Академический Документы

Профессиональный Документы

Культура Документы

Tme RX: Technical Data Sheet

Загружено:

Enrique HortaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Tme RX: Technical Data Sheet

Загружено:

Enrique HortaАвторское право:

Доступные форматы

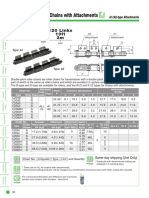

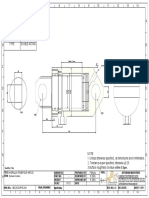

TECHNICAL DATA SHEET

STYLE RX

RING TYPE JOINT GASKET

TME RX

Description

Style TME RX is used in octagonal type grooved

flanges. Allowing interchangeability with the joints to

improve sealing efficiency. Pressure passage holes are

added to RX 82 through RX 91 allowing equalization of

pressure.

Style RX

23°

Tolerances: (Inches)

A (Width of Ring) ± 0.008

B, H (Height of Ring) ± 0.020

H P (Ave. Pitch Diameter of Ring) ± 0.007

23°(Angle) ± ½°

A

P

Available Gasket Material

STANDARD Maximum Hardness

Material

UNS ASME Brinell Rockwell

Soft Iron - D 90 56

Low Carbon Steel - S 120 68

4-6% Chrome ½% Moly (F5) K42544 F5 130 72

Type 304 Stainless Steel S30400 S304 160 83

Type 316 Stainless Steel S31600 S316 160 83

Alloy 321 S32100 S321 217 95

Alloy 625 N06625 INC625 200 93

Alloy 825 N08825 IN825 160 83

API 6A approved for manufacture.

23º ± 0º 30’

TECHNICAL DATA SHEET 23º ±

0º 30

F

’

P

H

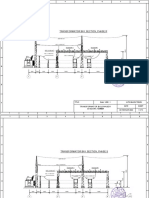

STYLE RX RING DIMENSIONS

E

D

C

R1 R1 R2 R2

A

O

Ring No. Pipe sizes and pressure class Pitch diame- Outside Width of Width of flat Height of Height Radius Depth of Width of Radius in Approx. Weight

rating for Type RX Ring Gaskets ter of ring diameter of ring outside of ring in ring groove groove groove distance

(groove) ring bevel between

m ade-up

flanges

API (PSI) P OD Ad C D Hd R1 E F R2 S

+0.02 ±0.008 ±0.006 0 +0.008 +0.02 max.

