Академический Документы

Профессиональный Документы

Культура Документы

A Theoretical Study On Surface Finish, Spacing Between Discs and Performance of Tesla Turbine

Загружено:

Somyadeep DuttaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

A Theoretical Study On Surface Finish, Spacing Between Discs and Performance of Tesla Turbine

Загружено:

Somyadeep DuttaАвторское право:

Доступные форматы

ISSN (Online) 2393-8021

IARJSET ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

National Conference on Emerging Trends in Engineering and Technology (NCETET’16)

Lourdes Matha College of Science & Technology, Thiruvananthapuram

Vol. 3, Special Issue 3, August 2016

A Theoretical Study on Surface Finish, Spacing

between Discs and Performance of Tesla Turbine

Rakesh Jose 1, Ajay Jose 2, Albin Benny 3, Asbin Salus 4, Bilbin Benny 5

Asst. Professor, Dept. of Mechanical Engg., Viswajyothi College of Engg & Technology, Vazhakulam, Cochin, India1

Viswajyothi College of Engg & Technology,Vazhakulam, Cochin, India 2, 3, 4, 5

Abstract: This turbine, invented by Nikola Tesla in (1856-1943), is a bladeless turbine. Tesla turbine disks and a

flexible test rig was designed and manufactured, and experimental results are studied. An analysis of the performance

and efficiency of the tesla turbine is carried out. The entire study of the flexible test rig has been explained in detail. In

this Turbine there are no blades, instead parallel and closely spaced discs were used. Resistance to flow of fluid

between the plates results in the energy transfer to the shaft on one side. High velocity water enters the disk at the inlet

pack through nozzle path tangent towards the outer edge of the discs. Convergent nozzle imparts higher velocity water

jet tangentially on disc. Lower-energy water spirals towards the exit port at the centre, adhesion, drag and centrifugal

forces continue to convert the kinetic energy to rotate the shaft. The results of the study represent various steps towards

the development of boundary layer turbine. It has been determined that the surface roughness and spacing has a major

part in the performance of the tesla disc turbines significantly. Efficiency can be improved at least up to 45%, which

has been deemed achievable.

Keywords: Boundary layer Turbine, disc Turbine, bladeless, Tesla. Turbine

I. INTRODUCTION

When an aircraft flies through the air, at high speed, there fluid mechanics. They considered the relative motion of

is a thin layer of air that sticks to the wing. This layer of rotating surfaces which sets up the transport equations

air goes the same speed as the airplane. There is describing the flow between parallel rotating disks and

then sheared action or shear plane between that boundary estimated the boundary layer thickness in laminar and

layer and the surrounding air around the aircraft. On that turbulent regimes, leading to expressions that gives the

shear plane is where the drag is formed that holds the width between consecutive disks. H.S. Couto shows how

aircraft back. Aerodynamics tells us that if we could, wave to calculate the total number of disks required for the

a magic wand over an aircraft and, eliminate or minimize desired performance. Finally behavior of the device acting

boundary layer drag the aircraft could fly 40% faster. In as an air compressor or water pump is looked up . Nikola

aerodynamics, boundary drag layer is totally unwanted Tesla [2] has filed a patent for a Turbine which uses

precept. But, Tesla was able to turn that precept around smooth rotating disks inside a volute casing. In his patent,

180degrees. Tesla perceived that boundary layer drag used Tesla described the forces of his machinery to be

to do something useful. High velocity water enters dependent on the fluid properties of adhesion and

tangentially to the outer periphery of the disk pack viscosity. Several turbines were designed and built by

through the inlet nozzle; it forms a boundary layer on Tesla but they were not commercially feasible at that time.

either side of the discs. The pressure ratio is pushing it Lack of sufficient manufacturing instruments, difficulties

towards the center of the turbine. It forms a helical path in handling high speeds, and dissipation of heat were the

down into the center of the device, and exit in the center, reasons for multiple disk devices not being developed

after it has transmitted all of its energy to the discs through further .Piotr Lampart [3] showed results of the design

the boundary layer drag. In this present work, A Tesla disc analysis of another Tesla bladeless turbine which could be

turbine and a flexible test rig designed and manufactured used for a co-generating micro-power plant of heat

by simple stock material. Experimental results carried out capacity 20 kW, which operated in an organic Rankin

by using water medium. The overall design of the turbine cycle using a low-boiling medium. Results showed

is very flexible allowing parameters to be varied in order interesting features in the flow parameters in the turbine

that their effect on the performance of the turbine can be inter disk space. The calculated efficiency of flow of the

measured. It is possible to change the number of discs, investigated turbine models show that the best solutions

disc spacing etc. could be as good as classical small bladed turbines.

