Академический Документы

Профессиональный Документы

Культура Документы

T-0702,03,04 - DIEULENT Storage Tank Design Report - Comments - 06-March-19

Загружено:

MauliОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

T-0702,03,04 - DIEULENT Storage Tank Design Report - Comments - 06-March-19

Загружено:

MauliАвторское право:

Доступные форматы

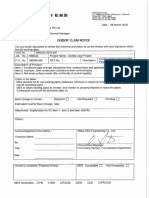

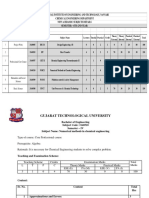

STATUS OF COMMENTS ON DILUENT STORAGE TANK DESIGN REPORT

PROJECT : THERMAL ARUMA PILOT(TAR) PROJECT

AECPL PROJECT NO: 18029

CLIENT: TATWEER PETROLEUM

DISCIPLINE: MECHANICAL

SR. NO. COMMENTS BY AECPL ACTION BY RAMSIS ENGINEERING (COMMENT STATUS) REMARKS

DOC. NO.:- TP-RSIP-01312-CAL-A4_REV A2

TITLE:- DESIGN CALCULATION REPORT FOR DILUENT

STORAGE TANK

The Yield Strength of the material(S275JR) as per design

temperature(100 DegC) shall be as per Annex M clause M.3.2, based

1 Refer respective document/drawing.

on this the design stress(Sd) and hydrotest stress(St) are calculated.

(Sht. 7 of 41)

The bottom shell course height mentioned is 6m, but it shall be 3m.

2 Refer respective document/drawing.

(Sht. 7 of 41)

The tensile strength of the material(S275JR) is 410MPA(for plate

thickness 3-100mm thick), but in calculations it is considered as

430MPA. Based on this the design stress(Sd) and hydrotest stress(St)

are calculated. (Sht. 7 of 41)

The Yield Strength of the material(S275JR) as per design

10 temperature(100 DegC) shall be as per Annex M Table M.1a. (Sht. Refer respective document/drawing.

17 of 41)

The Formula for required compression area at roof to shell junction as

per API 650 clause 5.10.5.2 mentioned is not correct, Please correct it.

3 Also the meaning and value used for claculations of the term "Fa" shall Refer respective document/drawing.

also be corrected as per API 650 clause 5.10.5.2

(Sht. 10 of 41)

As per our review the DLR value used in compression area calculation

4 shall be 31973.53N, but it is considered as 17524.81N. Please

check/correct. (Sht. 11 of 41)

In Point no. "B", it is mentioned that the "Figure F-2 (Detail d)", but

actually it shall be "Figure F-2 (Detail b)" as also this detail given in

5 Refer respective document/drawing.

drawing no. TP-RSIP-01313-DGA-A1(G.A. of Diluent Tank-T-0702)

(Sht. 11 of 41)

The meaning and value of term "Fy" mentioned in the formula for

required compression area at roof to shell junction shall be corrected

6 Refer respective document/drawing.

for modified design temperature as per API 650 Annex F clause F.4.1

(Sht. 11 of 41)

The curb angle size mentioned in design calculation report is 80x80x6

mm but in drawing no. TP-RSIP-01313-DGA-A1(G.A. of Diluent

7 Refer respective document/drawing.

Tank-T-0702) it is 80x80x8 mm. Please correct it in design calculation

report. (Sht. 12 of 41)

As per above given comments the areas mentioned in sht. No. 10, 11

8

and 12 of 41 will be revised. (Sht. 10,11,12 of 41)

Mentioned adapted design wind speed, Vd = 165 Km/hr is not clear as

9 Refer respective document/drawing.

the basic wind speed is 144.84Km/hr. (Sht. 12 of 41)

The value of modulus of elasticity(E) shall be as per max. design

9 Refer respective document/drawing.

temperature (100 DegC). (Sht. 15 of 41)

The Yield Strength(Fby) of the material(S275JR) for bottam plate as

10 per design temperature(100 DegC) shall be as per Annex M Table Refer respective document/drawing.

M.1a. (Sht. 17 of 41)

As per our review the DLR value(corroded weight due to roof load) shall

11 be 23.902KN, but it is considered as 18.016KN. Please check/correct. Refer respective document/drawing.

