Академический Документы

Профессиональный Документы

Культура Документы

RTU560 As IEC 61850 Gateways PDF

Загружено:

MOHAMMADОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

RTU560 As IEC 61850 Gateways PDF

Загружено:

MOHAMMADАвторское право:

Доступные форматы

RTU500 series Remote Terminal Unit

Function Description Release 11

Part 6: RTU500 Functions

Function Description Release 11

Revision

Document identity: 1KGT 150 798 V002 1

Revision: Date: Changes:

0 03/2013 Initial version

1 05/2013 New layout

2 02/2014 Update for Release 11.1

Chapter “interfaces and network” moved to function

description part 9

Chapter “Time management” updated

ABB AG 1KGT 150 798 V002 1

Function Description Release 11

Contents

1 Introduction ................................................................................. 1-1

1.1 About the RTU500 series Function Description .............................. 1-1

1.2 Preface .................................................................................................. 1-1

1.3 References ............................................................................................ 1-2

2 Host communication interface ................................................... 2-1

2.1 Physical interfaces .............................................................................. 2-1

2.2 Monitoring direction ............................................................................ 2-2

2.3 Command direction ............................................................................. 2-2

2.4 General interrogation .......................................................................... 2-2

2.5 Filtering of information ....................................................................... 2-2

2.6 Supervision of connection to host systems .................................... 2-2

2.7 Queue and buffer handling ................................................................. 2-3

2.7.1 Handling of overflow situations ....................................................... 2-3

Loss of changes of information ...................................................... 2-3

Loss of pulse counters ................................................................... 2-3

2.7.2 Queue storage timeout ................................................................... 2-4

2.8 Overview of the software structure ................................................... 2-4

3 Subdevice communication interface ......................................... 3-1

3.1 Data flow in monitoring direction ...................................................... 3-2

3.2 Command direction ............................................................................. 3-2

3.2.1 Data flow ........................................................................................ 3-2

3.2.2 Command output procedures ......................................................... 3-3

ABB AG 1KGT 150 798 V002 1 I

Contents Function Description Release 11

3.3 General interrogation .......................................................................... 3-4

3.4 Time synchronization .......................................................................... 3-5

3.5 System events ...................................................................................... 3-5

4 Substation automation system with IEC 61850 ........................ 4-1

4.1 RTU500 series in an IEC61850 system ............................................. 4-1

4.2 IEC61850 configurations..................................................................... 4-1

4.2.1 RTU500 series configured as IEC 61850 client .............................. 4-2

4.2.2 RTU500 series configured as IEC 61850 server ............................ 4-2

5 Programmable Logic Control (PLC) .......................................... 5-1

5.1 PLC – SCADA processing .................................................................. 5-1

5.1.1 PLC function ................................................................................... 5-1

5.1.2 PLC INPUT, PLC OUTPUT and internal flag memory.................... 5-2

5.1.3 PLC program memory .................................................................... 5-2

5.1.4 Retain variable section ................................................................... 5-2

5.1.5 Boot project file .............................................................................. 5-2

5.1.6 PLC application and tasks .............................................................. 5-2

5.1.7 I/O interface –- general I/O handling .............................................. 5-3

Input process image ....................................................................... 5-3

Redundancy switchover activities .................................................. 5-3

Input handler .................................................................................. 5-4

PLC core ........................................................................................ 5-4

Output handler ............................................................................... 5-4

Signal processing ........................................................................... 5-5

Messages and commands ............................................................. 5-5

System event processing ............................................................... 5-6

System command processing ........................................................ 5-6

System event messages ................................................................ 5-6

Characteristic technical data .......................................................... 5-6

II 1KGT 150 798 V002 1 ABB AG

Function Description Release 11 Contents

6 Redundancy ................................................................................ 6-1

6.1 Overview ............................................................................................... 6-1

6.2 RTU560 redundant CMU concept ...................................................... 6-1

6.2.1 Master and slave concept .............................................................. 6-3

6.2.2 Redundancy switchover ................................................................. 6-3

6.2.3 Impact on RTU functions ................................................................ 6-3

Process data processing ................................................................ 6-3

PLC functions ................................................................................. 6-4

Logic function ................................................................................. 6-4

Archive and Local Print, integrated HMI ......................................... 6-4

Time administration ........................................................................ 6-5

Simple Network Management Protocol (SNMP) ............................ 6-5

6.2.4 RTUtil500 configuration ................................................................ 6-10

6.2.5 RTU500 series redundant communication ................................... 6-11

Redundant Host Communication Interfaces ................................. 6-11

Redundant Subdevice Communication Interface ......................... 6-11

7 Start-up, Configuration and Time Management ........................ 7-1

7.1 Start-up procedures ............................................................................ 7-1

7.1.1 RTU System Start .......................................................................... 7-1

7.1.2 RTU560 CMU start ......................................................................... 7-2

7.1.3 RTU560 CMU integration ............................................................... 7-2

7.1.4 RTU560 CMU removal ................................................................... 7-3

7.2 RTU500 series configuration.............................................................. 7-4

7.2.1 General requirements..................................................................... 7-4

Configuration file load procedure ................................................... 7-4

7.3 RTU500 series Time Management ..................................................... 7-5

7.3.1 Time management principle ........................................................... 7-5

7.3.2 Time administration ........................................................................ 7-5

7.3.3 Time sources and time masters ..................................................... 7-7

7.3.4 RRTU System time qualifiers and signalization .............................. 7-7

7.3.5 Time zone and daylight saving ....................................................... 7-8

ABB AG 1KGT 150 798 V002 1 III

Contents Function Description Release 11

7.4 Time synchronization modes ............................................................. 7-9

7.4.1 Synchronization by NCC ................................................................ 7-9

7.4.2 Synchronization by NCC with external minute pulse .................... 7-10

7.4.3 Synchronization via (S)NTP ......................................................... 7-10

Unicast client features .................................................................. 7-13

Broadcast client features .............................................................. 7-14

Synchronization accuracy ............................................................ 7-15

7.4.4 Synchronization via radio clock .................................................... 7-16

7.4.5 Redundant Time Synchronization ................................................ 7-16

7.5 Synchronization of sub-RTUs .......................................................... 7-17

7.5.1 Synchronization with clock synchronization command ................. 7-17

7.5.2 Synchronization via SNTP server ................................................. 7-18

8 RTU500 series I/Os and I/O bus interface ................................. 8-1

8.1 I/O bus master and RTU500 series I/O .............................................. 8-1

8.2 Event flow through RTU500 series .................................................... 8-3

8.2.1 SLC – IOM task .............................................................................. 8-3

8.2.2 MPU ............................................................................................... 8-3

9 Status and diagnostic information ............................................ 9-1

9.1 Status and error report to NCC .......................................................... 9-1

9.2 Web server diagnosis ......................................................................... 9-1

9.2.1 System Diagnosis........................................................................... 9-1

9.2.2 Status Information .......................................................................... 9-2

9.3 RTU alarms and warnings .................................................................. 9-2

9.3.1 Board States and LED Signaling .................................................. 9-14

9.3.2 LEDs on 560CMU02 and 560CMU05 .......................................... 9-15

9.3.3 CMU states .................................................................................. 9-15

Boot state ..................................................................................... 9-15

Start-up state ................................................................................ 9-16

Alarm state ................................................................................... 9-16

Warning state ............................................................................... 9-17

