Академический Документы

Профессиональный Документы

Культура Документы

Quality Assurance Plan

Загружено:

Vicky GautamОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Quality Assurance Plan

Загружено:

Vicky GautamАвторское право:

Доступные форматы

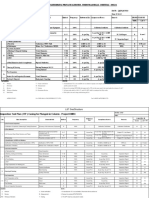

QUALITY ASSURANCE PLAN

A) DESIGN FEATURES

DESIGN CODE : ASME SEC VIII DIV 1 ED 2001 & TEMA Class 'C'

RADIOGRAPHY : SHELL : SPOT, DISH : FULL | EXPANSION BELLOW- FULL

HYDRO TEST PRESSURE : AS PER ORDER

REFERENCE HOLD POINTS

SR. COMPONENTS & CHARACTERISTICS DOCUMENT FORMAT OF

No. OPERATION CHECKS ACCEPTANCE RECORD EDES CLIENT

NORMS

B) DOCUMENT CONTROL

As per Clients P.O. and

1 Drg. Approval Drg. P W

requirements. Specification.

As per Welding

ASME sec VIII

2. Review of WPS / PQR details in Drgs. Records P R

Div 1 & Sec IX

C) INPROCESS CONTROL

Dimension ,Surface As per

Pressure part.

Defects, Physical respective

Material Identification Test

and Chemical material Specn

3. for shell. dished ends, Certificates - W/R

properties, ICG, UT & approved

tubes , tubesheet of Lab.

for thk above 25 Drgs.& Lab T.C.

mm etc.

Non Pressure Parts. As per

Materials Identification respective

Dimensions, Inspection

4. for skirt support, baffles Materials W -

Surface Defects Report

spacer tubes, tie rod, specn. &

gussets etc. Approved Drgs.

Weld soundness,

Test

5 PQR physical test. ASME sec IX P -

Reports

Material stamp transfer As per respect.

for shell, channel shell Dimensions, Materials Inspection

6 W R

tube sheet, dished end, Material grade. Specn. & Report

tubes etc. Approved Drgs.

Set up of long seams Weld geometry

of main shell courses , offset. Profile W.R.T ASME Sec VIII Internal

7 W R

skirt shell, channel shell Template ID, Div I Inspection

and fabricated pipes etc ovality. Etc. Report

Back chip of long seam Internal

8 Welding defects. ASME Sec V W R

welding & D. P. test Inspection

Report

Profile as per the

template and

Dimensions ASME Sec VIII

Dished ends Internal

9 Including thinning Div I & W R

forming Inspection

DP Test on knuckle Approved Drg.

Report

portion at KR, SF,

and edge etc.

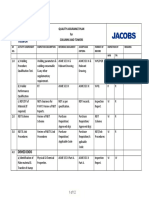

REFERENCE HOLD POINTS

SR. COMPONENTS & CHARACTERISTICS DOCUMENT FORMAT OF

No. OPERATION CHECKS ACCEPTANCE RECORD EDES CLIENT

NORMS

Dimension as per

approved drg, No. ASME Sec VIII

Tube sheet inspection Internal

10 of holes, pitch, Div I ,TEMA & W R

after reaming Inspection

Tube holes finish Approved Drg.

Report

grooving details

Circ Seams set up of

Weld geometry ASME Sec VIII

main shell courses, and Internal

11 offset, Alignment & Div I & W R

channel shell to Inspection

Dimensions. Approved Drg.

dishend Report

D.P. test of Back chip of

Internal

12 Circ Seam welding of Welding defects ASME Sec V W R

Inspection

Shells.

Report

Weld Geometry,

Set up of nozzle pipes Internal

13 Gasket Seat facing Approved Drg. W R

to Nozzle Flanges. Inspection

tell/tale hole.

Report

Set up of Nozzles on Weld geometry, ASME sec VIII

Internal

14 main shell and channel orientations, height, Div I & W R

Inspection

shells bolt hole Straddling Approved Drg.

