Академический Документы

Профессиональный Документы

Культура Документы

E560 CMG10 CS PDF

Загружено:

MOHAMMADОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

E560 CMG10 CS PDF

Загружено:

MOHAMMADАвторское право:

Доступные форматы

ABB AG RTU560

Remote Terminal Unit

Connections and Settings

Communication Unit 560CMG10

Application, characteristics and technical data

have to be taken from the hardware data sheet:

560CMG10 1KGT 150 645

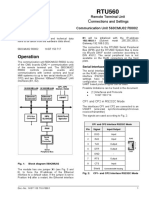

Operation

The 560CMG10 is a DIN Rail RTU consisting of

an integrated communication module (CMU) and

a power supply in a metal DIN Rail Housing.

The essential tasks of the 560CMG10 are:

Managing and controlling of the RTU211

I/O boards via the serial interface (Wired-

OR-Bus).

Reading Process events from the input

boards.

Writing commands to the output boards.

Fig. 1: Block diagram 560CMG10

Communications with control centers and

local MMI systems via the integrated

To force the IP-Address to a default value at start-

serial line interfaces and the implemented

up, the “Def. IP-Addr” switch on the front side (see

Ethernet 10/100BaseT LAN interface. Fig. 3) has to be switched “ON”. The 560CMG10

Managing the time base for the RTU560 starts with the factory settings for the Ethernet

station and synchronizing the I/O boards. Interface (see Fig. 2) which are 192.168.0.1 for

the IP- address with the network setting

Handling the dialogue between RTU560

255.255.255.0 for the subnet mask and

and Web-Browser via LAN interface.

192.168.0.20 for the gateway.

Switch „Def. IP- Address“

ON position OFF

?

Read IP address

Send Configuration from confi-

to RTU 192.168.0.1 guration file

Set Switch

„Def. IP-Address“

to „OFF“

Fig. 2: Use Switch „Def. IP-Addr“

Doc.-No.: 1KGT 150 646 V002 1 1

ABB AG

Connections and Settings 560CMG10 RTU560

CPA Interface CP1 and CP2 Interface

The CPA Interface is available on the RJ45

The CP1 and CP2 Interfaces USART (universal

connector. It can interface RS485 signals. The

synchronous/asynchronous receiver/transmitter)

bus is terminated by a 1 k resistor.

are available on the RJ45 connectors. They can

The settings have to be done by the RTUtil560 Interface RS232C signals. On both Interfaces

configuration tool. The signals are used according different UART based protocol types can be used.

to Tab. 1

The signals are used according to Tab. 2

CPA Interface RS485 Mode

CP1 and CP2 Interface RS232C Mode

Pin Signal

Pin Signal Input/Output

1 - Not used

1 DCD Input

2 TA Data -

2 RxD Input

RJ45

3 TB Data + RJ45

3 TxD Output

Rx 1

4 - Not used Rx 1

4 DTR Output

Tx 8

5 GND Signal Ground Tx 8

Jack

5 GND -

6 - Jack

7 RTS Output

7 - Not used

8 CTS Input

8 -

Shield Connected with housing

Tab. 1 CPA Interface RS485 Mode

Tab. 2 CP1- and CP2 Interface RS232C Mode

2 Doc.-No.: 1KGT 150 646 V002 1

ABB AG

Connections and Settings 560CMG10 RTU560

Ethernet Interface Power Supply DC- In

The supply voltage for the 560CMG10 is 24VDC.

The Ethernet Interface is available on a RJ45

The connector consists of a 3 pole pluggable

connector and supports different functions:

screw-terminal 5,08mm (see Tab. 4 and Fig. 3

Webserver-diagnostic with download of DC-IN). The max. input power is 67 Watt.

configuration files and firmware

TCP/IP based protocols IEC 60870-5-

104, DNP3, … Power -Supply

Integrated HMI DC-Out DC-IN Pin

The signals are used according to Tab. 3 Earth Earth 1

Vout (-) Vin (-) 2

Ethernet Interface

Vout (+) Vin (+) 3

Tab. 4: 3 Pole Power Connector

Pin Signal Input/Output

1 TD + Output

In some cases an external potential

isolation for the DC-Input is

2 TD - Output

! necessary. This can be done e.g. by

3 RD + Input a power supply unit 560PSU40/41.

RJ45

4 Not used

Lnk

5

1

Power Supply DC- Out

Act 8 The 560CMG10 provides 24VDC output power for

6 RD - Input max. 0.5A. The connector consists of a 3 pole

Jack pluggable screw-terminal 5,08mm (see Tab. 4 and

7 Not used

Fig. 3 DC-Out). The output power can only be

8 used for the relay output board (23BO61/62).