OK state ....................................................................................... 9-17

IV 1KGT 150 798 V002 1 ABB AG

Function Description Release 11 Contents

9.3.4 Communication interface states ................................................... 9-17

Serial interface states ................................................................... 9-17

Serial interface Boot and not configured state .............................. 9-17

Start-up state ................................................................................ 9-17

OK state ....................................................................................... 9-18

Error state .................................................................................... 9-18

Ethernet interface ......................................................................... 9-18

9.3.5 I/O boards, modems and real time clocks .................................... 9-19

LED indications for 23AA21, 23AE23 and 23BE23 ...................... 9-19

LED indications 23BA20 and 23BA22 or 23BA23 ........................ 9-20

LOC pushbutton ........................................................................... 9-20

Object command output with (1 out of n) check ........................... 9-21

Object command output and failure at (1 out of n) check: ............ 9-22

LED indications for 23WT25......................................................... 9-23

LED indications for 23WT23 or 23WT24 ...................................... 9-23

LED indications for 560RTC01 ..................................................... 9-24

LED indications for 560RTC02 ..................................................... 9-25

LED indications for 560RTC03 ..................................................... 9-26

9.3.6 LED indications for 23OK24 ......................................................... 9-26

9.3.7 LED indications of decentralized modules.................................... 9-27

LED indications for 23BA40 and 23BE40 ..................................... 9-27

10 System data interface ............................................................... 10-1

10.1 System events .................................................................................... 10-1

10.2 System commands .......................................................................... 10-12

11 Glossary of terms ..................................................................... 11-1

ABB AG 1KGT 150 798 V002 1 V

Function Description Release 11

1 Introduction

1.1 About the RTU500 series Function Description

The Function Description consists of several parts:

Document identity Part name Explanation

1KGT 150 793 Part 1: Overview Overview of the RTU500

series and system architecture

1KGT 150 794 Part 2: Rack Solutions Description of the RTU500

series rack solutions

1KGT 150 795 Part 3: DIN Rail Description of the RTU500

Solutions series DIN rail solutions

1KGT 150 796 Part 4: Hardware Overview of the RTU500

Modules series rack and DIN rail

modules

1KGT 150 797 Part 5: SCADA Description of the RTU500

Functions series SCADA functions

1KGT 150 798 Part 6: RTU500 Description of the RTU500

Functions series functions

1KGT 150 799 Part 7: Archive Description of the RTU500

Functions series Archive functions

1KGT 150 800 Part 8: Integrated HMI Description of the RTU500

series Integrated HMI interface

1KGT 159 896 Part 9: Interfaces and Description of the RTU500

Networks series Interface and Network

functions

Table 1: Parts of the Function Description

1.2 Preface

This document describes the following functions of the RTU500 series:

Host Communication Interface

Subdevice Communication Interface

IEC 61850 Engineering

Programmable Logic Control (PLC)

Redundancy

Start-up, Configuration and Time Management

Status and Diagnostic Information

System Data Interface

ABB AG 1KGT 150 798 V002 1 1-1

Introduction Function Description Release 11

References

1.3 References

[1] 1KGT 150 801 RTUtil500 Users Describes the usage of engineering

Guide tool RTUtil500 of the RTU500 series

Release 11

[2] Individual Ident RTU500 series Description of the Sub and Host

Protocol Communication Protocols

Descriptions

[3] 1KGT 150 853 Interfaces and Description of the relationship of

Protocols interfaces and protocols

Release 11

[4] RFC1157 A Simple

Network

Management

Protocol (SNMP)

[5] RFC1213 Management

Information Base

for Network

Management of

TCP/IP-based

internets: MIB-II

(second version)

[6] 1KGT 150 802 RTU500 series

Web Server

User's Guide

1-2 1KGT 150 798 V002 1 ABB AG

Function Description Release 11

2 Host communication interface

This chapter describes the general part of the Host Communication Interface (HCI)

of the RTU500 series. Communication with multiple host systems (e.g., NCCs) with

different communication protocols is one of the basic concepts for RTU500 series.

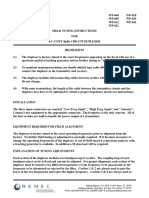

Figure 1: RTU500 series network

The RTU enables communication with up to 16 different host systems by using the

communication interfaces provided by the CMUs.

No interdependencies exist between the various instances of host communication

interfaces. Each interface has its own set of configuration parameters and runs

independently from other interfaces during runtime.

Because of the different requirements of protocols supported by RTU500 series,

this chapter describes only the general functions and principles of host

communication interfaces. For detailed information on the functions provided by

host communication interfaces for a specific protocol, refer to the corresponding

Interface Description for host communication.

2.1 Physical interfaces

Physical interfaces used for communication to host systems are limited only by the

available interfaces of a CMU and by their support of the selected communication

protocol.

Communication interfaces can be serial interfaces or Ethernet interfaces.

Configuration of the interfaces as host communication lines with their protocols is

completely performed in RTUtil500. There are no hardware switches to configure

the interfaces.

ABB AG 1KGT 150 798 V002 1 2-1

Host communication interface Function Description Release 11

Monitoring direction

For detailed information about available interface and protocol combinations of

different CMU types and existing restrictions, refer to [3].

2.2 Monitoring direction

All active host systems receive any message that is generated by the RTU. Any

message that comes from a substation and could be translated from one protocol

to another is sent to the active host systems.

2.3 Command direction

Commands sent to the RTU are accepted from all host systems, without

preference or priority. There is no restriction to the number of different commands

that can be handled at a time by the RTU.

If a command sequence is running, further operations requested by the same

object will be rejected until the current command sequence is completed, or until a

defined timeout has expired. The timeout period depends on the host

communication interface. A timeout period of approx. 30 s is frequently used.

If interlocking with local control authority is configured, all process commands are

rejected while the local control authority is active. For more details see Part 8:

Integrated HMI, section Control Authority component.

2.4 General interrogation

A host communication interface contains a database with the current state of the

process data and system data objects. When prompted with a general interrogation

command, the host communication interface sends the content of this database as

an answer.

The handling of general interrogations is protocol-specific. For detailed information

on a particular protocol, refer to the corresponding Interface Description related to

host communication.

2.5 Filtering of information

To avoid transmission of certain data points on certain host communication

interfaces, data points can be defined to be out of use by means of a setting that is

specific to the interface for host communication. This setting refers to data in

monitoring and command direction and can be set individually for each data object.

2.6 Supervision of connection to host systems

The RTU can manage up to 16 lines to host systems. System event messages

indicate the status of connections to a host system, and whether a communication

between the RTU and host systems failed:

SEV (101 ... 116): Host number x online, 1 ≤ x ≤ 16

2-2 1KGT 150 798 V002 1 ABB AG

Function Description Release 11 Host communication interface

Queue and buffer handling

2.7 Queue and buffer handling

Host communication interfaces receive any information addressed to internal

interfaces for host communication of the RTU. Information processing starts with

the reception of events from IC and depends on the protocol, which needs to be

supported by the host communication interface.

Because of the requirements of different protocols, there is no uniform method for

different HCIs for buffering or queuing events received from IC.

For a detailed description of queue and buffer handling, refer to the Interface

Description related to host communication for the protocol in question.

Common functionality and principles used by all host communication interfaces of

different protocols are described in the following chapters.