Report

DP test of back chip of

Internal

15 nozzles on main shell Welding Defects ASME sec V W R

Inspection

& channel shell

Report

welding

Weld geometry, ASME sec VIII

Set up of body flanges Internal

16 orientations, bolt Div I & W R

to channel shell Inspection

hole Straddling Approved Drg.

Report

Corners to be

Flush grinding of all

rounded off to a ASME sec VIII Inspection

17 nozzles from inside and W R

minimum of div 1 Report

rounding off of corners

3-mm radius.

Test Pressure : 1.25

Pneumatic test of RF kg/cm2g

ASME sec VIII Inspection

18 pads of all concerned Medium : air,to be W R

Div 1 Report.

nozzles checked with soap

solution

No.of baffles, baffle

Inspection of tube ASME Sec VIII Internal

orientation, spacing

19 bundle before insertion Div I ,TEMA & Inspection W R

tightness of

in shell Approved Drg. Report.

spacers,

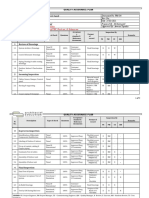

REFERENCE HOLD POINTS

SR. COMPONENTS & CHARACTERISTICS DOCUMENT FORMAT OF

No. OPERATION CHECKS ACCEPTANCE RECORD SKF CLIENT

NORMS

Orientation, tube

sheet to tube sheet

distance, weld

ASME Sec VIII Internal

Fit up of tube sheets to geometry,

20 Div I ,TEMA & Inspection W R

shell squareness of tube

Approved Drg. Report.

sheets w.r.t shell

bolt hole

straddling.

Test pressure 2.0

Hydro test of shell side ASME sec VIII Inspection

21 kg/cm2 g H W

after tubes expansion Div - 1 Report.

Under cuts, tacks,

Visual and Final

ensure that all ASME Sec VIII

dimensional inspection Inspection

22 welding is Div I & H W

prior to hydro test of Report.

completed, Approved Drg.

shell and channel shells.

dimensions, etc

Test press : 7.222

ASME Sec VIII

Hydrostatic testing of Kg/cm2 g Inspection

23 Div I & H W

shell side Medium : Water Report.

Approved Drg.

Period :30 min

Test press : 7.53

ASME Sec VIII

Hydrostatic testing of Kg/cm2 g Inspection

24 Div I & H W

tube side Medium : Water Report.

Approved Drg.

Period :30 min

Internal

25 Polishing Surface finish 180 GRID Inspection - W

Report.

Cleaning and painting SKF Std Inspection

26 Surface finish - W

of cs part Procedure Report.

Review of

documents like

Material Heat

Pre- dispatch & Issue of Chart, Test Inspection

27 - R R

Release note. Certificates Report

Inspection Reports

for previous stages

etc

Вам также может понравиться

- Rai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksДокумент4 страницыRai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksAjoy Prasad75% (4)

- QUALITY ASSURANCE PROTOCOLДокумент2 страницыQUALITY ASSURANCE PROTOCOLShah Newaz KabirОценок пока нет

- Working ITPДокумент4 страницыWorking ITPStephen BoodooОценок пока нет

- Dimensional Inspection Report TemplateДокумент1 страницаDimensional Inspection Report TemplateAlfian ImaduddinОценок пока нет

- 1.13 Inspection & Test PlansДокумент1 страница1.13 Inspection & Test Plansabimanyubawono100% (2)

- Sample - Template - Itp For Piping Fabrication and InstallationДокумент2 страницыSample - Template - Itp For Piping Fabrication and Installationmohd as shahiddin jafriОценок пока нет

- Inspection and Test Plan For Piping (PP/FRP Piping)Документ2 страницыInspection and Test Plan For Piping (PP/FRP Piping)Anonymous EyK4vt6Y100% (1)

- Proposed WPSДокумент2 страницыProposed WPSChisom Ikengwu100% (2)