±0.005 ±0.02 ±0008

0 0 0 -0.03 0 0

2000 3000 5000 Dimensions in inches Lbs

RX-20 1-1/2" 1-1/2" 1-1/2" 2.688 3.000 0.344 0.182 0.125 0.750 0.06 0.25 0.344 0.03 0.38 0.527

RX-23 2" … … 3.250 3.672 0.469 0.254 0.167 1.000 0.06 0.31 0.469 0.03 0.47 1.150

RX-24 … 2" 2" 3.750 4.172 0.469 0.254 0.167 1.000 0.06 0.31 0.469 0.03 0.47 1.330

RX-25 … … 3-1/8" 4.000 4.313 0.344 0.182 0.125 0.750 0.06 0.25 0.344 0.03 … 1.420

RX-26 2-1/2" … … 4.000 4.406 0.469 0.254 0.167 1.000 0.06 0.31 0.469 0.03 0.47 1.500

RX-27 … 2-1/2" 2-1/2" 4.250 4.656 0.469 0.254 0.167 1.000 0.06 0.31 0.469 0.03 0.47 1.730

RX-31 3" 3" … 4.875 5.297 0.469 0.254 0.167 1.000 0.06 0.31 0.469 0.03 0.47 1.910

RX-35 … … 3" 5.375 5.797 0.469 0.254 0.167 1.000 0.06 0.31 0.469 0.03 0.47 2.090

RX-37 4" 4" … 5.875 6.297 0.469 0.254 0.167 1.000 0.06 0.31 0.469 0.03 0.47 2.270

RX-39 … … 4" 6.375 6.797 0.469 0.254 0.167 1.000 0.06 0.31 0.469 0.03 0.47 2.540

RX-41 5" 5" … 7.125 7.547 0.469 0.254 0.167 1.000 0.06 0.31 0.469 0.03 0.47 2.720

RX-44 … … 5" 7.625 8.047 0.469 0.254 0.167 1.000 0.06 0.31 0.469 0.03 0.47 2.960

RX-45 6" 6" … 8.313 8.734 0.469 0.254 0.167 1.000 0.06 0.31 0.469 0.03 0.47 3.660

RX-46 … … 6" 8.313 8.750 0.531 0.263 0.188 1.125 0.06 0.38 0.531 0.06 0.47 8.560

RX-47 … … (8") 9.000 9.656 0.781 0.407 0.271 1.625 0.09 0.50 0.781 0.06 0.91 3.790

RX4-9 8" 8" … 10.625 11.047 0.469 0.254 0.167 1.000 0.06 0.31 0.469 0.03 0.47 5.360

RX-50 … … 8" 10.625 11.156 0.656 0.335 0.208 1.250 0.06 0.44 0.656 0.06 0.47 4.560

RX-53 10" 10" … 12.750 13.172 0.469 0.254 0.167 1.000 0.06 0.31 0.469 0.030 0.47 6.450

RX-54 … … 10" 12.750 13.281 0.656 0.335 0.208 1.250 0.06 0.44 0.656 0.060 0.47 5.360

RX-57 12" 12" … 15.000 15.422 0.469 0.254 0.167 1.000 0.06 0.31 0.469 0.03 0.47 26.400

RX-63 … … 14" 16.500 17.391 1.063 0.582 0.333 2.000 0.09 0.63 1.063 0.09 0.84 6.630

RX-65 16" … … 18.500 18.922 0.469 0.254 0.167 1.000 0.06 0.31 0.469 0.03 0.47 9.390

API 6A approved for manufacture.

23º ± 0º 30’

TECHNICAL DATA SHEET 23º ±

0º 30

F

’

P

H

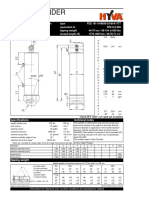

STYLE RX RING DIMENSIONS

E

D

C

R1 R1 R2 R2

A

O

Continued...

Ring No. Pipe sizes and pressure class Pitch Outside Width of Width of flat Height of Height Radius Depth of Width of Radius in Approx. Weight

rating for Type RX Ring Gaskets diameter of diameter of ring outside of ring in ring groove groove groove distance

ring ring bevel between

(groove) m ade-up

flanges

P OD Ad C D Hd R1 E F R2 S

API (PSI) +0.02 ±0.008 ±0.006 0 +0.008 +0.02 max.

