Академический Документы

Профессиональный Документы

Культура Документы

RIM-cell Testing in Australia (Perth)

Загружено:

jacs127Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

RIM-cell Testing in Australia (Perth)

Загружено:

jacs127Авторское право:

Доступные форматы

RIM-cell Technology

Quality Assurance Solution for Pile Load Verification

Project: RIM-cell Trial Installation and Testing

Location: Cockburn Central, Perth, Australia

Subcontractor: Belpile Pty Ltd

Worldwide and for over 20 years, needed. The low cost allows the RIM-cell

practitioners of foundation engineering to be installed in every pile so that

have been making good use of the verification can be performed on any pile

significant advantages of performing that may be of concern.

static load testing on piles and barrettes

A RIM-cell installed at or near to the toe

using the Osterberg Cell bi-directional

of the pile applies a continuously

test method. Commonly known as the

increasing load up to the working load or

O-cell test, the method provides a high

20-30% beyond it, similar to a proof load

quality and high accuracy static load

test and like the Osterberg cell, applies a

test, usually, but not always performed

bi-directional load to the foundation

on a dedicated foundation element that

element but is not designed to duplicate

is not incorporated into the foundation,

the high-resolution, sensitivity and

with the results used to optimise pile

individual calibration common to a

design. The Osterberg Cells are usually

genuine Osterberg Cell. As such, the

placed within the pile at the balance

RIM-cell load verification programme

point between soil resistances above

should always be complemented by a

and below that elevation and targeting

full-scale Osterberg Cell static load test

applied loads that often exceed 300% of

used to optimize the deep foundation

working load.

design prior to constructing the working

foundation.

The RIM-cells at Cockburn Central were

installed in a cement/sand grout injection

continuous flight auger pile. The first

installation was performed on a straight

shafted pile and the second on an under

reamed (belled) pile, a patented method

developed by Belpile. For each pile, the

single length steel reinforcing cage was

assembled with RIM-cell and associated

instrumentation and pushed into the wet

RIM-cell Attached To Reinforcing Cage

grouted pile on completion.

Even with the widespread adoption of

O-cell testing, in many cases, variability

of the site subsurface and construction

technique can result in significant

uncertainty about the performance of the

working piles that were not load-tested.

The RIM-cell offers a practical, cost-

effective solution to this problem,

allowing all stakeholders the opportunity

to enjoy a level of quality assurance not

previously possible. Although similar in

concept to the O-cell, the patented RIM-

cell is best suited as a pile load Completed Pile Construction

verification device, which is designed to

be installed and deployed on a large The RIM-cell comprises a steel pressure

number of production piles as a means confining pipe that fits inside the tip of the

of assessing the as built performance reinforcing cage with varying thickness of

behaviour of the foundation elements as cement grout inside enclosing the concrete

Copyright © Fugro Loadtest 2014 (continued over page)

RIM-cell Technology

Quality Assurance Solution for Pile Load Verification

fracture mechanism. While all RIM-cells the RIM-cell. Pressure was provided

are custom-sized and made to order, from ground level and monitored by both

they can also be manufactured in the an electronic transducer and a traditional

country of use with locally available Bourdon gauge at the pump. Pile top

materials thus minimizing overall costs. movement was monitored using an

automated digital level synchronized to

the data logging system.

Schematic Post Concreting and Fracture

The innovative concept of the RIM-cell is Test Setup and Testing in Progress

a pile fracturing mechanism that creates

a pressurized plane not only through the A self-sealing liquid was used to

grouted annulus of the RIM-cell but pressurize the RIM-cell from a high

through the entire inner concreted (or pressure grease pump. However, for

grouted) zone of the confining steel commercial applications, a proprietary

pipe. The RIM-cell then acts like a cement grout would be used, which will

hydraulic jack of a diameter equivalent allow both segments of the pile to be re-

to the reinforcing cage diameter. connected without the need for a second

stage grouting process.

