Академический Документы

Профессиональный Документы

Культура Документы

SGSCRSDS51 Non Electrical WallchartHRA2EN1602 PDF

Загружено:

Edin MujanovićОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SGSCRSDS51 Non Electrical WallchartHRA2EN1602 PDF

Загружено:

Edin MujanovićАвторское право:

Доступные форматы

2

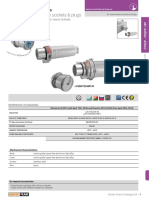

ATEX NON-ELECTRICAL EQUIPMENT:

GUIDANCE FOR MANUFACTURERS AND END USERS

TO BE USED IN CONJUNCTION WITH WALLCHART 1

ATEX RESPONSIBILITY

ATEX IECEx RESPONSIBILITY

NB – Notified Body HAZARDOUS AREA ZONE EQUIPMENT PROTECTION LEVEL (EPL)

EQUIPMENT CB – Certification Body

M – Manufacturer

CATEGORY

TYPE EXAMINATION PRODUCTION GAS DUST GAS DUST TYPE EXAMINATION PRODUCTION

NB NB 1 0 20 Ga Da CB CB

M M 2 1 21 Gb Db CB CB

Technical File stored with NB

M M 3 2 22 Gc Dc CB CB

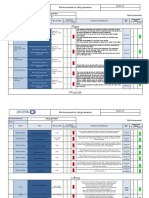

NON-ELECTRICAL PROTECTION CONCEPTS IGNITION HAZARD ASSESSMENT

EXISTING EUROPEAN STANDARDS NEW ISO / IEC / EUROPEAN STANDARDS

IDENTIFY ALL POTENTIAL IGNITION

STANDARD CODE ZONE STANDARD CODE ZONE

EN PROTECTION ISO/IEC/EN SOURCES (SEE TABLE BELOW LEFT)

CONCEPT

Gas Dust Gas Dust Gas Dust Gas Dust Gas Dust Gas Dust

13463-1 General Requirements 80079-36 WHICH APPLY TO YOUR PRODUCT

13463-2 fr fr 2 22 Flow Restriction Not applicable

1 21 Ex db 1

13463-3 d d Flameproof 60079-1

2 22 Ex dc 2

Ex pxb Ex pxb 1 21 DO THEY OCCUR DURING:

13463-7

Pressurised 60079-2 Ex pyb Ex pyb 1 21

(never published)

Ex pzc Ex pzc 2 22

Ex ta 20

Protection by Enclosure 60079-31 Ex tb 21 NORMAL EXPECTED RARE

EPL

Ex tc 22 OPERATION MALFUNCTION MALFUNCTION

13463-5 c c

1 21

Constructional Safety 80079-37 Ex h Ex h

1 21 Gc/Dc * N/A N/A

2 22 2 22

Gb/Db * * N/A

1 21 Control of Ignition 1 21

13463-6 b b

2 22 Sources

80079-37 Ex h Ex h

2 22

Ga/Da ** ** *

1 21 1 21

13463-8 k k Liquid Immersion 80079-37 Ex h Ex h * Describe the single measure applied to prevent the ignition

2 22 2 22

source from becoming effective. Where appropriate refer to

Mining Equipment 80079-38 Ex h Ex h (EPL Mb)

standards used and test reports which substantiate compliance

with the standards.

EXISTING EQUIPMENT LABEL MARKINGS NEWER EQUIPMENT LABEL MARKINGS ** Describe two independent measures used to prevent ignition

source from becoming effective. Again refer to relevant standards

Protection Concept IECEx Certificate No. and test reports.

© SGS United Kingdom Ltd – 2016 – All rights reserved - SGS is a registered trademark of SGS Group Management SA 5608/1114 – Issue 8 – February 2016

ATEX Certificate No.

Gas Group Equipment Protection Levels Maximum

(or Manufacturer’s N/A Need not be considered for this EPL

Baseefa15ATEX1111X Temperature Class External Surface

Technical File No.)

