_418157489Оценок пока нет

- A Lei Do Sucesso Napoleon Hill Download 2024 Full ChapterДокумент23 страницыA Lei Do Sucesso Napoleon Hill Download 2024 Full Chapterdavid.brown752100% (12)

- History of Drugs (Autosaved)Документ68 страницHistory of Drugs (Autosaved)Juan TowTowОценок пока нет

- Acfrogb0i3jalza4d2cm33ab0kjvfqevdmmcia - Kifkmf7zqew8tpk3ef Iav8r9j0ys0ekwrl4a8k7yqd0pqdr9qk1cpmjq Xx5x6kxzc8uq9it Zno Fwdrmyo98jelpvjb-9ahfdekf3cqptДокумент1 страницаAcfrogb0i3jalza4d2cm33ab0kjvfqevdmmcia - Kifkmf7zqew8tpk3ef Iav8r9j0ys0ekwrl4a8k7yqd0pqdr9qk1cpmjq Xx5x6kxzc8uq9it Zno Fwdrmyo98jelpvjb-9ahfdekf3cqptbbОценок пока нет

- Tan vs. Macapagal, 43 SCRAДокумент6 страницTan vs. Macapagal, 43 SCRANikkaDoriaОценок пока нет

- Summar Training Report HRTC TRAINING REPORTДокумент43 страницыSummar Training Report HRTC TRAINING REPORTPankaj ChauhanОценок пока нет

- PETE 689 Underbalanced Drilling (UBD) : Well Engineering Read: UDM Chapter 5 Pages 5.1-5.41Документ74 страницыPETE 689 Underbalanced Drilling (UBD) : Well Engineering Read: UDM Chapter 5 Pages 5.1-5.41Heris SitompulОценок пока нет

- K.M Nanavati v. State of MaharashtraДокумент6 страницK.M Nanavati v. State of MaharashtraPushpank PandeyОценок пока нет

- Upload A Document To Access Your Download: The Psychology Book, Big Ideas Simply Explained - Nigel Benson PDFДокумент3 страницыUpload A Document To Access Your Download: The Psychology Book, Big Ideas Simply Explained - Nigel Benson PDFchondroc11Оценок пока нет

- Adm Best Practices Guide: Version 2.0 - November 2020Документ13 страницAdm Best Practices Guide: Version 2.0 - November 2020Swazon HossainОценок пока нет

- HRM and The Business EnvironmentДокумент18 страницHRM and The Business Environmentsuzzette91Оценок пока нет

- Effect of Intensive Health Education On Adherence To Treatment in Sputum Positive Pulmonary Tuberculosis PatientsДокумент6 страницEffect of Intensive Health Education On Adherence To Treatment in Sputum Positive Pulmonary Tuberculosis PatientspocutindahОценок пока нет

- E 05-03-2022 Power Interruption Schedule FullДокумент22 страницыE 05-03-2022 Power Interruption Schedule FullAda Derana100% (2)

- Ivler vs. Republic, G.R. No. 172716Документ23 страницыIvler vs. Republic, G.R. No. 172716Joey SalomonОценок пока нет

- A Study On Investors Perception Towards Sharemarket in Sharekhan LTDДокумент9 страницA Study On Investors Perception Towards Sharemarket in Sharekhan LTDEditor IJTSRDОценок пока нет

- Contracts 2 Special ContractsДокумент11 страницContracts 2 Special ContractsAbhikaamОценок пока нет

- Operational Effectiveness + StrategyДокумент7 страницOperational Effectiveness + StrategyPaulo GarcezОценок пока нет

- Rosenberg Et Al - Through Interpreters' Eyes, Comparing Roles of Professional and Family InterpretersДокумент7 страницRosenberg Et Al - Through Interpreters' Eyes, Comparing Roles of Professional and Family InterpretersMaria AguilarОценок пока нет

- Life&WorksofrizalДокумент5 страницLife&WorksofrizalPatriciaОценок пока нет

- Evidentiary Value of NarcoДокумент2 страницыEvidentiary Value of NarcoAdv. Govind S. TehareОценок пока нет

- Kodak Case StudyДокумент8 страницKodak Case StudyRavi MishraОценок пока нет

- Oda A La InmortalidadДокумент7 страницOda A La InmortalidadEmy OoTeam ClésОценок пока нет

- Sophia Vyzoviti - Super SurfacesДокумент73 страницыSophia Vyzoviti - Super SurfacesOptickall Rmx100% (1)

- Critical Review For Cooperative LearningДокумент3 страницыCritical Review For Cooperative LearninginaОценок пока нет

- Digital Sytems Counters and Registers: Dce DceДокумент17 страницDigital Sytems Counters and Registers: Dce DcePhan Gia AnhОценок пока нет

- Department of Education: Republic of The PhilippinesДокумент2 страницыDepartment of Education: Republic of The PhilippinesShailac RodelasОценок пока нет

- Far Eastern University-Institute of Nursing In-House NursingДокумент25 страницFar Eastern University-Institute of Nursing In-House Nursingjonasdelacruz1111Оценок пока нет

- AdvacДокумент13 страницAdvacAmie Jane MirandaОценок пока нет

- Capgras SyndromeДокумент4 страницыCapgras Syndromeapi-459379591Оценок пока нет