In addition to its primary function as part

of a pile load verification procedure, a

Schematic Post Fracture and Pressurization secondary use of the RIM-cell is as an

alternative to traditional base grouting

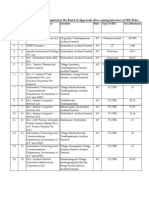

The RIM-cells used for this project were

methods. Unlike base grouting, the

designed and fabricated for the pile

effectiveness of which is not verifiable,

dimensions and loading requirement i.e.

the RIM-cell reliably uses the pile itself

for a pile diameter of 500 mm and cover

to pre-load the base and compress the

to the reinforcing bar of 100 mm, the

soil at the toe. Compressing the soil

outside diameter of the RIM-cell was

below the toe of a production pile by

275 mm with a confining pressure of

pre-loading significantly improves load-

34.5 MPa and a capacity of 1.75 MN.

displacement behaviour of the pile in

The embedded instrumentation used to

terms of soil stiffness response and

measure pile displacement comprised

strain compatibility, is fully verifiable and

tell-tale rod extensometers to measure

movement at both the top and base of

yields load-displacement results.

Copyright © Fugro Loadtest 2014 www.loadtest.com

Вам также может понравиться

- Stability of Steel Oil Storage Tanks Duncan OrazioДокумент20 страницStability of Steel Oil Storage Tanks Duncan Oraziojacs127Оценок пока нет

- 03 - SYNOPSIS - Garry CachoДокумент11 страниц03 - SYNOPSIS - Garry CachoSugar Ray0% (1)

- Matchstiq S1x Hardware Users ManualДокумент29 страницMatchstiq S1x Hardware Users Manualmartinsalas924gmail.comОценок пока нет

- Kodak SWOT Analysis and Financial RatiosДокумент31 страницаKodak SWOT Analysis and Financial RatiosZineb Elouataoui100% (1)

- Recent Experiences With Bi-Directional Static Load Testing 040506Документ9 страницRecent Experiences With Bi-Directional Static Load Testing 040506Personal LearnОценок пока нет

- O-Cell Brochure EnglishДокумент2 страницыO-Cell Brochure EnglishJose LlamoccaОценок пока нет

- Bromhead - A Simple Ring Shear ApparatusДокумент3 страницыBromhead - A Simple Ring Shear ApparatusDaniel Felipe Rodriguez RamirezОценок пока нет

- Flexural Strength of Soil-Cement Using Simple Beam With Third-Point LoadingДокумент3 страницыFlexural Strength of Soil-Cement Using Simple Beam With Third-Point LoadingsamerОценок пока нет

- LDF Twosteppet e 1120 Reva - Web 1Документ4 страницыLDF Twosteppet e 1120 Reva - Web 1jack macОценок пока нет

- 4 PG Leaflet Welding Inspection PDFДокумент3 страницы4 PG Leaflet Welding Inspection PDFBHARANIОценок пока нет

- 2.5.1 - Rollers Series PSV Where UsedДокумент5 страниц2.5.1 - Rollers Series PSV Where UsedMarco Antonio FloresОценок пока нет

- RIM-cell: Bi-Directional Load Testing For Production Piles Rim-Cell AdvantagesДокумент1 страницаRIM-cell: Bi-Directional Load Testing For Production Piles Rim-Cell AdvantagesManuel Alfredo Rojas GutierrezОценок пока нет

- International Society For Soil Mechanics and Geotechnical EngineeringДокумент5 страницInternational Society For Soil Mechanics and Geotechnical EngineeringYashwantОценок пока нет

- Verification of Pile Load Capacity Using Static Pile Load TestДокумент6 страницVerification of Pile Load Capacity Using Static Pile Load TestAbhijith T K 16210001Оценок пока нет

- Bi-Directional Pile Load Testing ProceduresДокумент22 страницыBi-Directional Pile Load Testing ProceduresHemant YesajiОценок пока нет