Shield Connected with

housing It is not allowed to use the output

Tab. 3 Ethernet Interface ! power for the process supply!

IO-Bus

560CMG10 Earthing

The connection to the local I/O boards is done by

a 20 pole female connector. The connection to the On the strength of safety and EMC protection it is

RTU560G serial peripheral bus (Wired OR-Bus) is important to make a connection as short as

possible to a system earth (may be DIN-rail or

done by a 20 pole male connector (see Fig. 3 IO-

BUS). The order of the 23AD62 module includes mounting plate). An ordinary 1.5mm 2 multi-core

wire (green/yellow) can be used and should not

one ribbon cable with the length of 19cm

exceed a length of 100 cm (39 inch). The first pin

(7,5inch). The ribbon cable should not exceed a

of the 3 pole DC-In connector is the earth-pin (see

length of 50cm (20inch).

Tab. 1 and Fig.3 DC-IN). The protection earth

must be connected there.

Attention: It is not allowed to pull The power supply terminal X38 (Vin -) is internal

! or to plug the 20 pole ribbon connected with the housing ground by jumper X43

cable during the operation (see Fig. 3 or Fig. 4). In rare cases (e.g. when

process. grounding signal zero to Vin (+)) the jumper X43

has to be removed. Opening of the housing is

done in the same way as for changing the CF

card.

Doc.-No.: 1KGT 150 646 V002 1 3

ABB AG

Connections and Settings 560CMG10 RTU560

Signaling

Firmware Version

The red LED of the 560CMG10 is controlled by

the RTU560 firmware. For the definition and The current firmware version will be delivered on

operation of the LED “ERR" please refer to the a CompactFlash memory card. A new firmware

release specific function description. The file can be loaded via the Web diagnostic tool into

connector embedded LEDs “Tx” and “Rx” are the removable CompactFlash memory card.

directly connected to the receiver/transmitter of For changing the CompactFlash memory card the

the communication line. The LEDs “LAN" are right side of the housing has to be opened (see

directly connected to the Ethernet-controller. Fig. 3).

Tab.2 describes the system LEDs of the

560CMG10. For changing the CF - card

! follow the instructions below:

LED Colour Meaning

ERR red Warning / Error

1. Disconnect the power-supply of the

T (3x) green Transmit data (CP1, 2, A)

560CMG10.

R (3x) green Receive data (CP1, 2, A)

Ethernet Activity / Link

2. Take care of ESD protection before

LAN (2x) green

opening the 560CMG10 housing.

IO-Bus (1x) green Serial Peripheral Bus

Power red One of the output voltage 3. Open the 4 screws on the right side of

Fail is fail the housing (see Fig. 3).

RUN green The CMU is reachable 4. Pull or plug only the CF-card. Don’t

via Ethernet touch other components.

RUN yellow The firmware is running

but not reachable via 5. Close the housing before the power-

Ethernet supply is connected to the 560CMG10

RUN OFF No firmware is running

Def. IP- red The default IP-address is

Addr active

Tab. 5: Meaning of LEDs

4 Doc.-No.: 1KGT 150 646 V002 1

ABB AG

RTU560 Connections and Settings 560CMG10

Settings

The settings of the Ethernet Interface are:

Hardware settings and operation of the

communication Interfaces of the 560CMG10 are Node name

carried out with the RTUtil560 configuration tool. IP address

For the configuration procedure of the

communication Interfaces and the IO-Bus, please Subnet mask

refer to the 560RTUtil user guide. Default gateway

The following parameters have to be defined for Routing information

all protocols:

The number of the host Interface.

Baudrate: 50 to 19 200 baud

Modem control:

Direct link (TxD/RxD only)

WT link full duplex (560FSM10/11 no

handshake)

WT link half duplex (560FSM10/11 with

RTS / DCD)

Dial up (external modem without

handshake, without RTS / CTS)

Loop switch unit (RP570/71 Host

Interface only)

Link with collision avoidance (TxD, RxD,

DCD, without handshake (DNP 3.0 only)

Doc.-No.: 1KGT 150 646 V002 1 5

ABB AG

Connections and Settings 560CMG10 RTU560

screws

DC-Out 24V DC-In

-

Error

+

Power

Run RTU560

CF-Card

Off On

Def. IP-Addr

560CMG10

IO-Bus

Tx

CPA CP1 Tx

CP2 LAN

Rx Rx

IO-Bus Tx Rx Tx RX Tx RX Lnk ACT

screws

Fig.3: Front and right side of the 560CMG10 housing

Fig. 4 : Placement of jumper X43 at CMU PCB.

