Академический Документы

Профессиональный Документы

Культура Документы

Material Related Aspects of Asphalt Recycling

Загружено:

Matei PopaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Material Related Aspects of Asphalt Recycling

Загружено:

Matei PopaАвторское право:

Доступные форматы

Material-Related Aspects of Asphalt

Recycling—State-of-the-Art

Robert Karlsson1 and Ulf Isacsson2

Downloaded from ascelibrary.org by WASHINGTON UNIV IN ST LOUIS on 06/27/14. Copyright ASCE. For personal use only; all rights reserved.

Abstract: Current knowledge on material-related aspects of asphalt recycling with focus on findings from fundamental studies is

summarized. By way of introduction, a general description of different types of asphalt recycling methods is given, after which a more

detailed compilation of material-related knowledge is presented. Special attention is given to the binder rejuvenation process at asphalt

recycling, that is the restoration of reclaimed binder properties. Studies concerning properties of recycled mixtures are also summarized.

DOI: 10.1061/共ASCE兲0899-1561共2006兲18:1共81兲

CE Database subject headings: Recycling; Asphalts; Material properties; Temperature; Mixtures.

Introduction existing asphalt. Emphasis is put on general findings from more

fundamental investigations. Besides the studies referred to in this

Asphalt recycling has been an important option in road mainte- paper, a great number of publications have been found. However,

nance and construction since the mid-1970s oil crisis, when con- these publications generally describe practical observations but do

struction costs inflated, especially the price on bitumen. Initially, not present more fundamental aspects of asphalt recycling, and,

recycled asphalt materials were primarily used on low-trafficked consequently, this type of paper is not included in this literature

roads. Over the years, considerable experience has been gained; review.

today recycling methods are also considered for heavy trafficked

roads, and the recycling ratio may be close to 100%. Reuse of

asphalt means that the complexity of the maintenance operation Methods and Strategies for Asphalt Recycling

increases, as the reclaimed material is more difficult to character-

ize compared to new material. During its service life, the old Any road in need of reconstruction or new overlay is a candidate

binder has been aged and the aggregate degraded. Further, the for recycling. During the years, a number of different methods

reclamation process may also contribute to the inhomogeneity of have been developed for reclaiming asphalt, each one being spe-

the recycled pavement material. Finally, possible worker’s health cialized to handle given tasks. Different classifications of asphalt

risks related to heating of asphalt or content of coal tar in re- recycling methods are found in the literature. One example of

claimed asphalt should also be taken into account. Consequently, such a classification is based on the location of the recycling

asphalt recycling is a more demanding and qualified task, requir- process 共in-place, in-plant兲. Another classification parameter used

ing extra knowledge and experience, compared to producing for subdividing of asphalt recycling methods concerns the extent

overlays of virgin asphalt. to which the reclaimed material is heated. In this case, the meth-

During the years, a number of more general state-of-the-art ods may be 共arbitrarily兲 divided into cold 共e.g., below 70° C兲,

共practice兲 reports on asphalt recycling have been published warm 共e.g., between 70 and 120° C兲, and hot 共e.g., above 120° C兲

共ARRA 2001; Button et al. 1994; Epps 1990; Kandhal 1997; recycling.

Kandhal and Mallick 1997; Servas 1980兲. This paper is a review The rest of this section is a brief description of methods used

of literature with focus on material properties and performance of for asphalt recycling. The description serves as an introduction to

recycled asphalt in bitumen bound bases and wearing courses. the review of recycled asphalt properties presented in coming

The main object of the paper is to compile material-related chapters. In addition to these methods, there are also methods that

knowledge on recycled asphalt contributing to optimum reuse of utilize existing pavement by simply milling or heating the sur-

face, thereby minimizing the amount of new asphalt material.

1

Senior Research Engineer, Division of Highway Engineering, Royal Strictly speaking, these are not examples of asphalt recycling

Institute of Technology, S-100 44, Stockholm, Sweden 共corresponding methods, since no reclaimed asphalt material is used.

author兲. E-mail robert.karlsson@byv.kth.se

2

Professor, Division of Highway Engineering, Royal Institute of

Technology, S-100 44, Stockholm, Sweden. E-mail ulf.isacsson@ In-Plant Asphalt Recycling

byv.kth.se During in-plant recycling of asphalt, the reclaimed asphalt is

Note. Associate Editor: Eyad Masad. Discussion open until July 1, mixed with new binder and/or new asphalt. In-plant recycling can

2006. Separate discussions must be submitted for individual papers. To

be divided into cold, warm, and hot recycling, depending on the

extend the closing date by one month, a written request must be filed with

the ASCE Managing Editor. The manuscript for this paper was submitted temperature required 共cf. previous discussion兲. Generally, an as-

for review and possible publication on February 25, 2003; approved on phalt plant needs minor adjustments to handle recycled asphalt,

April 27, 2005. This paper is part of the Journal of Materials in Civil but there are also more sophisticated techniques described that

Engineering, Vol. 18, No. 1, February 1, 2006. ©ASCE, ISSN 0899- require larger investments 共Decker 1997兲.

1561/2006/1-81–92/$25.00. The reclaimed asphalt is generated from milling, or ripping

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / JANUARY/FEBRUARY 2006 / 81

J. Mater. Civ. Eng. 2006.18:81-92.

and crushing of asphalt pavements. Milling is often performed in of hydrocarbons and aging of the binder. One way of minimizing

maintenance works to keep the pavement at a given level with such problems is simply to heat and mill the surface by multiple

respect to curbs and structural clearances before placing a new passes, thereby solving the problem of low thermal conduction,

overlay. The milled material is ready to use, fairly clean, and which prevents heat energy to penetrate the pavement to the de-

relatively uniform. Reclaimed asphalt that has been removed by sired total milling depth 共Carmichael et al. 1977兲. Gentle heating

ripping, for example, in complete removal of a pavement, should also means reduced emissions and aging. The increase in stiffness

be kept clean from soil, etc. as a consequence of heating 共IR radiation兲 during remixing has

The long-distance transport of material from the asphalt plant been observed to correspond to an increase in softening point

and back may result in considerable costs and environmental ef- 共Ring and Ball兲 of 3 – 5 ° C 共Isacsson et al. 1997兲. Direct gas flame

fects, which may be objectionable from a life cycle assessment burners have been abandoned in favor of infrared or hot air heat-

共LCA兲 point of view. Hot in-plant recycling is more common in ers for attaining higher temperatures. However, direct gas flame

Downloaded from ascelibrary.org by WASHINGTON UNIV IN ST LOUIS on 06/27/14. Copyright ASCE. For personal use only; all rights reserved.

urban areas than in less populated areas for transport reasons as burners are still used for drying and preheating the pavement

well as benefits of larger quantities. The use of mobile asphalt surface. Infrared heat is created by heating metal plates until they

plants limits the need for long transports. reach sufficiently high temperatures. The heat from the metal

Unless used directly, the reclaimed material needs to be stored. plates is then radiated down onto the surface of the pavement. To

To keep the material uniform, different types of mixtures should further improve conditions for road workers, equipment has been

be kept segregated in different stockpiles. Another possible ap- introduced that collects and incinerates emitted fumes. The use of

proach for achieving uniformity in reclaimed materials is to blend hot air in convective heating is a relatively new invention de-

reclaimed asphalt materials thoroughly, thereby obtaining more scribed in greater detail by Terrel et al. 共1997兲. The idea is to use

consistent properties. During storage, the outer layer of the stock- a burner to heat air to about 600° C and then to blow the hot air

pile normally sticks together, whereas the rest of the material onto the pavement surface. By controlling the combustion, the

remains intact. Measures to prevent exposure to direct sunlight oxygen level can be kept low, thus creating a virtually inert gas

and dampness are desirable. Ripped and reagglomerated material that can heat the pavement without causing excessive oxidation.

has to be crushed before use. Another advantage is that the hot air can be recirculated, thereby

Leaching of potentially harmful substances from stockpiles saving energy.

has been studied by Larsson et al. 共2000兲. Generally, from con- After heating and milling the pavement surface, generally

ventional asphalt, no alarming levels of pollutants or toxic sub- down to a depth of 30– 50 mm, new asphalt mix and/or new

stances have been found. However, water leached from stockpiles binder is added to the reclaimed asphalt. The added material may

of tar-containing asphalt or oil gravel contained high levels of be either a conventional asphalt mix or a specially designed mix

polyaromatic hydrocarbons 共PAH兲 and showed toxic effects 共mea- to correct imperfections in the reclaimed asphalt. An advantage of

sured using the Microtox bacteria test兲. milling the pavement hot is the fact that the aggregate normally is