(Sht. 17 of 41)

As per our review the MDLR value(corroded moment due to roof load)

12 shall be 56.2890KNM, but it is considered as 42.428KNM. Please Refer respective document/drawing.

check/correct. (Sht. 17 of 41)

As per above given comments the load condition 1 & 2 mentioned in

13 Refer respective document/drawing.

sht. No. 18 of 41 will be revised. (Sht. 18 of 41)

The Min. Yield Strength(Fty) of the material(S275JR) for bottam shell

14 course as per design temperature(100 DegC) shall be as per Annex M Refer respective document/drawing.

Table M.1a. (Sht. 18 of 41)

As per our review the PWR value(wind uplift pressure on roof) shall be

15 1.086KPA, but it is considered as 0.431KPA. Please correct it. Refer respective document/drawing.

(Sht. 18 of 41)

The calculations provided on the Sht No. 19 & 20 of 41 for W1, W2,

W3, uplift load cases, all. Anchor bolt stresses, P, Pmax, Pt, U/N, shall

16 Refer respective document/drawing.

be revised as per API 650 12th Edition, Addendum 2, Jan 2016.

(Sht. 19&20 of 41)

At Sht. No. 19 of 41 the MOC of anchor bolt mentioned is SA36 and At

Sht. No. 22 of 41 the MOC of anchor bolt mentioned is S275JR.

17 Refer respective document/drawing.

Please confirm which one is considered? As per our understanding it

shall be S275JR. (Sht. 19&22 of 41)

The yield stress of anchor bolt material(Fy) mentioned is 200MPA, but

18 Refer respective document/drawing.

it shall be 250MPA as per S275JR material. (Sht. 19 of 41)

Selected bolt size is M20, but as API 650 12th edition the minimum

19 Refer respective document/drawing.

anchor bolt size shall be 25.4mm plus the corrosion allowance.

20 Refer respective document/drawing.

No. of stiffeners in drg & BOM is 3

21

deleted in R1 revision

22 Refer respective document/drawing.

23 Refer respective document/drawing.

24 Refer respective document/drawing.

25 Refer respective document/drawing.

26 - New Comment

27 - New Comment

28 - New Comment

29 - New Comment

Вам также может понравиться

- SOL-DR-14-0142 R00 - Comment Sheet On HAL Civil Drawings On NIL-2n (UPDATE) - SignedДокумент2 страницыSOL-DR-14-0142 R00 - Comment Sheet On HAL Civil Drawings On NIL-2n (UPDATE) - SignedPieter HarryОценок пока нет

- 650-645 Design Requirements For Self-Supporting Roofs 9/24/07Документ5 страниц650-645 Design Requirements For Self-Supporting Roofs 9/24/07Nguyen ChuyenОценок пока нет

- Api 521 ErrataДокумент2 страницыApi 521 ErrataMarcioОценок пока нет

- Changes DC-Footing For Windows Date ChangeДокумент6 страницChanges DC-Footing For Windows Date ChangeMarcos MaОценок пока нет

- 15 2004erratasheet6 11 07Документ1 страница15 2004erratasheet6 11 07mohamed sameirОценок пока нет

- Diamant Oud Is 2005Документ8 страницDiamant Oud Is 2005obaidullah.dsuОценок пока нет

- Hexagon Documentation Site Export-4Документ100 страницHexagon Documentation Site Export-4Alberto VELOSA ROAОценок пока нет

- 15 2001erratasheet - 3 16 09Документ1 страница15 2001erratasheet - 3 16 09Abhisek MilanОценок пока нет

- 42 P 41 81 - PadmountedДокумент39 страниц42 P 41 81 - PadmountedSarmad HussainОценок пока нет

- Gusset 3.1. in Tension 3.1.1 TenДокумент6 страницGusset 3.1. in Tension 3.1.1 TenKARTHIK SGОценок пока нет

- 3D CFD simulation of flare flowДокумент16 страниц3D CFD simulation of flare flowIlman IhzaОценок пока нет

- Sepa15015 MFSFD CV 21 Cal 101 - 1Документ23 страницыSepa15015 MFSFD CV 21 Cal 101 - 1Pruthviraj JuniОценок пока нет