Temperature

ABC Engineering Manufacturer’s Name IECEx BAS 16.1111X

Buxton, SK17 9RZ, UK and Address Ambient Range

Ex h IIC T4 Ga –20°C to 40°C SINGLE IMPACT ENERGY LIMITS (Nm)

Type XYZ Pump Ex h IIIC T135ºC Da unless stated

Product Identification on label NON-

2015 s/n 1234 Tamb -30ºC to +50ºC EXPLOSION OTHER

Serial No. and (or inc.) SPARKING

Manufacturer’s Name GROUP MATERIALS (*)

Year of Manufacture ABC Engineering and Address

METALS

II 1GD ck IIC T4 Buxton, SK17 9RZ, UK

Temperature Class

Product GAS

Type XYZ Pump Identification

Tamb – 30ºC to +50ºC ATEX Notified Body

1180

Identification No. 2016 s/n 1234 5 (Hydrogen)

Serial No. and Year

(Zone 0/20 only) II 1GD of Manufacture IIC 60 3 (Hydrocarbons

Protection Concept Gas Group

Baseefa16ATEX1111X 1180 including acetylene)

Ambient Range ATEX Notified Body Ga

Identification No. IIB 125 10

ATEX Coding ATEX Coding ATEX Certificate No.

Dust Group IIA 125 20

IIC 125 10

Gb IIB 250 20

POSSIBLE IGNITION SOURCES (LIST FROM EN 1127-1) TECHNICAL FILE CONTENTS

IIA 500 40

Hot surfaces Lightning General description

IIC 250 20

Mechanical sparks Electromagnetic waves Ignition risk assessment

Gc IIB 500 40

Flames, hot gases Ionising radiation Design and manufacturing drawings IIA 500 80

Description and explanation necessary to understand operation of

Electrical sparks High frequency radiation DUST

product

Ultrasonics Da IIIA to IIIC 125 20

Stray electric currents Standards Assessment (or other solutions to meet EHSRs for ATEX)

Db

and Cathodic protection Adiabatic compression IIIA to IIIC 500 80

Calculations and examinations

Dc

Static electricity Chemical reaction Test Results (*) excluding materials specified in cl.6.4.2.1 a) of ISO 80079-36

SGS BASEEFA SERVICES •• IEC 61508 certification

SGS BASEEFA LIMITED tel. +44 (0)1298 766600

•• Training and technical advice

•• ATEX and IECEx equipment/component •• Quality system approval •• IECEx Service Facility Certification SGS Baseefa Ltd, fax. +44 (0)1298 766601

certification Rockhead Business Park, e-mail: baseefa@sgs.com

•• Assistance with DSEAR •• Technical file storage

•• IECEx Certificate of Personnel Competence (ATEX user directive) implementation Staden Lane, Buxton, SK17 9RZ www.sgs.co.uk/sgsbaseefa

•• Testing

Вам также может понравиться

- Wolf Safety Lamp Company - Atex Explained Leaflet - SL008 Issue 5Документ1 страницаWolf Safety Lamp Company - Atex Explained Leaflet - SL008 Issue 5omidОценок пока нет

- Aerial Lift TrainingДокумент81 страницаAerial Lift TrainingCesar Augusto Vera JaimesОценок пока нет

- Presentation For RiggingДокумент18 страницPresentation For RiggingRameese MuhammedОценок пока нет

- Fes TBT Mobile CraneДокумент1 страницаFes TBT Mobile CraneMohammed AtefОценок пока нет

- Oil and Gas Activity Operations ManualДокумент208 страницOil and Gas Activity Operations Manualkhalil_ahmedinОценок пока нет

- Power AscenderДокумент6 страницPower AscenderApriliando KurniawanОценок пока нет

- HSMC Employee Induction Procedure (Offices)Документ3 страницыHSMC Employee Induction Procedure (Offices)Anonymous 4e7GNjzGWОценок пока нет

- Ramapo College Vehicle Fueling SOPДокумент1 страницаRamapo College Vehicle Fueling SOPAnees EkОценок пока нет

- 10 Frequently Asked Questions About The Machinery DirectiveДокумент5 страниц10 Frequently Asked Questions About The Machinery Directivesujal_aminОценок пока нет

- Lifts and Lifting Equipment Policy and Best Practice NoteДокумент30 страницLifts and Lifting Equipment Policy and Best Practice NoteAnsara Pasir Tumboh100% (1)