In hot asphalt recycling, the reclaimed asphalt can be fed into not crushed and necessary corrections can be based on the origi-

the asphalt plant either after the drum, in the middle of the drum nal grading curve. Often, 15–25% fresh asphalt mix is added to

or in a parallel drum. Before mixing, the reclaimed asphalt may account for ruts, but additions in the range of 0–50% asphalt

be dried, thus avoiding problems when heating to elevated tem- material have been reported 共Potter and Mercer 1997; Button

peratures. Asphalt plants equipped for recycling may also feature et al. 1994兲. Finally, the recycled asphalt is laid using conven-

other types of devices specially designed to minimize binder tional pavers and compacted.

aging and emissions of hydrocarbons and dust. Examples are the The major difference between remixing and repaving is that no

counterflow drum mixer and microwave heaters. They allow up to fresh asphalt is added to the reclaimed asphalt in repaving. In-

100% reclaimed asphalt to be recycled, given that the material is stead, a separate layer of new asphalt is put on top of the old,

of acceptable quality 共NAPA 1996兲. Microwaves are absorbed by recycled asphalt. The repaving process may be characterized by

the aggregate to a greater extent than the binder, which minimizes the following steps. The pavement is heated and milled using a

aging 共Terrel and Abdulaziz 1987兲. However, relatively much rotary mill or scarifying teeth. A rejuvenator may be added to the

electric energy is needed in this case for heating, which may limit reclaimed material, after which the recycled material is spread

the environmental and economical benefits. and screeded. Finally, new asphalt is placed on top, and the two

layers are compacted using conventional rollers.

In-Place Asphalt Recycling Typically, 20– 25 mm of the old pavement is milled. The ad-

vantage of repaving, compared to solely heating the pavement

In-place asphalt recycling, sometimes referred to as “in situ as- surface, is that surface cracks can be interrupted and deeper sur-

phalt recycling,” can either be performed as remixing, repaving, face irregularities 共ruts, corrugations, etc.兲 restored 共Button et al.

cold in-place asphalt recycling or full depth reclamation. Remix- 1994兲. Comparing repaving and remixing, the advantage of re-

ing and repaving are sometimes referred to as “surface recycling.” paving is lower cost and more effective treatment of friction prob-

Remixing is a process in which the surface of the pavement is lems, since 100% new asphalt is placed as a surface layer. No

milled or scarified, after which new material may be added to the example of cold or warm repaving has been found in the

reclaimed material and mixed before laying and compacting the literature.

recycled asphalt. In in-place recycling operations, the needs for In cold and warm in-place recycling 共cold and warm remix-

transportation and storage are minimized. Recycled pavements ing兲, the pavement is cold milled and mixed with bitumen emul-

are often sealed or overlaid with virgin asphalt. In the latter case, sions, foamed bitumen, or soft bitumen. New aggregate can also

the purpose of remixing may be to disrupt cracks prior to placing be added. The warm alternative uses hot steam to heat the re-

an overlay with the aim of increasing the bearing capacity. claimed material. This facilitates both laying and compaction. The

In 共hot兲 remixing, the pavement is normally heated to tempera- weather conditions for cold recycling are normally limited to

tures well above 120° C. Heating the pavement to such high tem- 10° C and fairly dry weather 共Kearney 1997兲. The initial behavior

peratures requires special techniques to avoid excessive emissions of pavements obtained using the warm technique is generally bet-

82 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / JANUARY/FEBRUARY 2006

J. Mater. Civ. Eng. 2006.18:81-92.

ter than the behavior of pavements recycled cold; also, the opera- of the road surface such as skid resistance. It is often claimed that

tional season can be extended if recycled warm 共Jacobson 1996兲. the relatively longer wheelbase of remixing and repaving units

Full-depth reclamation may be an alternative if a roadbase lead to larger improvements to the longitudinal profile compared

shows inadequate bearing capacity and strengthening is neces- to other rehabilitation alternatives 共Potter and Mercer 1997兲. An-

sary. Full-depth reclamation allows complete reconstruction using other advantage of remixing and repaving is that they mill the

all existing pavement materials. One method of reclamation is to existing pavement when heated, which means that the aggregate

pulverize the existing surface and mix it with the aggregate base is much less degraded by the milling process, compared to cold

and subgrade soil, if necessary. Stabilizing material, such as milling.

granular materials, hydrated lime, fly ash, bitumen emulsions or In general, cold and warm recycling are performed on low or

foamed bitumen, can be added and mixed to provide a new base medium trafficked roads. Cold recycling performed using bitu-

共Huffman 1997; Luiro 1996兲. men emulsions may be prone to deform during the first weeks

Downloaded from ascelibrary.org by WASHINGTON UNIV IN ST LOUIS on 06/27/14. Copyright ASCE. For personal use only; all rights reserved.

after construction, since the water needs time to evaporate. In

cold recycling, heavy rains during construction may show very

Other Methods

negative consequences. Compared to cold recycling, warm recy-

A simple method of recycling asphalt 共asphalt granules兲 is to use cling is less affected by climate 共cool and damp conditions兲.

it on gravel roads or as base/subbase layers. This method of using A general aspect of the use of reclaimed materials is to pre-

high quality materials is questionable from both environmental serve high quality materials in demanding functions. For ex-

and economic points of view. However, for special applications, ample, the use of good quality aggregate from high-trafficked

such as frost-sensitive gravel roads, the use of asphalt granules wearing courses should preferably not be used as an overlay on a

may be motivated by its flexibility and healing capacity 共Jacobson low volume gravel road.

1996兲. A guide for selection of recycling method based on current

type of distress is given in Table 1.

Method Selection and Strategies for Efficient

Recycling

Bitumen Rejuvenation

In many publications, the importance of investigating causes of

distresses leading to the need for rehabilitation is emphasized. It The constitution of a recycled binder depends on the composition

is clear that some distresses are likely to reoccur in recycled pave- of the original binder, aging during service, the constitution of the

ments, if not considered in rehabilitation method selection and new binder added 共rejuvenator兲, and the final production includ-

design process. Generally, use of more new 共virgin兲 material fa- ing mixing, laying, and compaction. The recycled binder needs to

cilitates in the adjustment of properties of the old 共reclaimed兲 maintain desired properties for another service period. This means

asphalt, which in turn should result in improved pavement perfor- that a recycled binder usually has to be altered to perform satis-

mance. At the same time, the benefits of using old asphalt de- factorily in the future by the addition of a properly selected reju-

crease, since the extra work involved in asphalt recycling has to venator. The purpose of this section is to summarize current

be compensated by savings in new material. From an environ- knowledge on bitumen rejuvenation. The chapter starts with a

mental point of view, recycling should not be performed at any brief description of binder aging, followed by a description of

cost, because haulage and heating may show such negative envi- rejuvenators. Then, a more detailed account of the rejuvenation

ronmental effects, that they cannot be justified by savings in new process is given. Finally, literature related to the constitution and

materials. Today, the use of life cycle approaches is becoming properties of rejuvenators is reviewed.

more and more common for estimating environmental impacts.

The suitability of different recycling methods for rehabilitation

Bitumen Aging

can be assessed based on whether recycling is performed in-plant

or in-place, as well as at what temperature and to which depth Since the process of aging to a great extent influences the binder

recycling is performed. Availability of equipment and personnel, properties in an asphalt layer, binder aging is a factor of great

etc., is of course another important issue in method selection. importance in asphalt recycling. Comprehensive research has

In-plant recycling shows the advantage that existing equip- been performed to investigate the process of aging and only a

ment may be used after various degrees of modification. Further, brief description of the causes and consequences of binder aging

smaller quantities of reclaimed asphalt can be added continuously is given in this paper. The description provides a background for

to new asphalt with relatively good control of material properties, the measures that can be taken to rejuvenate old binders. For

thus producing overlays of high quality. The great advantage of more details on binder aging, a number of publications can be

in-place recycling is obviously minimized haulage and need for recommended 共Branthaver et al. 1993; Davison et al. 1994;

new materials, resulting in both economical and environmental Johansson 1998; Petersen 1984, 2000兲.

benefits. Another advantage of in-place recycling, compared to Aging mainly leads to increased stiffness but also bring about

conventional surfacing or heating, is that cracks can be inter- changes in physicochemical properties as ductility and adhesion.

rupted before a new overlay is placed. In full depth reclamation, Generally, aging influences binder performance and consequently

distresses originating from layers deeper down in the pavement the asphalt mixture. The main mechanisms related to bitumen

can be addressed. To increase bearing capacity, the lower layers aging are oxidation, evaporation, exudation, and physical

need to be stabilized or additional overlays be placed on top of hardening.

the old pavement. After full depth reclamation, additional over- Oxidation is an irreversible process mainly controlled by the

lays can be laid on a more stable and homogeneous foundation, reactivity of the binder and the amount of oxygen available

thereby, for example, avoiding reflective cracks to reappear. In through diffusion 共Tuffour and Ishai 1990兲. Oxidative reactions

repaving, a new overlay is placed simultaneously with the re- are promoted at higher energies, i.e., by high temperatures and

cycled layer, thus providing an opportunity to modify properties exposure to light of high energy 共e.g., UV light兲, which enhances

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / JANUARY/FEBRUARY 2006 / 83

J. Mater. Civ. Eng. 2006.18:81-92.

Table 1. Guide for Selection of Recycling Method 关after ARRA 共1992兲 Gooswilligen 1989兲. The sensitivity toward evaporation differs

and Kandhal 共1997兲兴 between binders and can be reduced by minimizing the amount of

Type of Hot Hot Cold Full the most volatile components.

pavement Cold in-plant in-place in-place depth Exudation results from loss of oily components, which exude

distress planing recycling recycling recycling reclamation from the bitumen into the aggregate. This type of aging is influ-

Surface defects

enced by the chemistry of the bitumen as well as the porosity of

the aggregate.