II. LITERATURE REVIEW Warren Rice [4] shows the most important parameters that

affect the efficiency and performance of disc turbine. Rice

J.B. Duarte, H.S. Couto, and D. Bastos-Netto [1].reviews constructed six disks turbine and conveys some aspects of

the basic physical principles behind Tesla Turbine, using them, with the main purpose as to determine the feasibility

Copyright to IARJSET DOI 10.17148/IARJSET 235

ISSN (Online) 2393-8021

IARJSET ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

National Conference on Emerging Trends in Engineering and Technology (NCETET’16)

Lourdes Matha College of Science & Technology, Thiruvananthapuram

Vol. 3, Special Issue 3, August 2016

of this kind of turbo machinery. Starting from Tesla´s

patent, the turbine was operated with compressed air

exhausting into the atmosphere, some changes with the

angle of the nozzle and the use of a supersonic nozzle

were made. Later, some improvements were made by

reducing the gap. The comparison between analytical data

and results from these experiment shows that the

geometry, speed combination and flow rate used in the

turbine where not close to those values indicated by the

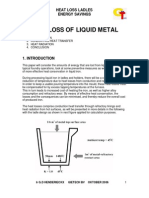

analyses for optimum turbine efficiency. Rice observed Fig. 1: Nozzle Arrangement – line diagram for Test Rig

max efficiency of 24%. By applying Bernoulli’s equation, at point1 and at point2

Warren Rice and K. Boyd [5] studied laminar flow of a P1 / ρ g + V12 /2g + Z1 = P2 / ρ g + V22 /2g + Z2 (1)

fluid which is incompressible between rotating discs. K.

Boyd did propose complete solution for inlet region for Where,

various inlet conditions .A complete statement of problem P1 = Pressure at point 1

is formulated from the Naiver stokes equation with three V1 = velocity at point1

parameters flow rate, Reynolds number and tangential Z1 = Z2 Pressure head (at same elevation)

velocity. Both the turbulent and laminar flow considered P2 = Pressure at point 2

and suggested torque, Efficiency, Power and Pressure drop V2 = velocity at point 2

are the function of flow, velocity and Reynolds number. ρ = water density =1000kg/m3 g = 9.81m/s2

Almost every literature has considered the fluid to be

incompressible and laminar. In general, it is observed that We know the flow rate i.e. Q = 0.22 lit/s=0.00021m3/s and

the efficiency of the rotor can be very high, almost equal P1 = 19lb/ in2 = 1.18 bar

to that achieved by conventional bladed rotors. Although But, by continuity equation.

any kind of fluid can be used in Tesla turbine, most of the

literature uses a Newtonian fluid for simplification except Q = A1V1 = A2V2 (2)

for experimental test .From the literature, we establish the

parameters that affects the performance of turbine namely Where A2 = area of cross section at pt 2 = 21 mm2

Distance between the discs, Number of discs, Discs

surface roughness, Number of nozzles. The following A1 = π / 4 * D2 = 3.14 / 4 * 0.0152 = 0.000225m2

assumptions are considered for the V1 = Q/A1 = 0.00022 /0.000225 = 0.98 m/s

experimental work. V2 = Q/A 2 = 0.00022/ (22 * 10 -6 ) = 10.48 m/s

i) Steady flow

ii) Incompressible fluid flow Now put this value of V1 and V2 in equation (1) to get P2.

iii) body forces are neglected But Z1 = Z2, both the pt at same level. Now (1) becomes.

iv) Full admission of working fluid in the outer P / ρ g + V1 2 /2g = P / ρ g + V2 2 /2g

periphery of the discs.

P2 = [(1.18 * 105 /9810 + 0.982/19.62) - (10.482 / 19.62)]

III. THEROTICAL ANALYSIS 9810

= 0.45 Bar

Inlet Nozzle construction fabricated as shown in fig 1 for

Test Rig. Water incompressible fluid selected for Now P = F/A .

performance measurement with assuming flow is steady

flow. Constant Parameters: We know the value of P2; Put this value in above equation

to get Force acting on discs thickness.

Spacing between Discs: 2mm F = P2 * A2 = 69622.74 *20 * 10-6 = 1.532 N (force acting

Medium: Water on 12mm area only)

Disc thick: 2mm But, we know the jet force formula from pelton turbine

Outlet Nozzle Size: 32mm2

Material of Discs: SS304 F = ρ A(V - U) 2 COS Ø (3)

Disk Dia: 152mm

Inlet Size: 21mm2 Where, A = jet area = A2 = 21 mm2,

No of discs: 6 V = velocity of jet = V2,

Surface Finish: smooth U = Relative velocity of discs. & Ø = 10º angle of jet.

