Академический Документы

Профессиональный Документы

Культура Документы

Technical Details

Загружено:

Prashant TrivediИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Technical Details

Загружено:

Prashant TrivediАвторское право:

Доступные форматы

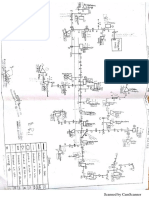

) Overhead Line

Pole Foundation hole should be drilled in the ground with the use of earth-augers. However, if earth-augers are not available a dog pit of the size I.2 x O.6 m should

be made in the direction of the line.

The depth of the pit shall be in accordance-with the length of the pole to be planted in the ground as given in respective Indian Standards.

2) Tubular Pole

Steel Tubular Poles, Rolled Steel Joists and Rails – A suitable pad of cement concrete, stone or steel shall be provided at the bottom of the pit, before the metallic

pole is erected.

Where metal works are likely to get corroded ( points where the pole emerges out of the ground ), a cement concrete muff, 20 cm above and 20 cm below the

ground with sloping top shall be provided.

3) RCC Pole

RCC poles generally have larger cross-section than the PCC poles and, therefore, the base plates

or muffing are usually not provided for these types of poles.

However, for PCC poles, a base plate ( 40 x 40 x 7 cm concrete block ) shall be provided. Cement concrete muff with sloping top may also be provided, 20 cm

above and 20 cm below-the ground level, when the ground or local conditions call for the same.

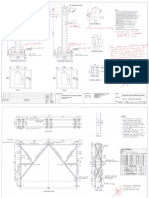

4) H.V Line (120m To 160m Span)

The insulators should be attached to the poles directly with the help of ‘D’ type or other suitable clamps in case of vertical configuration of conductors or be

attached to the cross arms with the help of pins in case of horizontal configuration

Pin insulator:; and recommended for use on straight runs and up to maximum of 10’ deviation.

The disc insulators are intended for use a pole positions having more than 30’ angle or for dead ending of I1 kV lines.

For lines having=, a bend of 10” to 30’, either double cross arms or disc insulators should be used for HT lines up to 11 kV. For low and medium voltage line,

shackle insulators should be used

For Vertical configuration for Conductor erection:

Distance between Pole’s Top to Disc insulation=200mm.

Between Disc insulator to Disc Insulator=1000mm.

Between Disc insulator to Guy Wire=500mm.

5) Stay Wire Angle with Pole

Overhead lines supports at angles and terminal positions should be well stayed with stay wire, rod, etc. The angle between the pole and the wire should be about

45” and in no case should be less than 30”. If the site conditions are such that an angle or more than 30“ between the pole and the stay wire cannot be obtained,

special stays such as, foot stay, flying stay or struts may be used

Hard drawn galvanized steel wires should be used as stay wires. The tensile strength of these wires shall not be less than 70 kgf/mm2. Only standard wires should

be used for staying purpose.

Вам также может понравиться

- How to Build a Global Model Earthship Operation II: Concrete WorkОт EverandHow to Build a Global Model Earthship Operation II: Concrete WorkОценок пока нет

- Abstract of Is 5613 (Part 1, 2, 3)Документ6 страницAbstract of Is 5613 (Part 1, 2, 3)Jignesh ParmarОценок пока нет

- Getco - Sor 2018-19Документ12 страницGetco - Sor 2018-19Anonymous KC6pTURheОценок пока нет

- 33 KV Spec ProcessДокумент16 страниц33 KV Spec ProcessKaran K EEEОценок пока нет

- REC Standards To FollowДокумент3 страницыREC Standards To FollowkvsudheendraОценок пока нет

- Transmission LinesДокумент15 страницTransmission LinesHafizulla Sheik100% (1)

- 11kV Line - WorkДокумент4 страницы11kV Line - Worksbpathi50% (2)

- StandardДокумент3 страницыStandardAnonymous m4MF1gОценок пока нет

- OHLДокумент106 страницOHLvaithy1990Оценок пока нет

- Technical Specifications 11kvДокумент106 страницTechnical Specifications 11kvprasanthvenkatesh60% (5)