Raveling ⫻ ⫻ ⫻

Physical hardening can occur over a long period of time and is

Bleeding ⫻ ⫻ ⫻

believed to arise from molecular structuring. The degree of mo-

共Flushing兲

lecular structuring is influenced by temperature. The effect of

Low skid ⫻ ⫻ ⫻

resistance

physical hardening can be reversed by, for example, changing the

Downloaded from ascelibrary.org by WASHINGTON UNIV IN ST LOUIS on 06/27/14. Copyright ASCE. For personal use only; all rights reserved.

temperature.

Deformation

Of special interest to asphalt recycling is the fact that the de-

Corrugations ⫻ ⫻ ⫻

gree of aging is strongly influenced by void content of the mixture

Rutting— ⫻ ⫻ ⫻

共Dickinson 1980; Kemp and Predoehl 1981; Kemp and Sherman

shallow

1984兲. Porous asphalt pavements have shown penetration at 25° C

Rutting— ⫻ ⫻ ⫻

as low as 5 dmm 共Ekblad and Isacsson 1995; van der Kooij and

deep

Verberg 1996兲. Stockpiling has also been reported to contribute to

Cracking/load associated

aging as the binder in this case is more exposed to air 共McMillan

Alligator ⫻ ⫻ ⫻

and Palsat 1985兲. The process of recycling will lead to further

Longitudinal ⫻ ⫻ ⫻ ⫻ aging of the old binder, especially if recycled hot. A study of hot

wheel

in-place asphalt recycling projects revealed that the penetration at

path

25° C was reduced about 20% during the recycling process, if no

Pavement ⫻ ⫻ ⫻

new materials were added 共AGRA 1996兲. However, some mea-

edge

sures may be taken to reduce this negative influence, such as

Slippage ⫻ ⫻

gentle heating. For example, during in-plant mixing, the old as-

Cracking/nonload associated

phalt granules must not be exposed to the burner flame or super-

Block ⫻ ⫻ ⫻ heated new aggregate.

共shrinkage兲

Longitudinal ⫻ ⫻

joint Rejuvenators

Transversal ⫻ ⫻ ⫻

共thermal兲 During the years, a number of materials with the purpose of al-

Reflection ⫻a 共⫻兲 ⫻ ⫻ tering properties of old binders at asphalt recycling have been

Maintenance patching

proposed. This group of materials goes by different names as

reclaiming, recycling, modifying or softening agents 共additives兲,

Spray ⫻ ⫻

recycling modifiers, rejuvenators but also fluxing, extender or

Skin ⫻ ⫻

aromatic oils. In this paper, the term rejuvenator is used to de-

Pothole ⫻ ⫻

nominate all products used for rejuvenation of old binders.

Deep 共hot ⫻ ⫻ Besides bitumen, bitumen emulsions, cut backs, and foamed

mix兲

bitumen, a number of additives have been used as rejuvenators. In

Problem base/subgrade 共soft, wet兲 ⫻ a list compiled by Roberts et al. 共1996兲, a distinction is made

Ride quality/roughness between softening agents and rejuvenating agents, where soften-

General ⫻ ⫻ ⫻ ing agents plainly are aimed at lowering the viscosity of aged

uneveness bitumen, whereas rejuvenating agents also are added for the pur-

Depressions ⫻ ⫻ ⫻ ⫻ pose of restoring physical and chemical properties of the old

共settlement兲 binder:

High ⫻ ⫻ ⫻ ⫻ 1. Softening agents

spots

• Asphalt flux oils 共generally blended with bitumen to re-

共heaving兲

a

duce the viscosity兲;

If milling is performed as part of the recycling process. • Lube stock 共a fraction of crude oil that has viscosity simi-

lar to lube oils兲;

• Lubricating or crankcase oil 共usually highly aliphatic兲;

not only the reaction rates but also the number of different reac- and

tions that can occur 共Tyrion 2000兲. As a consequence, differences • Slurry oil 共bottoms from the catalytic cracking process兲.

in activation energy levels for different reactions means that aging 2. Rejuvenating agents

mechanisms at service temperature 共long-term aging兲 and produc- • Lube extracts 共highly naphtenic or aromatic fractions re-

tion 共short-term aging兲 are expected to be different. Oxidation moved from lube stock by solvent extraction兲; and

changes the chemical composition of binders. A major outcome of • Extender oils 共aromatic oils from lube stock, mostly used

aging is the formation of polar functional groups, which increases for extending asphalt-rubber blends兲.

the viscosity by increasing the intermolecular interactions. It is not obvious that all these types of products are appropriate

Evaporation of volatile components of binders, especially with regard to performance and/or the environment.

from thin films, can result in substantial changes in binder prop- A rejuvenator should restore the reclaimed binder characteris-

erties, if the binders are exposed to high temperatures 共van tics to a consistency level appropriate for construction purposes

84 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / JANUARY/FEBRUARY 2006

J. Mater. Civ. Eng. 2006.18:81-92.

and pavement performance, and, at the same time, optimize the

chemical characteristics with regard to durability. A rejuvenator

should also provide sufficient additional binder to coat any new

aggregate that is added to the reclaimed mixture and satisfy mix-

ture design requirements. Further, rejuvenators should be easy to

disperse in the old binder, be uniform from batch to batch, and

practical to use, for example, by preventing flashing, smoking,

and health risks 共Epps et al. 1980兲.

Specifications applied to rejuvenators vary and a compilation

of current practice is not justified by the purpose of this paper.

Downloaded from ascelibrary.org by WASHINGTON UNIV IN ST LOUIS on 06/27/14. Copyright ASCE. For personal use only; all rights reserved.

Conceptualization of the Rejuvenation Process

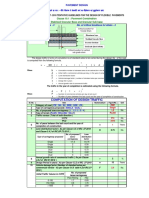

Fig. 1. Penetration values of the inner and outer binder layer versus

In hot in-plant or in-place asphalt recycling operations, fresh time during diffusion 关after Carpenter and Wolosick 共1980兲兴.

binder and aggregate are mixed with reclaimed asphalt. The fresh

binder should be a rejuvenator or soft bitumen in order to achieve

a final mix of fresh and old binder showing acceptable consis- prepared by heating the reclaimed asphalt to 116° C and mixed

tency. Mixing of binders is influenced by mechanical mixing as with rejuvenator 共20% of total binder content兲. The samples were

well as diffusion, and requires compatibility between the binders allowed to cure in an uncompacted state for a specified time. At

共Karlsson 2000兲. Incomplete mixing during hot recycling has predetermined time intervals, an incremental extraction process

been indicated in field by comparably low compaction tempera- was initiated. The recycled mix was immersed in trichloroethyl-

ture 共Taverner et al. 1990兲 or propensity to deform easier 共Potter ene and left for 3 min before the solution was decanted. The

and Mercer 1997; Oliver 2001兲, but is likely more pronounced in remaining mix was treated with solvent to remove all the remain-

cold recycling 共Ulmgren 1982兲, where mixing is limited by the ing binder. The two binder solutions obtained were recovered,

existence of asphalt granules of aggregate glued together. providing two samples representing the outer and inner layer of

The efficiency of binder mixing at asphalt recycling was the recycled binder film.

investigated by Lee et al. 共1983兲 using dyes to determine the The consistency of each layer should vary with time, if the

effectiveness in spreading of rejuvenator throughout the recycled diffusion process is working as hypothesized. Fig. 1 shows that

mixture. The dye, -naphtenol, was mixed with the rejuvenator the outer and inner layers finally approaches the same consis-

and then visually detected in the recycled asphalt concrete. It was tency, close to that of a mixture of rejuvenator and old binder of

concluded that mixing of binders on a macroscale was mainly corresponding content. Fig. 1 also shows the variation in binder

accomplished by mechanical mixing. stiffness of reclaimed material 共the outer layer stiffer than the