6 Doc.-No.: 1KGT 150 646 V002 1

ABB AG

RTU560 Connections and Settings 560CMG10

Doc.-No.: 1KGT 150 646 V002 1 7

ABB AG

Connections and Settings 560CMG10 RTU560

ABB AG

Power Technologies Division

Power Technology Systems

Kallstadter Str.1, D 68309 Mannheim

Telephone: +49 (0) 621 381-7592

Fax: +49 (0) 621 381-7622

www.abb.com

8 Doc.-No.: 1KGT 150 646 V002 1

Вам также может понравиться

- 2005-07 Ranger 500 EFI 2X4 4X4 Service ManualДокумент345 страниц2005-07 Ranger 500 EFI 2X4 4X4 Service ManualBrian Cook100% (5)

- Chevrolet Captiva Service Manual. MAINTENANCE AND REPAIR.Документ57 страницChevrolet Captiva Service Manual. MAINTENANCE AND REPAIR.krisdiarto@gmail.com96% (23)

- CRX Seat Diassembly & Assembly 1Документ9 страницCRX Seat Diassembly & Assembly 1ocdank19806116Оценок пока нет

- Group 2 (ME 03) - Hoa Phat GroupДокумент42 страницыGroup 2 (ME 03) - Hoa Phat GroupLê Thành DanhОценок пока нет

- RTU560 InterfaceДокумент15 страницRTU560 Interfacehare ramОценок пока нет

- E560 Cmu04 CSДокумент4 страницыE560 Cmu04 CSAlikОценок пока нет

- P010-0UG PROMAINT User Guide V307 R4Документ81 страницаP010-0UG PROMAINT User Guide V307 R4Ilaiyaa RajaОценок пока нет

- MICROSOL XELL - CONITEL C300 SLAVE Config. Guide For DMTДокумент32 страницыMICROSOL XELL - CONITEL C300 SLAVE Config. Guide For DMTIlaiyaa RajaОценок пока нет

- Defect EliminationДокумент4 страницыDefect EliminationHossein100% (1)

- A320 Documentation (1 CMP) PDFДокумент198 страницA320 Documentation (1 CMP) PDFRamakrishnan AmbiSubbiah75% (4)

- Maxstar140str (KK013519)Документ52 страницыMaxstar140str (KK013519)mrtans0% (1)

- Abb Ag: Remote Terminal Unit Onnections and Settings DIN Rail RTU 560CIG10Документ16 страницAbb Ag: Remote Terminal Unit Onnections and Settings DIN Rail RTU 560CIG10Cosmic Garash 2Оценок пока нет

- E560 Cid11 CS PDFДокумент15 страницE560 Cid11 CS PDFmaximiliano tonsich100% (1)

- E560 Cmu02 CSДокумент4 страницыE560 Cmu02 CSAlikОценок пока нет

- Operation: Connections and Settings Communication Unit 560CMD11Документ10 страницOperation: Connections and Settings Communication Unit 560CMD11Tayeb AmeriОценок пока нет

- E560 Cmu05 CSДокумент4 страницыE560 Cmu05 CSNyrlanОценок пока нет

- Abb Ag: OperationДокумент4 страницыAbb Ag: OperationCosmic Garash 2Оценок пока нет

- 520AOD01 CS enДокумент13 страниц520AOD01 CS enBhageerathi SahuОценок пока нет

- E560 Cmu80 CSДокумент4 страницыE560 Cmu80 CSCosmic Garash 2Оценок пока нет

- Operation: Connections and Settings Communication Unit 560CMU02 R0001Документ4 страницыOperation: Connections and Settings Communication Unit 560CMU02 R0001Cosmic Garash 2Оценок пока нет

- Connections and Settings: Communication Unit 560CMR01Документ4 страницыConnections and Settings: Communication Unit 560CMR01Mohammed MostefaiОценок пока нет

- GFK0682EДокумент2 страницыGFK0682EsabasthianОценок пока нет

- 520CMD01 CS enДокумент4 страницы520CMD01 CS enDJ ThangОценок пока нет

- RS485 Board (3.3V/5V) User Manual: 1. DescriptionДокумент5 страницRS485 Board (3.3V/5V) User Manual: 1. DescriptionCopyMaster2Оценок пока нет

- T-BOX ManualДокумент26 страницT-BOX ManualAndronic SergiuОценок пока нет

- E560 CMG10 DBДокумент5 страницE560 CMG10 DBHoang NguyenОценок пока нет

- Rs485 Modbus CommunicationДокумент44 страницыRs485 Modbus CommunicationmaninderpreetОценок пока нет