- BT 23 Tec Le HD SH 1006Документ5 страницBT 23 Tec Le HD SH 1006tongtonglian780Оценок пока нет

- Calculation B7Документ5 страницCalculation B7gayan jayasingheОценок пока нет

- CS Pipe Wall Thickness CalculationДокумент16 страницCS Pipe Wall Thickness CalculationunnicyriacОценок пока нет

- Bes 1 Agni 2017Документ53 страницыBes 1 Agni 2017aff123051Оценок пока нет

- Fatigue PDFДокумент37 страницFatigue PDFbharatbelladОценок пока нет

- 17_GT2011-45243-An Aerodynamic Design Methodology for Low Pressure Axial Fans WithДокумент9 страниц17_GT2011-45243-An Aerodynamic Design Methodology for Low Pressure Axial Fans WithkcpatnaikОценок пока нет

- Creep Design PDFДокумент4 страницыCreep Design PDFSugumar SОценок пока нет

- CasingДокумент4 страницыCasingAlejandro ManriqueОценок пока нет

- 06745JS2 (7) - Strength Calculations of Module4 (IBR)Документ23 страницы06745JS2 (7) - Strength Calculations of Module4 (IBR)Pratik Ray Chaudhury100% (3)

- Interview Question.Документ7 страницInterview Question.PankajDhobleОценок пока нет

- Flange Leakage Test As Per Asme Boiler & Pressure Vessel CodeДокумент12 страницFlange Leakage Test As Per Asme Boiler & Pressure Vessel CoderssambhiОценок пока нет

- Changes DC-Pile For Windows Date ChangesДокумент7 страницChanges DC-Pile For Windows Date ChangesMarcos MaОценок пока нет

- Assignment 1 - Fluid StaticsДокумент3 страницыAssignment 1 - Fluid StaticsaarijОценок пока нет

- ASME Section III NP ExtractДокумент6 страницASME Section III NP ExtractAnonymous UoHUagОценок пока нет

- Table-1 Scope of Work Supply (MR For ACHE)Документ6 страницTable-1 Scope of Work Supply (MR For ACHE)Avinash ShuklaОценок пока нет

- Casting Quality Factor Ec 302.3.3 ASME B31.3 2020 PDFДокумент3 страницыCasting Quality Factor Ec 302.3.3 ASME B31.3 2020 PDFedisjdavОценок пока нет

- How To Design A Thermally-Efficient Integrated BLDC Motor Drive PCBДокумент12 страницHow To Design A Thermally-Efficient Integrated BLDC Motor Drive PCBMi ChuckОценок пока нет

- Owner's Engineering Services for Teesta/Korotoa 200 MW Solar ProjectsДокумент2 страницыOwner's Engineering Services for Teesta/Korotoa 200 MW Solar ProjectsgohilnarendraОценок пока нет

- 46 - 2.vendor Claim Notice No. HB8242-2019-001 - 0001Документ30 страниц46 - 2.vendor Claim Notice No. HB8242-2019-001 - 0001karthikaОценок пока нет

- Calculations Tank S6Документ19 страницCalculations Tank S6Joshue Adele100% (1)

- Hole Configuration EffectДокумент5 страницHole Configuration EffectDavnОценок пока нет

- API 650 Load CombinationsДокумент10 страницAPI 650 Load Combinationsศุภกฤต รักในหลวงОценок пока нет

- 2ESR-2461 - MKT Metall-Kunststoff-Technik GMBH & Co. KGДокумент2 страницы2ESR-2461 - MKT Metall-Kunststoff-Technik GMBH & Co. KGbisagantiОценок пока нет

- Flutter Analysis of Last Stage Steam Turbine PowerДокумент14 страницFlutter Analysis of Last Stage Steam Turbine Powerji.lang.vuОценок пока нет

- Bell Delaware Method English 2Документ10 страницBell Delaware Method English 2aldairОценок пока нет

- Optimize AFC Stress AnalysisДокумент8 страницOptimize AFC Stress Analysissaurabh shuklaОценок пока нет

- Optimum Sizing of Cooling TowersДокумент7 страницOptimum Sizing of Cooling Towerssohailffc100% (1)

- ASME Code Calculations For Companion FlangesДокумент9 страницASME Code Calculations For Companion FlangesKamlesh DalavadiОценок пока нет

