Академический Документы

Профессиональный Документы

Культура Документы

Crossing Slots: 1/2-13 NC - 1.0 DEEP

Загружено:

David BumbaloughОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Crossing Slots: 1/2-13 NC - 1.0 DEEP

Загружено:

David BumbaloughАвторское право:

Доступные форматы

33-07 Crossing Slots

In this project, the material is a fairly tough H13 steel. The machining requires two holes and two slots that cross

each other, with a tolerance. Make a complete program to machine the holes and slots.

2.251+0.000

1.499+0.002

1/2-13 NC - 1.0 DEEP (2)

-0.002

-0.000

2.50

0.75

5.00

5.75

0.41

0

0

0.75

1.499+0.002

-0.000

2.251+0.000

-0.002

0.06x45°

2 PLCS

6.25

MATERIAL - H13 STEEL - GROUND BLOCK 6.25 x 5.75 x 2.50

ò To develop the part program, follow these conditions:

1. Use ∅1.0 spot drill to make a 0.02 x 45° chamfer

2. Drill the two holes to 1.25 full depth

3. Tap the two holes 1/2-13

4. Use ∅5/8 roughing end mill with a 0.06 x 45° corner built-in

5. Use ∅5/8 finishing end mill with a 0.06 x 45° corner built-in

6. Program nominal drawing sizes - not mid-tolerances !

Answer this question: Based on the drawing tolerances, how many offsets are required for finishing?

Explain why.

Peter Smid CNC Programming Handbook 33-07 [ 1 ]

Вам также может понравиться

- How To Become Untrackable - Part 1 - SurvivopediaДокумент12 страницHow To Become Untrackable - Part 1 - SurvivopediaDavid Bumbalough100% (1)

- Bolted Joint Member StiffnessДокумент15 страницBolted Joint Member StiffnessKurtОценок пока нет

- Tortort Manufacturing 80% Milled Receivers AK47Документ6 страницTortort Manufacturing 80% Milled Receivers AK47David BumbaloughОценок пока нет

- HK94, MP5, Parts KitsДокумент6 страницHK94, MP5, Parts KitsDavid BumbaloughОценок пока нет

- The Complete Guide To Growing Corn in Containers - Garden and HappyДокумент17 страницThe Complete Guide To Growing Corn in Containers - Garden and HappyDavid BumbaloughОценок пока нет

- Epoxy ResinДокумент17 страницEpoxy ResinIrfan AliОценок пока нет

- Sk6 ToleranceДокумент1 страницаSk6 Tolerancen1ghtfallОценок пока нет

- Effect of stimulus voltage on muscle contractionДокумент12 страницEffect of stimulus voltage on muscle contractionPavel MilenkovskiОценок пока нет

- Welding Consumable Control ProcedureДокумент15 страницWelding Consumable Control ProcedureJoni Carino Suni89% (9)

- Weight Calculations Specific Weight (G/CM)Документ15 страницWeight Calculations Specific Weight (G/CM)Ranjeet Kumar ThakurОценок пока нет

- "Tech Notes": Stone Matrix Asphalt (SMA)Документ4 страницы"Tech Notes": Stone Matrix Asphalt (SMA)abdikarim_omarОценок пока нет

- Book 1Документ11 страницBook 1TahirJabbarОценок пока нет

- AVE and Composite Reliability CalculatorДокумент3 страницыAVE and Composite Reliability Calculatorshankar_mission100% (2)

- Certification 3g Dan 4g Aws d1Документ12 страницCertification 3g Dan 4g Aws d1AvebFrederiksenОценок пока нет

- Effective Width CalculationДокумент2 страницыEffective Width CalculationtosifsayyedОценок пока нет

- Repeating Groove: Without A Subprogram, Using The Incremental Mode AsДокумент1 страницаRepeating Groove: Without A Subprogram, Using The Incremental Mode AsDavid BumbaloughОценок пока нет

- 30-05 Cutter Radius Offset - Part 1Документ1 страница30-05 Cutter Radius Offset - Part 1David BumbaloughОценок пока нет

- Following: DrawingДокумент1 страницаFollowing: DrawingNacho BusinessОценок пока нет