To the writers’ knowledge, the first laboratory investigations of inner layer兲.

diffusion of a rejuvenator into an old binder were performed by Similar investigations have also been performed by Noureldin

Zearley 共1979兲 and by Carpenter and Wolosick 共1980兲. They used and Wood 共1987兲, who stored samples of uncompacted asphalt

a stage extraction method 共cf. the following discussion兲 to deter- mixtures for 15 h at 78° C, after which the binder films were

mine the rate at which a rejuvenator in an asphalt mixture mi- extracted in four stages. The samples were soaked for 5 min in

grated into the old binder. Carpenter and Wolosick 共1980兲 also trichloroethylene in increments of 200, 200, 300, and 700 mL to

compared these experiments with measurements of mechanical get the extracted bitumen in four fractions. The results obtained

properties after storage for certain periods of time. They hypoth- by Noureldin and Wood 共1987兲 confirmed the findings of Carpen-

esized that the diffusion of rejuvenators into aged bitumen at as- ter and Wolosick 共1980兲, that is the binder layer close to the

phalt recycling could be described in steps as follows. First, the aggregate remained stiffer than the outer layers during the diffu-

rejuvenator forms a very low-viscosity layer that surrounds the sion process studied.

aggregate, which is coated with very high-viscosity aged asphalt

cement. Then, the rejuvenator begins to penetrate the aged asphalt

Rejuvenator Diffusion

cement layer, thereby decreasing the amount of new rejuvenator

covering the bitumen-coated aggregate particles and softening the Knowledge regarding diffusion of bituminous binders into each

old bitumen. After a given time period, no raw rejuvenator re- other is of fundamental interest in asphalt recycling. Oliver

mains, and the diffusion of rejuvenator continues. Simultaneously, 共1975兲 studied diffusion of dodecylbenzene and two oil fractions

the viscosity of the inner layer 共closest to the aggregate兲 is low- into three different bitumens, using a method of tritium labeling.

ered, and the viscosity of the outer layer is increased. As time The study was undertaken to investigate the possibility of replac-

goes on, equilibrium is approached over the majority of the shell ing weathered binder at the pavement surface with an oversprayed

of bitumen. oil formulation, thereby extending the life of the surfacing. To

Carpenter and Wolosick 共1980兲 also called attention to the fact determine the diffusion coefficient, a thin layer 共⬍1 m兲 of dif-

that the rate of diffusion of different components in the rejuvena- fusant was applied to the top of a bitumen cylinder, 1.25 cm in

tor might be different. Further, they stated that incomplete mixing diameter and 0.5 cm high. The tritium labeled diffusant was then

of old and added binder causes problems in predicting of perfor- allowed to penetrate the bitumen for some time after which the

mance, and, if incomplete mixing of old and new binder occurs, bitumen was sliced using a microtome. The radioactivity

the long-term field pavement performance will be affected. was measured at different depths and the diffusion coefficient

The concept of the diffusion process described above was ex- calculated.

perimentally verified by Carpenter and Wolosick 共1980兲 using a One of the conclusions drawn from Oliver’s study 共1975兲 was

stage extraction method, in which the inner and outer layers of the that the diffusion rate could be increased by adding diluent oil

recycled binder film was extracted separately. The samples were fractions or by raising the temperature. The diffusion rate was

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / JANUARY/FEBRUARY 2006 / 85

J. Mater. Civ. Eng. 2006.18:81-92.

unaffected by a skin on top of the bitumen cylinder caused by Consistency

photooxidation. It was also stated that for the oils constituted of In order to meet specified target viscosities for recycled binders,

molecules of different size and configuration, only an average mixing rules have been applied to determine the amount of reju-

diffusion coefficient could be determined. Oliver 共1975兲 also con- venator required, given the viscosities of the old binder and the

cluded that the diffusion coefficient depends on the temperature in rejuvenator. Arrhenius 共1887兲 was first to establish a relationship

an Arrhenius-type relationship. describing viscosity of mixes of two liquids 关Eq. 共1a兲兴. All mixing

Oliver 共1975兲 also performed experiments on diffusion of oil rules use some kind of logarithmic relationship between amount

fractions obtained by size exclusion chromatography 共SEC兲 and of each binder and the resulting viscosity. The following are ex-

liquid chromatography 共LC兲. It was found that higher molecular amples of such mixing rules:

weight fractions diffused more rapidly than the lower molecular ln共mix兲 = x ln共1兲 + 共1 − x兲ln共2兲 共1a兲

weight oil fractions, which was unexpected. Oliver 共1975兲 also

Downloaded from ascelibrary.org by WASHINGTON UNIV IN ST LOUIS on 06/27/14. Copyright ASCE. For personal use only; all rights reserved.

found that the more aliphatic fractions obtained from LC diffused

ln共mix兲 = x ln共1兲 + 共1 − x兲ln共2兲 + x共1 − x兲G12 共1b兲

more rapidly than naphthenic and condensed aromatic fractions,

and concluded that molecular shape was more important than

ln共ln共mix兲兲 = x ln共ln共1兲兲 + 共1 − x兲ln共ln共2兲兲 共1c兲

molecular weight, i.e. thin aliphatic compounds diffuse more rap-

idly than bulky condensed compounds. where mix = viscosity of the mixture; 1 and 2 = viscosity of

Rejuvenator diffusion has also been studied using Fourier Binders 1 and 2, respectively; x = volume percentage of Binder 1;

transform infrared spectroscopy using attenuated total reflectance and G12 = interaction factor between Binders 1 and 2.

共FTIR-ATR兲 by Karlsson 共2000兲. Using FTIR-ATR, diffusion of Eq. 共1b兲 was presented by Grunberg and Nissan 共1949兲 and

three rejuvenators and several chemical compounds, referred to as applied by Davison et al. 共1994兲 to mixtures of several bitumi-

markers, were monitored when diffusing through a number of nous binders. It was concluded that G12 varies for different sets of

binders. The results were verified by a limited number of rheo- binders. For mixtures of bitumens, G12 was close to zero, whereas

logical diffusion measurements 共Karlsson and Isacsson 2003兲. mixtures of bitumen and highly aromatic rejuvenators rendered

The magnitude of the diffusion rates determined by Oliver 共1975兲 G12 values as low as −10. This was explained by the ability of

and by Karlsson 共2000兲 and Karlsson and Isacsson 共2002兲 was these rejuvenators to disperse the asphaltenes in bitumen. Clearly,

found to be of the same order. Fick’s law was also found valid to by use of Eqs. 共1a兲 and 共1c兲, differences in interactions between

model diffusion and the use of an Arrhenius relationship was binders cannot be taken into account. However, the results pre-

confirmed appropriate to model the influence of temperature. sented by Davison et al. 共1994兲 indicate that Eq. 共1a兲 a might be

Classical diffusion models, such as Stoke–Einstein equation, better for mixtures of bitumens and Eq. 共1c兲 better for mixtures of

claiming proportionality between rate of diffusion and viscosity bitumens and rejuvenators.

of the diffusion medium, was used to investigate possible influ- Mixing rules have also been developed for critical tempera-

ences of bitumen aging on rejuvenator diffusion. The rate of re- tures in Superpave mix design. Critical temperatures at low, in-

juvenator diffusion above 50° C was found to be fairly indepen- termediate, and high temperatures can be calculated for mixtures

dent of degree of aging 共Karlsson and Isacsson 2002兲, which was of old and new binders by assuming a linear relationship between

explained by the ability of a relatively unaffected, soft maltene the amount of each binder and the critical temperature of the

phase to provide the medium for diffusion. Hence, rejuvenator mixture 共McDaniel and Anderson 2001兲. Soleymani et al. 共1999兲

diffusion takes place at a considerably faster rate than expected have studied relationships between proportions of soft binder/

from the classical models of diffusion. Diffusion rates determined rejuvenator and stiff bitumen and performance grade and master

using markers of different size and polarity demonstrated large curve parameters and found linear relationship between the pro-

influence of polarity and indicated inverse proportionality be- portion of rejuvenator and the following performance related

parameters:

tween diffusion rate and the square of the molecular weight of the

• log G*, where G* = complex shear modulus;

markers.