- Hmtmta2 Main PDFДокумент10 страницHmtmta2 Main PDFONNDWELA RAMALAMULAОценок пока нет

- CRS Pump-CompДокумент3 страницыCRS Pump-CompDr Ganesh Kame (Dr Kame)Оценок пока нет

- Significant Changes in ACI Code Appendix DДокумент6 страницSignificant Changes in ACI Code Appendix DSumanthОценок пока нет

- Design Loads and Assumptions for Elevated Station ConcourseДокумент3 страницыDesign Loads and Assumptions for Elevated Station ConcourseHarikrishnaОценок пока нет

- RD 810Документ73 страницыRD 810Ashish MishraОценок пока нет

- A Quick PCB Thermal Calculation For Power Electronic Devices With Exposed Pad Packages PDFДокумент14 страницA Quick PCB Thermal Calculation For Power Electronic Devices With Exposed Pad Packages PDFwnaciОценок пока нет

- $RPC3METДокумент3 страницы$RPC3METAJEC IndiaОценок пока нет

- Iso 7345:1997Документ10 страницIso 7345:1997Blaise Roithridh100% (1)

- Aerodynamics Handbook Covers Atmospheric Properties and Vehicle DesignДокумент98 страницAerodynamics Handbook Covers Atmospheric Properties and Vehicle DesignSoufiane HazelОценок пока нет

- Woup DS2 HBP Ea 1380 0003 - 001Документ5 страницWoup DS2 HBP Ea 1380 0003 - 001胡子Оценок пока нет

- Equations For DesignДокумент5 страницEquations For DesignNikash9112802Оценок пока нет

- Thermoelectric Energy Conversion Devices: R 2016 Elsevier Inc. All Rights ReservedДокумент9 страницThermoelectric Energy Conversion Devices: R 2016 Elsevier Inc. All Rights ReservedJanuar Mathematicoi PhytagoreansОценок пока нет

- PMSG For Wind PowerДокумент6 страницPMSG For Wind PoweromokhafeОценок пока нет

- HFY-3800-1600-CIV-RPT-0021 - A - Foundation Design Calculation Depropaniser (C-923010)Документ30 страницHFY-3800-1600-CIV-RPT-0021 - A - Foundation Design Calculation Depropaniser (C-923010)prasadcspОценок пока нет

- Ca No: Cejz/Jslr/ of 2017-2018Документ25 страницCa No: Cejz/Jslr/ of 2017-2018Pankaj BansalОценок пока нет

- Allowable Pipe Spans LoadsДокумент84 страницыAllowable Pipe Spans LoadsMalcolm Hutton100% (5)

- Uht 80 Uht82Документ1 страницаUht 80 Uht82ALI MESSAOUDIОценок пока нет

- TP 2011 469Документ28 страницTP 2011 469Catanescu Alexandru-LaurentiuОценок пока нет

- TRD 301 Annex 1 Design PDFДокумент14 страницTRD 301 Annex 1 Design PDFarjun prajapatiОценок пока нет

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysОт EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysОценок пока нет

- Click To Edit Master Title StyleДокумент5 страницClick To Edit Master Title StyleFerry Chun LongОценок пока нет

- Calcium Silicate Block and Pipe Thermal Insulation: Standard Specification ForДокумент4 страницыCalcium Silicate Block and Pipe Thermal Insulation: Standard Specification ForNour MasmoudiОценок пока нет

- 8 Different Type of Yoga.8625330.powerpointДокумент3 страницы8 Different Type of Yoga.8625330.powerpointMauliОценок пока нет

- Check PointsДокумент1 страницаCheck PointsMauliОценок пока нет

- Calcium Silicate Block and Pipe Thermal Insulation: Standard Specification ForДокумент4 страницыCalcium Silicate Block and Pipe Thermal Insulation: Standard Specification ForNour MasmoudiОценок пока нет

- CodeДокумент9 страницCodeMauliОценок пока нет

- Calcium Silicate Block and Pipe Thermal Insulation: Standard Specification ForДокумент4 страницыCalcium Silicate Block and Pipe Thermal Insulation: Standard Specification ForNour MasmoudiОценок пока нет

- Lug Calculation 200klДокумент7 страницLug Calculation 200klMauliОценок пока нет