- OR Non Linear Programming PracticalsДокумент50 страницOR Non Linear Programming PracticalsPRATIKSHA 20MTS5721Оценок пока нет

- 03b GCMS-QP2020 BrochureДокумент16 страниц03b GCMS-QP2020 BrochureosklavОценок пока нет

- Project Rubrics PDFДокумент2 страницыProject Rubrics PDFvixit thakurОценок пока нет

- Efficient CNC program for drilling 10 holesДокумент1 страницаEfficient CNC program for drilling 10 holesDavid BumbaloughОценок пока нет

- 30-06 Cutter Radius Offset - Part 2Документ1 страница30-06 Cutter Radius Offset - Part 2David BumbaloughОценок пока нет

- Developing The "Right" Modularization Decisions For Mining Modules in ChinaДокумент28 страницDeveloping The "Right" Modularization Decisions For Mining Modules in ChinaKhaled GameaОценок пока нет

- Smitch ChartДокумент3 страницыSmitch ChartBharat ChОценок пока нет

- Crecimiento Vs Consumo de Sustrato Virt. Generic: Paso (H)Документ1 страницаCrecimiento Vs Consumo de Sustrato Virt. Generic: Paso (H)brenditaperaltaОценок пока нет

- Adv Experimental WorksheetДокумент9 страницAdv Experimental WorksheetSushma ThakurОценок пока нет

- SCR T8 Weatherproof SeriesДокумент2 страницыSCR T8 Weatherproof Seriesgenius solutionОценок пока нет

- Assembly Systems and Line Balancing at Butterfly Grinder - MixerДокумент5 страницAssembly Systems and Line Balancing at Butterfly Grinder - MixerAnonymous DgVCa2hCОценок пока нет

- Animal Mass, kg Metabolic rate, W 270: Use Gauss-Seidel method without relaxation to ε = 5%Документ7 страницAnimal Mass, kg Metabolic rate, W 270: Use Gauss-Seidel method without relaxation to ε = 5%Kuna KunavathiОценок пока нет

- Workshop 10oct2018Документ36 страницWorkshop 10oct2018lijun xuОценок пока нет

- Exp BootДокумент3 страницыExp BootEdgar Enrique Garcia FloresОценок пока нет

- Decision Tree for Product Development and InvestmentДокумент5 страницDecision Tree for Product Development and InvestmenthesmonoОценок пока нет

- Number of customers at a cafe within 5 minutesДокумент1 страницаNumber of customers at a cafe within 5 minutesSitiNadyaSefrilyОценок пока нет

- Silicon NPN Epitaxial Planar Type: Composite TransistorsДокумент3 страницыSilicon NPN Epitaxial Planar Type: Composite TransistorsJosé AdelinoОценок пока нет

- Electro-Optics Drawing TitleДокумент2 страницыElectro-Optics Drawing TitleHarish KumarОценок пока нет

- 1 PlanoДокумент1 страница1 PlanoJosue alfonso Jimenez moralesОценок пока нет

- Rehabilitation Center - Space ProgДокумент21 страницаRehabilitation Center - Space ProgAine OdalerОценок пока нет

- CANOPY rev02 wind loads steel section checkДокумент14 страницCANOPY rev02 wind loads steel section checkHussein MuslihОценок пока нет

- 35-01 Program ChangeДокумент2 страницы35-01 Program ChangeDavid BumbaloughОценок пока нет

- Nanto RabДокумент8 страницNanto RabDwikyyОценок пока нет

- Global Money Dispatch: Credit Suisse EconomicsДокумент8 страницGlobal Money Dispatch: Credit Suisse EconomicsPéter AradványiОценок пока нет

- 2 WBB0 Nov 2018 AnswersДокумент5 страниц2 WBB0 Nov 2018 AnswersMurat SahilliogluОценок пока нет

- Temperature distribution in solid with convection boundaryДокумент11 страницTemperature distribution in solid with convection boundaryEdwin Orozco ReyesОценок пока нет

- Habitaculo EmergenteДокумент1 страницаHabitaculo EmergenteJosue alfonso Jimenez moralesОценок пока нет

- ExceeeeeeeeeeeelДокумент4 страницыExceeeeeeeeeeeelROBERTO JOSE AVILA HUACCHAОценок пока нет

