Академический Документы

Профессиональный Документы

Культура Документы

Central Cooling Equipment

Загружено:

arjantinАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Central Cooling Equipment

Загружено:

arjantinАвторское право:

Доступные форматы

SECTION 23 60 00 – CENTRAL COOLING EQUIPMENT

PART 1: GENERAL

1.1 GENERAL:

A. This standard is intended to provide useful information to the Professional Service Provider

(PSP) to establish a basis of design. The responsibility of the engineer is to apply the

principles of this section such that the University may achieve a level of quality and

consistency in the design and construction of their facilities. Deviations from these guidelines

must be justified through LCC analysis and submitted to the University for approval.

B. UT Dallas desire is to ensure that all new refrigeration equipment delivered to campus

conforms to EPA guidelines for refrigerants and is serviceable by UT Dallas Facilities

Management. The goal is to have equipment provided that is designed for and provided with

final replacement HFC refrigerants.

C. UT Dallas desire is to standardize on refrigerant types as a means for minimizing the number

of refrigerants in inventory. The specified refrigerant must be approved in advance by the

Owner.

D. Areas where large quantities of refrigerant are to be stored or used shall be provided with local

alarm annunciation, ventilation systems and signage.

E. It is the intent that all refrigeration equipment be 100% serviceable by UT Dallas Facilities

Management personnel. Exotic refrigeration systems that require specialty service equipment,

refrigeration charges, or other non-standard components are not acceptable without prior

approval by UT Dallas Facilities Management.

1.2 DESIGN:

A. UT Dallas desire is to have condensing equipment located as close as possible to evaporator.

1. Environmental Chambers. Where refrigeration equipment is used, condensing equipment

shall be located at the chamber. Ventilation shall be provided for removal of heat from

condensing unit. Adequately sized access and egress to condensing equipment shall be

provided for preventative maintenance and removal of equipment. Refrigeration piping

shall be designed for return of oil to compressor location. Exceptions may be approved by

owner for large loads on a case-by-case basis. In such cases, owner shall approve locations

of condensing compressor.

B. Low and ultra-low temperature refrigeration shall be accomplished with multiple compressors.

Refrigerant for each compressor/evaporator circuit shall be independent and of types listed

below. Auto-cascading refrigerant circuits are not acceptable.

PART 2: PRODUCTS

2.1 GENERAL:

A. The refrigerants listed in this section comply with EPA guidelines as final HFC refrigerants

and conform to UT Dallas inventory requirements.

3/21/2013 Issuance UTD – Section 23 60 00 Page 1 of 2

Central Cooling Equipment

B. Manufacturer specialty refrigerant blends, refrigerant charges available only from the original

manufacturer or refrigerant requiring special ordering are not acceptable.

2.2 ACCEPTABLE HFC REFRIGERANT TYPES AND APPLICATION:

A. R134a (replaces R12): Medium temperature applications. Packaged refrigeration and air

conditioning equipment.

B. R404a (replaces 502): Medium and low temperature applications. Reach-in and walk-in

coolers and freezers, environmental chambers.

C. R404a high stage with R23 (replaces R13, R502, R503), Ethane or Propane low stage.

Multi-stage low and ultra-low temperature applications. Reach-in freezers.

D. R407c (replaces R22): Medium and low temperature applications. Air conditioning

equipment.

[LEED EA prerequisite 3 Refrigeration Management – Zero use of CFC-based refrigerants in

new base building HVAC&R systems. When reusing existing base building HVAC

equipment, complete a comprehensive CFC phase-out conversion prior to project completion.]

[LEED EA credit 4 Enhanced Refrigerant Management - Select refrigerants and HVAC&R that

minimize or eliminate the emission of compounds that contribute to ozone depletion and global

warming AND do not install fire suppression systems that contain ozone-depleting substances (CFCs,

HCFCs or Halons).]

PART 3: EXECUTION

3.1 REFRIGERANT REMOVAL:

A. Open discharge of refrigerants is not acceptable. All refrigerants shall be recovered utilizing

appropriate recovery equipment and in accordance with current regulatory guidelines.

B. Refrigeration equipment scheduled for demolition and removal shall have refrigerant charge

removed. Technician performing removal shall be licensed under the State of Texas for such

work. Technician shall provide statement indicating that refrigerant has been removed.

Statement shall include date of removal, printed and signed name of technician, license number

of technician and type of refrigerant removed. Statement shall be affixed to equipment with

copy included with final project documents.