- IRC78-2014 B-3 Appendix-9 Bi-Axial Load Testing of Piles - Draft 27-10-2017 PDFДокумент22 страницыIRC78-2014 B-3 Appendix-9 Bi-Axial Load Testing of Piles - Draft 27-10-2017 PDFHemant YesajiОценок пока нет

- Make Sure The UTM Fits The Application: Materials CharacterizationДокумент3 страницыMake Sure The UTM Fits The Application: Materials CharacterizationUti MichaelОценок пока нет

- 2.2 Rollers - Technical - Design - and - Data PDFДокумент4 страницы2.2 Rollers - Technical - Design - and - Data PDFFelipe Reyes GallardoОценок пока нет

- Automated Incremental Loading TestДокумент2 страницыAutomated Incremental Loading TestRavi MehtaОценок пока нет

- EN25-27_magic_bild_evo205Документ3 страницыEN25-27_magic_bild_evo205Michel GuayОценок пока нет

- Subsea 7 Welding Inspection ScreenДокумент3 страницыSubsea 7 Welding Inspection ScreenPasquale CutriОценок пока нет

- Terradrive: A Brief Guide To Pile TestingДокумент4 страницыTerradrive: A Brief Guide To Pile TestingMars TinОценок пока нет

- Automated Plate Load Test: Aplt CapabilitiesДокумент2 страницыAutomated Plate Load Test: Aplt CapabilitiesjoseriquОценок пока нет

- University of Salahaddin College of Engineering Civil DepartmentДокумент17 страницUniversity of Salahaddin College of Engineering Civil DepartmentStan JamelОценок пока нет

- GeoconДокумент1 страницаGeoconhugoq21hugoОценок пока нет

- C1568 08 (2013)Документ6 страницC1568 08 (2013)diego rodriguez100% (2)

- EagleBurgmann - Fabric Expansion Jont PDFДокумент28 страницEagleBurgmann - Fabric Expansion Jont PDFAnh VoОценок пока нет

- Pile Load Test: IS: 2911 (Part 4) - 1985 IS: 14893-2001Документ5 страницPile Load Test: IS: 2911 (Part 4) - 1985 IS: 14893-2001Dwijendra Chanumolu100% (1)

- Pile Load Testing for Bored Piles in Soil (PLTBSДокумент4 страницыPile Load Testing for Bored Piles in Soil (PLTBSNetzoo FlixОценок пока нет

- Positive Sealing PlugДокумент2 страницыPositive Sealing PlugGuido FloresОценок пока нет

- Soil Nailing TestingДокумент122 страницыSoil Nailing TestingParvatha Vardhan GandrakotaОценок пока нет

- Screw Piling Info SheetsДокумент9 страницScrew Piling Info SheetsGlen WardОценок пока нет

- D1635D1635M-12 Standard Test Method For Flexural Strength of Soil-Cement Using Simple Beam With Third-Point LoadingДокумент3 страницыD1635D1635M-12 Standard Test Method For Flexural Strength of Soil-Cement Using Simple Beam With Third-Point Loadingouari.ouariОценок пока нет

- CaseStudy FMEA Ball Mill V1Документ2 страницыCaseStudy FMEA Ball Mill V1Andres Acosta RozoОценок пока нет

- STATIC AXIAL PILE LOAD TESTДокумент15 страницSTATIC AXIAL PILE LOAD TESTcecdesign09Оценок пока нет

- Abrasion Resistance C944Документ4 страницыAbrasion Resistance C944SAPTIONOОценок пока нет

- Transportation Lab ManualДокумент48 страницTransportation Lab ManualZain Ali AwanОценок пока нет

- A Simulations Test For The Selection of Coatings and Surface Treatments For Plastics Injection Moulding MachinesДокумент9 страницA Simulations Test For The Selection of Coatings and Surface Treatments For Plastics Injection Moulding MachinesCassioLopesОценок пока нет

- Fabric Brochure Letter Rev2 Web PDFДокумент28 страницFabric Brochure Letter Rev2 Web PDFMoamenОценок пока нет