2.7.1 Handling of overflow situations

If the amount of information received from IC is larger than the amount of

information that can be transmitted to the host system, changes of information or

values of pulse counters may be lost depending on the time and the

communication settings being used.

Loss of changes of information

In the event of a loss of changes of information by a particular HCI, the latest state

of the information will either be sent spontaneously or is available for read access,

e.g., using a general interrogation.

Host communication interfaces use the following system event for signaling the

loss of changes of information:

SEV (117 ... 132): Host interface x: At least one change of information lost

with 1 ≤ x ≤ 16

The system event signals the loss of changes of information by the HCI in

question. The system event is set if a change of information is lost for the first time.

It is reset by an HCI implementation-specific algorithm.

Further diagnostic information about the internal status of the relevant host

communication interfaces are added to the system diagnosis of the RTU.

Loss of pulse counters

To ensure host systems are provided with the most important values as long as

possible, the RTU uses a replacement process for pulse counter values.

Pulse counters consist of two readings – intermediate readings (IR) and end of

period readings (EPR).

If the queue is full, IR messages are no longer stored. Only EPR messages are

stored, overwriting any IR messages still in the queue until no more queued IR

messages are left.

To store new EPR messages, the RTU then overwrites the oldest EPR message in

the queue. The queue now only contains EPR messages dating backwards from

the current time.

Host communication interfaces use the following system event for signaling:

SEV (133 … 148): Host interface x: At least one pulse counter lost with 1 ≤ x ≤ 16

The system events are set to signalize that pulse counters states are lost. If the

first time a pulse counter was replaced and is reset by an HCI implementation

specific algorithm, the system event is set.

ABB AG 1KGT 150 798 V002 1 2-3

Host communication interface Function Description Release 11

Overview of the software structure

Further diagnosis information about the internal status of the concerned host

communication interfaces are added to the system diagnosis of the RTU.

2.7.2 Queue storage timeout

If the connection to a host system is offline for any given time, the queue content

can be saved into a process image after a configured time to avoid reporting of

information. The image can be processed at a configured time. In this case, all

changes of information are lost and the current process values have to be read by

the host system using a general interrogation.

Detailed diagnostic information about queue storage timeouts of the relevant host

communication interfaces are added to the system diagnosis of the RTU (see

chapter Status and diagnostic information (page 9-1)).

2.8 Overview of the software structure

The internal software of Host Communication Interfaces (HCI) follows a three-layer

architecture:

Interface to Internal Communication (IC)

Application layer in monitoring and command direction

Link layer

NCC

Host Communication

Interfaces (HCI)

Link Layer

Application Layer Application Layer

Monitoring Direction Command Direction

Interface to

Internal

Communication

Internal Communication (IC)

Figure 2: Interface to IC – Application layer – Link layer

2-4 1KGT 150 798 V002 1 ABB AG

Function Description Release 11

3 Subdevice communication interface

This chapter describes the general part of the Subdevice Communication Interface

(SCI) of the RTU500 series. The SCI is used for communication between the RTU

and subordinate devices. Subordinate devices are RTUs or, in general, other

intelligent electronic devices (IED).

Communication with multiple IEDs with different communication protocols is one of

the basic concepts of the RTU500 series.

The following figure shows an example of a network configuration with subordinate

devices:

Figure 3: RTU500 series network

The SCI supports various communication protocols. For detailed information on

protocol-specific configuration parameters, refer to the Interface Description for the

relevant protocol.

All aspects of the SCI, its communication lines, and the protocols used on these

lines are configured in RTUtil500. There are no hardware switches to configure the

interfaces.

The SCI can manage up to 32 devices per line. An RTU supports up to 32

sub-lines.

The assignment of UART sub-protocols to serial interfaces is completely at the

user's disposal. There are no dependencies between different protocols run on a

CMU. The only restriction is the number of communication protocols supported by

a firmware package. Not all communication protocols can run concurrently on a

CMU board. Only certain combinations of protocols are allowed.

Protocols that do not operate on a UART basis are limited to the interfaces CPA

and CPB on the 560CMU05 R0002.

ABB AG 1KGT 150 798 V002 1 3-1

Subdevice communication interface Function Description Release 11

Data flow in monitoring direction

Ethernet- and TCP/IP-based protocols can be used only with Ethernet interfaces.

The structure of the SCI is independent of the protocol and shown in the following

figure.

Internal Communication

Sub-Device

Communication Interface to

Interface (SCI) Internal

Communication

Application Layer Application Layer

Monitoring Direction Command Direction

Link Layer

Sub-Device

Figure 4: Internal structure of the SCI

3.1 Data flow in monitoring direction

The link layer checks any messages received from a subordinate device for validity

with regard to the message format specified for the configured protocol. If the

message is valid, it is handed over to the application layer for the monitoring

direction.

The application layer for the monitoring direction decodes the user data. All values,

flags, and other information, are mapped to the RTU's internal format. (For details

on the mapping of message data to the RTU's internal format, refer to the Interface

Description for the relevant protocol.)

If the user data is valid and configured as being a part of this SCI, it is forwarded to

Internal Communication

Queuing between link layer and application layer is secured to eliminate the loss of

messages. The relevant queue sizes are excluded from configuration in RTUtil500.

3.2 Command direction

3.2.1 Data flow

The application layer detects and checks all messages on Internal Communication

for control direction, assuming that the messages are configured as being part of

this SCI.

3-2 1KGT 150 798 V002 1 ABB AG

Function Description Release 11 Subdevice communication interface

Command direction

The application layer for the control direction encodes the user data. All values,

flags, and other information, are mapped to the protocol-specific format. (For

details on the mapping of message data to the RTU's internal format, refer to the

Interface Description for the relevant protocol.)

The user data is forwarded to the link layer. The link layer adds link information and

forwards the data to the subordinate line.

Queuing between link layer and application layer is secured to eliminate the loss of

messages. The relevant queue sizes are excluded from configuration in RTUtil500.

Some protocols require the application layer for the control direction of the SCI to

simulate messages, which are not sent by the subordinate line protocol, and to

forward them to Internal Communication to ensure consistency with the RTU's

internal sequences.

Process commands and status check instructions (during start up) can be issued

simultaneously to all IED connected to a subdevice communication line.

3.2.2 Command output procedures

Commands for objects can be issued either in a one-step procedure (direct

operate) or, for requests at a higher security level, in a two-step procedure (select

before operate). The two-step procedure significantly lowers the risk of errors in

command direction.

Upon reception, any SELECT command is first checked against the RTU's internal

information. Check items include whether the object is available and whether no

other object is already reserved. If the command successfully passes the check,

and if a protocol is available that supports two-step command procedures, the

SELECT command received is converted to the protocol-specific

format/procedures, and forwarded to the referring I/O devices (e.g., subordinate

RTUs, IEDs). Confirmation of the SELECT command depends on the

acknowledgement by the I/O device. If only one-step command procedures are

supported, the SCI acknowledges the reservation with a positive confirmation.

The reservation is valid for 20 seconds. Within that time frame, either the

corresponding EXECUTE command or a DESELECT command should be

received. If the EXECUTE and the DESELECT command are not received, the SCI

cancels the reservation of the object.

If an EXECUTE command is received within the allowed time frame, the RTU

checks whether the referring object equals the reserved object. If the objects are

identical, the command is executed. If the objects differ, the EXECUTE command

is rejected and answered with a negative confirmation. The command procedure is

finished after the activation termination for the command in question has been

transmitted.