- Duct ListДокумент5 страницDuct ListMauliОценок пока нет

- Offcon DNV Zorro SkidДокумент6 страницOffcon DNV Zorro SkiddakidofdaboomОценок пока нет

- Ready Recknor For Vessel CalculationДокумент57 страницReady Recknor For Vessel CalculationMauli100% (1)

- Equipment List - 05.07.2019 - r2 With WeightsДокумент8 страницEquipment List - 05.07.2019 - r2 With WeightsMauliОценок пока нет

- Pressure: Introduction To Pressure - Psi and Pa - Online Pressure Units ConverterДокумент3 страницыPressure: Introduction To Pressure - Psi and Pa - Online Pressure Units ConverterMauliОценок пока нет

- Ready Recknor For Vessel CalculationДокумент57 страницReady Recknor For Vessel CalculationMauli100% (1)

- Ready Recknor For Vessel CalculationДокумент57 страницReady Recknor For Vessel CalculationMauli100% (1)

- Gear Pump Datasheets 2Документ12 страницGear Pump Datasheets 2MauliОценок пока нет

- What Is The Relation Between Gauge Pressure Absolute Pressure Atmospheric Pressure and Vacuum Pressure - QuoraДокумент3 страницыWhat Is The Relation Between Gauge Pressure Absolute Pressure Atmospheric Pressure and Vacuum Pressure - QuoraMauliОценок пока нет

- Scope of Work Doc-Fire Hydrant SystemДокумент2 страницыScope of Work Doc-Fire Hydrant SystemMauliОценок пока нет

- Ready Recknor For Vessel CalculationДокумент57 страницReady Recknor For Vessel CalculationMauli100% (1)

- Detailed Pump Datasheet Engineering ConsultantДокумент12 страницDetailed Pump Datasheet Engineering ConsultantMauliОценок пока нет

- Detailed Pump Datasheet Engineering ConsultantДокумент12 страницDetailed Pump Datasheet Engineering ConsultantMauliОценок пока нет

- Calendar 2013 by JABIR.MAДокумент368 страницCalendar 2013 by JABIR.MAPramod Kumar SaxenaОценок пока нет

- 70KL Tank Technical DrawingsДокумент10 страниц70KL Tank Technical DrawingsMauliОценок пока нет

- Centrifugal Pump Datasheets 1Документ12 страницCentrifugal Pump Datasheets 1MauliОценок пока нет

- Gear Pump Datasheets 1Документ12 страницGear Pump Datasheets 1MauliОценок пока нет

- Boq of 100kl Storage TankДокумент6 страницBoq of 100kl Storage TankMauliОценок пока нет

- Thermal Aruma Pilot (Tar) Project 18029 Tatweer Petroleum MechanicalДокумент2 страницыThermal Aruma Pilot (Tar) Project 18029 Tatweer Petroleum MechanicalMauliОценок пока нет

- Anchor Bolts Anchor Bolts: Projected Tension Area: Structural Details 1 Structural Details 2Документ7 страницAnchor Bolts Anchor Bolts: Projected Tension Area: Structural Details 1 Structural Details 2Johneey DeepОценок пока нет

- Calendar 2013 by JABIR.MAДокумент368 страницCalendar 2013 by JABIR.MAPramod Kumar SaxenaОценок пока нет

- Lithium BromideДокумент2 страницыLithium BromideaktekshareОценок пока нет

- AIRCOVE - Cooling Load CalculationДокумент37 страницAIRCOVE - Cooling Load CalculationSol S.Оценок пока нет

- ASEJ-D-19-00186-Comments From Reviewer No. 1Документ19 страницASEJ-D-19-00186-Comments From Reviewer No. 1Ismacahyadi Mohamed JaisОценок пока нет

- Composites and Emulsion (Grade 10)Документ15 страницComposites and Emulsion (Grade 10)hazemmtaha00Оценок пока нет

- Experiment 12 Fluid FrictionДокумент4 страницыExperiment 12 Fluid FrictionHadoosh2786% (7)

- Tsiampousi A 2011 PHD ThesisДокумент480 страницTsiampousi A 2011 PHD ThesisDEEPAK KUMAR SINGHОценок пока нет