- Fabric Brochure Letter Rev2 WebДокумент28 страницFabric Brochure Letter Rev2 WebchuongОценок пока нет

- Fabric Brochure Letter Rev2 Web PDFДокумент28 страницFabric Brochure Letter Rev2 Web PDFMoamenОценок пока нет

- Alternative Deployed Pumping Systems: Improving Productivity While Lowering Life Cycle CostsДокумент4 страницыAlternative Deployed Pumping Systems: Improving Productivity While Lowering Life Cycle CostsAdel ALkhaligyОценок пока нет

- Fa 98 DT 5Документ2 страницыFa 98 DT 5aquiles30Оценок пока нет

- Dynamic Pile Load Test PDFДокумент5 страницDynamic Pile Load Test PDFSumit Ghose0% (1)

- U HarelandДокумент4 страницыU Harelandmfazaeli40Оценок пока нет

- Sea Construction Sep Oct 2013Документ2 страницыSea Construction Sep Oct 2013Trần KhươngОценок пока нет

- WORKING TOO SOFTДокумент11 страницWORKING TOO SOFTnearmonkeyОценок пока нет

- Automated Plate Load Test: Aplt CapabilitiesДокумент2 страницыAutomated Plate Load Test: Aplt Capabilitiesmahdi sardarОценок пока нет

- Pile Load TestДокумент6 страницPile Load TestChristian JhansiОценок пока нет

- Elcometer 124 Thickness Gauge Product Data SheetДокумент2 страницыElcometer 124 Thickness Gauge Product Data SheetMohamedОценок пока нет

- Data Sheet: Elcometer 124 Thickness GaugeДокумент3 страницыData Sheet: Elcometer 124 Thickness GaugeMohamed NouzerОценок пока нет

- High Strain Intergrity Dynamic TestДокумент9 страницHigh Strain Intergrity Dynamic Testkartick adhikaryОценок пока нет

- Quality Assurance of Bored Pile FoundationsДокумент6 страницQuality Assurance of Bored Pile Foundationshugojameswood0% (1)

- Quick Response - . - Results You Can Trust: by The Foundation Testing ExpertsДокумент2 страницыQuick Response - . - Results You Can Trust: by The Foundation Testing ExpertsGeoAnálisis de Colombia SASОценок пока нет

- 26.05.2021-METHOD STATEMENT - VERTICAL LOAD TEST by Anchor MethodДокумент16 страниц26.05.2021-METHOD STATEMENT - VERTICAL LOAD TEST by Anchor MethodpdksubudhiОценок пока нет

- Fe Safe Rubber BrochureДокумент6 страницFe Safe Rubber Brochureali soydaşОценок пока нет

- VFPE Geomembrane Installation For Landfill Capping Applications EngineeringДокумент3 страницыVFPE Geomembrane Installation For Landfill Capping Applications EngineeringDAVE MARK EMBODOОценок пока нет

- Hydraulic Pullout Resistance of A Geomembrane With Locking Extensions Embedded in ConcreteДокумент4 страницыHydraulic Pullout Resistance of A Geomembrane With Locking Extensions Embedded in ConcretemithileshОценок пока нет

- 7TKK001208 - EM Direct Test Access Port - CS - DGTДокумент1 страница7TKK001208 - EM Direct Test Access Port - CS - DGTgabriel molinaОценок пока нет

- Core Compression - P1000AДокумент1 страницаCore Compression - P1000ARohit ChawlaОценок пока нет

- Cranes - Function TestДокумент7 страницCranes - Function TestJose CastroОценок пока нет

- Radio Stations: Installation, Design and PracticeОт EverandRadio Stations: Installation, Design and PracticeРейтинг: 5 из 5 звезд5/5 (2)

- 14) Webinar Content - Stone Columns For Improving Weak GroundsДокумент110 страниц14) Webinar Content - Stone Columns For Improving Weak GroundsEswara PrasadОценок пока нет

- Abrahamson and SilvaДокумент31 страницаAbrahamson and Silvajacs127Оценок пока нет