±0.005 0 0 0 -0.03 0 ±0.02 0 ±0008

2000 3000 5000 Dimensions in inches Lbs

RX-66 … 16" … 18.500 19.031 0.656 0.335 0.208 1.250 0.06 0.44 0.656 0.06 0.47 7.52

RX-69 18" … … 21.000 21.422 0.469 0.254 0.167 1.000 0.06 0.31 0.469 0.03 0.47 20.14

RX-70 … 18" … 21 21.656 0.781 0.407 0.271 1.625 0.09 0.5 0.781 0.06 0.72 11.63

RX-73 20" … … 23.000 23.469 0.531 0.263 0.208 1.250 0.06 0.38 0.531 0.06 0.59 22.10

RX-74 … 20" … 23.000 23.656 0.781 0.407 0.271 1.625 0.09 0.50 0.781 0.06 0.72 0.790

RX-82 … … … 2.250 2.672 0.469 0.254 0.167 1.000 0.06 0.31 0.469 0.03 0.47 0.880

RX-84 … … … 2.500 2.922 0.469 0.254 0.167 1.000 0.06 0.31 0.469 0.03 0.47 0.880

RX-85 … … … 3.125 3.547 0.531 0.263 0.167 1.000 0.06 0.38 0.531 0.06 0.38 1.79

RX-86 … … … 3.563 4.078 0.594 0.335 0.188 1.125 0.06 0.44 0.656 0.06 0.38 1.98

RX-87 … … … 3.938 4.453 0.594 0.335 0.188 1.125 0.06 0.44 0.656 0.06 0.38 3.22

RX-88 … … … 4.875 5.484 0.688 0.407 0.208 1.250 0.06 0.50 0.781 0.06 0.38 2.98

RX-89 … … … 4.500 5.109 0.719 0.407 0.208 1.250 0.06 0.50 0.781 0.06 0.38 6.82

RX-90 … … … 6.125 6.875 0.781 0.479 0.292 1.750 0.09 0.56 0.906 0.06 0.72 17.10

RX-91 … … … 10.250 11.297 1.188 0.780 0.297 1.781 0.09 0.69 1.313 0.09 0.75 3.31

RX-99 (8") (8") … 9.250 9.672 0.469 0.254 0.167 1.000 0.06 0.31 0.469 0.03 0.47 …

RX-201 … … 1-3/8" 1.813 2.026 0.226 0.126 0.057 b 0.445 0.02 c 0.16 0.219 0.03 … …

1-

RX-205 … … 2.250 2.453 0.219 0.120 0.072 b 0.437 0.02 c 0.16 0.219 0.02 … …

13/16"

RX-210 … … 2-9/16" 3.500 3.844 0.375 0.231 0.125 b 0.750 0.03 c 0.25 0.375 0.03 … …

RX-215 … … 4-1/16" 5.125 5.547 0.469 0.210 0.167 b 1.000 0.06 c 0.31 0.469 0.03 … …

a

The pressure passage hole illustrated in the RX ring cross section applies to rings RX-82 through RX-91 only. Centerline of hole shall be located at mid point of

dimension C. Hole diameter shall be 0.06 inches for rings RX-82 through RX-85, 0.09 inches for rings RX-86 and RX-87, and 0.12 inches for rings RX-88

through RX-91.

b

Tolerance on these dimensions is +0, - 0.015

c

Tolerance on these dimensions is +0.02, +0

d

A plus tolerance of 0.008 inches for width A and height H is permitted, provided the variation in width or height of any ring does not exceed 0.004 inches

through its entire circumference.

(8”) Denotes crossover flange connection.

API 6A approved for manufacture.

Вам также может понравиться

- Tme BX: Technical Data SheetДокумент2 страницыTme BX: Technical Data SheetEnrique HortaОценок пока нет

- Tme R: Technical Data SheetДокумент5 страницTme R: Technical Data SheetEnrique HortaОценок пока нет

- Sbfi Rwy-15-33 Vac 20211104Документ1 страницаSbfi Rwy-15-33 Vac 20211104Fábio KastelamaryОценок пока нет

- VNT Brochure NewДокумент5 страницVNT Brochure Newda vin ciОценок пока нет

- D297 Strainers CraneFS DS 1021 p139Документ1 страницаD297 Strainers CraneFS DS 1021 p139ธนาธิป 002Оценок пока нет

- Detail C - Cable Detail D - Height Detail A - : Routing Powertail/FeederДокумент1 страницаDetail C - Cable Detail D - Height Detail A - : Routing Powertail/Feedervinod 7Оценок пока нет

- RX Rotary Union (2 - 3 - ) Dual Flow BrochureДокумент2 страницыRX Rotary Union (2 - 3 - ) Dual Flow BrochureFelySaezОценок пока нет

- Kerosene StripperДокумент10 страницKerosene StripperToni100% (1)

- Building ReferencesДокумент266 страницBuilding Referencesaya maapОценок пока нет

- Steel Sun and Planet GearДокумент1 страницаSteel Sun and Planet GearAmarnathОценок пока нет

- Block Mill Pass Profile PDFДокумент1 страницаBlock Mill Pass Profile PDFAmit RayОценок пока нет

- Chainc2040a1 enДокумент1 страницаChainc2040a1 enArmor MachineryОценок пока нет

- Strainer PN32: Features & BenefitsДокумент1 страницаStrainer PN32: Features & BenefitsGabriel RodriguezОценок пока нет

- CGT Fury PCBA-Snubber Bracket - Sheet1Документ1 страницаCGT Fury PCBA-Snubber Bracket - Sheet1Haris OsmanagicОценок пока нет

- Fakm - Vor-Dme Rwy 02 - Vor-01 12dec2013Документ1 страницаFakm - Vor-Dme Rwy 02 - Vor-01 12dec2013DeanОценок пока нет

- Motor Handle For Manual Rotating RBSДокумент1 страницаMotor Handle For Manual Rotating RBSIrfhan FebrianОценок пока нет