- 06,250 (-1), 260 To 240 RS-232 Communications Wiring Diagram: TechnotesДокумент1 страница06,250 (-1), 260 To 240 RS-232 Communications Wiring Diagram: TechnoteswarwarОценок пока нет

- Manual PLC Click ModbusДокумент44 страницыManual PLC Click ModbusDavid Mtz ZuritaОценок пока нет

- Atc-1000 Users Manual v2 0Документ4 страницыAtc-1000 Users Manual v2 0dung110baclieuОценок пока нет

- Mgate Mb3170/Mb3270 Quick Installation Guide: Version 8.1, November 2019Документ7 страницMgate Mb3170/Mb3270 Quick Installation Guide: Version 8.1, November 2019Abd AbdallahОценок пока нет

- Industrial Ethernet Module T-Box: Operating ManualДокумент20 страницIndustrial Ethernet Module T-Box: Operating Manualojrr77Оценок пока нет

- Rtu - SasДокумент19 страницRtu - SasNitin KumarОценок пока нет

- Connection Choices:: Chapter 6: PLC Connection GuideДокумент4 страницыConnection Choices:: Chapter 6: PLC Connection GuideSayed Ibrahim GhanemОценок пока нет

- Mgate Mb3170/Mb3270 Quick Installation Guide: Edition 7.1, February 2016Документ6 страницMgate Mb3170/Mb3270 Quick Installation Guide: Edition 7.1, February 2016heikelОценок пока нет

- Idm-6830 and Idm-7842dag (C)Документ22 страницыIdm-6830 and Idm-7842dag (C)BOsy Ying LoОценок пока нет

- SCADA EstimationДокумент18 страницSCADA Estimationrajinder_hpiphОценок пока нет

- Connections and Settings: Communication Unit 560CMU02Документ5 страницConnections and Settings: Communication Unit 560CMU02Mohammed MostefaiОценок пока нет

- LM5 RIOL Lite DatasheetДокумент12 страницLM5 RIOL Lite DatasheetStilux VoltОценок пока нет

- UT-2201 User ManualДокумент1 страницаUT-2201 User ManualSeka Vilar SorucoОценок пока нет

- 500NMD20 OI enДокумент7 страниц500NMD20 OI enDJ ThangОценок пока нет

- Abb Ag: OperationДокумент4 страницыAbb Ag: OperationCosmic Garash 2Оценок пока нет

- BuR X20 HardwareДокумент14 страницBuR X20 HardwarecelinОценок пока нет

- Device Profile Document MODBUS TAPCON 230 Expert 2195774-00 ENДокумент20 страницDevice Profile Document MODBUS TAPCON 230 Expert 2195774-00 ENSUBSTATION TOSYALIОценок пока нет

- IC200ACC415 DS RS232 RS485 Interface Adapter VersaMaxMicroNano GFK1834 2002Документ1 страницаIC200ACC415 DS RS232 RS485 Interface Adapter VersaMaxMicroNano GFK1834 2002jav_08Оценок пока нет

- ELEGOO BT16 Bluetooth UART ModuleДокумент10 страницELEGOO BT16 Bluetooth UART ModuleAhmadiAnouarОценок пока нет

- RS-232 To RS-485: User ManualДокумент6 страницRS-232 To RS-485: User ManualEdward MainaОценок пока нет

- 05 - Module de Communication Modbus TCP Rx3iДокумент13 страниц05 - Module de Communication Modbus TCP Rx3iZouhair IguerhzifenОценок пока нет

- Cpu 201 enДокумент2 страницыCpu 201 enAnis Fikri AzhariОценок пока нет

- BACnet Gateway 201-BEДокумент2 страницыBACnet Gateway 201-BERICADO LOPEZ OROZCOОценок пока нет

- 31-302 Eng Ds Pcd3m6560-ProfibusДокумент2 страницы31-302 Eng Ds Pcd3m6560-ProfibusZé CerqueiraОценок пока нет

- Gateway IOT BrochureДокумент9 страницGateway IOT BrochureBenjamin BarrientosОценок пока нет

- ADDENDUM Aegis II Communication Driver Card Manual RevDДокумент30 страницADDENDUM Aegis II Communication Driver Card Manual RevDEduardoОценок пока нет

- P142 OrderForm - v46 - 032021 - MBAДокумент11 страницP142 OrderForm - v46 - 032021 - MBATuan Dang AnhОценок пока нет