While a command object is selected, no other command objects within the

interlocking scope of the selected object may be selected. Other selections will be

rejected. If no object is selected, multiple process command objects can be

executed in parallel using a direct operate procedure.

The scope of command selection interlocking depends on the configuration of the

parameter Process command interlocking mode.

Parameter name Parameter location

Process command interlocking mode RTU parameter

ABB AG 1KGT 150 798 V002 1 3-3

Subdevice communication interface Function Description Release 11

General interrogation

Parameter value Explanation

Interlocking per IO device / IO bus and Selection is interlocked against other

group commands of the same I/O device (e.g.

subordinate RTUs, IEDs) and the same

command group. Valid command

groups are:

Object Commands Outputs (SCO,

DCO)

Regulation Commands Outputs

(RCO)

Setpoint Commands Outputs (ASO,

DSOx)

Bit-string outputs (BSOxx)

Interlocking per object Selection is interlocked only against the

same object

Interlocking per object with command Selection is interlocked only against the

priority same object, but selection can be

overridden by a command originating

from an originator (e.g., HCI, PLC,

Integrated HMI) with higher command

priority.

The HCIs with the lowest host numbers

have the highest priority, followed by

PLCs, Integrated HMIs and web servers

of the RTU500 series.

Select and execute commands can

override the selection.

Table 2: Output procedures for interlocking

In the event that a process command is rejected because of a selection mismatch

or a pending command confirmation, a system event message of the type

SEV#242 .. SEV#260: Process command collision with command of X is sent to

the originator of the rejected command. The system event message contains

information about the originator sending the command that caused rejection.

3.3 General interrogation

The general interrogation command is automatically executed by the SCI in the

following situations:

During system start-up

In the event of a redundancy switchover (also to update the process data

from subordinate devices if the relevant CMU board is not part of the

redundant system)

When the line state of the subordinate device has changed from offline to

online

If the general interrogation command is not supported by the configured protocol,

the SCI simulates a general interrogation, e.g., by reading all values or using other

procedures, to obtain the actual values of the subordinate devices.

3-4 1KGT 150 798 V002 1 ABB AG

Function Description Release 11 Subdevice communication interface

Time synchronization

3.4 Time synchronization

Time synchronization of a subordinate device is autonomously managed by the

SCI and implemented only if supported by the configured protocol.

Time synchronization needs to be configured once for every sub-line. Only one

time synchronization mode can be configured per line.

Parameter name Parameter location

Time interval of clock synchronization Line parameters

commands

Upon synchronization of the RTU, the SCI reads the RTU's internal time and sends

it within a configured time period to all subordinated devices that are in an online

state.

CAUTION

If the RTU has no valid time information, no Time synchronization command is

sent to any subordinate device.

3.5 System events

The SCI manages and controls system events for each device that is connected to

the line.

Several SEVs are controlled by the SCI. They depend on the configuration of the

SEV in RTUtil500 and on the type of device, e.g., IED, RTU.

For more details, see chapter System events (page 10-1).

ABB AG 1KGT 150 798 V002 1 3-5

Function Description Release 11

4 Substation automation system with IEC 61850

4.1 RTU500 series in an IEC61850 system

As an IEC 61850 client, the RTU500 series provides NCC gateway functionality by

connecting an IEC 61850 station bus to NCCs. As an IEC 61850 server, the RTU

operates as an IEC 61850 IED, providing data to an IEC 61850 network from

subordinate devices or signals that are directly connected. The figure below shows

integration of the RTU in an IEC 61850 system.

Network Control

Center

Diagnosis

Network Control level

IEC 60870-5-101 / IEC 60870-5-104

DNP / DNP over LAN/WAN

Station level

Gateway

RTU560

RTU560 client

Integrated

HMI

Station bus IEC 61850-8

Bay level IED 1 IED 2 IED 3 RTU560 Integrated

server HMI

Process level

Figure 5: Integration of RTU500 series in an IEC 61850 system

The standard functions of the RTU500 series, such as local I/Os and connections

via legacy protocols, are available in both the client and the server configuration.

4.2 IEC61850 configurations

Using RTUtil500, you can configure an RTU as an IEC 61850 client, an IED or an

IEC 61850 server IED. Separate projects are required if different IED types need to

be configured.

It is not possible to configure an entire IEC 61850 network with multiple RTU clients

or servers in a single project.

The following chapters show examples of RTU client and server configurations.

ABB AG 1KGT 150 798 V002 1 4-1

Substation automation system with IEC 61850 Function Description Release 11

IEC61850 configurations

4.2.1 RTU500 series configured as IEC 61850 client

As an IEC 61850 client, the RTU connects NCCs with an IEC 61850 network.

Additional local I/Os and connections via legacy protocols are possible. In this

configuration, the RTU does not support any GOOSE communication.

For more information, refer to the relevant protocol description.

The following figure shows an RTU500 series that is configured as an IEC 61850

client.

NCC

connection

RTU560 IEC101

Slave

(NCC GW)

SCI HCI

IEC61850 IEC103

Local I/O PLC HMI

Client Master

IEC61850-8-1

e.g.

IEC103

IED IED IED IED

Figure 6: RTU500 series configured as a IEC 61850 client

4.2.2 RTU500 series configured as IEC 61850 server

As an IEC 61850 server, the RTU provides data to an IEC 61850 network. Possible

data sources are IEDs that are connected via legacy protocols, local I/Os, or PLC

applications.

CAUTION

In this configuration the RTU supports horizontal GOOSE communication with

other IEC 61850 IEDs as well. The GOOSE data received from the IEC 61850

network could be used only in a PLC application.

4-2 1KGT 150 798 V002 1 ABB AG

Function Description Release 11 Substation automation system with IEC 61850

IEC61850 configurations

The following figure shows an RTU that is configured as an IEC 61850 server.

IEC61850-8-1

RTU560 IEC61850

Server

(RTU-IED)

GOOSE

SCI HCI

DNP3 IEC103

Local I/O PLC HMI

Master Master

e.g. e.g.

DNP3 IEC103

IED IED IED IED

Figure 7: RTU500 series as an IEC 61850 server

For more information, refer to the relevant protocol description.

For a detailed description of the engineering process, refer to the corresponding

chapter in the RTUtil500 User's Guide.

ABB AG 1KGT 150 798 V002 1 4-3

Function Description Release 11

5 Programmable Logic Control (PLC)

This chapter describes the PLC function, which is the RTU500 series' runtime

system for control applications. The PLC function has been designed in

accordance with IEC 61131-3. For systems engineering, version 2.11 of the

MULTIPROG wt programming and debugging system is used.

5.1 PLC – SCADA processing

The PLC is an integral part of the RTU system and is used to exchange data with

SCADA.

from / to Network Control Center from / to MULTIPROG wt

Internal

Communication

Boot

PLC project

PLC

INPUT file

program

memory .

memory

(I) .

PLC

SCADA function

PLC PLC

OUTPUT internal

memory flag

(Q) RTU560 memory

Config-

files

.

.

from / to I/O hardware

from / to sub RTU

Figure 8: PLC – SCADA processing in RTU500 series

The figure above shows the basic elements of the PLC in interaction with SCADA.

They are described in the following chapters.