- GA Drawing SO2 Scrubber - R1-To SadiartoДокумент1 страницаGA Drawing SO2 Scrubber - R1-To SadiartoAyahKenzieОценок пока нет

- GA Drawing SO2 Scrubber - R1Документ1 страницаGA Drawing SO2 Scrubber - R1AyahKenzieОценок пока нет

- H Bridge: Acc. ISO13850Документ5 страницH Bridge: Acc. ISO13850Mario Alfaro CanoОценок пока нет

- F.T - Arnes QR Tipo X Anticaidas y Sujecion para Kit AlpinismoДокумент6 страницF.T - Arnes QR Tipo X Anticaidas y Sujecion para Kit AlpinismoSOCORRO RENDONОценок пока нет

- Cylinder Top PDFДокумент1 страницаCylinder Top PDFpushpender bajajОценок пока нет

- Sd06e01b01 07enДокумент1 страницаSd06e01b01 07enAli Abdul MannanОценок пока нет

- Propeller Shaft: SectionДокумент13 страницPropeller Shaft: SectionEduardo ColinОценок пока нет

- SELECTION Radiator Valve DIN 42560 Type A - ENG PDFДокумент2 страницыSELECTION Radiator Valve DIN 42560 Type A - ENG PDFSiniša PerčićОценок пока нет

- E60H Series: Rotary EncoderДокумент1 страницаE60H Series: Rotary EncoderkopihitammorningbakeryОценок пока нет

- SELECTION Radiator Valve DIN 42560 Type A - ENG PDFДокумент2 страницыSELECTION Radiator Valve DIN 42560 Type A - ENG PDFSiniša PerčićОценок пока нет

- Low Pressure Second Stage Regulators LV5503B Series: Materials ApplicationДокумент1 страницаLow Pressure Second Stage Regulators LV5503B Series: Materials ApplicationMarcos Mezahuaman LaimeОценок пока нет

- Telescopic CylinderДокумент2 страницыTelescopic CylinderReference mapiyeОценок пока нет

- 1597 KI Avant Tone Horn S140 HELLA ENДокумент2 страницы1597 KI Avant Tone Horn S140 HELLA ENUlyses MorataОценок пока нет

- Furnace Coil DrawingДокумент1 страницаFurnace Coil DrawingpurОценок пока нет

- XL120RFS Ex3 Revision DanielHuberДокумент1 страницаXL120RFS Ex3 Revision DanielHuberBigPantsОценок пока нет

- A2 Mybmrchuc: VDP-1507-G0011-D01-01Документ1 страницаA2 Mybmrchuc: VDP-1507-G0011-D01-01tênchỉđểgọiОценок пока нет

- Vio50-6b Vio55-6b 2311Документ8 страницVio50-6b Vio55-6b 2311hakkinenjanne94Оценок пока нет

- RE HiMisExtДокумент1 страницаRE HiMisExtJulien LardyОценок пока нет

- Assembly Elec Gland ESF4 Page1Документ1 страницаAssembly Elec Gland ESF4 Page1tututasОценок пока нет

- Oga 01 40Документ4 страницыOga 01 40hasmukh parmarОценок пока нет

- Flange OutletДокумент1 страницаFlange OutletdolensiallaganОценок пока нет

- Road Wheels & Tires: SectionДокумент5 страницRoad Wheels & Tires: SectionTESA MOTORSОценок пока нет

- B 126 GДокумент4 страницыB 126 GJitendra BagalОценок пока нет

- Pub033 006 00 0219Документ6 страницPub033 006 00 0219tulaskarОценок пока нет

- P Gleason Locator 22.3Документ1 страницаP Gleason Locator 22.3VikramОценок пока нет

- Rooster RandДокумент1 страницаRooster Randapi-371028301Оценок пока нет

- Legrand 36252Документ1 страницаLegrand 36252helmi.rifkiОценок пока нет

- Steel Helical Gears: Spur Gears Spur GearsДокумент1 страницаSteel Helical Gears: Spur Gears Spur GearsjaseОценок пока нет

- Pub087 005 00 - 1014Документ4 страницыPub087 005 00 - 1014PrakashОценок пока нет