END OF SECTION 23 60 00

3/21/2013 Issuance UTD – Section 23 60 00 Page 2 of 2

Central Cooling Equipment

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- 500 Logo Design Inspirations Download #1 (E-Book)Документ52 страницы500 Logo Design Inspirations Download #1 (E-Book)Detak Studio DesainОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Abu Hamza Al Masri Wolf Notice of Compliance With SAMs AffirmationДокумент27 страницAbu Hamza Al Masri Wolf Notice of Compliance With SAMs AffirmationPaulWolfОценок пока нет

- The Internal Environment: Resources, Capabilities, Competencies, and Competitive AdvantageДокумент5 страницThe Internal Environment: Resources, Capabilities, Competencies, and Competitive AdvantageHenny ZahranyОценок пока нет

- Philips Circular ExperienceДокумент20 страницPhilips Circular ExperiencearjantinОценок пока нет

- Social Media Guide: For Professional ServicesДокумент39 страницSocial Media Guide: For Professional ServicesarjantinОценок пока нет

- Noise and Vibration Control For Hvac Piping and EquipmentДокумент15 страницNoise and Vibration Control For Hvac Piping and EquipmentarjantinОценок пока нет

- Chilled Beams in Heating: Design Criteria and Case StudyДокумент8 страницChilled Beams in Heating: Design Criteria and Case StudyarjantinОценок пока нет

- 4th Sem Electrical AliiedДокумент1 страница4th Sem Electrical AliiedSam ChavanОценок пока нет

- Ikea AnalysisДокумент33 страницыIkea AnalysisVinod BridglalsinghОценок пока нет

- Strobostomp HD™ Owner'S Instruction Manual V1.1 En: 9V DC Regulated 85maДокумент2 страницыStrobostomp HD™ Owner'S Instruction Manual V1.1 En: 9V DC Regulated 85maShane FairchildОценок пока нет

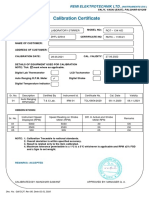

- Calibration CertificateДокумент1 страницаCalibration CertificateSales GoldClassОценок пока нет

- The Rise of Populism and The Crisis of Globalization: Brexit, Trump and BeyondДокумент11 страницThe Rise of Populism and The Crisis of Globalization: Brexit, Trump and Beyondalpha fiveОценок пока нет

- Presentation Report On Customer Relationship Management On SubwayДокумент16 страницPresentation Report On Customer Relationship Management On SubwayVikrant KumarОценок пока нет

- CSEC Jan 2011 Paper 1Документ8 страницCSEC Jan 2011 Paper 1R.D. KhanОценок пока нет

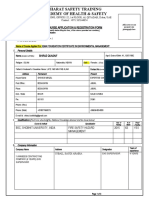

- BST Candidate Registration FormДокумент3 страницыBST Candidate Registration FormshirazОценок пока нет

- Himachal Pradesh Important NumbersДокумент3 страницыHimachal Pradesh Important NumbersRaghav RahinwalОценок пока нет

- A320 Basic Edition Flight TutorialДокумент50 страницA320 Basic Edition Flight TutorialOrlando CuestaОценок пока нет

- Guide To Growing MangoДокумент8 страницGuide To Growing MangoRhenn Las100% (2)

- 2016 066 RC - LuelcoДокумент11 страниц2016 066 RC - LuelcoJoshua GatumbatoОценок пока нет

- FIRE FIGHTING ROBOT (Mini Project)Документ21 страницаFIRE FIGHTING ROBOT (Mini Project)Hisham Kunjumuhammed100% (2)

- PVAI VPO - Membership FormДокумент8 страницPVAI VPO - Membership FormRajeevSangamОценок пока нет

- Electrical ConnectorsДокумент5 страницElectrical ConnectorsRodrigo SantibañezОценок пока нет

- Mid Term Exam 1Документ2 страницыMid Term Exam 1Anh0% (1)

- Review of Related LiteratureДокумент4 страницыReview of Related LiteratureCarlo Mikhail Santiago25% (4)

- What Is Retrofit in Solution Manager 7.2Документ17 страницWhat Is Retrofit in Solution Manager 7.2PILLINAGARAJUОценок пока нет

- Arduino Based Voice Controlled Robot: Aditya Chaudhry, Manas Batra, Prakhar Gupta, Sahil Lamba, Suyash GuptaДокумент3 страницыArduino Based Voice Controlled Robot: Aditya Chaudhry, Manas Batra, Prakhar Gupta, Sahil Lamba, Suyash Guptaabhishek kumarОценок пока нет

- Laporan Praktikum Fisika - Full Wave RectifierДокумент11 страницLaporan Praktikum Fisika - Full Wave RectifierLasmaenita SiahaanОценок пока нет

- Transparency Documentation EN 2019Документ23 страницыTransparency Documentation EN 2019shani ChahalОценок пока нет

- Tradingview ShortcutsДокумент2 страницыTradingview Shortcutsrprasannaa2002Оценок пока нет

- Hexoskin - Information For Researchers - 01 February 2023Документ48 страницHexoskin - Information For Researchers - 01 February 2023emrecan cincanОценок пока нет

- What Caused The Slave Trade Ruth LingardДокумент17 страницWhat Caused The Slave Trade Ruth LingardmahaОценок пока нет

- Sustainable Urban Mobility Final ReportДокумент141 страницаSustainable Urban Mobility Final ReportMaria ClapaОценок пока нет

- G.R. No. 185449, November 12, 2014 Del Castillo Digest By: DOLARДокумент2 страницыG.R. No. 185449, November 12, 2014 Del Castillo Digest By: DOLARTheodore DolarОценок пока нет

- Form16 2018 2019Документ10 страницForm16 2018 2019LogeshwaranОценок пока нет