Medium: Water Now put the values in above equation to get U

Flow rate: 0.22lit/s line

Pressure: 18lb/in2 (V-U)2= 1.532 /(1000*21*10-6 *0.98) = 12.47

Copyright to IARJSET DOI 10.17148/IARJSET 236

ISSN (Online) 2393-8021

IARJSET ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

National Conference on Emerging Trends in Engineering and Technology (NCETET’16)

Lourdes Matha College of Science & Technology, Thiruvananthapuram

Vol. 3, Special Issue 3, August 2016

(V - U) = 8.66 effect on the overall performance of the turbine. The

U = 1.81 m/s features of this turbine Test Rig designed and

We know the angular momentum for rotating part manufactured according to the experience noted from the

reviews. The disc diameter is 152mm (6in), the

L = mrU (4) thicknesses of each of the discs are 2mm, and rotor-to-

housing diametrical clearance is 1mm. An overall view of

Where L = angular momentum, r= radius of disk. the turbine is shown in Fig. 1(a). The discs have 2 central

outlet port, since this configuration was observed to be

But, L = Iω (5) more efficient by Rice [4].

Where I = moment of inertia & ω = Angular velocity

In this case,

I = ISHAFT + IDISCS (6)

I SHAFT =MR2

Where M= mass of the shaft=1.09kg, R= Radius of shaft =

15mm.

I SHAFT = 1.082*(15/100)2 * 9.81 = 0.0238 N/mm2 (7)

Fig. 2: Parts of Multiple disc Turbine.

2 2

I = 1/2 * M d (a +b ) (8)

The nozzle was designed so as to increase the kinetic

Where, Md= Mass of disk= 0.280 kg, energy of the flowing medium by making use of its

a = inner radius of disc = 30mm, internal energy and pressure and the nozzle must supply

b= outer radius of disc = 76mm. effective mass flow on each disc & space. Nozzle is

designed by keeping in mind coefficient of discharge and

I DISC = 1/2 * 0.280(0.0152+0.0762)= 0.032Nm2 energy conservation law . Like in venturimeter, it imparts

For 6 discs equal jet on each disc and with its convergent shape it

increases the kinetic energy of the jet as shown in fig.3.

I DISCS = 0.032 * 6 = 0.192Nmm2 The diameter of the central hole is 30mm. In order to

Now from (6) include the outlet of the fluid, the shaft is supported by

I = 0.032 + 0.192 = 0.195N/mm 2 means of bearings inside it

now, from (4) & (5) L = Iω

ω = mrU / I = (2.73 * 0.076 * 1.81 )/ 0.195

ω = 19.20 rad /s For 6 discs

But,

ω = 2πN / 60 (9)

N = 19.20 X 3.75 X 60 / 6.28 = 183.44 rpm.

Now Torque T = F * R (10)

From equation (3) & (10)

T = 1.532 * 0.076 = 0.116Nmm.

Now, Fig. 3: Cross Section of Test Rig

P = 2 πNT / 60 (11)

By putting the values of N and T, we get An Effect of Spacing between Discs and Surface finish on

the Performance of Disc Turbine The experimental test rig

P = (6.28 X 183.44 X0.116)/60 was designed to study the Turbine performance as in

P = 2.22 watt. Fig.4.The test rig used for the present work consists of a 3

cylinder piston pump. Rubber O-rings are also used for air

IV. EXPERIMENTAL SET UP tight joint between casing and side plate. The shaft with

disk supported on two bearings. In previous studies

The design of the turbine is very flexible as shown in fig.2, medium used was air, but in this work, water is considered

which allows varying the parameters to measure their as the medium. And at the constant flow rate, to provide

Copyright to IARJSET DOI 10.17148/IARJSET 237

ISSN (Online) 2393-8021

IARJSET ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

National Conference on Emerging Trends in Engineering and Technology (NCETET’16)

Lourdes Matha College of Science & Technology, Thiruvananthapuram

Vol. 3, Special Issue 3, August 2016

high-pressure water we use positive displacement pump as Using this for changing parameters used by the turbine ,

in fig.4. The test rig is developed such that, it can measure these investigation permits, variations in the number of

the various parameters that are required to determine the discs to get the Performance comparisons data. In this

performance of the Turbine. Flow rate varies from the study five variations in discs spacing and three variations

9Lit/m to 30lit/m. in surface roughness is considered. Same constant

parameters are considered in theoretical analysis. Variable

parameters are the spacing between discs, flow and surface

finish of the discs.

V. RESULT AND DISCUSSION

Nozzle size are designed in such way that it should impart

equal forces on all the discs for minimum spacing and also

for maximum spacing between the discs. After conducting

all the experiments according to the experimental matrix,

we studied that this turbine works efficiently for six discs.