- jjjjj jjjjj jj u = u u H0, tL = 0 u H1, tL = 0 u Hx, 0L = Sin Hπ xL y (zzzzz zzzzz zz 1Документ5 страницjjjjj jjjjj jj u = u u H0, tL = 0 u H1, tL = 0 u Hx, 0L = Sin Hπ xL y (zzzzz zzzzz zz 1Amir Masoud AbdolОценок пока нет

- L3 - FT - CINTA LED - Edison Opto - PLCC Lightbar FPC (IP54) Series - Eng - V3 - UnlockedДокумент10 страницL3 - FT - CINTA LED - Edison Opto - PLCC Lightbar FPC (IP54) Series - Eng - V3 - Unlockedjordy.2051.tagcsacОценок пока нет

- L10 - FT - CINTA LED - Edison Opto - PLCC Lightbar FPC (IP54) Series - Eng - V3Документ10 страницL10 - FT - CINTA LED - Edison Opto - PLCC Lightbar FPC (IP54) Series - Eng - V3Djanira JaramilloОценок пока нет

- Río Del Carrizal - Arroyo Seco 5+000 A 8+490.28Документ1 страницаRío Del Carrizal - Arroyo Seco 5+000 A 8+490.28David PaniaguaОценок пока нет

- Concentration of I-Vs Reaction RateДокумент4 страницыConcentration of I-Vs Reaction RateJulieОценок пока нет

- Río Del Carrizal - Arroyo Seco PERFIL 5+000 A 8+490.28 Rev - 04Документ1 страницаRío Del Carrizal - Arroyo Seco PERFIL 5+000 A 8+490.28 Rev - 04Luis AlcalaОценок пока нет

- DBC 1 Data Sheet 4921210129 UkДокумент13 страницDBC 1 Data Sheet 4921210129 UkLOI HOОценок пока нет

- Central CompositeДокумент9 страницCentral CompositenormalОценок пока нет

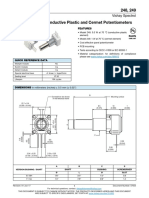

- Vishay Spectrol: FeaturesДокумент5 страницVishay Spectrol: Featureseguerra.mantenimientoОценок пока нет

- Calculate composite cross-section propertiesДокумент1 страницаCalculate composite cross-section propertiesVivek KumarОценок пока нет

- Undefined Title: Bloque - Nuevo - Bmf:cut - VKДокумент15 страницUndefined Title: Bloque - Nuevo - Bmf:cut - VKDarwin Joan AvendañoОценок пока нет

- Electrical Engineering Portal ComДокумент45 страницElectrical Engineering Portal ComRitesh SharmaОценок пока нет

- Mid Draft Difference Between Port and StbdДокумент2 страницыMid Draft Difference Between Port and StbdGary LampenkoОценок пока нет

- Histograms-SpreadsheetДокумент12 страницHistograms-SpreadsheetwaduОценок пока нет

- Week5 Histograms SpreadsheetДокумент12 страницWeek5 Histograms SpreadsheetJatin GargОценок пока нет

- 248, 249 1/2" (12.7 MM) Conductive Plastic and Cermet PotentiometersДокумент20 страниц248, 249 1/2" (12.7 MM) Conductive Plastic and Cermet PotentiometersRahmat Nur IlhamОценок пока нет

- Power Transistor ( 60V, 3A) : 2SB1184 / 2SB1243Документ3 страницыPower Transistor ( 60V, 3A) : 2SB1184 / 2SB1243vali2daduicaОценок пока нет

- Scara:1:500/100: N10.6 - CVG N10.6 - CD10Документ1 страницаScara:1:500/100: N10.6 - CVG N10.6 - CD10Tibi TibiОценок пока нет

- Wind Design To Cp3 - 1972: Namulemu Catholic Church General Wind Input TablesДокумент3 страницыWind Design To Cp3 - 1972: Namulemu Catholic Church General Wind Input TablesSolomon Ndugwa BalemeziОценок пока нет

- MINIMIZE ENERGY FOR WATER HEATINGДокумент29 страницMINIMIZE ENERGY FOR WATER HEATINGyekambaramОценок пока нет