- Fencing, Compound Wall and Gate (Pranoti) - 1Документ36 страницFencing, Compound Wall and Gate (Pranoti) - 1MG100% (1)

- Gate Slides 25july18 WITH FULL SLIDEДокумент38 страницGate Slides 25july18 WITH FULL SLIDEamanОценок пока нет

- Duct BankДокумент7 страницDuct BankAwotiku AbimbolaОценок пока нет

- Abstract of Is 1255Документ6 страницAbstract of Is 1255Jignesh ParmarОценок пока нет

- Ducts ManholesДокумент3 страницыDucts ManholesKhay SaadОценок пока нет

- Item F-161 Wire Fence With Steel Posts (Class C and D Fence)Документ4 страницыItem F-161 Wire Fence With Steel Posts (Class C and D Fence)Wansa Pearl FoundationsОценок пока нет

- Scet Chemical 1 Year Bee PPT Group-3: Earthing and Its TypesДокумент22 страницыScet Chemical 1 Year Bee PPT Group-3: Earthing and Its TypesdhruvОценок пока нет

- Earthing: Earth Continuity Conductor or Earth WireДокумент6 страницEarthing: Earth Continuity Conductor or Earth WireAditya SinghaniaОценок пока нет

- Chain Link Fencing: Galvanised Green Pve Coated/Galvanised CoreДокумент3 страницыChain Link Fencing: Galvanised Green Pve Coated/Galvanised CorevanmurthyОценок пока нет

- Abstract of IS: 3043 Code For Earthing PracticeДокумент4 страницыAbstract of IS: 3043 Code For Earthing PracticeArun.V1984Оценок пока нет

- 220KV SWYD Surface GravelingДокумент2 страницы220KV SWYD Surface Gravelingabdulyunus_amirОценок пока нет

- Gi Conduit LayingДокумент5 страницGi Conduit LayingPrasad PanchatsaramОценок пока нет

- Facility ManagementДокумент7 страницFacility ManagementTajudeen IbrahimОценок пока нет

- Specification For ConstructionДокумент5 страницSpecification For ConstructionJoven MasbanuaОценок пока нет

- LV and MV Construction StandardsДокумент23 страницыLV and MV Construction StandardssemajamesОценок пока нет

- BouldernetsinstallДокумент4 страницыBouldernetsinstallJimmy ThomasОценок пока нет

- Method Statement - FA Silo-12.69m LVLДокумент5 страницMethod Statement - FA Silo-12.69m LVLArunkumarОценок пока нет

- Stringing TerminologyДокумент2 страницыStringing TerminologyAmit MandolОценок пока нет

- Abstract of CPWD For Internal Electrification WorkДокумент4 страницыAbstract of CPWD For Internal Electrification WorkJignesh ParmarОценок пока нет

- TECHNICAL SPECIFICATIONS CONSTRUCTION RodelДокумент12 страницTECHNICAL SPECIFICATIONS CONSTRUCTION Rodelmary joy PanamaОценок пока нет

- Techinical Specifications Welcome To NescoДокумент54 страницыTechinical Specifications Welcome To NescotejzabОценок пока нет

- JIS 3653-1994 Underground CableДокумент19 страницJIS 3653-1994 Underground CableTuong Nguyen Duc Minh100% (2)

- Wire Fence With Steel Posts (Classes C and D Fences)Документ4 страницыWire Fence With Steel Posts (Classes C and D Fences)Devrim GürselОценок пока нет

- Electric Earthing and ShockДокумент17 страницElectric Earthing and ShockRamakrishna ChaitanyaОценок пока нет

- Earth Mat For Underground Metro StationДокумент2 страницыEarth Mat For Underground Metro Stationzaheeruddin_mohdОценок пока нет

- Track Structure On BridgesДокумент85 страницTrack Structure On BridgesSudipto PaulОценок пока нет

- Checklist For Cable Trench (Indoor & Outdoor)Документ4 страницыChecklist For Cable Trench (Indoor & Outdoor)Rupesh KhandekarОценок пока нет

- Earthing Details As Is-3043Документ5 страницEarthing Details As Is-3043Pramod B.Wankhade88% (8)