Due to the nozzle opening, for three discs jet imparted on

6mm2 areas only and for six discs jet area imparted on

12mm2 area means six disc pack use more jet forces

Fig. 4: Experimental Set up.

comparatively three discs. Then all the experiments were

carried out for six discs and by varying spacing like 0mm

In this study 4 variations in the number of discs used for

0.55mm, 1.4mm, 2.60mm, 3mm Fig 5a & 5b shows the

same set up. Experiments carried out 6 discs and spacing

variation of speed with respective flow. As flow increases

0.55mm, 1.10mm, 1.4mm, 2.6mm, 3mm. And surface

speed increases. But when spacing increases the speed

finish varies from smooth to 500ra.

decreases, because for Minimum spacing, friction or shear

Design of Experiments carried out in the following

force between disc and jet increases, rotating disc form a

manner. Spiral grooves machined on discs surfaces by

boundary layer around the wall and jet also form boundary

using lathe machine and fixture.

around it. Jet high velocity boundary layer drags the discs.

Disc is rotating comparatively at low speed hence disc

TABLE 1 EXPERIMENTAL DESIGN MATRIX

trying to oppose jet velocity. Due to this shear forces

developed between two boundary layers. And Kinetic

energy of jet utilized for disc rotation.

Flow + = 30Llit/m and

Flow - = 9.2lit/m Fig.5a: A plot of Flow v/s Speed for 6 smooth discs and

Spacing + = 3mm and Spacing - = 0.55mm 2.5mm spacing

Surface finish + =smooth and Surface finish - = 500ra

For 2.5 mm spacing, more amount of jet water passing

A. Determination of Speed of the Rotor. through the gap comparatively 0.5mm spacing, boundary

In the test rig used in this research, the speed output (N) layer forms between discs, but jet boundary layer and disc

can be obtained directly by means of a Taco Meter. The boundary layer apart from each other. Jet uses the

methodology for the use of this device is simple. At the maximum kinetic energy to carry the fluid between discs.

both end the shaft centering operation done which is And flow rate difference is also observed at the outlet. For

provision to insert a tip of Taco Meter. This method was minimum spacing flow rate is comparatively less than

found to be accurate and inexpensive. Then angular maximum spacing. For 0.55 mm spacing, boundary layer

velocity obtained by using formula. forms between discs, but jet boundary layer and disc

boundary layer overlap with each other. Jet uses the

ω = 2πN / 60 (12) maximum kinetic energy to drag discs.

Copyright to IARJSET DOI 10.17148/IARJSET 238

ISSN (Online) 2393-8021

IARJSET ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

National Conference on Emerging Trends in Engineering and Technology (NCETET’16)

Lourdes Matha College of Science & Technology, Thiruvananthapuram

Vol. 3, Special Issue 3, August 2016

starting the frictional force between the drum and the band

will increase the force reading on one balance and

decrease it on the other.

The difference between the two readings is used to

calculate torque, because the radius of the driven drum is

known. Once we knew the spring balance we can

determine the torque by equation.

S = Spring Balance

Where, D = Drum Dia.,

tb = Belt thickness,

Fig. 5b: A plot of Flow v/s Speed for 6 smooth discs and T = (D+ tb) X 9.81 * S (13)

0.55mmn spacing

Then the Output Power calculated by

Fig.6 shows the speed variation with respective flow, Here P = 2πNT / 60

6 rough (spiral grooves) discs used with 2mm spacing.

From these readings plot, we observed that the First, confirm that you have the correct template for

experimental curve closer to the theoretical curve, actually your paper size. This template has been tailored for

theoretical curve plot by considering impulse force only output on the

but existence of friction force or drag force due to

boundary layer effect difference found for three various

conditions as shown in fig 5 & 6. Spiral grooves on discs

surfaces machined in such way that once jet enters the

groove it follows the spiral path and exists thru central

port. During rotation of discs centripetal force also exist

which act inward to outward and that opposes to jet to

come rapidly at the central port and due to this jet passes

thru long spiral path and kinetic energy of jet utilized to

drag the discs

Fig.7: A plot of flow v/s Power at various flow rates for

six discs and 05mm spacing.

To determine the efficiency, we have to determine I/P

power [10].

By the following formula

Pi/p = = ρ g Q h ( 14)

Fig. 6: A plot of Flow v/s speed for 6 Rough discs and Where , P static Pressure

1.4mm spacing

But , P = γ x h ( 15)

A. Output torque, power and efficiency

Torque on the shaft measured by Prony Break And ρ g γ

dynamometer. The methodology for the use of this device h = Water column height.

is simple. Essentially the measurement is made by Where ,ρ = Density of water Q = flow of fluid m/s ,

wrapping a belt around the output shaft of the unit and

measuring the force transferred to the belt through friction. Input Power Pi/p= P = ρ g Q h ( 16)

The friction is increased by tightening the belt until the Hydraulic Efficiency = Power O/P / Power I/P (17)

frequency of rotation of the shaft is reduced. In its simplest

form an engine is connected to a rotating drum by means By considering one case for sample calculations of

of an output shaft. A friction band is wrapped. Around half efficiency.