- Coalescence of Surfactant-Laden Drops by A Phase Field MethodДокумент20 страницCoalescence of Surfactant-Laden Drops by A Phase Field MethodAlfredo SoldatiОценок пока нет

- Gujarat Technological University: Page 1 of 4Документ4 страницыGujarat Technological University: Page 1 of 4Mehul MunshiОценок пока нет

- IM ECEN 30054 - Fundamentals of Instrumentation and ControlДокумент57 страницIM ECEN 30054 - Fundamentals of Instrumentation and ControlVictoria AlarconОценок пока нет

- Pushover AnalysisДокумент12 страницPushover AnalysisNikhilVasistaОценок пока нет

- Tritan TX1001Документ2 страницыTritan TX1001qiongyao cuiОценок пока нет

- Vortex TubeДокумент4 страницыVortex TubeJournalNX - a Multidisciplinary Peer Reviewed JournalОценок пока нет

- Design and Optimisation of Organic Ranking Cycle and Absorption Chiller For Heat Recovery of Petroleum RefiningДокумент75 страницDesign and Optimisation of Organic Ranking Cycle and Absorption Chiller For Heat Recovery of Petroleum RefiningAndRew SteFanusОценок пока нет

- Determining Erodibility and RSS NumbersДокумент2 страницыDetermining Erodibility and RSS NumbersAngel PadillaОценок пока нет

- FLUID FILM AND BOUNDARY LUBRICATIONДокумент21 страницаFLUID FILM AND BOUNDARY LUBRICATIONBhupender Singh ChughОценок пока нет

- MarsRule InlandДокумент30 страницMarsRule Inlandpeng inОценок пока нет

- Analysis and Design of Multistory Building Using Composite StructureДокумент15 страницAnalysis and Design of Multistory Building Using Composite Structuredillibabu rОценок пока нет

- 5.accidental Car Impact Analysis and CFDДокумент6 страниц5.accidental Car Impact Analysis and CFDprojectzfourОценок пока нет

- PVT & Eos Modelling: Using Pvtsim SoftwareДокумент71 страницаPVT & Eos Modelling: Using Pvtsim SoftwareMario HuasasquicheОценок пока нет

- Microchannel Heat Exchanger As EvaporatorДокумент11 страницMicrochannel Heat Exchanger As EvaporatorAbhilash TilakОценок пока нет

- Design of Hydraulic and Pneumatic SystemsДокумент1 страницаDesign of Hydraulic and Pneumatic Systemsroscilla50% (2)

- Weather Watch Study NotesДокумент5 страницWeather Watch Study Notesapi-336664994Оценок пока нет

- SSAT Institute of Engineering Numerical Methods Course DetailsДокумент18 страницSSAT Institute of Engineering Numerical Methods Course DetailsDharam PatelОценок пока нет

- 61 TOP Hydraulic Machines - Mechanical Engineering Multiple Choice Questions and Answers List - MCQs Preparation For Engineering Competitive ExamsДокумент12 страниц61 TOP Hydraulic Machines - Mechanical Engineering Multiple Choice Questions and Answers List - MCQs Preparation For Engineering Competitive ExamsNagaraj MuniyandiОценок пока нет

- Topic1 StaticДокумент29 страницTopic1 StaticMohamad Muslihuddin RazaliОценок пока нет

- DLL-earth-and-life - 5Документ4 страницыDLL-earth-and-life - 5Marilla ReybethОценок пока нет

- Ductility and Strength Behavior of Reinforced Concrete Columns Confined by Glass and Carbon FRP SheetsДокумент23 страницыDuctility and Strength Behavior of Reinforced Concrete Columns Confined by Glass and Carbon FRP SheetsJm CampitanОценок пока нет

- 62-69 Engineer's Notebook DudaДокумент5 страниц62-69 Engineer's Notebook DudaMichael LagundinoОценок пока нет

- To Determine Manning's Coefficient and Chezy Coefficient of Laboratory FlumeДокумент3 страницыTo Determine Manning's Coefficient and Chezy Coefficient of Laboratory FlumeRahat Usman0% (1)

- Opening Area Calculation: PT Menara Alfa SemestaДокумент1 страницаOpening Area Calculation: PT Menara Alfa SemestaCak NhassОценок пока нет