- Abstract of IS 1255 (Installation & Maintenance of Cable) : 1) Route IndicatorДокумент12 страницAbstract of IS 1255 (Installation & Maintenance of Cable) : 1) Route IndicatorAnonymous 4gDItzОценок пока нет

- Earthing SystemДокумент8 страницEarthing SystemAhmed BoussoffaraОценок пока нет

- Rev DrainДокумент6 страницRev DrainRaj RahulОценок пока нет

- Importance of Earthing & PracticesДокумент26 страницImportance of Earthing & PracticesPraveen KumarОценок пока нет

- المواصفات العامة لجسور وجسور السكك الحديدية من الحديد والصلب 2Документ232 страницыالمواصفات العامة لجسور وجسور السكك الحديدية من الحديد والصلب 2Amjed AlbattatОценок пока нет

- Shaft Sinking 903Документ13 страницShaft Sinking 903Rajnish bediaОценок пока нет

- Fencing, Compound Wall and Gate: by Ar. Pranoti LadДокумент49 страницFencing, Compound Wall and Gate: by Ar. Pranoti Ladbishal dasОценок пока нет

- Abstract of Is 3043Документ4 страницыAbstract of Is 3043Jignesh ParmarОценок пока нет

- Footing Systems Part AДокумент16 страницFooting Systems Part ASixd WaznineОценок пока нет

- Intro To CablesДокумент56 страницIntro To CablesAhdab ElmorshedyОценок пока нет

- Electrical CheckListДокумент33 страницыElectrical CheckListYudo Heru PribadiОценок пока нет

- PIPEДокумент10 страницPIPEJoshua SykamОценок пока нет

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsОт EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsОценок пока нет

- Transactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173От EverandTransactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173Оценок пока нет

- An Introduction to Metal-Working (Illustrated)От EverandAn Introduction to Metal-Working (Illustrated)Рейтинг: 2.5 из 5 звезд2.5/5 (2)

- How to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityОт EverandHow to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityОценок пока нет

- Cabins & Cottages, Revised & Expanded Edition: The Basics of Building a Getaway Retreat for Hunting, Camping, and Rustic LivingОт EverandCabins & Cottages, Revised & Expanded Edition: The Basics of Building a Getaway Retreat for Hunting, Camping, and Rustic LivingОценок пока нет

- N0. 5/2 (T/NT) /2020/data Bank/Pers.: Wapcos LimitedДокумент1 страницаN0. 5/2 (T/NT) /2020/data Bank/Pers.: Wapcos LimitedPrashant TrivediОценок пока нет

- Exploring The IEEE C37.234 Guide For Protective Relay Application To Power System BusesДокумент10 страницExploring The IEEE C37.234 Guide For Protective Relay Application To Power System BusesPrashant TrivediОценок пока нет

- Protection Phillosphy With ScadaДокумент11 страницProtection Phillosphy With ScadaPrashant TrivediОценок пока нет

- Understanding Electrical Treeing Phenomena in XLPEДокумент8 страницUnderstanding Electrical Treeing Phenomena in XLPEPrashant TrivediОценок пока нет

- 77 PE 12 10 310-314 BendaoudДокумент6 страниц77 PE 12 10 310-314 BendaoudPrashant TrivediОценок пока нет

- Prospects of Bulk Power EHV and UHV Transmission (PDFDrive)Документ20 страницProspects of Bulk Power EHV and UHV Transmission (PDFDrive)Prashant TrivediОценок пока нет

- Technical Specification For 7/3.66 EARTH WIRE: Rail Coach Factory, Rae BareliДокумент8 страницTechnical Specification For 7/3.66 EARTH WIRE: Rail Coach Factory, Rae BareliPrashant TrivediОценок пока нет

- Specification of LT Capcitor PannelДокумент12 страницSpecification of LT Capcitor PannelPrashant TrivediОценок пока нет

- Ep 21 00 00 01 SPДокумент13 страницEp 21 00 00 01 SPPrashant TrivediОценок пока нет