- 03 McVay FinalДокумент47 страниц03 McVay Finaljacs127Оценок пока нет

- Https WWW - Irctc.co - in Eticketing PrintsdfTicketДокумент2 страницыHttps WWW - Irctc.co - in Eticketing PrintsdfTicketJayamkondanОценок пока нет

- Ocell Test in IndaiДокумент3 страницыOcell Test in IndaiSushanta TakhellambamОценок пока нет

- AICTE Tentetive 2017-18Документ9 страницAICTE Tentetive 2017-18jacs127Оценок пока нет

- Hussien 2016Документ54 страницыHussien 2016jacs127Оценок пока нет

- O CellsДокумент7 страницO Cellsjacs127Оценок пока нет

- O-Cells in QatarДокумент4 страницыO-Cells in Qatarjacs127Оценок пока нет

- Anderson 2001Документ6 страницAnderson 2001jacs127Оценок пока нет

- A Unified Procedure For Earth Pressure CalculationsДокумент5 страницA Unified Procedure For Earth Pressure Calculationsjacs127Оценок пока нет

- Challenges to Quality Control in Bored Cast-In-Situ Piling in Growing Urban EnvironmentsДокумент17 страницChallenges to Quality Control in Bored Cast-In-Situ Piling in Growing Urban Environmentsjacs127Оценок пока нет

- ISGTI BrochureДокумент2 страницыISGTI Brochurejacs127Оценок пока нет

- E 146Документ7 страницE 146jacs127Оценок пока нет

- Haripur River Water Intake GA, SectionДокумент1 страницаHaripur River Water Intake GA, Sectionjacs127Оценок пока нет

- BRC Ju Jcs Bhavin 22102017Документ2 страницыBRC Ju Jcs Bhavin 22102017jacs127Оценок пока нет

- Indigo TKT of MR Jaykumar Shukla 18 Oct Ccu Del BDQДокумент4 страницыIndigo TKT of MR Jaykumar Shukla 18 Oct Ccu Del BDQjacs127Оценок пока нет

- Industry Academia Brochure 18-11-2017Документ2 страницыIndustry Academia Brochure 18-11-2017jacs127Оценок пока нет

- Mou With DD Ws DR Do Bio DigesterДокумент15 страницMou With DD Ws DR Do Bio Digesterjacs127Оценок пока нет

- Code of Practice For Oil Storage Installations 1992Документ22 страницыCode of Practice For Oil Storage Installations 1992Hassan SleemОценок пока нет

- Code of Practice For Oil Storage Installations 1992Документ22 страницыCode of Practice For Oil Storage Installations 1992Hassan SleemОценок пока нет

- Brown 1969Документ6 страницBrown 1969jacs127Оценок пока нет

- Mesotech MS1000 PDFДокумент2 страницыMesotech MS1000 PDFArnoldo López MéndezОценок пока нет

- Bio DigesterBrochureДокумент2 страницыBio DigesterBrochurejacs127Оценок пока нет

- Shaking Table Tests and Stability Analysis of Steep Nailed SlopesДокумент16 страницShaking Table Tests and Stability Analysis of Steep Nailed Slopesjacs127Оценок пока нет

- Chapter 2Документ42 страницыChapter 2Manoj SinghОценок пока нет

- Vopak BHДокумент1 страницаVopak BHjacs127Оценок пока нет

- Co-Ordinates in UTM and Degree MinuteДокумент2 страницыCo-Ordinates in UTM and Degree Minutejacs127Оценок пока нет

- Business Plan Report-Auto-Acoustic IncДокумент10 страницBusiness Plan Report-Auto-Acoustic IncLongyin WangОценок пока нет

- To Hospital Information SystemsДокумент46 страницTo Hospital Information SystemsMaricar SombradoОценок пока нет

- Root BlueStacks Beta & Gain R/W Access in Under 10 StepsДокумент3 страницыRoot BlueStacks Beta & Gain R/W Access in Under 10 StepsSiddharth GoelОценок пока нет