the drum's circumference and each end attached to a

separate spring balance. A substantial pre-load is then Q = 0.22lit/s = 2.2 * 10 -4 m3 /s

applied to the ends of the band, so that each spring balance Pline = 0.47 bar = 3238.3N/mm2

has an initial and identical reading. When the engine is Hydraulic Efficiency = 2.2 X 10-4 *3238.3 = 7.1%

Copyright to IARJSET DOI 10.17148/IARJSET 239

ISSN (Online) 2393-8021

IARJSET ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

National Conference on Emerging Trends in Engineering and Technology (NCETET’16)

Lourdes Matha College of Science & Technology, Thiruvananthapuram

Vol. 3, Special Issue 3, August 2016

VI. CONCLUSIONS

Study and analysis of this work concludes that the Number

of discs, spacing between the discs and the surface finish

of discs affects the performance of tesla turbine

significantly This work was carried out to study the

performance of tesla disc turbine operating on water

medium, however previous studies and experimentation

carried out with air and steam medium. Rotor speed

increases with the number of discs up to a certain level

due to increasing area of contact of jet water and wall and

it leads to the increase in friction force and boundary layer

effect. For wide spacing between the discs it works as

impulse turbine only. For appropriate spacing between

discs it works with impulse force and also boundary layer

effect. For minimum spacing equipment vibration also

increases for high speed compare to maximum gap, Hence

vibration analysis became important factor. Present

experiments showed that the losses occurring in the nozzle

are large and hence this needs to be tackled for improving

the overall efficiency of the Tesla disc turbine.

Experimental work shows that the efficiency of disc

turbine may be increased by 5 to 6% by using spiral

groove discs (Rough discs).

A. Suggestion for Future Work

Some of the following topics would be interesting for

further investigation. In a future study, it will be

interesting to analyze the influence of the inlet nozzle

numbers and positions .The influence of the disc holes and

the outlet nozzle size must be also analyzed. Influence of

the composite material for discs on the turbine

performance. Compressible analysis of the multiple disc

turbines

REFERENCES

[1] H.S.Couto, J.B.F. Duarte and D. Bastos-Netto,Tesla Turbine

Revisit, Department of Mechanical Engineering, 8th Asia- Pacific

International Symposium on Combustion and Energy Utilization,

October 2006, Sochi, Russian Federation

[2] N Tesla, Tesla turbine, United States Patent, May 1913.

[3] Piotr Lampart and Krzysztof Kosowski. Design analysis of Tesla

micro-turbine operating on a low boiling medium, Polish Maritime

Research, Special issue 2009S1; pp. 28-33.

[4] W. Rice, An Analytical and Experimental Investigation of

Multiple- series A, Vol. 87, No. 1 Jan. 1965, pp. 29-36 Disk

Turbines, Journal of Engineering for Power, Trans. ASME.

[5] K.Boyd and W. Rice, Laminar inward flow of an incompressible

fluid between rotating disk, with full Peripheral Admission, Journal

of Applied Mechanics, June 1968, pp. 229-237.

[6] N.Huybrechts, Numerical Study of a Tesla Turbine, Free

University of Brussels, Applied Mechanics Department.

[7] F.William Beans, Investigation into the Performance characteristics

of a Friction Turbine Flow, Journal of Space Craft, Vol. 3, No. 1,

January 1966, pp. 131-134.

[8] L.Matsch, and W.Rice. Flow at low Reynolds number with partial

admission between rotating disk. Journal of Applied Mechanics,

Vol. 35, Trans. ASME, Vol. 90 series E, March 1968. pp. 768-770.

[9] P.N.Modi and S.M.Seth. Hydralics and Fluid Mechnics including

Hydralic Machines. HFM Publication, Fifth Edition 2005, pp.221,

284-289, 915-973.

[10] K. SheshagiriHebbar, K.Sridhara and P. A. Paranjpe. 1970,

Performance of Conical Jet Nozzles in Terms of Discharge Coefficient,

Journal of the Aeronautical Society of India, Vol. 22, No 1, pp.3-9

Copyright to IARJSET DOI 10.17148/IARJSET 240

Вам также может понравиться

- An Effect of Surface Finish and Spacing Between Discs On The Performance of Disc TurbineДокумент7 страницAn Effect of Surface Finish and Spacing Between Discs On The Performance of Disc TurbineAry KageОценок пока нет

- Study OF Operation OF Tesla Turbine: International Journal of Advance Research in Engineering, Science & TechnologyДокумент5 страницStudy OF Operation OF Tesla Turbine: International Journal of Advance Research in Engineering, Science & Technologyreventhk465Оценок пока нет