- Aws B2.4-2012Документ15 страницAws B2.4-2012Vicky Gautam0% (1)

- Aws B2.4-2012Документ15 страницAws B2.4-2012Vicky Gautam0% (1)

- QAP CondenserДокумент3 страницыQAP CondenserisaacОценок пока нет

- Company Logo Added to QAP DocumentДокумент4 страницыCompany Logo Added to QAP Documentmanoj thakkar100% (1)

- L&T GeoStructure casing inspection planДокумент2 страницыL&T GeoStructure casing inspection plansanil50% (2)

- Standard Inspection and Test Plan For Api6D Valves: A GSL Company - Quality EndorsedДокумент4 страницыStandard Inspection and Test Plan For Api6D Valves: A GSL Company - Quality EndorsednithyaОценок пока нет

- 2.8.2. Indicative QAP - ColumnsДокумент12 страниц2.8.2. Indicative QAP - ColumnsAshish Dhok0% (1)

- QC FORMДокумент3 страницыQC FORMRicardo LourençoОценок пока нет

- FGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDДокумент10 страницFGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDBhanu Pratap Choudhury100% (1)

- Quality Plan and Checklist (HVAC) - Sandvik G BlockДокумент3 страницыQuality Plan and Checklist (HVAC) - Sandvik G BlockParasОценок пока нет

- Welding Repair Procedure for PT. Juhdi Sakti EngineeringДокумент4 страницыWelding Repair Procedure for PT. Juhdi Sakti EngineeringRiky SumantriОценок пока нет

- Pickling Procedure 20 - 08Документ2 страницыPickling Procedure 20 - 08Siriepathi SeetharamanОценок пока нет

- WPS - Smaw - 2Документ6 страницWPS - Smaw - 2Harkesh RajputОценок пока нет

- BPV IX-16-3 QW-283 - ButteringДокумент1 страницаBPV IX-16-3 QW-283 - ButteringyutweldingОценок пока нет

- WP 11 Corrosion Protection Tape CoatingДокумент3 страницыWP 11 Corrosion Protection Tape CoatingKarthikОценок пока нет

- Natural Gas Transportation Development Project - Siak Riau: Inspection Test Plan (Itp) at ShopДокумент3 страницыNatural Gas Transportation Development Project - Siak Riau: Inspection Test Plan (Itp) at Shopanang_priОценок пока нет

- EXternal ITP PDFДокумент8 страницEXternal ITP PDFjaineranaОценок пока нет

- Hydrostatic Test Report SummaryДокумент1 страницаHydrostatic Test Report SummaryCipta AdikaryaОценок пока нет

- Weld Visual Report Rev.0Документ1 страницаWeld Visual Report Rev.0John TerryОценок пока нет

- Test Pack Format: Contents of Hydrostatic Test PackagesДокумент2 страницыTest Pack Format: Contents of Hydrostatic Test PackagesmiteshОценок пока нет

- 8 Material ControlДокумент8 страниц8 Material ControlPrakash RajОценок пока нет

- Hydrotest QI304-sampleДокумент3 страницыHydrotest QI304-sampleHanuman Rao100% (1)

- Pressure Vessel Inspection and Test Plan ChecklistДокумент4 страницыPressure Vessel Inspection and Test Plan ChecklistkorbelОценок пока нет

- Inspection Test Plan Fuel Gas Conditioning SkidДокумент19 страницInspection Test Plan Fuel Gas Conditioning SkidDin AizuОценок пока нет

- Fit Up & Weld VisualДокумент2 страницыFit Up & Weld VisualBhanu Pratap ChoudhuryОценок пока нет

- Qap HPCLДокумент13 страницQap HPCLdarshan100% (1)

- Wps For Smaw06-001 (Pipe 6g CS)Документ10 страницWps For Smaw06-001 (Pipe 6g CS)walitedisonОценок пока нет

- Welded Tube Joint SpecДокумент8 страницWelded Tube Joint SpecAvinash ShuklaОценок пока нет