- Water Purity Conversion ChartДокумент1 страницаWater Purity Conversion ChartKhizerAliRaoОценок пока нет

- Engineering Simulation Predicts Production QualityДокумент23 страницыEngineering Simulation Predicts Production QualityvikeshmОценок пока нет

- Stephen WerstДокумент23 страницыStephen WerstLeong Weng KeongОценок пока нет

- 12 Plants You'Ll Want in Your SHTF Garden - SurvivopediaДокумент21 страница12 Plants You'Ll Want in Your SHTF Garden - SurvivopediaDavid BumbaloughОценок пока нет

- Tomato Fertilizer - How To Feed Your Plants For The Ultimate HarvestДокумент11 страницTomato Fertilizer - How To Feed Your Plants For The Ultimate HarvestDavid BumbaloughОценок пока нет

- This Little Weed Is One of The Most Useful Medicines On The PlanetДокумент6 страницThis Little Weed Is One of The Most Useful Medicines On The PlanetDavid BumbaloughОценок пока нет

- Gun Control and The Founding Fathers Intent - The - Truth - and - JusticeДокумент9 страницGun Control and The Founding Fathers Intent - The - Truth - and - JusticeDavid BumbaloughОценок пока нет

- Feedrate Q+A: # Answer 1Документ2 страницыFeedrate Q+A: # Answer 1David BumbaloughОценок пока нет

- Providers - PrivacytoolsДокумент7 страницProviders - PrivacytoolsDavid BumbaloughОценок пока нет

- Exercises After Abdominal SurgeryДокумент5 страницExercises After Abdominal SurgeryDavid BumbaloughОценок пока нет

- 15-01 Reference Points - MillДокумент1 страница15-01 Reference Points - MillDavid BumbaloughОценок пока нет

- Scaling Function Q+A: # Answer 1Документ2 страницыScaling Function Q+A: # Answer 1David BumbaloughОценок пока нет

- 49-01 Documenting Programs Q+AДокумент1 страница49-01 Documenting Programs Q+ADavid BumbaloughОценок пока нет

- 44-01 Machining With TailstockДокумент1 страница44-01 Machining With TailstockDavid BumbaloughОценок пока нет

- 46-01 Horizontal MachiningДокумент1 страница46-01 Horizontal MachiningDavid BumbaloughОценок пока нет

- Calculating XY Points of a Blend Arc Dimensioned to its CenterДокумент1 страницаCalculating XY Points of a Blend Arc Dimensioned to its CenterDavid BumbaloughОценок пока нет

- Scaling Exercise: Use T01 Ø20 End MillДокумент1 страницаScaling Exercise: Use T01 Ø20 End MillDavid BumbaloughОценок пока нет

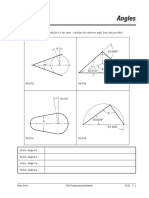

- Angles: in The Four Exercises, The Objective Is The Same - Calculate The Unknown Angle From Data ProvidedДокумент1 страницаAngles: in The Four Exercises, The Objective Is The Same - Calculate The Unknown Angle From Data ProvidedDavid BumbaloughОценок пока нет

- Verifying Programs Q+A: # Answer 1Документ2 страницыVerifying Programs Q+A: # Answer 1David BumbaloughОценок пока нет

- 49-01 Documenting Programs Q+A PDFДокумент1 страница49-01 Documenting Programs Q+A PDFDavid BumbaloughОценок пока нет

- Calculating XY Points of a Blend Arc Dimensioned to its CenterДокумент1 страницаCalculating XY Points of a Blend Arc Dimensioned to its CenterDavid BumbaloughОценок пока нет

- Unknown Radius: Chine Shop MagazineДокумент1 страницаUnknown Radius: Chine Shop MagazineDavid BumbaloughОценок пока нет

- CNC Machining Q+A: Major Criteria for Running First PartДокумент2 страницыCNC Machining Q+A: Major Criteria for Running First PartDavid BumbaloughОценок пока нет

- 53-02 Locators PDFДокумент1 страница53-02 Locators PDFDavid BumbaloughОценок пока нет