- Features: Switching RegulatorДокумент7 страницFeatures: Switching RegulatorCesar GastaldiОценок пока нет

- Ilovepdf Merged PDFДокумент18 страницIlovepdf Merged PDFRahul BaroОценок пока нет

- Preliminary Submission Drawings: Monolithic Ringbeams & Slab Layout (Ringbeams at First Floor Slab Level)Документ1 страницаPreliminary Submission Drawings: Monolithic Ringbeams & Slab Layout (Ringbeams at First Floor Slab Level)TerrenceОценок пока нет

- P1359 SWA S001 - Rev4Документ1 страницаP1359 SWA S001 - Rev4geethsanОценок пока нет

- SH PDFДокумент1 страницаSH PDFchandraОценок пока нет

- Acople 5R10Документ1 страницаAcople 5R10Jose Emilio Carrero AngaritaОценок пока нет

- 13.1 Tampak Samping Trafo 1 RantauДокумент3 страницы13.1 Tampak Samping Trafo 1 Rantaubeembo_boysОценок пока нет

- Crosby® Wide Body Shackles85Документ1 страницаCrosby® Wide Body Shackles85elias aouadОценок пока нет

- Manual de Servicio Equipo SD Pato Primo JVC - Ux-G355 - g357Документ43 страницыManual de Servicio Equipo SD Pato Primo JVC - Ux-G355 - g357AULIS LOORОценок пока нет

- Stainless Steel Worms: Spur Gears Spur GearsДокумент3 страницыStainless Steel Worms: Spur Gears Spur GearsOriental BearingОценок пока нет

- P.O. Bc23-00002 Drawing For Approval r.0Документ1 страницаP.O. Bc23-00002 Drawing For Approval r.0Hadjer BouchlaghemОценок пока нет

- Fee 191-5-6830-241b-K1777-Granelero 42M3Документ2 страницыFee 191-5-6830-241b-K1777-Granelero 42M3hugoОценок пока нет

- Info Tecnica PekosДокумент1 страницаInfo Tecnica PekosRobertoОценок пока нет

- Cameron Manual Type F FCДокумент7 страницCameron Manual Type F FCEnrique HortaОценок пока нет

- Cameron Manual Type F FCДокумент7 страницCameron Manual Type F FCEnrique HortaОценок пока нет

- Catalog 2Документ44 страницыCatalog 2Enrique HortaОценок пока нет

- FlexSuite User English PDFДокумент38 страницFlexSuite User English PDFEnrique HortaОценок пока нет

- Cameron Manual Gate Valve FLДокумент2 страницыCameron Manual Gate Valve FLEnrique HortaОценок пока нет

- Weco Butterfly ValvesДокумент3 страницыWeco Butterfly ValvesEnrique HortaОценок пока нет

- Flexmark User English PDFДокумент49 страницFlexmark User English PDFEnrique HortaОценок пока нет

- Tme CS: Technical Data SheetДокумент1 страницаTme CS: Technical Data SheetEnrique HortaОценок пока нет

- Tme Si: Technical Data SheetДокумент1 страницаTme Si: Technical Data SheetEnrique HortaОценок пока нет

- Lone StarДокумент1 страницаLone StarEnrique HortaОценок пока нет

- Dorian Tool Threading Grooving and API CatalogДокумент88 страницDorian Tool Threading Grooving and API CatalogEnrique HortaОценок пока нет

- 2a33687 Exl Back Pressure Relief Valve PDFДокумент51 страница2a33687 Exl Back Pressure Relief Valve PDFEnrique HortaОценок пока нет

- Ram-Type BOPs U BOP at BULLET UII BOP UL PDFДокумент24 страницыRam-Type BOPs U BOP at BULLET UII BOP UL PDFEnrique HortaОценок пока нет

- 2a33687 Exl Back Pressure Relief ValveДокумент19 страниц2a33687 Exl Back Pressure Relief ValveEnrique HortaОценок пока нет

- MCM Catalog Rev 16Документ31 страницаMCM Catalog Rev 16Enrique HortaОценок пока нет

- Program of ActivitiesДокумент2 страницыProgram of ActivitiesVon Limuel LopezОценок пока нет

- Progressive Muscle Relaxation ExerciseДокумент2 страницыProgressive Muscle Relaxation Exerciseraghu2362704100% (1)