- Experimental Investigation of Tesla Turbine and ItsДокумент3 страницыExperimental Investigation of Tesla Turbine and Itsemir_delic2810Оценок пока нет

- Design and Off-Design Analysis of A Tesla Turbine Utilizing CO2 As Working FluidДокумент6 страницDesign and Off-Design Analysis of A Tesla Turbine Utilizing CO2 As Working Fluidbillthegunm0% (1)

- Design and Structural Thermal Analysis of Gas Turbine Rotor Blade With Radial Holes Using SolidworksДокумент5 страницDesign and Structural Thermal Analysis of Gas Turbine Rotor Blade With Radial Holes Using SolidworksEditor IJTSRDОценок пока нет

- Ijirt157883 PaperДокумент10 страницIjirt157883 PaperMilan ĐurićОценок пока нет

- Design and Computational Analysis of 1 KW TeslaДокумент5 страницDesign and Computational Analysis of 1 KW Teslaemir_delic2810Оценок пока нет

- Vitaletal 2021 SNApplied SciencesДокумент11 страницVitaletal 2021 SNApplied Sciences01988Оценок пока нет

- Experimental Thermal and Fluid Science: A.L. Neckel, M. GodinhoДокумент10 страницExperimental Thermal and Fluid Science: A.L. Neckel, M. GodinhoPett PeeveОценок пока нет

- Dhanasekaran 2005Документ19 страницDhanasekaran 2005Robin WilliamsОценок пока нет

- Tesla Turbine2Документ8 страницTesla Turbine2Tahir DemirОценок пока нет

- Evaluation of A Potential Flow Model For Wind Turbine DesignДокумент15 страницEvaluation of A Potential Flow Model For Wind Turbine Designmohamed farmaanОценок пока нет

- Isi 18Документ25 страницIsi 18ntik 23Оценок пока нет

- PIV Measurements of Flow Over A Riblet SurfaceДокумент8 страницPIV Measurements of Flow Over A Riblet Surfacemuka osmanОценок пока нет

- Paper 1011Документ10 страницPaper 1011SthefanoОценок пока нет

- T Elsa 06108756Документ4 страницыT Elsa 06108756Anonymous SlyvspdBОценок пока нет

- Pillala2021 Article ALinearCascadeTunnelForFlowInvДокумент10 страницPillala2021 Article ALinearCascadeTunnelForFlowInvMohamed SolimanОценок пока нет

- Vortex Behaviour of An Unbaffled Surface Aerator PDFДокумент6 страницVortex Behaviour of An Unbaffled Surface Aerator PDFjbsantoОценок пока нет

- Flow Characteristics in Mixers Agitated by Helical Ribbon Blade ImpellerДокумент15 страницFlow Characteristics in Mixers Agitated by Helical Ribbon Blade ImpellerValmir QuadrosОценок пока нет

- Jmse 10 01501Документ25 страницJmse 10 01501Vikram C KОценок пока нет

- The Tesla Turbine RevisitedДокумент7 страницThe Tesla Turbine Revisitedg1150111Оценок пока нет

- The Design of A Test Rig and Study of The Performance and Efficiency of A Tesla Disc TurbineДокумент15 страницThe Design of A Test Rig and Study of The Performance and Efficiency of A Tesla Disc Turbinearturo ortegaОценок пока нет

- Water 15 02312Документ18 страницWater 15 02312RIZAL MUXОценок пока нет

- Hyd ReportДокумент19 страницHyd Reportparthadhav2020.mech1Оценок пока нет

- Power Calculations For Tesla TurbineДокумент10 страницPower Calculations For Tesla TurbineNajam Ul QadirОценок пока нет

- NooriRahimAbadi CFDBased 2017Документ47 страницNooriRahimAbadi CFDBased 2017aminardakaniОценок пока нет

- Applied Thermal Engineering: Julien Pellé, Souad HarmandДокумент12 страницApplied Thermal Engineering: Julien Pellé, Souad HarmandHalil AKSUОценок пока нет

- SchraderEtal-HSVA ShipAerodynamics ProcNuTTS 2018Документ9 страницSchraderEtal-HSVA ShipAerodynamics ProcNuTTS 2018saubu8xОценок пока нет

- Axial Mixing in Annular Centrifugal ExtractorsДокумент11 страницAxial Mixing in Annular Centrifugal ExtractorsHendriОценок пока нет

- Cross-Flow Turbine Design For Variable Operating Conditions: SciencedirectДокумент10 страницCross-Flow Turbine Design For Variable Operating Conditions: SciencedirectvcockscribdОценок пока нет

- Design, Construction and Simulation of Tesla Turbine: Keywords - Physical Model, CFD Simulation, RadialДокумент9 страницDesign, Construction and Simulation of Tesla Turbine: Keywords - Physical Model, CFD Simulation, RadialhatemОценок пока нет