- Piping Fabrication Installation QCP On SiteДокумент1 страницаPiping Fabrication Installation QCP On SiteTarun PatelОценок пока нет

- Welding Report For PipingДокумент1 страницаWelding Report For PipingRifki HasyaОценок пока нет

- ITP - (Pressure Testing Piping) PDFДокумент3 страницыITP - (Pressure Testing Piping) PDFSUNNY BOSS100% (1)

- Inspection, Flushing & Testing of Piping-21Документ6 страницInspection, Flushing & Testing of Piping-21Saurabh Kumar VermaОценок пока нет

- NRP QapДокумент10 страницNRP QapKevin Mathew100% (1)

- ITP For Steel Structure1Документ3 страницыITP For Steel Structure1吴兴泊Оценок пока нет

- Piping PWHT Quality Control and Inspection Report FormДокумент1 страницаPiping PWHT Quality Control and Inspection Report FormSamer Bayati100% (2)

- Inspection and Test Plan for TEA Product CoolerДокумент7 страницInspection and Test Plan for TEA Product CoolerJamal Mohamed Rahamathullah100% (1)

- Sample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Документ2 страницыSample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Dhvanit JoshiОценок пока нет

- Welding Procedure Specification For Storage Tank & Piping SystemДокумент3 страницыWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadОценок пока нет

- Material Inspection Report: Project Name Date InspДокумент22 страницыMaterial Inspection Report: Project Name Date InspRafiqKuОценок пока нет

- Inspection and Test Plan Piping Works Main Deck, Service Platform, Module, EtcДокумент3 страницыInspection and Test Plan Piping Works Main Deck, Service Platform, Module, Etcaditya kokoОценок пока нет

- Itp Piping PDFДокумент4 страницыItp Piping PDFdashОценок пока нет

- Pressure Vessel ITP Rev 0Документ10 страницPressure Vessel ITP Rev 0SLC HosurОценок пока нет

- Fit-Up Inspection ReportДокумент27 страницFit-Up Inspection ReportAlfian ImaduddinОценок пока нет

- Long Seam Inspection ProcedureДокумент4 страницыLong Seam Inspection ProcedureDeepak100% (1)

- WPS Pipe 08'' SHD 40 SMAW REV02Документ2 страницыWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejОценок пока нет

- Painting & Inspection FormatДокумент1 страницаPainting & Inspection FormatABEC Trombay siteОценок пока нет

- Qap 8000ce Reactor - Repat - 1Документ2 страницыQap 8000ce Reactor - Repat - 1AliasgarОценок пока нет

- Procedure For DYE PENETRANT TestingДокумент10 страницProcedure For DYE PENETRANT TestingKarrar Talib100% (1)

- Project:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportДокумент4 страницыProject:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportEngr Saeed AnwarОценок пока нет

- Steel Structure Inspection and Test PlanДокумент4 страницыSteel Structure Inspection and Test PlanABAID ULLAHОценок пока нет

- Precision Storage Vessels PVT LTD: Pressure Test ReportДокумент2 страницыPrecision Storage Vessels PVT LTD: Pressure Test ReportSenthil Kumaran100% (1)

- Qap Reciever TanksДокумент6 страницQap Reciever Tanksyamunaengg2011Оценок пока нет

- Qap ReactorДокумент6 страницQap ReactorPARMAR MUKESHОценок пока нет

- Rai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksДокумент4 страницыRai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksVijaya Barani100% (1)

- 2 - Minor Losses in Pipes - Balsiger Bastos BehmДокумент11 страниц2 - Minor Losses in Pipes - Balsiger Bastos BehmCarlos TomeyОценок пока нет

- Primary WsДокумент291 страницаPrimary WsVicky GautamОценок пока нет

- 07 Maths QPДокумент3 страницы07 Maths QPVicky GautamОценок пока нет

- CIDCO Auction Report for Plot 26 in Ghanoli SchemeДокумент1 страницаCIDCO Auction Report for Plot 26 in Ghanoli SchemeVicky GautamОценок пока нет