- Instructions For Completing This Form: Form 000.653.F0100 Job Safety AnalysisДокумент7 страницInstructions For Completing This Form: Form 000.653.F0100 Job Safety AnalysisMuhammad Umar Gondal100% (1)

- Work at HeightДокумент11 страницWork at HeightEhsanОценок пока нет

- Toolbox Talk FormДокумент4 страницыToolbox Talk FormPrem Preetham DsouzaОценок пока нет

- Lock Out Tag Out SafetyДокумент2 страницыLock Out Tag Out SafetyAhmed IbrahimОценок пока нет

- 1910.66 Osha PDFДокумент35 страниц1910.66 Osha PDFluiseduardo_plcОценок пока нет

- Title: Safe Work Procedure TemplateДокумент1 страницаTitle: Safe Work Procedure TemplateBenouna FertОценок пока нет

- Safe Work Permit Rev. 06: BASF Corporation Title: Beaumont Site Function: Health & Safety Procedure No.: Page: 1 ofДокумент22 страницыSafe Work Permit Rev. 06: BASF Corporation Title: Beaumont Site Function: Health & Safety Procedure No.: Page: 1 ofIvan BaracОценок пока нет

- OHS PROC 113 BarricadesДокумент9 страницOHS PROC 113 BarricadesPhillip L100% (1)

- Revised 2015 Work Zone Traffic Control ManualДокумент31 страницаRevised 2015 Work Zone Traffic Control ManualTrainer 1 TVSОценок пока нет

- Webbing SlingДокумент3 страницыWebbing Slingmoha19841Оценок пока нет

- Eis 28Документ4 страницыEis 28Ab AUОценок пока нет

- Weekly Tower Light Check ListДокумент1 страницаWeekly Tower Light Check ListpjosesmОценок пока нет

- Tower Light Inspection ChecklistДокумент1 страницаTower Light Inspection ChecklistHabib ur rahmanОценок пока нет

- Work at Height Checklist PDFДокумент1 страницаWork at Height Checklist PDFDEEPAKОценок пока нет

- HSE Budget 2022 MOST IMPORTANT: This Only Implies For Health and Safety Implications Recommended Equipment Supplier: Al-Asayel Health and SafetyДокумент2 страницыHSE Budget 2022 MOST IMPORTANT: This Only Implies For Health and Safety Implications Recommended Equipment Supplier: Al-Asayel Health and SafetyRehan AbbasiОценок пока нет

- Safety ProgramДокумент21 страницаSafety ProgramSits RdddОценок пока нет

- Gas Testing BY Commissioning Hse TeamДокумент36 страницGas Testing BY Commissioning Hse Teamsaquib eqbalОценок пока нет

- Definition of Lifting EquipmentДокумент4 страницыDefinition of Lifting Equipmentadriancovalciuc4863Оценок пока нет

- Programa Contra CaidasДокумент31 страницаPrograma Contra CaidasMaria Alejandra Bugallo Rodriguez100% (1)

- Osha 1910.178 Industrial Trucks RegulationsДокумент49 страницOsha 1910.178 Industrial Trucks RegulationsAngel Noriega CanoОценок пока нет

- NR 11 - Powered Industrial TrucksДокумент58 страницNR 11 - Powered Industrial TrucksCPSST100% (1)

- WSH Guidelines Safe Use of Lorry CraneДокумент38 страницWSH Guidelines Safe Use of Lorry CraneMuhammad RidwanОценок пока нет

- Các Ví D Tai N N Xe NângДокумент36 страницCác Ví D Tai N N Xe NânglykhanhhuyОценок пока нет

- Fatal falls from heightДокумент3 страницыFatal falls from heightEric LimОценок пока нет

- HSE FRM-16 HSE Budget WorksheetДокумент2 страницыHSE FRM-16 HSE Budget WorksheetUmair KhanОценок пока нет

- CH 2-Amphoux Physiopathological Aspects of Personal Equipment For Protection Against FallsДокумент16 страницCH 2-Amphoux Physiopathological Aspects of Personal Equipment For Protection Against FallsRodrigo MendesОценок пока нет