• ␦, where ␦ = phase angle;

• log S, where S = stiffness;

Properties of Recycled Binders • m, where m = creep rate;

• R, where R = rheological index 共“sufficiently accurate” rela-

The constitution of bitumen is responsible for its road perfor- tionship兲; and

mance. In order to work well, properties influencing rheology, • c, where c = crossover frequency 共sufficiently accurate

cohesion, adhesion, and durability must be optimized. In asphalt relationship兲.

recycling, the same applies to the recycled binder, i.e., the mix-

ture of rejuvenator and aged bitumen. It may seem relatively easy Chemical Constitution

to soften an aged bituminous binder by addition of low-viscosity Research aiming at relating chemical constitution to binder per-

rejuvenators. However, maintaining stability 共a bitumen showing formance has been going on for many decades with varying suc-

good stability is a homogeneous system where the asphaltenes are cess. Of particular interest is prediction of durability, which is

well peptized/dissolved and prevented from precipitation or floc- difficult to determine by short-term laboratory tests. Most of the

culation兲 and durability of the recycled binder is also necessary. findings presented in this section focus on the fractional compo-

These two requirements may counteract each other, as the com- sition of recycled binders and the constitution of rejuvenators

ponents that enhance stability and durability may not be very suitable to restore the composition of reclaimed binders. Finally,

effective at reducing viscosity 共Newcomb et al. 1984; Peterson health related aspects of rejuvenators are shortly commented.

et al. 1994兲. The rest of this chapter is a review of literature According to Heithaus 共1962兲, binder stability is achieved by

related to rejuvenation of reclaimed binders by addition of reju- high solvency or peptizing power of the maltene phase and high

venators in order to achieve desired consistency and chemical peptizability of the asphaltene phase. A rejuvenator should be

constitution of recycled binders. composed in such a way that it increases the peptizing power of

86 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / JANUARY/FEBRUARY 2006

J. Mater. Civ. Eng. 2006.18:81-92.

the maltene phase 共Venable et al. 1983兲. Heithaus showed that Rejuvenators containing waxes should be avoided, since

oxidative aging normally decreases the peptizing power of the waxes may affect the low temperature properties of the final blend

n-pentane maltene phase. However, results presented by Karlsson 共Peterson et al. 1994兲. Waxes strongly associate at lower tempera-

and Isacsson 共2003兲 indicate that aging rather leads to increasing tures, and are, in general, defined as a fraction of saturates that

polar interactions than to decreasing stability. Consequently, re- crystallizes upon cooling. Other suggested negative effects of

search presented hitherto does not indicate that influence of aging waxes are poor adhesion to some aggregates and a tendency to

is a critical issue. cause increase in permanent deformations of asphalt mixtures.

Extensively low stability may be manifested in low ductility as However, recent research on waxes gives a more complex picture

well as a sharply increased shear viscosity at diminishing shear of the composition of waxes, and waxes obtained from different

rate 共Peterson et al. 1994兲, which exceptionally may lead to phase bitumens may show different constitutions 共Redelius and Isacsson

separation. Binder stability is a consequence of mutual solubility 2002兲.

Downloaded from ascelibrary.org by WASHINGTON UNIV IN ST LOUIS on 06/27/14. Copyright ASCE. For personal use only; all rights reserved.

of all components constituting a binder. The stability depends on The health aspects associated with emissions from rejuvena-

the distribution of solubility parameters and molecular size. A tors also require consideration. From a technical point of view,

high content of polar and aromatics 共determined by ASTM 2007兲 highly aromatic oils are the choice of preference 共Peterson et al.

are believed to enhance dispersion of asphaltenes 共Dunning and 1994兲, but such oils are also a source of emissions of PAH, which

Mendenhall 1977; Newcomb et al. 1984兲. However, the observa- include a number of substances, proven to be carcinogenic. Fur-

ther, regarding health aspects, the content of volatile compounds

tions made by Verhaeghe and Van Assen 共1992兲 and Gannon et al.

should be kept at a level as low as possible.

共1980兲 indicate that the fractional composition 共determined by

ASTM D2007兲 of the recycled binder is additive, i.e., the frac-

tional composition is proportional to the amount of each binder

and their fractional composition. Laboratory Studies of Recycled Asphalt Concrete

If the rejuvenator is manufactured from the same crude as the

old binder subject to rejuvenation, the stability of the recycled Recycling is a more demanding task than conventional paving

binder is likely optimized, since the chemistry of the two binders regarding method selection, mix design and, to some extent, also

is similar and therefore probably highly compatible. As aging the paving procedure. The variation in material properties is gen-

leads to an irreversible increase in content of viscosity building erally larger in reclaimed asphalt compared to fresh material, a

components, rejuvenators should preferably show as low content problem being difficult to account for as it originates from varia-

of asphaltenes as possible. Research carried out in Texas suggests tions in the old pavement. In spite of this fact, the initial perfor-

the method of supercritical fractionation of residues from crude mance of a recycled pavement is today normally considered as

good as that of a newly constructed one of the same type 共Epps

oil distillation to be used in manufacturing of rejuvenators of

1990; Button et al. 1995; Kandhal et al. 1995; Potter and Mercer

desired chemical constitution 关Chaffin et al. 共1997兲兴. Supercritical

1997兲, provided that the reclaimed asphalt does not show irreme-

fractionation of residues means that the residue is dissolved in a

diable shortcomings. Many types of distresses related to poor ma-

“bad” solvent by aid of high pressure 共and high temperature兲. By

terials may reoccur, if not properly considered. Generally, most

reducing pressure 共and temperature兲 in steps, a number of differ-

types of negative observations of recycled asphalt performance

ent fractions are obtained.

have been attributed to parameters of great importance in method

The amount of saturates 共determined by ASTM D2007兲 in re-

selection 共bearing capacity兲 and mix design 共inadequate binder

juvenators was proposed by Kari et al. 共1980兲 to be limited to

content, binder stiffness, and/or aggregate gradation兲. However,

30% of the rejuvenator. The limit obtained was based on blends of studying material properties of reclaimed asphalt is difficult due

a number of rejuvenators and one aged California Coastal bitu- to its complex constitution and unknown history. Furthermore,

men. The blends with rejuvenators containing more than 30% during the recycling process, curing needs to be taken into ac-

saturates failed to meet the bitumen specifications used then. count 共rejuvenation, breaking of emulsions, etc.兲.

Saturates 共paraffins兲 determined by Corbett fractionation 共ASTM Low variability of reclaimed asphalt is essential to achieve

D4124兲 were found to show detrimental effects on hardening sus- desired properties of recycled asphalt. Variability in stockpiled

ceptibility 共according to PAV aging兲 and ductility, if the content of materials should be kept low by separating different materials

saturates determined in this way was higher than 15% of the with regard to type of asphalt, amount of deleterious material, etc.

recycled binder 共Peterson et al. 1994兲. This finding was supported 共McDaniel and Anderson 2001兲. One way to improve homogene-

by Newcomb et al. 共1984兲 reporting that blends of bitumen with ity is to remove unwanted features of the old road 共e.g., road

rejuvenators of high content of saturates 共according to ASTM markings兲, crack seals and other sources of inhomogenities prior

D2007兲 showed higher aging index 共viscosity at 140° F after/ to the reclamation process. Thorough mixing of the stockpiled

before RTFO aging兲, while high content of aromatics and polars materials improves homogeneity. Regarding variability, degrada-

contributed to improved ductility. tion of aggregate during service, fines from deleterious materials,

McMillan and Palsat 共1985兲 also tested viscosity of recycled cold milling and crushing of ripped asphalt concrete, which all are

binders after TFOT. It was suggested that maximum amount of influencing the aggregate gradation, should also be taken into

distillate should be no more than 1% 共by volume, determined by account. At stockpile sampling, it is essential that samples taken

ASTM D402兲 to ensure that only distilled binders were used and as far as possible reflect the whole stockpile.

not cut back bitumens. Noureldin and Wood 共1990兲 observed sub- Cold recycled asphalt is more difficult to screed and compact

stantial differences between TFO-aged blends of one old binder due to lower workability, which may lead to higher air void con-

and three different rejuvenators. All blends were designed to cor- tent and greater risk for unevenness and rutting compared to hot

respond to a virgin binder AC-20 of penetration 65 dmm at 25° C. recycled asphalt 共Jacobson 1995兲. However, low air void content

Interestingly, the blend with a commercial rejuvenator, rich in is frequently reported in connection with recycled objects. The

aromatics, showed the lowest hardening susceptibility 共even reason is often too much binder added for the purpose of soften-

lower than the virgin AC-20兲. ing the reclaimed asphalt concrete and making it workable

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / JANUARY/FEBRUARY 2006 / 87