- TN40CMSP002 2 0 2Документ192 страницыTN40CMSP002 2 0 2emmasustechОценок пока нет

- List of Formal Approval SEZДокумент34 страницыList of Formal Approval SEZsampuran.das@gmail.comОценок пока нет

- Real Time Operating Systems: Programme Elective - IIДокумент66 страницReal Time Operating Systems: Programme Elective - IIDr D S Naga Malleswara RaoОценок пока нет

- 5.LDR Based Highways Road Light Failed Intimation Using GSMДокумент44 страницы5.LDR Based Highways Road Light Failed Intimation Using GSMfotronichs velloreОценок пока нет

- Storage Devices and MediaДокумент37 страницStorage Devices and MediaHaya MuqattashОценок пока нет

- Tata Nifty India Digital Exchange Traded Fund - LeafletДокумент4 страницыTata Nifty India Digital Exchange Traded Fund - LeafletSatyam TiwariОценок пока нет

- Resume For Broadcasting InternshipДокумент7 страницResume For Broadcasting Internshipbcrqs9hr100% (2)

- Life Cycle Assessment of BuildingДокумент12 страницLife Cycle Assessment of BuildingBAIMOURNE BOURNEBE100% (1)

- MyReMeDi Presentation - For Hospitals - Ver 4.0Документ16 страницMyReMeDi Presentation - For Hospitals - Ver 4.0Jahidur Rahman DipuОценок пока нет

- KA7630/KA7631: Fixed Multi-Output RegulatorДокумент6 страницKA7630/KA7631: Fixed Multi-Output RegulatorTecnico GenioОценок пока нет

- Project Digital ClockДокумент12 страницProject Digital ClockMd. Arif Hasan MasumОценок пока нет

- CM20150930 35537 44540Документ2 страницыCM20150930 35537 44540fangrui maiОценок пока нет

- SOP DoconДокумент38 страницSOP DoconAcep GunawanОценок пока нет

- FPGA Applications in SpaceДокумент5 страницFPGA Applications in SpacePiyush JainОценок пока нет

- Laser Scanning TechnologyДокумент13 страницLaser Scanning TechnologyVirgilio F. Abundo Jr.Оценок пока нет

- Try Latest & Free DELL EMC DES-6322 Real DumpsДокумент11 страницTry Latest & Free DELL EMC DES-6322 Real Dumpskaronbill0% (1)

- F - Systems TasksДокумент30 страницF - Systems Taskstuandanhbk10Оценок пока нет

- AIM OF THE EXPERIMENT:-Binary To Decimal, Gray Code Apparatus RequiredДокумент8 страницAIM OF THE EXPERIMENT:-Binary To Decimal, Gray Code Apparatus RequiredSai KaneОценок пока нет

- Digital Literacy Research ReportДокумент54 страницыDigital Literacy Research ReportSaul SalekyОценок пока нет

- Pawai Dam MVRWSS Project Progress in PannaДокумент4 страницыPawai Dam MVRWSS Project Progress in PannaWater Supply Project PannaОценок пока нет

- (Power Electronics and Power Systems) Slobodan N. Vukosavic - Grid-Side Converters Control and Design (2018, Springer International Publishing)Документ288 страниц(Power Electronics and Power Systems) Slobodan N. Vukosavic - Grid-Side Converters Control and Design (2018, Springer International Publishing)Isabella Bianchin100% (2)

- Revised Demolition Code SS 557:2010Документ4 страницыRevised Demolition Code SS 557:2010Jianhua WuОценок пока нет

- FO Components & SystemsДокумент104 страницыFO Components & SystemsNikos Tsagkopoulos Anastasia DimakiОценок пока нет

- Public Health Engineering Department, Haryana Public Health Engineering Division No.2, Panipat Notice Inviting TenderДокумент17 страницPublic Health Engineering Department, Haryana Public Health Engineering Division No.2, Panipat Notice Inviting Tenderpmcmbharat264Оценок пока нет