- AL-LIN-50002 - 2009-Oct-27 - Rev3Документ25 страницAL-LIN-50002 - 2009-Oct-27 - Rev3Prashant TrivediОценок пока нет

- CT PT La DrawingДокумент6 страницCT PT La DrawingPrashant TrivediОценок пока нет

- N - Arc Consulting IrconДокумент13 страницN - Arc Consulting IrconPrashant TrivediОценок пока нет

- Technical Specification For 11Kv DG Set: Rail Coach Factory, Rae BareliДокумент38 страницTechnical Specification For 11Kv DG Set: Rail Coach Factory, Rae BareliPrashant Trivedi0% (1)

- LT ACDB Rae BareliДокумент41 страницаLT ACDB Rae BareliPrashant TrivediОценок пока нет

- AL-LIN-10013 - InsulatorДокумент7 страницAL-LIN-10013 - InsulatorPrashant TrivediОценок пока нет

- Current Transformers: For Worldwide CooperationДокумент40 страницCurrent Transformers: For Worldwide CooperationPrashant TrivediОценок пока нет

- Joints and Terminations of Polymeric Cables For Working Voltages From 6.6 KV Up To and Including 33 KV - Performance Requirements and Type TestsДокумент14 страницJoints and Terminations of Polymeric Cables For Working Voltages From 6.6 KV Up To and Including 33 KV - Performance Requirements and Type TestsPrashant TrivediОценок пока нет

- 50V Battery, Battery Charger and DCDBДокумент14 страниц50V Battery, Battery Charger and DCDBPrashant TrivediОценок пока нет

- C 10: D D D S: "What Gets Measured Gets Managed."Документ16 страницC 10: D D D S: "What Gets Measured Gets Managed."Prashant TrivediОценок пока нет

- 11kv Side NCT Sizing (High Impedance) PDFДокумент1 страница11kv Side NCT Sizing (High Impedance) PDFPrashant TrivediОценок пока нет

- Bus Bar Sizing Cal 400kv r0Документ4 страницыBus Bar Sizing Cal 400kv r0Prashant TrivediОценок пока нет

- Attachment For BB CalcultionsДокумент4 страницыAttachment For BB CalcultionsPrashant TrivediОценок пока нет

- New Doc 2018-03-23Документ1 страницаNew Doc 2018-03-23Prashant TrivediОценок пока нет

- Lightning Arrester LatestДокумент3 страницыLightning Arrester LatestPrashant TrivediОценок пока нет

- Indian Standard: Recommended Short-Circuit Ratings of High Voltage PVC Cables (Документ14 страницIndian Standard: Recommended Short-Circuit Ratings of High Voltage PVC Cables (Prashant TrivediОценок пока нет

- Code of Practice For Design, Installation and Maintenance For Overhead Power LinesДокумент19 страницCode of Practice For Design, Installation and Maintenance For Overhead Power LinesPrashant TrivediОценок пока нет

- Indian Standard: Specification For On-Load Tap-Changers 0. ForewordДокумент26 страницIndian Standard: Specification For On-Load Tap-Changers 0. ForewordPrashant TrivediОценок пока нет

- Control Room: Partner For Contact: Order No.: Company: Customer No.Документ27 страницControl Room: Partner For Contact: Order No.: Company: Customer No.Prashant TrivediОценок пока нет

- Dry Type TransformersДокумент5 страницDry Type TransformersPrashant TrivediОценок пока нет

- Section 14 Unab Rid Dged Written VersionДокумент17 страницSection 14 Unab Rid Dged Written VersionPrashant TrivediОценок пока нет

- Electrical Engineering Hand BookДокумент22 страницыElectrical Engineering Hand Bookjicksonjohn100% (1)

- Module 7: Out of Step Protection: Power Swing Detection, Blocking and Out-of-Step RelaysДокумент2 страницыModule 7: Out of Step Protection: Power Swing Detection, Blocking and Out-of-Step RelaysramkumarelecОценок пока нет