- Maths PaperДокумент8 страницMaths PaperVicky GautamОценок пока нет

- Knowledge (35 Marks) : Page 1 ofДокумент12 страницKnowledge (35 Marks) : Page 1 ofVicky GautamОценок пока нет

- Atomic Energy Education SocietyДокумент10 страницAtomic Energy Education SocietyVicky GautamОценок пока нет

- Atomic Energy Education SocietyДокумент10 страницAtomic Energy Education SocietyVicky GautamОценок пока нет

- Atomic Energy Central School EVS AssessmentДокумент6 страницAtomic Energy Central School EVS AssessmentVicky GautamОценок пока нет

- Chemical Resistance Chart: PN 41-6018/rev.c January 2010Документ16 страницChemical Resistance Chart: PN 41-6018/rev.c January 2010rezaokeОценок пока нет

- Hindi Question PaperДокумент7 страницHindi Question PaperVicky GautamОценок пока нет

- Atomic Energy Education Society: Subject: English Time: 2 Hours Max. Marks: 50Документ10 страницAtomic Energy Education Society: Subject: English Time: 2 Hours Max. Marks: 50CSGОценок пока нет

- Reading (20 Marks) A) Read The Passage Carefully and Answer The Following Questions. (5marks)Документ12 страницReading (20 Marks) A) Read The Passage Carefully and Answer The Following Questions. (5marks)Vicky GautamОценок пока нет

- Homi Jehangir BhabhaДокумент6 страницHomi Jehangir BhabhahaldodderiОценок пока нет

- Kisan MouldingsДокумент1 страницаKisan MouldingsVicky GautamОценок пока нет

- 2018 HindiДокумент7 страниц2018 HindiVicky GautamОценок пока нет

- Creep DescriptionДокумент11 страницCreep DescriptionGerry AnandaОценок пока нет

- Sa2 I Evs QPДокумент7 страницSa2 I Evs QPVicky GautamОценок пока нет

- Tech Specs For VendorДокумент2 страницыTech Specs For VendorVicky GautamОценок пока нет

- 08172015131038apatite and Rock PhosphateДокумент22 страницы08172015131038apatite and Rock PhosphateVicky GautamОценок пока нет

- Knowledge (35 Marks) : Page 1 ofДокумент12 страницKnowledge (35 Marks) : Page 1 ofVicky GautamОценок пока нет

- Plastic CodeДокумент4 страницыPlastic CodeVicky GautamОценок пока нет

- BS en 479-1995Документ4 страницыBS en 479-1995Vicky GautamОценок пока нет

- InTech-Corrosive Effects of Chlorides On MetalsДокумент41 страницаInTech-Corrosive Effects of Chlorides On MetalsAndrey756Оценок пока нет

- In Service InspectionДокумент1 страницаIn Service InspectionVicky GautamОценок пока нет

- PURANIK - Basic Principle of Valuation (P&M)Документ38 страницPURANIK - Basic Principle of Valuation (P&M)Vicky GautamОценок пока нет

- SA2 I Hindi QPДокумент9 страницSA2 I Hindi QPVicky GautamОценок пока нет

- Vedic Astrology OverviewДокумент1 страницаVedic Astrology Overviewhuman999100% (8)

- Pitfalls of HIV Infection - Dr. Rizqi Amalia, Sp.AДокумент46 страницPitfalls of HIV Infection - Dr. Rizqi Amalia, Sp.AandreknhОценок пока нет

- The Anglican Digest - Winter 2022Документ64 страницыThe Anglican Digest - Winter 2022The Anglican Digest100% (1)

- What Is RTN/Microwave TechnologyДокумент27 страницWhat Is RTN/Microwave TechnologyRavan AllahverdiyevОценок пока нет

- Instrukcja Pellets Fuzzy Logic - ENGДокумент53 страницыInstrukcja Pellets Fuzzy Logic - ENGxilef84Оценок пока нет