- Medium-Solidity Vertical Axis Wind Turbines For UsДокумент11 страницMedium-Solidity Vertical Axis Wind Turbines For UsCarolina CuraçáОценок пока нет

- Turbine Gas-Path Heat Transfer: Wright-Patterson Air Force Base, Ohio, U.S.AДокумент36 страницTurbine Gas-Path Heat Transfer: Wright-Patterson Air Force Base, Ohio, U.S.AHenriqueОценок пока нет

- 2) Numerical Simulations of A Fully Submerged Propeller Subject To VentilationДокумент18 страниц2) Numerical Simulations of A Fully Submerged Propeller Subject To VentilationEugene Jin LeowОценок пока нет

- Energies: Enhanced Heat Transfer of A Heat Exchanger Tube Installed With V-Shaped Delta-Wing Baffle TurbulatorsДокумент23 страницыEnergies: Enhanced Heat Transfer of A Heat Exchanger Tube Installed With V-Shaped Delta-Wing Baffle Turbulatorsmustafa11dahamОценок пока нет

- Bayley 1970Документ7 страницBayley 1970Huynhiemquoc80Оценок пока нет

- RANS Simulation of The Separated Flow Over A Bump With Active ControlДокумент9 страницRANS Simulation of The Separated Flow Over A Bump With Active Controlshakeel6787Оценок пока нет

- Anand 2020Документ11 страницAnand 2020enterlogОценок пока нет

- Design Analysis of Tesla Micro-Turbine Operating On A Low-Boiling MediumДокумент6 страницDesign Analysis of Tesla Micro-Turbine Operating On A Low-Boiling MediumHaidar RahmanОценок пока нет

- Progress Report MinorДокумент12 страницProgress Report Minoreue99332Оценок пока нет

- Reynolds Number Efects On The Aerodynamic Performance of Small VawtsДокумент13 страницReynolds Number Efects On The Aerodynamic Performance of Small VawtsOmer Ghassan Abdulkareem Hassan AlsultanОценок пока нет

- Comparison of Methods ForДокумент13 страницComparison of Methods ForClaudio NovaesОценок пока нет

- Cold Flow Analysis of Trapped Vortex Combustor Using Two Equation Turbulence ModelsДокумент12 страницCold Flow Analysis of Trapped Vortex Combustor Using Two Equation Turbulence ModelsAnonymous 6SivdzjОценок пока нет

- Blade Number Impact On Pressure and Performance of Archimedes Screw Turbine UsingДокумент8 страницBlade Number Impact On Pressure and Performance of Archimedes Screw Turbine UsingShahzaib KhanОценок пока нет

- Design and Development of Vertical Axis Wind TurbiДокумент10 страницDesign and Development of Vertical Axis Wind TurbiAhmed BelalОценок пока нет

- Straalsund JHE 2018Документ22 страницыStraalsund JHE 2018alvin bautistaОценок пока нет

- Tuned Liquid Dumper PDFДокумент7 страницTuned Liquid Dumper PDFdorivolosОценок пока нет

- 3893-Manuscript With Authors Details-20572-1-10-20210914 VvvveeerrrrrrДокумент10 страниц3893-Manuscript With Authors Details-20572-1-10-20210914 VvvveeerrrrrrRoberto Zambrano SepulvedaОценок пока нет

- The Effect of Swirl On Array of Turbulent Impinging Jets: ICMIEE18-104Документ5 страницThe Effect of Swirl On Array of Turbulent Impinging Jets: ICMIEE18-104bariОценок пока нет

- The Design and Analysis of Gas Turbine Blade: Research PaperДокумент3 страницыThe Design and Analysis of Gas Turbine Blade: Research PaperSai SushmaОценок пока нет

- The Tesla Turbine Revisited, 2006Документ6 страницThe Tesla Turbine Revisited, 2006emir100% (1)

- Energy Conversion and Management: N.K. Sarma, A. Biswas, R.D. MisraДокумент11 страницEnergy Conversion and Management: N.K. Sarma, A. Biswas, R.D. MisraOmer OrtegaОценок пока нет

- Development of Turbulence Models For Shear Flows BДокумент28 страницDevelopment of Turbulence Models For Shear Flows BHelen ChoiОценок пока нет

- Compressed Air Flow Within Aquifer Reservoirs of CAES PlantsДокумент22 страницыCompressed Air Flow Within Aquifer Reservoirs of CAES PlantssasikalasivakumarОценок пока нет

- Static and Thermal Analysis of Gas Turbine Rotor BladeДокумент15 страницStatic and Thermal Analysis of Gas Turbine Rotor BladeJUKANTI VISHWASОценок пока нет