- LiFi FAQДокумент2 страницыLiFi FAQGurpreet SinghОценок пока нет

- Application Notes: Application Notes P14X/En Ap/B54 Micom P141, P142, P143Документ178 страницApplication Notes: Application Notes P14X/En Ap/B54 Micom P141, P142, P143Dũng Đinh TiếnОценок пока нет

- WAGO - 60278165 PSF-5.0-compressed PDFДокумент300 страницWAGO - 60278165 PSF-5.0-compressed PDFravichandran0506Оценок пока нет

- Korg M3 Manual en InglesДокумент241 страницаKorg M3 Manual en InglesElio José Torrez VargasОценок пока нет

- ZL-7901A en V2.5 PDFДокумент7 страницZL-7901A en V2.5 PDFgwamitiОценок пока нет

- Laplace TransformsДокумент81 страницаLaplace TransformsChristopher OrtegaОценок пока нет

- Netscout Tap Connect Guide 733-0604 PDFДокумент76 страницNetscout Tap Connect Guide 733-0604 PDFFabricio VindasОценок пока нет

- Tips For Upgrading Amps AV502Документ8 страницTips For Upgrading Amps AV502gmaldo7183100% (6)

- Paper 03 GM 0984Документ7 страницPaper 03 GM 0984surojjОценок пока нет

- Seeed Music Shield DatasheetДокумент6 страницSeeed Music Shield Datasheetk_goulasОценок пока нет

- Monitor AocДокумент58 страницMonitor AocjonatanactosОценок пока нет

- TMP - 11281-Error Codes - Canon - Ir3300 - Page 11424020151Документ3 страницыTMP - 11281-Error Codes - Canon - Ir3300 - Page 11424020151nichoОценок пока нет

- Introduction To Arduino PDFДокумент13 страницIntroduction To Arduino PDFAbhinav ChoudharyОценок пока нет

- 984 SystemmanualДокумент328 страниц984 SystemmanualMark TaylorОценок пока нет

- EMD SyllabusДокумент2 страницыEMD Syllabuskkk212Оценок пока нет

- Electrical Diagrams: Ac Motor Control SystemДокумент80 страницElectrical Diagrams: Ac Motor Control SystemJohn fredy cuervo100% (1)

- Thrane & Thrane Explorer 700Документ2 страницыThrane & Thrane Explorer 700alamgir77Оценок пока нет

- BDX 53 FДокумент4 страницыBDX 53 FNoelОценок пока нет

- GCC 28 enДокумент6 страницGCC 28 enEduardo VicoОценок пока нет

- Course "EEM 42 Three-Phase Asynchronous Machines: Dahlander Motors"Документ38 страницCourse "EEM 42 Three-Phase Asynchronous Machines: Dahlander Motors"Daus VillaОценок пока нет

- Dual, Simultaneous Sampling, 16-Bit/14-Bit, 4 Msps Sar Adcs, Differential InputsДокумент32 страницыDual, Simultaneous Sampling, 16-Bit/14-Bit, 4 Msps Sar Adcs, Differential InputsDaniel DiazОценок пока нет

- RSSI and RX Levels TroubleshootДокумент15 страницRSSI and RX Levels TroubleshootPuneet Kumar100% (8)

- TTA MCC in Withdrawable DesignДокумент8 страницTTA MCC in Withdrawable DesignLaurentiu CatalinОценок пока нет

- ELTE2.3 DBS3900 LTE TDD Basic Feature DescriptionДокумент92 страницыELTE2.3 DBS3900 LTE TDD Basic Feature DescriptioneuniceikaОценок пока нет

- ABB - IDPGHV - Customer Day 2017 - October 3 Power Quality PDFДокумент59 страницABB - IDPGHV - Customer Day 2017 - October 3 Power Quality PDFAhmadBintangNegoroОценок пока нет

- Build The Class AB Push Pull Amplifier.: Report OnДокумент19 страницBuild The Class AB Push Pull Amplifier.: Report Onreal print100% (1)

- Gas Sensor Module For Refrigeration Air Quality ZMOD4450Документ22 страницыGas Sensor Module For Refrigeration Air Quality ZMOD4450Camilo PradaОценок пока нет

- IRC5Документ549 страницIRC5HugoRamosОценок пока нет