- Ventilation Plan TemplateДокумент11 страницVentilation Plan TemplatePlank89Оценок пока нет

- Use of Stepladders 05Документ1 страницаUse of Stepladders 05cardyОценок пока нет

- NR 33 Work in Confined Space PDFДокумент11 страницNR 33 Work in Confined Space PDFp100% (1)

- Bulldozer SOP FinalДокумент10 страницBulldozer SOP Finaljean claude BledouОценок пока нет

- Iso 2201Документ11 страницIso 2201kirandevi1981Оценок пока нет

- Rack Safety Guide for EmployeesДокумент7 страницRack Safety Guide for EmployeesBhaskar ShuklaОценок пока нет

- Fall Prevention Plan: (Only Applicable To Contractor That Have Work Activities More Than 03 Meters and Above.)Документ21 страницаFall Prevention Plan: (Only Applicable To Contractor That Have Work Activities More Than 03 Meters and Above.)Md ShahinОценок пока нет

- Hazards in Port and Dock OperationsДокумент5 страницHazards in Port and Dock Operationsven1959Оценок пока нет

- Topic For TBMДокумент19 страницTopic For TBMdauxomОценок пока нет

- Crane Lift PlanДокумент4 страницыCrane Lift Planabdalla el-saadaneyОценок пока нет

- Jha Clarke Engine PumpДокумент4 страницыJha Clarke Engine Pumpperquino oasanОценок пока нет

- Safe Lifting Operations in The WorkplaceДокумент14 страницSafe Lifting Operations in The WorkplacetlalovićОценок пока нет

- FC 4.1.8 - Critical Lift PlanДокумент1 страницаFC 4.1.8 - Critical Lift PlanJosef Demner Tiu PaspeОценок пока нет

- Code of Practive For Safe Use and Operation of Suspended Working PlatformДокумент62 страницыCode of Practive For Safe Use and Operation of Suspended Working PlatformthowchinОценок пока нет

- Alpaccess: Wind Turbine Maintenance & RepairsДокумент7 страницAlpaccess: Wind Turbine Maintenance & RepairsDragos StateОценок пока нет

- Shailesh Job Safety Analysis in Steel Manufacturing Unit and Recommendations To Improve The Work Safety EnvironmentДокумент21 страницаShailesh Job Safety Analysis in Steel Manufacturing Unit and Recommendations To Improve The Work Safety EnvironmentNandini RajОценок пока нет

- Emergency Evacuation PlanДокумент5 страницEmergency Evacuation PlanAbraar AhmedhОценок пока нет

- Lifting Operations Risk AssessmentДокумент4 страницыLifting Operations Risk AssessmentIdris AdeniranОценок пока нет

- Risk Assessment for Rope Change at MGD Sentosa IslandДокумент6 страницRisk Assessment for Rope Change at MGD Sentosa IslandRod CavicchioniОценок пока нет

- Compliance Record Folder Checklist For Consultants/ ContractorsДокумент1 страницаCompliance Record Folder Checklist For Consultants/ ContractorsNijasОценок пока нет

- SWMS - Blind IstallationДокумент12 страницSWMS - Blind IstallationParasОценок пока нет

- Know Your Safety ZoneДокумент14 страницKnow Your Safety ZoneSiwakoti HSEОценок пока нет

- Intelocked Panel Switch Sockets & Plugs: CPSCP - FSQCP / BPДокумент2 страницыIntelocked Panel Switch Sockets & Plugs: CPSCP - FSQCP / BPvenkatesh tekkaliОценок пока нет

- Safety in Useing Crane - 0 PDFДокумент40 страницSafety in Useing Crane - 0 PDFEdin MujanovićОценок пока нет

- Types of protection for electrical equipment in explosive gas atmospheresДокумент1 страницаTypes of protection for electrical equipment in explosive gas atmospheresphilippe69Оценок пока нет

- Safe LiftingДокумент22 страницыSafe LiftingMahmoud Abdallah67% (3)

- iecexOD504 Ed2.0 enДокумент70 страницiecexOD504 Ed2.0 enEdin MujanovićОценок пока нет

- Renewable Energy WebquestДокумент8 страницRenewable Energy Webquestapi-265481598Оценок пока нет