5.1.1 PLC function

The PLC function is a licensed software package. It enables a CMU to run PLC

applications, and to communicate with MULTIPROG wt for loading and debugging

applications. After the function has been added to the configuration, it is started at

boot time of the CMU.

Once started on a CMU, the PLC function is running in shared mode with low

priority compared to the SCADA software.

It is possible to design a configuration in which PLC function and SCADA activities

run on different CMUs. Since both communicate via Internal Communication, the

PLC function may run on any CMU within the RTU. This approach provides

maximum processing power to each activity.

ABB AG 1KGT 150 798 V002 1 5-1

Programmable Logic Control (PLC) Function Description Release 11

PLC – SCADA processing

5.1.2 PLC INPUT, PLC OUTPUT and internal flag memory

The PLC function has its own memory for any data areas that are allocated at start

time. The basic function of a PLC application is to read data from the INPUT (I)

memory and to write the calculation results to the OUTPUT (Q) memory. The data

is then transferred to SCADA via Internal Communication. For a detailed

description, see chapter I/O interface –- general I/O handling (page 5-3). The

internal memory is a memory area (M) that can be used by the PLC application as

required.

5.1.3 PLC program memory

The program memory (in RAM) contains the PLC application. The PLC function

loads and executes the application from this memory. The application also includes

the entire address information required for data exchange with SCADA and

INPUT / OUTPUT memory. The program memory may be loaded by MULTIPROG

wt or from the boot project.

At load time of the application, the PLC function checks whether all data points are

included in the RTU configuration. If not all data points are included, a system

message [13.5.4] ACTIVITY ERROR FOR PLC IN RACK X SLOT Y: START

ERROR is generated (see chapter RTU alarms and warnings (page 9-2)).

5.1.4 Retain variable section

®

A subset of the PLC program data can be stored on the CompactFlash / SD Card

of the RTU. This data will be restored after system start-up.

®

The retain variables are stored on the CompactFlash card every 20 seconds, but

only if the contents of the variable section have changed. Manual saving of the

variable section is also possible by using a special function block within the PLC

program. Note that the storage cycle for this operation is limited to 20 seconds.

5.1.5 Boot project file

The boot project file is a file generated by MULTIPROG wt. The file is named

bootfile.pro and contains the PLC application. It resides in the nonvolatile flash

memory of the CMU. If no boot project is found at boot time, the PLC function

starts without an application. If a boot project is found at boot time, it is loaded to

PLC program memory, and started (cold start).

5.1.6 PLC application and tasks

A PLC application is generated by MULTIPROG wt as a result of the successful

compilation of a project on the PC. The application can then be loaded to program

memory (RAM) for testing and debugging, or to FLASH memory as a boot project

that is started automatically at boot time of the RTU.

A PLC application is processed on the CMU by one or more tasks, according to the

definitions specified in MULTIPROG wt. A task may be defined as a CYCLIC,

EVENT, or SYSTEM type. SYSTEM tasks are can be connected to System

Programs (SPGs, see PLC help). The EVENT type is not supported. Tasks of the

CYCLIC type are activated at a specified time interval. Task cycle time is defined

by the user in MULTIPROG wt. The minimum cycle time is 10 ms.

The PLC cycle time can be incremented at intervals of 1 ms but is rounded to

10 ms values during each PLC cycle. When calculating the cycle time of a task

cycle, make sure to take the RTU's signal configuration and the typical event load

into account. The actual PLC cycle time depends on the overall situation within the

RTU software. If SCADA and PLC are configured on the same CMU, they share

the MPU. SCADA has priority over PLC as it requires more CPU time in the event

of a burst of signal events, compared to idle loop. This may stretch PLC cycle time.

5-2 1KGT 150 798 V002 1 ABB AG

Function Description Release 11 Programmable Logic Control (PLC)

PLC – SCADA processing

If the PLC is required to perform a high amount of real-time processing, it is

recommended to run the PLC on a dedicated CMU.

A PLC task can be monitored by a watchdog with a definable timeout. If the time

required to process the program is longer than the watchdog time, program

execution stops. Using MULTIPROG wt, the PLC application can be programmed

to restart after an elapsed watchdog error (SPG 10).

5.1.7 I/O interface –- general I/O handling

The I/O interface of a PLC provides data transfer from SCADA to the PLC and vice

versa.

During start-up of a PLC application, each task reads its input signals directly from

the SCADA database, which contains the latest data received. In running mode,

however, the I/O interface works with an n-stage process image, as described

below (also see the following figure).

Internal Communication

Input queues

Command Message

queue queue

PLC core

INPUT OUTPUT

DPI memory memory

SCO SPI

DPI Value0 Application AMI Value

DCO AMI

Value1 Task(s) OV

... BL

TimeTag AND ...

Input SCO SE TimeTag Output

PID

handler EX OR DCO SE handler

... ...

Value Value0

COT Value1

... COT

...

Figure 9: I/O interface of a PLC

Input process image

The data relevant to the PLC is filtered from Internal Communication, and is written

to the corresponding process image for commands, messages, system events or

system commands. The maximum number of entries in the process image

depends on the data type.

The n-stage process image contains the oldest n-1 changes as received from

Internal Communication while the PLC task is being processed, as well as the

current value. If more than n-1 changes are received, any changes of information

between the n-1 received value in the image and the current value are lost.

Redundancy switchover activities

If a controlled switchover occurs between two redundant CMUs, the active CMU

stops the activities and performs an internal restart. The line driver on the

communication interfaces will switch to high impedance of the tri-state.

The standby CMU will continue the start procedure. From the viewpoint of the

RTU560 system, it is a warm start. The now active CMU starts communication on

the serial lines and initializes communication to their host and subordinated

devices. The I/O boards will not perform a reset. The PDP module takes over

communication on the RTU560 peripheral bus and reads all values from the I/O

boards.

ABB AG 1KGT 150 798 V002 1 5-3

Programmable Logic Control (PLC) Function Description Release 11

PLC – SCADA processing

The actual state of all CMUs in a (non-)redundant configuration is indicated by

SEVs #149 to #164 and #224 to #239:

SEV (#149 … #164) CMU #x is inoperable, 1 ≤ x ≤ 16

SEV (#224 … #239) CMU #x is active, 1 ≤ x ≤ 16

A redundant pair of communication units will report the following SEV states:

CMU Normal operation One CMU is faulty

SEV 149 – SEV 224 – SEV 149 – SEV 224 –

164 239 (active) 164 239 (active)

(inoperable) (inoperable)

Active CMU No Yes No Yes

Standby CMU No No Yes No

Table 3: SEV states

Input handler

At the beginning of each PLC task cycle, the task executes an input handler. The

input handler evaluates the data point signals in the input process image that were

received in the meantime. Any signals configured for the task are transferred to the

INPUT memory of the PLC. If multiple occurrences of a signal are waiting in the

queue, the input handler transfers only the first occurrence to the INPUT memory

and writes the remaining signals back to the queue for processing in the next PLC

task cycle.

For any commands received, the input handler sets the corresponding SE (select)

or EX (execute) flag of the PLC data type in the INPUT memory to TRUE. This

setting applies to a single task cycle and depends on the Select state of the

received command. For details, see the following table:

Received SCADA PLC EX state PLC SE state

Select state of

command

0 TRUE (for one FALSE

cycle)

1 FALSE TRUE (for one cycle)

Table 4: Select and Execute states for commands in INPUT memory

PLC core

The PLC core processes the PLC application in one or more tasks, reading from

the INPUT memory, and writing the calculation results to the OUTPUT memory.