- THE BASIC TYPES OF SPEECHES PPTДокумент14 страницTHE BASIC TYPES OF SPEECHES PPTKevin BanezОценок пока нет

- SDOF SystemsДокумент87 страницSDOF SystemsAhmet TükenОценок пока нет

- Updated WorksheetДокумент5 страницUpdated WorksheetJohn Ramer Lazarte InocencioОценок пока нет

- Concept of Lokmitra Kendra in Himachal PradeshДокумент2 страницыConcept of Lokmitra Kendra in Himachal PradeshSureshSharmaОценок пока нет

- The Technology Procurement HandbookДокумент329 страницThe Technology Procurement HandbookAlexander Jose Chacin NavarroОценок пока нет

- Managing Markets Strategically: Professor Noel CaponДокумент49 страницManaging Markets Strategically: Professor Noel CaponChristiandeuxОценок пока нет

- Brp-Rotax Chassis Approval FormДокумент3 страницыBrp-Rotax Chassis Approval Formdelta compОценок пока нет

- Emcee Script For Recognition DayДокумент3 страницыEmcee Script For Recognition DayRomeo Jr. LaguardiaОценок пока нет

- Hemax-530 PDFДокумент2 страницыHemax-530 PDFNice BennyОценок пока нет

- Cimo Guide 2014 en I 3Документ36 страницCimo Guide 2014 en I 3lakisОценок пока нет

- Operation and Service 69UG15: Diesel Generator SetДокумент72 страницыOperation and Service 69UG15: Diesel Generator Setluis aguileraОценок пока нет

- Natal Chart Report PDFДокумент17 страницNatal Chart Report PDFAnastasiaОценок пока нет

- Reviewer in PE&H 1st Quarter 18-19Документ7 страницReviewer in PE&H 1st Quarter 18-19rhex minasОценок пока нет

- OPENING & CLOSING PROGRAM NARRATIVE REPORT (Grade 7)Документ4 страницыOPENING & CLOSING PROGRAM NARRATIVE REPORT (Grade 7)Leo Jun G. Alcala100% (1)

- Modular Heavy Duty Truck TransmissionДокумент6 страницModular Heavy Duty Truck Transmissionphucdc095041Оценок пока нет

- NGCP - Procedures and Requirements For Energy ProjectsДокумент17 страницNGCP - Procedures and Requirements For Energy ProjectspurplebasketОценок пока нет

- Aristotle Metaphysics Lambda Accessed 201111 Classicalk LibraryДокумент19 страницAristotle Metaphysics Lambda Accessed 201111 Classicalk Librarygijsbo2000Оценок пока нет

- Fiedler1950 - A Comparison of Therapeutic Relationships in PsychoanalyticДокумент10 страницFiedler1950 - A Comparison of Therapeutic Relationships in PsychoanalyticAnca-Maria CovaciОценок пока нет

- UntitledДокумент5 страницUntitledapril montejoОценок пока нет

- Bombas KMPДокумент42 страницыBombas KMPReagrinca Ventas80% (5)

- Empowerment Technology Lesson 4 PDFДокумент18 страницEmpowerment Technology Lesson 4 PDFqueenless eightyoneОценок пока нет

- NCRA Membership InformationДокумент1 страницаNCRA Membership Informationbkharkreader1301Оценок пока нет

- Sensor de Temperatura e Umidade CarelДокумент1 страницаSensor de Temperatura e Umidade CarelMayconLimaОценок пока нет

- Effect of Minor and Trace Elements in Cast IronДокумент2 страницыEffect of Minor and Trace Elements in Cast IronsachinguptachdОценок пока нет

- TinkerPlots Help PDFДокумент104 страницыTinkerPlots Help PDFJames 23fОценок пока нет

- Ib Psychology - Perfect Saq Examination Answers PDFДокумент2 страницыIb Psychology - Perfect Saq Examination Answers PDFzeelaf siraj0% (2)

- Mobility StrategyДокумент38 страницMobility StrategySoubhagya PОценок пока нет

- Analyst - Finance, John Lewis John Lewis PartnershipДокумент2 страницыAnalyst - Finance, John Lewis John Lewis Partnershipsecret_1992Оценок пока нет