- Ongc FinalДокумент35 страницOngc FinalSurmeet SinghОценок пока нет

- Proven, Reliable, Versatile PowerДокумент15 страницProven, Reliable, Versatile Poweramir moniriОценок пока нет

- Sud Chemie CatalystsДокумент142 страницыSud Chemie CatalystsBo Gray100% (4)

- Kerosene Distillate Hydrotreating Options for Jet Fuel SpecificationsДокумент3 страницыKerosene Distillate Hydrotreating Options for Jet Fuel SpecificationsRio Rinaldi100% (2)

- States of Matter: Lakshya Daily Assignment (LDA-1) Theory QuestionДокумент18 страницStates of Matter: Lakshya Daily Assignment (LDA-1) Theory QuestionArnav AmbreОценок пока нет

- Solar EnergyДокумент59 страницSolar EnergyRei RaguindinОценок пока нет

- Kill Sheet Calculation Formulas Pressure & Gradient FormulasДокумент2 страницыKill Sheet Calculation Formulas Pressure & Gradient FormulasLucas NunesОценок пока нет

- Types of LNG CarriersДокумент11 страницTypes of LNG CarriersAnonymous icnhaNsFОценок пока нет

- Work Breakdown StructureДокумент4 страницыWork Breakdown StructureGeethaОценок пока нет

- Carrier 58cta070Документ14 страницCarrier 58cta070ITLHAPNОценок пока нет

- Day 1 - Session 2 - Michael Peisser - OMV - ENG PDFДокумент13 страницDay 1 - Session 2 - Michael Peisser - OMV - ENG PDFthbdgcfОценок пока нет

- Bankable Feasibility Study Thar Lignite Mine Work ProgressДокумент27 страницBankable Feasibility Study Thar Lignite Mine Work ProgressdonnypsОценок пока нет

- King Salman Energy ParkДокумент4 страницыKing Salman Energy ParkLarry Stanford0% (1)

- ID Control Analysis of Hazards Potential in PDFДокумент11 страницID Control Analysis of Hazards Potential in PDFDevi ELОценок пока нет

- NFPA Codes & Standards - 2Документ1 страницаNFPA Codes & Standards - 2karpanai100% (2)

- 9 - Energy-Storage-Technologies PDFДокумент42 страницы9 - Energy-Storage-Technologies PDFVinnieОценок пока нет

- Catalogo Medidores Rotativos para Gas NaturalДокумент8 страницCatalogo Medidores Rotativos para Gas Naturalinglegs75Оценок пока нет

- APSA L/LC/LE Nitrogen Generators CatalogueДокумент23 страницыAPSA L/LC/LE Nitrogen Generators CatalogueAndika PratamaОценок пока нет

- National Greenhouse Accounts Factors July 2011Документ78 страницNational Greenhouse Accounts Factors July 2011anerus1375Оценок пока нет

- Acknowledgement PageДокумент9 страницAcknowledgement PagePrashant BarveОценок пока нет

- Understanding Oil Gas BusinessДокумент349 страницUnderstanding Oil Gas BusinesslogicloverОценок пока нет

- 4 CokeДокумент6 страниц4 CokePoshin ShrivastavОценок пока нет

- Coiled Tubing Underbalanced Drilling in Alaska's Lisburne FieldДокумент3 страницыCoiled Tubing Underbalanced Drilling in Alaska's Lisburne Fieldswaala4realОценок пока нет

- UTT Student Seeks Data on CNG Usage and Carbon EmissionsДокумент5 страницUTT Student Seeks Data on CNG Usage and Carbon EmissionsDillon RamsookОценок пока нет

- CBerto El Tordillo FieldДокумент68 страницCBerto El Tordillo Fieldner68Оценок пока нет

- Windmill PlantДокумент10 страницWindmill PlantPatoriku KunОценок пока нет

- Iffco PresentationДокумент16 страницIffco Presentationalok sahuОценок пока нет

- Bio Fuels Blending & Technology PresentationДокумент62 страницыBio Fuels Blending & Technology PresentationDaniel KunnigerОценок пока нет

- 3 Mysella S3 N 40Документ2 страницы3 Mysella S3 N 40Anibal RiosОценок пока нет