Output handler

At the end of each task cycle, the output handler is executed. It checks if the Send

condition is TRUE for each OUTPUT data point. For details, see the following

table. If the Send condition is TRUE, the output handler sends the condition to

Internal Communication.

Data point type Data point send condition

SPI, DPI, STI, DMIx, The Value flag, or any quality flag, has changed

BSIx, ITI compared to last task cycle.

AMI, MFI Any quality flag has changed compared to last task

cycle or the TR (transmit) flag is set.

5-4 1KGT 150 798 V002 1 ABB AG

Function Description Release 11 Programmable Logic Control (PLC)

PLC – SCADA processing

Data point type Data point send condition

SCO, DCO, RCO, ASO, The SE (select) or EX (execute) flag has a status

BSOx, DSOx, FSO change compared to the last task cycle and COT

(cause of transmission) is not zero.

SSC The EX (execute) flag has a status change compared to

the last task cycle and COT (cause of transmission) is

not zero.

Table 5: Data point Send conditions for the PLC output handler

Signal processing

This chapter describes the possible signal flow between a network control center

(NCC), the PLC, and the I/O processing or subordinate RTU.

Messages and commands

Process data points that can be connected via hardware can be defined from the

I/O hardware or sub RTU (both are referred to as I/O device hereafter) using a PLC

function.

This function also allows the definition of virtual process data points. Virtual

process data points are handled by a network control center (NCC) in the same

way as process data points but are not processed by the I/O device.

Network Control Center (NCC)

Virtual Virtual

Confirm. command message

Normal

command

PLC Normal

message

PLC used PLC used

command message

I/O Processing or Sub RTU

Figure 10: Signal flow between NCC, PLC, and I/O device

The figure above shows, in principle, the logical signal flow of messages and

commands between NCC and I/O device.

The following signal types are supported by the PLC:

Virtual message

Adding a virtual message to a PLC task in the configuration enables the PLC

to send a message to the NCC. This message cannot be sent by the I/O

device. Virtual messages are represented in the OUTPUT memory of the

PLC.

Virtual command

Adding a virtual command to a PLC task in the configuration enables the

PLC to receive this command from the NCC and return the confirmations. As

the command is invisible to the I/O device, the I/O device is unable to

execute it. Virtual commands for activation or deactivation are represented in

the INPUT memory. Virtual commands for confirmations are represented in

the OUTPUT memory.

ABB AG 1KGT 150 798 V002 1 5-5

Programmable Logic Control (PLC) Function Description Release 11

PLC – SCADA processing

Message used by PLC

Messages are part of the regular signal flow between I/O device and NCC.

Selecting a message data point for use by the PLC in the configuration

enables the PLC to receive this message. Messages used by the PLC are

represented in the INPUT memory of the PLC.

Command used by PLC

Commands are part of the regular signal flow between I/O device and NCC.

Selecting a command data point for use by the PLC in the configuration

enables the PLC to send and receive the command and the confirmations.

Commands for activation or deactivation used by the PLC are represented in

the OUTPUT memory. Commands for confirmations used by the PLC are

represented in the INPUT memory.

In order for the PLC to receive data from or send data to data points, PLC-specific

information needs to be configured for the data points.

System event processing

System events (SEVs) are received by the PLC. SEVs of sub-RTUs are not

supported. Selecting a SEV for use by the PLC in the configuration enables the

PLC to receive the system event (similar to messages from the I/O device).

System command processing

System Single Commands (SSCs) can be received and sent by the PLC. Selecting

an SSC for use by the PLC enables the PLC to handle the SSC in the same

manner as commands used by the PLC.

System event messages

There are two SEVs available for signaling the state of active PLC tasks:

System Event #046: At least one PLC function not running

System Event #047: At least one PLC cycle time exceeded

Characteristic technical data

Property Value

1000 Boolean instruction lines approx. 10 ms

1000 BOOL8 and INT instruction lines approx. 10 ms

Shortest task cycle period configurable 10 ms

Memory capacity (program/data) ≤ 8 MB configurable

absolute

Program memory consumption approx. 10 kB per 1 000 instructions

Program memory capacity per POU 64 kB

I/O image capacity configurable max. 2 000 INPUT and 2 000 OUTPUT

signals

Maximum number of user tasks 15

Table 6: Characteristic technical data

5-6 1KGT 150 798 V002 1 ABB AG

Function Description Release 11

6 Redundancy

6.1 Overview

Being able to access stations in energy transmission and distribution networks at

all times is a fundamental requirement of network operators. RTU560 manages this

requirement by providing a sophisticated redundancy concept that includes the

following features:

Redundant power supply (only RTU560)

Redundant communication lines, or links

Redundant communication units (CMU) (only RTU560)

With this concept, RTU560 fulfills the highest availability requirements.

6.2 RTU560 redundant CMU concept

As a key component of the redundancy concept, one or more pairs of CMU boards

exist for communication lines and functions that are critical to the operation of the

station. In the event of an error condition, the RTU560 initiates a switchover to the

standby CMU. The standby CMU performs a warm start and subsequently takes

over the tasks from the faulty CMU.

One pair of CMUs in an RTU560 configuration can be defined as a redundant

communication set. In the event of an error of an active CMU, the system initiates a

switchover to the redundant standby CMU. The standby CMU performs a cold start

and subsequently takes over processing from the faulty CMU. Other redundant

sets of CMUs in the configuration will not be affected in their operation.

There are three redundancy types of RTU560 CMU modules:

The active CMU, which is the active (i.e., running) device

The standby CMU, which monitors the active CMU and is prepared to take

over as an active device

The non-redundant CMU, which operates continuously

Supervising the state of the RTU560 in such a scenario requires the standby CMU

and the active CMU to monitor each other, in order to be able to take over the state

of a failed CMU if necessary. For instance, a standby CMU in a failed state is not

allowed to switch over; the active CMU must inform the host about the failure in the

standby CMU. On the other hand, the standby CMU must detect a silent failure of the

active CMU (without any alarm or warning message) and take over the active state.

ABB AG 1KGT 150 798 V002 1 6-1

Redundancy Function Description Release 11

RTU560 redundant CMU concept

Figure 11: RTU560 configuration with redundant CMU modules

The above picture shows an example of a redundant RTU560.

The redundant CMUs A and B may have the following configuration:

NCC1 and NCC2 communicate via a serial line protocol (e.g. DNP 3.0).

The I/O modules are organized in two PDP groups and connected to the

CMU 1 of each group.

Some IEDs (e.g., the protection relays for the main transformers) are of high

importance, and are therefore connected to the redundant CMUs A2 and B1.

The non-redundant CMUs may have the following tasks:

A third NCC

PLC

Process event / Disturbance file / Load profile archive

IEDs (e.g. additional protection relays)

6-2 1KGT 150 798 V002 1 ABB AG

Function Description Release 11 Redundancy

RTU560 redundant CMU concept

6.2.1 Master and slave concept

For time administration within the RTU560, a time master needs to be defined

using RTUtil500. All other configured CMU modules are defined as slave CMUs.

The time master is responsible for time administration of the entire system, and for

synchronizing all slave CMUs.

In addition, a system administration master is automatically defined for every

RTU560 system. The system administration master supervises the entire system.

