Академический Документы

Профессиональный Документы

Культура Документы

Class Notes

Загружено:

jennifer0 оценок0% нашли этот документ полезным (0 голосов)

6 просмотров1 страницаMSL Case study- Operations Management

Авторское право

© © All Rights Reserved

Доступные форматы

TXT, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документMSL Case study- Operations Management

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате TXT, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

6 просмотров1 страницаClass Notes

Загружено:

jenniferMSL Case study- Operations Management

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате TXT, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

MSL Case study for Operations Management

Class Notes

Cycle time= 5minutes (bottleneck time)

Hourly capacity = 60/5 = 12 Units per hour.

Throughput time=2+5+4+2+4+2+5= 24 minutes

The total utilization of the process:

={((5x(2/5)+2x(5/5)+2x(4/5)))/9} x 100

= 62.22%

Work Duration:

26 days a month, 9 hours per day (Inc. 30 min of lunch; 2 x 10 minutes = 20 minutes

of tea break )

Number of workers = 12

Operating time per day = (9hr-50min) = 490min

Working hours/worker = 490*26/ = 212.33hrs

NOTE: it is noted that the process time in the video is different.

Video Reference: https://www.youtube.com/watch?v=aXjEDGq29h0&feature=youtu.be

Cycle time= 100 sec (bottleneck for housing assembly)

Throughput time= 44+10+100+45+20+40+6+50= 315 sec

Maximum Task Time = Throughput time+ Wait time = 315s+4hrs = 14715sec

Utilization= [(44/100) + (10/100) +(100/100)+ (35/100) +(45/100) + (35/100)

+(10/100) +(20/100) + (40/100) +(6/100) + (50/100)]/11 = 36%

Cycle time (Time taken in bottleneck process) = 100 Sec

Output rate = Operating time per day/cycle time= 490*60/100 = 294 units

Sum of task time = 395Sec

Theoretical Min. Number of Station = Sum of task time / Cycle Time = 395/100 = 3.95

= 4

Вам также может понравиться

- MARKETRESEARCH SurveyДокумент2 страницыMARKETRESEARCH SurveyjenniferОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Assignment MSL CaseДокумент8 страницAssignment MSL CasejenniferОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Marriott CaseДокумент1 страницаMarriott CasejenniferОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Case Study Analysis On Scientific Glass Inventory ManagementДокумент19 страницCase Study Analysis On Scientific Glass Inventory Managementjennifer100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- MSL Case StudyДокумент1 страницаMSL Case StudyjenniferОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Pumps and Filters: 345D, 349D, and 349D Excavator Hydraulic SystemДокумент2 страницыPumps and Filters: 345D, 349D, and 349D Excavator Hydraulic SystemTeknik MakinaОценок пока нет

- Dm02 FTTM AdvДокумент36 страницDm02 FTTM AdvAnonymous 5cMeyYyxhОценок пока нет

- ViewSonic Q19wb-3 VS11578 Pow. Delta EADP-45AF BFДокумент70 страницViewSonic Q19wb-3 VS11578 Pow. Delta EADP-45AF BFaladinthewizardОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- VarmaДокумент86 страницVarmanandy39Оценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Auto Chassis NotesДокумент90 страницAuto Chassis Notesanishsukumar000gmailcomОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Tutorial 5 UpdatedДокумент2 страницыTutorial 5 UpdatedChiraag ChiruОценок пока нет

- Leadership Culture and Management Practices A Comparative Study Between Denmark and Japan PDFДокумент70 страницLeadership Culture and Management Practices A Comparative Study Between Denmark and Japan PDFMichelle Samillano PasaheОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- U441d - Brake - Rear (Air)Документ6 страницU441d - Brake - Rear (Air)bennieОценок пока нет

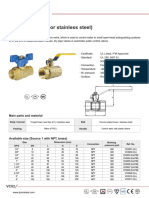

- VC02 Brass Ball Valve Full Port Full BoreДокумент2 страницыVC02 Brass Ball Valve Full Port Full Boremahadeva1Оценок пока нет

- API Valves: A. API Gate Valves B. Mud Gate Valves C. API Plug ValvesДокумент15 страницAPI Valves: A. API Gate Valves B. Mud Gate Valves C. API Plug Valveskaveh-bahiraeeОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Punjab ULBRFPVolume IAttachmentdate 21 Nov 2016Документ214 страницPunjab ULBRFPVolume IAttachmentdate 21 Nov 2016NishantvermaОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Dri-Su-1824-Q-Induction MotorДокумент8 страницDri-Su-1824-Q-Induction MotorTaufiq Hidayat0% (1)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Learn PowerShell Core 6.0Документ800 страницLearn PowerShell Core 6.0Felippe Coelho100% (2)

- ABS Buckling Requirements For OffshoreДокумент94 страницыABS Buckling Requirements For Offshorecurvedbrain100% (1)

- Anti Banned HostДокумент1 276 страницAnti Banned HostVicky Kumar?skОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- 8 PCO Training Invitation Letter December 2018Документ2 страницы8 PCO Training Invitation Letter December 2018sayo goraОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1091)

- Pakistan Machine Tool Factory Internship ReportДокумент14 страницPakistan Machine Tool Factory Internship ReportAtif MunirОценок пока нет

- Mariveles ChlorinatorДокумент1 страницаMariveles ChlorinatorJhn Cbllr BqngОценок пока нет

- Parts List - Lycoming Engines Numerical Parts HistoryДокумент243 страницыParts List - Lycoming Engines Numerical Parts HistoryFernando Servian Dalmas100% (3)

- Piston and Connecting Rod Assembly TopicsДокумент1 страницаPiston and Connecting Rod Assembly TopicsgandhiramОценок пока нет

- Platinum Collection v-22 Osprey ManualДокумент24 страницыPlatinum Collection v-22 Osprey ManualP0wer3D100% (2)

- Summary Key ParameterДокумент18 страницSummary Key ParameterAndry JatmikoОценок пока нет

- Etop Tata DocomoДокумент5 страницEtop Tata DocomoSrikanth Kumar KonduriОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Why JSON in PostgreSQL Is AwesomeДокумент7 страницWhy JSON in PostgreSQL Is AwesomeTeo TokisОценок пока нет

- S A 20190725Документ4 страницыS A 20190725krishaОценок пока нет

- Chiller: Asian Paints Khandala PlantДокумент19 страницChiller: Asian Paints Khandala PlantAditiОценок пока нет

- LG Mobile CompanyДокумент6 страницLG Mobile Companymallickantonio6559Оценок пока нет

- My Restaurant API DocumentДокумент60 страницMy Restaurant API DocumentJosé FranciscoОценок пока нет