- CFD Analysis of Heat Transfer in Helical Coil Tube in Tube Heat ExchangerДокумент8 страницCFD Analysis of Heat Transfer in Helical Coil Tube in Tube Heat ExchangerIJIERT-International Journal of Innovations in Engineering Research and TechnologyОценок пока нет

- Of Vortex Generators"": Final ReportДокумент7 страницOf Vortex Generators"": Final Reportramazan akyolОценок пока нет

- Fluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984От EverandFluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984Оценок пока нет

- Tutorial 4 Assignment AДокумент2 страницыTutorial 4 Assignment A030929Оценок пока нет

- 19 - Heavy Crude Oil ProcessingДокумент22 страницы19 - Heavy Crude Oil ProcessingSHREEОценок пока нет

- Lab #3 - Flow Over WeirsДокумент12 страницLab #3 - Flow Over WeirsDeborah SongОценок пока нет

- Cañerias Del EnfriadorДокумент4 страницыCañerias Del EnfriadorAlex BravoОценок пока нет

- Control Valves For Critical ApplicationsДокумент2 страницыControl Valves For Critical Applicationshichtn2009Оценок пока нет

- Quiz (Rock-Fluid)Документ7 страницQuiz (Rock-Fluid)Maqsood IqbalОценок пока нет

- Bio Filters: 06 CE 6024 Air Pollution Control EngineeringДокумент8 страницBio Filters: 06 CE 6024 Air Pollution Control EngineeringDr.RATISH MENONОценок пока нет

- Basics of Computational Fluid DynamicsДокумент15 страницBasics of Computational Fluid DynamicsSrini RaoОценок пока нет

- Che144 Marcet Boiler Lab ReportДокумент9 страницChe144 Marcet Boiler Lab ReportAbdul AliffОценок пока нет

- Electronic Heat TransferДокумент31 страницаElectronic Heat TransferShashank PansariОценок пока нет

- Lecture 08 Energy TransportДокумент25 страницLecture 08 Energy TransportFarahin BurhanОценок пока нет

- Ceccato CDX 4 840 6999100156 Eng LRДокумент6 страницCeccato CDX 4 840 6999100156 Eng LRKing MaxОценок пока нет

- Air Separation PlantДокумент12 страницAir Separation Plantsarsoos15Оценок пока нет

- CH 8. Chemical Equilibrium (Chem +1)Документ40 страницCH 8. Chemical Equilibrium (Chem +1)Dipin Preet SinghОценок пока нет

- Process DiagramsДокумент139 страницProcess DiagramsvtavimsatОценок пока нет

- Sewage Treatment PlantДокумент14 страницSewage Treatment PlantSanjay SahulОценок пока нет

- Cetamine Performance SpecificationДокумент2 страницыCetamine Performance SpecificationdanielОценок пока нет

- Symbols andДокумент17 страницSymbols andWaldir Jesús Rodríguez JuárezОценок пока нет

- Flash SteamДокумент9 страницFlash SteamMuhammad RofiОценок пока нет

- Heat Loss of Liquid MetalДокумент7 страницHeat Loss of Liquid Metalmarcotulio123Оценок пока нет

- Me 311 Plates Compilation Danreb PeritДокумент5 страницMe 311 Plates Compilation Danreb PeritRika MaeОценок пока нет

- Batch 5 Study and Analysis of Fluid Flow Rate For Different Concentrate in Compact Heat Exchanger-Converted-1Документ68 страницBatch 5 Study and Analysis of Fluid Flow Rate For Different Concentrate in Compact Heat Exchanger-Converted-1Tirupati Reddy GuduriОценок пока нет

- Caesar-Ii-Pipe Stress AnalysisДокумент1 страницаCaesar-Ii-Pipe Stress AnalysisGerry MalapitanОценок пока нет

- Omega Air Product Data Sheet Filter Housing P-VACДокумент2 страницыOmega Air Product Data Sheet Filter Housing P-VACĐức Hoàn DươngОценок пока нет

- Vnt19-Area 13 Mil-R0Документ6 страницVnt19-Area 13 Mil-R0Hân TiênОценок пока нет

- NACA Duct VsДокумент10 страницNACA Duct VsewaigeОценок пока нет

- Example 6-10. A Home Water Softener Has 0.1 M: SolutionДокумент7 страницExample 6-10. A Home Water Softener Has 0.1 M: SolutionSamuel GarcíaОценок пока нет

- Natural Gas Processing Plants - LindeДокумент12 страницNatural Gas Processing Plants - LindekareemОценок пока нет

- 06 B04 - Bucher - Qxeh-2 - 100-P-000096-EnДокумент13 страниц06 B04 - Bucher - Qxeh-2 - 100-P-000096-EnYanis Anis HabetОценок пока нет

- Chem 1-8Документ43 страницыChem 1-8Cabacungan, John VinceОценок пока нет