During start-up, the communication boards select the active communication board

with the lowest rack address and slot address as the system administration master.

The time master can also be configured with redundant CMU modules. In the event

of a failure, the system will then automatically switch over to the second CMU,

which is defined as a secondary master.

6.2.2 Redundancy switchover

A redundancy switchover will be triggered if system errors are detected on one of

the active CMUs or on a PLC program using a single system command.

A redundancy switchover will not be triggered by the following:

Failure of a communication link to a master system or subsystem

Firmware or configuration errors

PLC alarm condition initiated by a PLC program

A redundancy switchover can also be forced by the connected NCCs using the

System Single Commands (SSC):

SSC (#016 … #031) Switch-over to CMU #x, 1 ≤ x ≤ 16

6.2.3 Impact on RTU functions

Process data processing

The Process Data Processing (PDP) module takes over communication on the

RTU560 peripheral bus and reads all values from the I/O boards.

The counter values (ITI) are transferred during the following cycle.

ABB AG 1KGT 150 798 V002 1 6-3

Redundancy Function Description Release 11

RTU560 redundant CMU concept

PLC functions

PLC functions configured on a redundant CMU board

In the event of a redundancy switchover, the PLC program on the new active CMU

waits for a complete refresh of the I/O data for the Process Data Base (PDB) of the

PLC module. Upon successful refresh, a cold start of the PLC application is

performed.

CAUTION

The *.pro PLC configuration file has to be loaded to both redundant boards. It will

not be distributed automatically.

After a restart of a PLC program timers and storage, functions are started with

their initial values.

PLC Function configured on a non-redundant CMU board

This PLC program is not stopped because of a redundancy switchover. During

switchover, the PLC will continue to run using the latest actual values available.

The PLC program is thus able to read the status of the system, allowing it to define

its actions during the switchover period. Upon completion of the start-up of new

active CMU, all data points originating from a redundant CMU are updated. The

PLC then continues in normal operation. It is possible to combine redundant PLC

tasks and non-redundant PLC tasks in a single RTU560 system.

Logic function

The Logic function can only be configured on one CMU of an RTU560 and

supports CMU redundancy. In the event of a redundancy switchover, all derived

process information is recomputed during the switchover process.

Archive and Local Print, integrated HMI

The Disturbance Data Archive, the Load Profile Archive, and the Local Print

function have to run on non-redundant CMUs.

CAUTION

If process archives are used on a redundant system, data loss can occur.

In the event of a switchover, the process archive is NOT synchronized. Archive

recording is suspended during switchover.

6-4 1KGT 150 798 V002 1 ABB AG

Function Description Release 11 Redundancy

RTU560 redundant CMU concept

Time administration

It is possible to connect the real-time-clocks 560RTC01, 560RTC02, or 560RTC03

to a redundant pair of CMUs.

When using real-time-clocks in a CMU redundancy scenario, make sure to connect

the Serial Peripheral Bus (SPB) to both the active CMU and the standby CMU. The

SPB takes care of reading the time information.

Simple Network Management Protocol (SNMP)

Basic concepts

The Simple Network Management Protocol is a UDP-based network protocol. It is

used in network management systems to monitor network-attached devices for

conditions that warrant administrative attention.

In a typical SNMP usage scenario, an administrative computer, called "manager" or

"client", has the task of monitoring a group of devices on a computer network. Each

managed system continuously runs a software component, called an "agent",

which acts as server and reports information via SNMP to the manager.

Essentially, an SNMP server represents monitor data as variables. The variables

accessible via SNMP are organized in hierarchies. These hierarchies and other

metadata, e.g., type and description of the variable, are described by Management

Information Bases (MIBs). For detailed information about SNMP and MIB, refer to

[4] and [5].

In the RTU560, SNMP is used to monitor network devices (or elements) connected

to the RTU560. That means that RTU560 acts as manager (client), and requests

information from connected SNMP servers.

CAUTION

The RTU560 does not support SNMP as server. No SNMP agent can be run on

an RTU560. It is therefore not possible to monitor or manage an RTU560 via

SNMP.

CAUTION

RTU560 supports only version 1 of the SNMP protocol. Network elements to be

monitored by RTU560 must answer requests in SNMPv1 format.

The monitoring of connected network elements serves to determine whether the

elements are operable. For this purpose, the RTU560 requests standard variables

via SNMP. The requested variables pertain to the system group that is mandatory

for all managed systems.

ABB AG 1KGT 150 798 V002 1 6-5

Redundancy Function Description Release 11

RTU560 redundant CMU concept

In detail, the following SNMP variables are requested:

iso/org/dod/internet/mgmt/mib/system/sysObjectID (1,3,6,1,2,1,1,2)

The vendor's authoritative identification of the network element. Static

identification in form of a SNMP object identifier.

iso/org/dod/internet/mgmt/mib/system/sysUpTime (1,3,6,1,2,1,1,3)

The time (in hundredths of a second) since the network element was last

re-initialized. While network element is running and operable, the time tick

returned must increase.

These variables are requested every 30 seconds from each configured network

element. The results of the requests, representing the state of the network element,

are combined in a system event. The network element numbers are mapped to the

corresponding system events SEV#192 to #223.

A network element and the corresponding system event are operable when the all

of the following conditions apply:

The network element answers to both requests.

The returned variables are in the correct format.

The value of the sysUpTime variable changed from one request to another.

For monitoring via SNMP, the RTU560 supports non-redundant and redundant

configurations.

Non-redundant CMU configuration

The following figure shows a non-redundant CMU configuration:

Figure 12: Non-redundant SNMP monitoring configuration

RTU560 provides SNMP-based monitoring of network elements for one element

per Ethernet interface, i.e., each SNMP manager monitors a single network

element.

6-6 1KGT 150 798 V002 1 ABB AG

Function Description Release 11 Redundancy

RTU560 redundant CMU concept

Redundant CMU configuration

The following figure shows a redundant CMU configuration:

Figure 13: Redundant SNMP monitoring configuration

The redundant configuration follows the concept described in the previous chapter.

A pair of CMUs is defined as a redundant communication set. In the event of an

error of an active CMU, the system will switch over to the redundant standby CMU,

which will continue processing after performing a cold start. In this redundancy

concept, SNMP monitoring can be used to perform a switchover in the event that

the network element connected to the active CMU should fail.

In redundant configurations, one network element is connected to the active CMU

and another network element is connected to the standby CMU. The active CMU

and the standby CMU are assigned the same IP address but only one CMU is

online at a time. The connected network elements, on the other hand, have

different IP addresses because both are online at any time.

Both network elements are configured in the SNMP Network Element Supervision

parameter of the active CMU. The parameters for the main system refer to the

network element connected to the active CMU. The parameters for the standby

system refer to the network element connected to the standby CMU.

ABB AG 1KGT 150 798 V002 1 6-7

Redundancy Function Description Release 11

RTU560 redundant CMU concept

SNMP configuration (RTUtil500)

In RTU560, the parameters for SNMP monitoring are part of the Ethernet interface

configuration. For each Ethernet interface in a RTU560, a single SNMP manager

can be configured to monitor a device connected to that interface.

Parameter name Parameter location

SNMP Network Element Supervision Ethernet Interface parameters

CAUTION

The maximum number of SNMP managers per RTU is 32.

For each Ethernet interface, a single SNMP manager can be configured.

Consequently, two SNMP manager can be configured on a CMU with two

Ethernet interfaces.