J. Mater. Civ. Eng. 2006.18:81-92.

共Rogge et al. 1994兲. Determination of the amount of rejuvenator first one was obtained using a given binder and aggregate of given

needed, especially at cold recycling, appears to be an act of bal- particle size distribution. The mixture was aged to a given degree,

ance between, on the one hand, workability and raveling, and on compacted and broken up manually, after which it was blended

the other hand, avoiding problems like bleeding and insufficient with a new mixture and finally compacted again. The binder of

stability. this mixture was recovered and the viscosity determined. The

Laboratory investigations on recycled asphalt mixtures can second mixture containing the same aggregate 共type and grada-

mainly be divided into two categories: evaluations on perfor- tion兲 was manufactured using another binder. After compaction,

mance of recycled asphalt and studies on the degree of mixing the binder was recovered and its viscosity measured. The viscos-

between reclaimed binder and rejuvenator. Within the former cat- ity determined in this case was close to the viscosity of the binder

egory, most of the studies reported were found to be of applied in the first mixture. Further, the nominal binder and void content

character and limited extent. These “technical” reports were not of two mixtures were the same. The recycled mixture showed

Downloaded from ascelibrary.org by WASHINGTON UNIV IN ST LOUIS on 06/27/14. Copyright ASCE. For personal use only; all rights reserved.

taken into account in this paper, the purpose of which is to sum- comparably lower resilient modulus, higher wheel tracking rate

marize more fundamental knowledge regarding material-related and longer fatigue life 共controlled strain兲, which are signs of a

aspects on asphalt recycling. Below is a description of studies on softer binder. Oliver 共1975兲 concluded that the reclaimed and

mixing of reclaimed binders and rejuvenators, followed by short fresh binders were not fully mixed, since the reclaimed asphalt

reviews on performance-related properties of recycled asphalt. may form agglomerates of aggregate and filler, hard for the fresh

binder to penetrate. Incomplete mixing would create areas with a

softer binder, which could not be counterbalanced by the areas

Mixing-Related Studies on Mixtures

containing harder binder. It should be noted that the reclaimed

The investigation performed by Carpenter and Wolosick 共1980兲, and fresh asphalt was mixed for three minutes, compacted and

previously mentioned, was supplemented with mechanical tests, then cured for 1 h, all at a temperature of 150° C.

showing the change in recycled asphalt properties over time as a

consequence of binder diffusion. They measured resilient modu-

lus, creep compliance, permanent deformation properties and Performance-Related Studies

Marshall stability and reported, among other things, that “the re-

silient modulus values for the recycled samples showed a rather Resilient and Permanent Deformations

dramatic variation with time.” van der Kooij and Verburg 共1996兲 Both resilient and permanent deformations of asphalt concrete are

performed experiments using reclaimed porous asphalt containing of great interest in pavement engineering. The resilient response

a severely aged binder with a penetration at 25° C as low as about is related to bearing capacity and cracking and the permanent

5 dmm. van der Kooij and Verburg performed wheel track, Mar- response to development of ruts. Typical observations described

shall stability, Cantabro, and indirect tensile tests. They argued below are related to unexpectedly high resilient deformations or

that, despite the severely aged reclaimed asphalt, the response to initially high rate of permanent deformation. Except for the initial

these tests could not originate from separate fresh and old binders, behavior of cold recycled asphalt, a general picture cannot be

but from a mix of both. They drew the conclusion that fresh observed. In cold recycled pavements, using bitumen emulsions

binder mixes with old binder, despite severe aging, but no evi- as rejuvenator, there is normally a longer period of lower strength

dence was found for complete mixing. Unfortunately, the condi- before the final level is reached 共Kazmierowski et al. 1992兲. Re-

tions differ too much between the two investigations presented in garding cold recycling, the strength is mainly influenced by mois-

this paragraph to allow any detailed comparison. ture content 共Castedo 1987; Bardesi Orue-Echevarría et al.,

In the work to incorporate reclaimed asphalt in the Superpave 1996兲. Consequently, high air void content facilitates in drying

system, a study was conducted using the Superpave Shear Tester 共curing兲 process 共Kazmierowski et al. 1992; Jacobson 1995兲.

to investigate whether reclaimed asphalt granules act as “black Estakhri 共1994兲 evaluated 20 objects where reclaimed asphalt

rocks,” i.e., if the old binder coating the reclaimed asphalt inter- was blended with bitumen emulsions and conventional mixtures.

acts with the new binder. In this study, reclaimed asphalt was Recycled mixtures that had Hveem stabilities greater than 24

added to new asphalt in ratios of 10 and 40%. The mixing process were found to perform successfully, whereas mixtures having sta-

was performed to simulate three cases where 共1兲 no mixing oc- bilities lower than 12 failed due to permanent deformations.

curs 共black rocks兲; 共2兲 real performance is reflected; and 共3兲 old Stiffness modulus and creep tests reported 共Carpenter and

and new binder are mixed. In the first case, the old binder was Wolosick 1980; Kari et al. 1980; Kadar 1996兲 indicate that the

removed from the reclaimed asphalt prior to mixing and in the rejuvenation process may not always be complete after the recy-

last case, the old binder was recovered and mixed with the new cling operation. In the field, initially higher permanent deforma-

binder prior to mixing with the aggregate. Case 2 was aimed at tion rates have been observed on hot remixed roads as well as on

simulating the recycling process performed during in-plant as- hot remixed test sections subjected to accelerated pavement test-

phalt recycling. The shear tests used were repeated shear at con- ing 共Potter and Mercer 1997兲. According to Tia et al. 共1983兲,

stant height, simple shear, and frequency sweep tests. For all three instability may also occur, if the difference in viscosity between

shear tests used, at 40% addition of reclaimed asphalt, there were the old binder and the rejuvenator is too large. However, Edwards

distinct differences between Case 1 on one hand and Cases 2 and and Mayhew 共1989兲 did not observe any significant difference in

3 on the other. No significant difference was observed at 10% wheel track rate between cores taken from conventional 共40 mm兲,

addition. Similar to the results presented above by Carpenter and remixed and repaved overlays.

Wolosick 共1980兲 and van der Kooij and Verburg 共1996兲, this re- Epps et al. 共1980兲 observed differences in Marshall stability

sult also implies that the old binder in reclaimed asphalt interacts and resilient modulus between laboratory-compacted samples and

with the new binder. hot mix recycled cores taken from the field. These differences

Oliver 共2001兲 has also addressed the issue of binder mixing were attributed to differences in compaction characteristics,

using a mechanical testing approach. Two asphalt mixtures were which meant that air void content of the field compacted cores

manufactured, below called recycled and fresh, respectively. The were much higher compared to the laboratory compacted

88 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / JANUARY/FEBRUARY 2006

J. Mater. Civ. Eng. 2006.18:81-92.

samples. Verhaeghe and Van Assen 共1992兲 studied properties of very expensive to perform in the field, and performance studies

hot in-place recycled asphalt. They found that laboratory condi- require a long period of time before final conclusions can be

tioning of recycled samples led to significantly increased stiffness drawn. Consequently, extensive field studies are comparably

and an even more pronounced decrease in Poisson’s ratio. Ver- scarce, and therefore most results referred to in this review have

haeghe and Van Assen 共1992兲 also stretched the importance of been obtained from laboratory tests. On the other hand, laboratory

applying the rejuvenator evenly throughout the recycled mixture, tests will always leave questions about how well reality is re-

as inhomogeneities in the recycled asphalt were identified and flected. A major concern in this study has been to assess the

believed to affect deformation behavior. reliability by which reported behavior of recycled asphalt is re-

flecting real pavement performance or being a consequence of

Fatigue sample preparation or testing procedure used.

It is known that stiffness is an important factor in asphalt fatigue. Among many areas of importance in asphalt recycling, the

Downloaded from ascelibrary.org by WASHINGTON UNIV IN ST LOUIS on 06/27/14. Copyright ASCE. For personal use only; all rights reserved.

In controlled stress fatigue testing, a stiffer binder is expected to following topics were considered of special interest:

lead to longer fatigue life, whereas the opposite applies to con- • Variability of reclaimed asphalt;

trolled strain testing, assuming that test-related parameters are the • Rejuvenation of old binders and constitution of rejuvenators;

same 共Judycki 1991兲. Fatigue life of laboratory manufactured and

samples of recycled asphalt has been studied by, among others, • Mixing of materials and curing processes.