- Aac Block Adhesive: Product DescriptionДокумент2 страницыAac Block Adhesive: Product DescriptionmaznahОценок пока нет

- Tyco TY8281 TFP680 - 03 - 2023Документ17 страницTyco TY8281 TFP680 - 03 - 2023First LAstОценок пока нет

- How To Use Dr. Foster's Essentials: Essential Oils and BlendsДокумент5 страницHow To Use Dr. Foster's Essentials: Essential Oils and BlendsemanvitoriaОценок пока нет

- EC6702-Optical Communication and NetworksДокумент18 страницEC6702-Optical Communication and Networkskasim_1983Оценок пока нет

- ArduinoДокумент15 страницArduinoAlvarez TomasОценок пока нет

- Lisa - Add New Front: Process Matching/Installation and Qualification (IQ)Документ62 страницыLisa - Add New Front: Process Matching/Installation and Qualification (IQ)Thanh Vũ NguyễnОценок пока нет

- Moral Theories: Presented By: Sedrick M. MallariДокумент27 страницMoral Theories: Presented By: Sedrick M. MallariAlyssa De PaduaОценок пока нет

- Advanced Technologies of CDQ Plant Advanced Technologies of CDQ PlantДокумент12 страницAdvanced Technologies of CDQ Plant Advanced Technologies of CDQ Plant조기현Оценок пока нет

- March 17, 2016 Strathmore TimesДокумент24 страницыMarch 17, 2016 Strathmore TimesStrathmore TimesОценок пока нет

- Weekly Report 52Документ196 страницWeekly Report 52Erceanu DanОценок пока нет

- On The Problem of The External World in The Ch'Eng Wei Shih LunДокумент64 страницыOn The Problem of The External World in The Ch'Eng Wei Shih LunGuhyaprajñāmitra3100% (1)

- Telemark PulloverДокумент2 страницыTelemark Pulloverkidknits100% (1)

- Heat Exchanger Design and Drawing FundamentalsДокумент11 страницHeat Exchanger Design and Drawing Fundamentalsjeevanantham 5846Оценок пока нет

- Avh p6050dvd EngДокумент119 страницAvh p6050dvd EngcaimanaterОценок пока нет

- HSS Article LimitState Plastification 0718 060120Документ3 страницыHSS Article LimitState Plastification 0718 060120clam2014Оценок пока нет

- Cryptography 01092014Документ19 страницCryptography 01092014Anshu MittalОценок пока нет

- Conflict and Factional Disputes - Siegel & BealsДокумент12 страницConflict and Factional Disputes - Siegel & BealsDanielОценок пока нет

- Unit-I EsДокумент53 страницыUnit-I Eschethan.naik24Оценок пока нет

- General Biology 2: Quarter 3, Module 1 Genetic EngineeringДокумент20 страницGeneral Biology 2: Quarter 3, Module 1 Genetic EngineeringRonalyn AndaganОценок пока нет

- Minicargador Cat 246Документ22 страницыMinicargador Cat 246Juanca FerroОценок пока нет

- Briefing Paper No 4 CV Electrification 30 11 17 PDFДокумент5 страницBriefing Paper No 4 CV Electrification 30 11 17 PDFAlex WoodrowОценок пока нет

- Ben Wilkins PRISON MADNESS and LOVE LETTERS: THE LOST ARTДокумент5 страницBen Wilkins PRISON MADNESS and LOVE LETTERS: THE LOST ARTBarbara BergmannОценок пока нет

- DPT ProcedureДокумент3 страницыDPT ProcedureAmit HasanОценок пока нет

- CSSBI Tablas de Carga Perfiles PDFДокумент60 страницCSSBI Tablas de Carga Perfiles PDFRamón RocaОценок пока нет

- 2023-05-11 St. Mary's County TimesДокумент40 страниц2023-05-11 St. Mary's County TimesSouthern Maryland OnlineОценок пока нет