CAUTION

Each SNMP manager can supervise one connected network element.

If more elements shall be supervised in the same network, several CMUs or a

CMU with two Ethernet interfaces must be used.

Each SNMP manager must have a unique number. Possible numbers are 1 .. 32.

The configured number defines the system event that represents the supervision

state of the network element.

Parameter name Parameter location

SNMP Network Element Number Ethernet Interface parameters

The system event representing the monitoring state can have one of the following

values:

Operable

Not operable

The configuration specific to the network element configuration is performed in the

SNMP Network Element Supervision parameter.

Configuration of this parameter depends on the CMU configuration type

(non-redundant vs. redundant).

For non-redundant configurations, only the parameters for the network element

main system are relevant. In these configurations the parameters for the standby

system are not taken into account.

For each network element, a name can be defined in the configuration. This name

is used for documentation purposes.

6-8 1KGT 150 798 V002 1 ABB AG

Function Description Release 11 Redundancy

RTU560 redundant CMU concept

Parameter name Parameter location

Network element name SNMP Network Element Supervision

The IP address of the network element is configured in the SNMP Network

Element Supervision parameter.

Parameter name Parameter location

Network element IP address SNMP Network Element Supervision

CAUTION

All configured network elements must be visible to the Ethernet interface that

connects to the network.

Consequently, the IP address and subnet mask of the Ethernet interface must be

set in accordance with the rules for TCP/IP networking.

In redundant configurations, a name and an IP address is configured for each

network element. In redundant configurations, an automatic switchover in the event

of a breakdown can be set as an additional parameter. In this setup, monitoring of

the network element is used for switching over from the active CMU to the standby

CMU in the event that the element connected to the active CMU becomes

inoperable.

Parameter name Parameter location

Switch over in case of breakdown SNMP Network Element Supervision

CAUTION

If both network elements in a redundant configuration become inoperable, the

system acts as follows:

If the first network element becomes inoperable, a single switchover is performed

(from active CMU to stand-by CMU).

If the second element becomes inoperable, the system remains in its current

state. No switchback takes place.

ABB AG 1KGT 150 798 V002 1 6-9

Redundancy Function Description Release 11

RTU560 redundant CMU concept

6.2.4 RTUtil500 configuration

Configuration of the master and slave board in a redundant CMU configuration is

performed in the RTUtil500 engineering tool.

RTUtil500 identifies two configuration aspects:

Time administration mode

Initial redundancy mode

Time administration mode defines a redundant, or non-redundant, CMU as the

time master. The time master is responsible for time administration of the entire

system. In order to serve as a time master, a real time clock (560RTC01,

560RTC02, or 560RTC03) needs to be connected to the relevant CMU.

Initial redundancy mode defines the default redundancy configuration of a CMU

after successful start-up of a system that operates properly. The following values

are available for Initial redundancy mode:

Active

Standby

Figure 14: Time administration mode and Initial redundancy mode

6-10 1KGT 150 798 V002 1 ABB AG

Function Description Release 11 Redundancy

RTU560 redundant CMU concept

Figure 15: Redundant CMU configuration in RTUtil500

6.2.5 RTU500 series redundant communication

NCCs and IEDs can have redundant communication lines to the RTU. The

availability of redundant lines depends on the used protocol type.

Redundant Host Communication Interfaces

Redundant communication lines to NCCs are available for the following protocols:

IEC 60870-5-101

IEC 60870-5-104

RP570/71

Conitel 300

DNP3

DNP3 LAN/WAN

For more information, refer to the relevant protocol description.

Redundant Subdevice Communication Interface

Redundant subdevice communication lines are available for the following protocols:

IEC 60870-5-101

IEC 60870-5-104

Conitel 300

Modbus

Modbus TCP/IP

The functionality of redundant subdevice communication lines is handled by SSCs

and monitored by SEVs.- For more information, refer to the corresponding sections

of this document.

ABB AG 1KGT 150 798 V002 1 6-11

Redundancy Function Description Release 11

RTU560 redundant CMU concept

Modem pools for Subdevice Communication Interfaces

Dial-up modems can be connected to the serial, or Ethernet, communication

interface of a CMU.

Multiple devices can be connected to one or several modems. Redundant

communication lines to subordinate devices can also be configured. The pool of

modems connected to the system is managed by RTU560.

The Modem Pool function is controlled by means of SSCs. Generation of the SSCs

is based on commands from the NCCs. For more information, refer to the relevant

sections in this document.

SSC ( #3 … #11 ): System Single Commands

6-12 1KGT 150 798 V002 1 ABB AG

Function Description Release 11

7 Start-up, Configuration and Time Management

7.1 Start-up procedures

The RTU500 series supports two start-up types:

Single CMU start-up

Multiple CMU start-up

Only the RTU560 supports multiple CMU start-ups. The single CMU start-up is a

special case of the multiple CMU start-up.

An RTU560 series system may contain several CMUs, e.g., 560CMU02 R0002,

560CMU05. Activities, such as communication protocols, I/O bus interfaces or PLC

functions, may be configured as required to be running on different CMUs.

RTU500 series supports the following start-up procedures:

RTU System Start

Power ON or reset of the RTU system is common to all RTUs of the RTU500

series

RTU560 CMU Start

Power ON or reset of a CMU of an RTU560 system

RTU560 CMU Integration

Hot-plugging of a CMU into a running RTU560 (only in RTU560 systems with

multiple CMUs)

RTU Protocol Restart

Communication protocols often provide specific methods to restart the RTU.

The RTU may support various protocols. For information on the available

restart methods, refer to the relevant protocol description.

7.1.1 RTU System Start

System start of a RTU500 series (Power ON or reset of the RTU) is managed by

System Control, which is running on the master CMU. The system start sequence

is as follows:

After CMU start (see chapter RTU560 CMU start (page Fehler!

Verweisquelle konnte nicht gefunden werden.)), System Control requests

the configured boards and waits 5 s for their registration (only for RTU560).

RTU System Control starts the configured activities on the registered CMUs

in the following order:

Archive and Print functions

Host Communication Interfaces (slave protocols, no communication)

Subdevice Communication Interfaces (master protocols)

I/O bus interfaces (PDP)

PLC and local function tasks

Subdevice interfaces and I/O bus request data from subdevices and I/O

boards. System Control waits until they report their databases to be up to

date.

The configured host interface(s) start(s) communication with the NCC.

ABB AG 1KGT 150 798 V002 1 7-1

Start-up, Configuration and Time Management Function Description Release 11

Start-up procedures

System monitoring is started to enable removal and insertion of CMUs (only

for RTU560).

7.1.2 RTU560 CMU start

When a CMU is started after Power ON or a reset command by an NCC or web

server of an RTU560, the CMU performs the following start-up sequence:

Initialize and test hardware (RAM, FLASH, watchdog, etc.), load firmware

from flash memory

Send the following system message: “CMU x: Starting up …”

If a CMU starting to participate at the system bus, the SEV “CMU x:

operable” is send.

Check if other CMUs are present in the RTU for 5 s. If other CMUs are

present in the RTU for 5 s, the CMU compares its own firmware and

configuration to that of all CMUs present in RTU in the following manner:

The major release version number of the firmware (e.g.: 11 for a Version

11.1.1.0) must be the same on every CMU. If the version number of the

firmware release is not the same on every CMU, the CMU stops further