Kennedy and Perez 共1978兲, Servas et al. 共1984兲, and Oliver Variability is to a great extent a question of careful handling of

共2001兲. In fact, the fatigue test observations described showed materials. One way to limit the variability of reclaimed material is

fatigue behavior as expected from stiffness values determined. to consider unwanted impurities of the old road 共e.g., road mark-

ings, coal tar and soil兲 and sources of inhomogeneities such as

Low Temperature Properties crack seals and patches. Another way of reducing variability is to

As a result of insufficient rejuvenation 共high stiffness兲, recycled thoroughly mix the reclaimed materials. If the variability is suf-

asphalt may show higher susceptibility to low temperature crack- ficiently low, it should be possible to more accurately modify

ing compared to newly constructed pavements 共Taverner et al. deficiencies in, for example, aggregate gradation, binder content

1990; Tam et al. 1992兲. Tam et al. 共1990兲 called attention to the and stiffness, provided that the proportion of virgin material

need for using soft binders and/or limitations on the recycling added is high enough.

ratios allowed, in order to improve low temperature performance Regarding rejuvenation of old binders, it can be concluded that

of recycled asphalt. recent research 共applicable to both cold and hot recycling兲 shows

Studies by Terrel and Fritchen 共1977兲 indicated that hot re- the importance of carefully considering the choice of rejuvenator

cycled mixtures were comparable to conventional mixtures when in order to optimise chemical composition of the recycled binder,

studying effects of freeze–thaw cycling. Cold recycled asphalt is thereby, for example, improving aging resistance and reducing

more sensitive toward freeze–thaw action, but 1–2% bitumen binder stiffness. Developments in bituminous binder manufactur-

emulsion was found sufficient to bring sensitivity down to accept- ing, for example by supercritical fractionation, may lead to more

able levels 共Jacobson 1995兲. effective rejuvenators. In cold recycling, rejuvenators like bitu-

men emulsions and foamed bitumen, are currently subject to re-

Water Susceptibility search and development, which hopefully will improve future

Generally, pavements exhibiting stripping should in principle not performance of cold recycled pavements.

be recycled, since the problem is likely to re-occur 共Rogge et al. The studies reviewed in this paper indicate that mixing be-

1994; Scott 1992; Terrel et al. 1997兲. However, if stripping sus- tween old and new binders occurs to a large extent, but maybe not

ceptible mixtures are recycled, anti-stripping additives should be completely. Incomplete mixing during hot recycling is indicated

used 共DeKold and Amirkhanian 1992兲. by comparably low compaction temperature 共Taverner et al.

Mixtures containing 15–20% reclaimed asphalt do not exhibit 1990兲 or propensity to initial rutting 共Oliver 2001兲 but is likely

higher moisture susceptibility than corresponding mixtures con- more pronounced in cold recycling 共Ulmgren 1982兲, where mix-

taining 100% virgin asphalt 共DeKold and Amirkhanian 1992兲. As ing is limited by the existence of asphalt granules glued together

a matter of fact, there are indications that addition of old asphalt by an aged binder. In other words, the recycled asphalt may be-

leads to lower water susceptibility 共Jacobson 1999兲. One possible have as if the binder is softer compared to the fully mixed recov-

explanation is that old asphalt granules are already covered with ered binder. The studies on binder diffusion presented do not

binder, which enhances resistance to stripping. Further, recycled show that diffusion restrain from the creation of homogeneous

asphalt concrete sometimes contains more binder compared to recycled binder films, even though diffusion may be time con-

virgin asphalt concrete 共in order to soften the old asphalt con- suming at low temperature, but is not effective across large

crete兲, which also may increase the resistance to stripping. granules.

According to Epps et al. 共1980兲, type of rejuvenator used Generally, recycled asphalt does not seem to behave much

shows little influence on water susceptibility, provided that the differently compared to conventional asphalt of the same type, if,

materials are properly mixed and the desired viscosity is obtained. in principle, material components and composition as well as pro-

duction method are the same.

In practice however, reclaimed asphalt often shows some dif-

Discussion ferences compared to new asphalt, which need to be taken into

account. For example, at cold recycling excess of rejuvenator is

Generally, field trials are necessary for final performance assess- often added to facilitate the processing of the reclaimed mixture.

ment of new types of materials and/or methods. However, road The obvious reason is that reclaimed asphalt has a history during

trials show the disadvantage of being site dependent and conse- which its properties have changed. Typically, the reclaimed binder

quently definite conclusions are difficult to draw based on a lim- is aged, the fine material content is increased, and materials of

ited number of field observations. Regular parameter studies are different origin are mixed. The success of asphalt recycling de-

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / JANUARY/FEBRUARY 2006 / 89

J. Mater. Civ. Eng. 2006.18:81-92.

pends on proper assessment of pavement objects or reclaimed Carmichael, T., Boyer, R. E., and Hokansson, L. D. 共1977兲. “Modeling

asphalt prior to recycling, which in turn is essential in method heater techniques for in-place recycling of asphalt pavements.” J. As-

selection and mix design. However, asphalt recycling is in general sociation of Asphalt Paving Technologists, 46, 526–540.

performed under a tight budget with limited resources to spend on Carpenter, S. H., and Wolosick, J. R. 共1980兲. “Modifier influence in the

production control and additives, which means that the perfor- characterization of hot-mix recycled material.” Transportation Re-

search Record 777, Transportation Research Board, Washington,

mance of recycled asphalt is, after all, a result of compromises

D.C., 15–22.

between economical, practical and technical demands.

Castedo, H. 共1987兲. “Significance of various factors in the recycling of

This study has mainly been focused on fundamental aspects of asphalt pavements on secondary roads.” Transportation Research

asphalt recycling, and especially two topics, where increased Record 1115, Transportation Research Board, Washington, D.C.,

knowledge was considered important, were recognized: 125–133.

• The binder mixing process characterized using mixtures; and Chaffin, J. M., Liu, M., Davison, R. R., Glover, C. J., and Bullin, J. A.

Downloaded from ascelibrary.org by WASHINGTON UNIV IN ST LOUIS on 06/27/14. Copyright ASCE. For personal use only; all rights reserved.

• The quality of recycled binders. 共1997兲. “Supercritical fractions as asphalt recycling agents and pre-

Regarding mixing of old binder and rejuvenator, a major ques- liminary aging studies on recycled asphalts.” Ind. Eng. Chem. Res.,

tion still to be answered concerns the degree of mixing obtained 36, 656–666.

when placing the recycled mixture on the road. The degree of Davison, R. R., Bullin, J. A., Glover, C. J., Chaffin, J. M., Peterson, G.

mixing should be influenced by, among other things, mixing tem- D., Lunsford, K. M., Lin, M. S., Liu, M., and Ferry, M. A. 共1994兲.

perature, properties of reclaimed material and production method. “Verification of an asphalt aging test and development of superior

The quality of a recycled binder includes different aspects as recycling agents and asphalts.” Texas Transportation Institute, and

consistency, aging properties and structural stability, which all are Chemical Dept., Texas A&M Univ, College Station, Tex.

Decker, D. S. 共1997兲. “State-of-the practice for use of RAP in hot mix

related to the chemical constitution of the old binder and the

asphalt.” J. Association of Asphalt Paving Technologists, 66,

rejuvenator. Concerning asphalt recycling, bitumen structural sta-

704–722.

bility may be of special interest as two binders are mixed, which DeKold, S. P., and Amirkhanian, S. N. 共1992兲. “Reuse of moisture-

in turn could influence the interaction between the chemical com- damaged asphaltic concrete pavements.” Transportation Research

pounds and thereby the stability of the recycled binder. During the Record 1337, Transportation Research Board, Washington, D.C.,

last few years, increased interest in bitumen structural stability 79–88.

has been demonstrated 共Redelius 2000; Karlsson and Isacsson Dickinson, E. J. 共1980兲. “The hardening of Middle East petroleum as-

2003兲. Results presented by Karlsson and Isacsson 共2003兲 indi- phalts in pavement surfacings.” J. Association of Asphalt Paving

cate that bitumen structural stability should not be a major prob- Technologists, 49, 30–57.

lem in connection to asphalt recycling. Dunning, R. L., and Mendenhall, R. L. 共1977兲. “Design of recycled as-

phalt pavements and selection of modifiers.” Recycling of Bituminous

Pavements, ASTM STP 662, L. E. Wood, ed., American Society for

Testing and Materials, Philadelphia, 35–46.

Acknowledgment

Edwards, A. C., and Mayhew, H. C. 共1989兲. “Recycled asphalt wearing

courses.” Research Rep. No. 225, Transport and Road Research Labo-

The financial support provided by the Swedish National Road ratory, U.K.

Administration through the Centre for Research and Education in Ekblad, J., and Isacsson, U. 共1995兲. “Hot in-place asphalt pavement

Maintenance and Operations in Traffic Channels is gratefully recycling—Investigations during 1994.” Rep. No. TRITA-IP AR 95-

acknowledged. 37, Division of Highway Engineering, Royal Institute of Technology,

Stockholm, Sweden 共in Swedish兲.

Epps, J. A. 共1990兲. “Cold recycled bituminous concrete using bituminous

References materials.” Synthesis of Highway Practice 16, National Cooperative

Highway Research Program, Transportation Research Board, Wash-

AGRA Earth & Environmental Limited 共AGRA兲. 共1996兲. “Development ington, D.C.

of guidelines for the design of hot in-place recycled asphalt concrete Epps, J. A., Little, D. N., and Holmgreen, R. J. 共1980兲. “Guidelines for

mixtures.” Rep. No. EA-13746, Edmonton. Alta., Canada. recycling pavement materials.” Rep. No. 224, NCHRP, Washington,

Arrhenius, S. 共1887兲. “Über die innere Reibung verdünnter wässeriger D.C.