- 53-04 Contour Points 2Документ1 страница53-04 Contour Points 2David BumbaloughОценок пока нет

- Calculate Contour Change Points 1Документ1 страницаCalculate Contour Change Points 1David BumbaloughОценок пока нет

- Trig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartДокумент1 страницаTrig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDavid BumbaloughОценок пока нет

- 20-02 Rapid Motion FormulasДокумент2 страницы20-02 Rapid Motion FormulasDavid BumbaloughОценок пока нет

- 19-01 Tool LengthДокумент1 страница19-01 Tool LengthDavid BumbaloughОценок пока нет

- TN 28C - Thin Brick Veneer PDFДокумент9 страницTN 28C - Thin Brick Veneer PDFAnonymous PjmE9RJcghОценок пока нет

- Grandflor PU Mortar MD - TDSДокумент3 страницыGrandflor PU Mortar MD - TDSron iluminОценок пока нет

- Booster Pump Capacity CalculationДокумент29 страницBooster Pump Capacity CalculationARUL SANKARANОценок пока нет

- Free Stock Hight TensileДокумент1 страницаFree Stock Hight TensileIRWANОценок пока нет

- PWD CSRДокумент210 страницPWD CSRRakesh Paraliya100% (2)

- gr110 200 PDFДокумент65 страницgr110 200 PDFMuthu MohammadОценок пока нет

- Fire Cabinets: and AccessoriesДокумент4 страницыFire Cabinets: and AccessoriesSaiko AlyОценок пока нет

- Stainless Steel & Sugar Industry ReportДокумент13 страницStainless Steel & Sugar Industry Reportapi-19798491Оценок пока нет

- Polyflor Global Approved AdhesivesДокумент24 страницыPolyflor Global Approved AdhesivesRatna Ayu K 201102Оценок пока нет

- Cec 313 Lect NoteДокумент10 страницCec 313 Lect NoteSamson Mide FolorunshoОценок пока нет

- Plastic Manufacturing ProcessesДокумент6 страницPlastic Manufacturing ProcessesHimanshu TiwariОценок пока нет

- Malaca Sas: ManufactureДокумент25 страницMalaca Sas: Manufacturesamuel rondon upeguiОценок пока нет

- Rewari PIPE ERECTION SpecificationДокумент71 страницаRewari PIPE ERECTION Specificationkselvan_1100% (1)

- Manufacturing Process MESCETДокумент22 страницыManufacturing Process MESCETSarvan P PОценок пока нет

- EXPANSION JOINTS GUIDEДокумент24 страницыEXPANSION JOINTS GUIDEHossein DoudiОценок пока нет

- MMEE 313 - Elements of Pyrometallurgy Study GuideДокумент6 страницMMEE 313 - Elements of Pyrometallurgy Study GuideResego PhiriОценок пока нет

- Mechanical Properties of Al-14Si-2.5Cu-0.5Mg Aluminum-Silicon P/M AlloyДокумент5 страницMechanical Properties of Al-14Si-2.5Cu-0.5Mg Aluminum-Silicon P/M AlloySathwikRaoОценок пока нет

- Surface Discontinuities of Bolts, Screws, and Studs, Inch and Metric SeriesДокумент5 страницSurface Discontinuities of Bolts, Screws, and Studs, Inch and Metric SeriesROHITОценок пока нет

- Gate Valve For Piping (Api 600, 602, 603) : Key SpecificationsДокумент14 страницGate Valve For Piping (Api 600, 602, 603) : Key Specificationsswapnil PATILОценок пока нет

- Bosta Catalogue Export (ENG)Документ362 страницыBosta Catalogue Export (ENG)Rene van ErkelensОценок пока нет

- SolderingDesoldering 2Документ34 страницыSolderingDesoldering 2delfino santosОценок пока нет

- 2.ferrous & Non Ferrous Metal & AlloysДокумент14 страниц2.ferrous & Non Ferrous Metal & AlloysMuhammad TanweerОценок пока нет

- Gliss Master Product SheetДокумент58 страницGliss Master Product SheetDiana JitariuОценок пока нет

- Bending and Folding Machine DifferenceДокумент1 страницаBending and Folding Machine DifferenceabdiОценок пока нет