Lösungen.” Z. Phys. Chem., 1, 285–298 共in German兲. Estakhri, C. 共1994兲. “Field performance of maintenance treatments con-

Asphalt Recycling and Reclaiming Association 共ARRA兲. 共1992兲. An structed with reclaimed asphalt pavement 共RAP兲.” Research Rep. 187-

overview of recycling and reclamation methods for asphalt pavement 24, Texas Transportation Institute.

rehabilitation, Annapolis, Md. Gannon, C. R., Wombles, R. H., Ramey, C. A., Davis, J. P., and Little, W.

Asphalt Recycling and Reclaiming Association 共ARRA兲. 共2001兲. Basic V. 共1980兲. “Recycling conventional and rubberized bituminous con-

asphalt recycling manual, Annapolis, Md. crete pavements using recycling agents and virgin asphalts as modifi-

Bardesi Orue-Echevarría, A., Gordillo, G. J., and Hernando del Cura, A. ers.” J. Association of Asphalt Paving Technologists, 49, 95–122.

共1996兲. “Cold in-place recycling of asphalt mixes with emulsion. Grunberg, L., and Nissan, A. H. 共1949兲. “Mixture law for viscosity.”

Project carried out on the N-II Highway. Evolution properties.” Rep. Nature (London), 164, 799–800.

No. 1.017, Euroasphalt and Eurobitume Congress, Strasbourg, France. Heithaus, J. J. 共1962兲. “Measurement and significance of asphaltene pep-

Branthaver, J. F., et al. 共1993兲. “Binder characterisation and evaluation— tization.” J. Inst. Pet., 48共458兲, 45–53.

volume 2: Chemistry.” SHRP-A-368, Strategic Highway Research Huffman, J. E. 共1997兲. “Full depth reclamation: State-of-the-practice.” J.

Program, Washington, D.C. Association of Asphalt Paving Technologists, 66, 760–775.

Button, J. W., Little, D. N., and Estakhri, C. K. 共1994兲. “Hot in-place Isacsson, U., Ekblad, J., Johansson, S., and Krigsman, B. 共1997兲. “Varm

recycling of asphalt concrete.” Synthesis of Highway Practice 193, återvinning av asfaltbeläggningar på vägen—Sammanfattning av er-

National Cooperative Highway Research Program. farenheter från försök utförda 1993–95.” TRITA-IP AR 97-19, Divi-

Button, J. W., Little, D. N., and Estakhri, C. K. 共1995兲. “Performance and sion of Highway Engineering, Royal Institute of Technology, Stock-

cost of selected hot in-place recycling projects.” Transportation Re- holm, Sweden 共in Swedish兲.

search Record 1507, Transportation Research Board, Washington, Jacobson, T. 共1995兲. “Kall återvinning av asfalt—En teknik under utveck-

D.C., 51–61. ling: VTIs erfarenheter baserade på laboratorieförsök och uppföljning

90 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / JANUARY/FEBRUARY 2006

J. Mater. Civ. Eng. 2006.18:81-92.

av vägförsök.” VTI notat 66-1995, Swedish Road and Transport Re- 148–167.

search Institute, Linköping, Sweden, 共in Swedish兲. National Asphalt Pavement Association 共NAPA兲. 共1996兲. “Recycling hot

Jacobson, T. 共1996兲. “Återvinning av asfaltbeläggning—Svenska erfaren- mix asphalt pavements.” IS 123, National Asphalt Pavement Associa-

heter.” Swedish Road and Transport Research Institute, Linköping, tion, Lanham, Md.

Sweden, 255 共in Swedish兲. Newcomb, D. E., Nusser, B. J., Kiggundu, B. M., and Zallen, D. M.

Jacobson, T. 共1999兲. “Varm återvinning av asfalt i verk.” VTI-notat 22- 共1984兲. “Laboratory study of the effects of recycling modifiers on

1999, Swedish National Road and Transport Research Institute, aged asphalt cement.” Transportation Research Record 968, Transpor-

Linköping, Sweden 共in Swedish兲. tation Research Board, Washington, D.C., 66–77.

Johansson, L. S. 共1998兲. “Bitumen aging and hydrated lime.” TRITA-IP Noureldin, A. S., and Wood, L. E. 共1987兲. “Rejuvenator diffusion in

FR-98-38, Doctoral dissertation, Division of Highway Engineering, binder film for hot-mix recycled asphalt pavement.” Transportation

Royal Institute of Technology, Stockholm, Sweden. Research Record 1115, Transporation Research Board, Washington,

Judycki, J. 共1991兲. Fatigue of asphalt mixes, Road and Transport Labo- D.C. 51–61.

Downloaded from ascelibrary.org by WASHINGTON UNIV IN ST LOUIS on 06/27/14. Copyright ASCE. For personal use only; all rights reserved.

ratory, Univ. of Oulu, Finland. Noureldin, A. S., and Wood, L. E. 共1990兲. “Evaluating recycled asphalt

Kadar, P. 共1996兲. “Field and laboratory properties of recycled asphalt binders by the thin-film over test.” Transportation Research Record

pavement.” Asphalt Review, Australia, 9–12. 1269, Transporation Research Board, Washington, D.C., 20–25.

Oliver, J. W. H. 共1975兲. “Diffusion of oils in asphalts.” Rep. No. 9, Aus-

Kandhal, P. S. 共1997兲. “Recycling: State-of-the-practice.” J. Association

tralian Road Research Board, Vermont South, Victoria, Australia.

of Asphalt Paving Technologists, 66, 760–775.

Oliver, J. W. H. 共2001兲. “The influence of the binder in RAP on recycled

Kandhal, P. S., and Mallick, R. B. 共1997兲. “Pavement recycling guide-

asphalt properties.” Int. J. Road Materials and Pavement Design,

lines for state and local governments.” FHWA-SA-98-042, National

2共3兲, 311–325.

Center for Asphalt Technology, Washington, D.C.

Petersen, J. C. 共1984兲. “Chemical composition of asphalt as related to

Kandhal, P. S., Rao, S. S., Watson, D. E., and Young, B. 共1995兲. Perfor-

asphalt durability: State of the art.” Transportation Research Record

mance of recycled hot mix asphalt mixtures in state of Georgia, Na- 999, Transporation Research Board, Washington, D.C., 13–30.

tional Center for Asphalt Technology. Petersen, J. C. 共2000兲. “Chemical composition of asphalt as related to

Kari, W. J., Andersen, N. E., Davidson, D. D., Davis, H. L., Doty, R. N.,

asphalt durability.” Asphaltenes and asphalts, developments in petro-

Escobar, S. J., Kline, D. L., and Stone, T. K. 共1980兲. “Prototype speci-

leum science 40B, Elsevier, New York.

fications for recycling agents used in hot-mix recycling.” J. Associa-

Peterson, G. D., Davison, R. R., Glover, C. J., and Bullin, J. A. 共1994兲.

tion of Asphalt Paving Technologists.

“Effect of composition on asphalt recycling agent performance.”

Karlsson, R. 共2000兲. “Laboratory studies of bitumen rejuvenator diffusion

Transportation Research Record 1436, Transporation Research Board,

using FTIR-ATR.” TRITA-IP FR 00-65, Division of Highway Engi-

Washington, D.C., 38–46.

neering, Royal Institute of Technology, Stockholm, Sweden.

Potter, J. F., and Mercer, J. 共1997兲. “Full-scale performance trials and

Karlsson, R., and Isacsson, U. 共2002兲. “Bitumen rejuvenator diffusion as

accelerated testing of hot-mix recycling in the UK.” Proc., 8th Int.

influenced by aging.” Int. J. Road Materials and Pavement Design,

3共2兲, 167–182. Conf. on Asphalt Pavements, International Society for Asphalt Pave-

Karlsson, R., and Isacsson, U. 共2003兲. “Investigations on bitumen rejuve- ments, Seattle, 593–607.

nator diffusion and structural stability.” J. Association of Asphalt Pav- Redelius, P. G. 共2000兲. “Solubility parameters and bitumen.” Fuel, 79,

ing Technologists, 72 463–501. 27–35.

Kazmierowski, T. J., Bradbury, A., Cheng, S., and Raymond, C. 共1992兲. Redelius, P., Lu, X., and Isacsson, U. 共2002兲. “Non-classical wax in bi-

“Performance of cold in-place recycling in Ontario.” Transportation tumen.” Int. J. Road Materials and Pavement Design, 3共1兲, 7–21.