- Delta DVPДокумент2 страницыDelta DVPyahia abdelliОценок пока нет

- Data Sheet: Communication Unit 560CMR01Документ5 страницData Sheet: Communication Unit 560CMR01Mohammed MostefaiОценок пока нет

- Extension of Existing SCADA System For Chittagong-Feni-Bakhrabad Gas Transmission Pararell Pipeline ProjectДокумент7 страницExtension of Existing SCADA System For Chittagong-Feni-Bakhrabad Gas Transmission Pararell Pipeline ProjectHarun RashidОценок пока нет

- ATC-2000 Datasheet V4.0Документ2 страницыATC-2000 Datasheet V4.0bacОценок пока нет

- Gateway e 2m G SHDSL 2 3 4 6 Mbps nx64 ModemДокумент2 страницыGateway e 2m G SHDSL 2 3 4 6 Mbps nx64 ModemfatimarconnectОценок пока нет

- MbgatewayДокумент4 страницыMbgatewayCie CieОценок пока нет

- RM-012-IP - TCP To RS-485 ConverterДокумент2 страницыRM-012-IP - TCP To RS-485 ConverterSHARAB IMTIAZОценок пока нет

- Communication Interface: SD20 Series Digital IndicatorДокумент28 страницCommunication Interface: SD20 Series Digital IndicatorChristianОценок пока нет

- LoRa-E5 Module Datasheet - V1.0Документ18 страницLoRa-E5 Module Datasheet - V1.0Вадим МкртчянОценок пока нет

- Dokumen - Tips - Protocol Description Iec 60870 5 101Документ18 страницDokumen - Tips - Protocol Description Iec 60870 5 101alextivanОценок пока нет

- COM 02 030 DatasheetДокумент14 страницCOM 02 030 DatasheetpawallerОценок пока нет

- EZ035 ES-U-3001-M - USB-COMi-M - Manual-1Документ9 страницEZ035 ES-U-3001-M - USB-COMi-M - Manual-1shazziiiОценок пока нет

- G703 Interface Adapter IB40 201 7Документ9 страницG703 Interface Adapter IB40 201 7renjithas2005Оценок пока нет

- CISCO PACKET TRACER LABS: Best practice of configuring or troubleshooting NetworkОт EverandCISCO PACKET TRACER LABS: Best practice of configuring or troubleshooting NetworkОценок пока нет

- SWM0101 MCP Software Configuration Guide V311 R1Документ850 страницSWM0101 MCP Software Configuration Guide V311 R1Ilaiyaa RajaОценок пока нет

- 994 0145 D20E Ethernet IOModule Manual V100 R0Документ148 страниц994 0145 D20E Ethernet IOModule Manual V100 R0zerothonОценок пока нет

- 507-0101-ML Rev 04Документ1 страница507-0101-ML Rev 04Ilaiyaa RajaОценок пока нет

- SWM0101 G500 Software Configuration Guide V100 R0 PDFДокумент625 страницSWM0101 G500 Software Configuration Guide V100 R0 PDFIlaiyaa RajaОценок пока нет

- 994 0152 G500 Instruction Manual V260 R1Документ121 страница994 0152 G500 Instruction Manual V260 R1Ilaiyaa RajaОценок пока нет

- 977-0556-AD Rev 03Документ1 страница977-0556-AD Rev 03Ilaiyaa RajaОценок пока нет

- SWM0101 G500 Software Configuration Guide V100 R0 PDFДокумент625 страницSWM0101 G500 Software Configuration Guide V100 R0 PDFIlaiyaa RajaОценок пока нет

- Workbench IO Configuration ManualДокумент37 страницWorkbench IO Configuration ManualIlaiyaa RajaОценок пока нет

- Workbench User ManualДокумент89 страницWorkbench User ManualIlaiyaa RajaОценок пока нет

- XCell Troubleshooting ManualДокумент196 страницXCell Troubleshooting ManualIlaiyaa RajaОценок пока нет

- XCell User GuideДокумент49 страницXCell User GuideIlaiyaa RajaОценок пока нет

- XCell Troubleshooting ManualДокумент196 страницXCell Troubleshooting ManualIlaiyaa RajaОценок пока нет

- XCell User GuideДокумент49 страницXCell User GuideIlaiyaa RajaОценок пока нет

- Workbench User ManualДокумент89 страницWorkbench User ManualIlaiyaa RajaОценок пока нет

- Workbench IO Configuration ManualДокумент37 страницWorkbench IO Configuration ManualIlaiyaa RajaОценок пока нет

- Workbench User ManualДокумент89 страницWorkbench User ManualIlaiyaa RajaОценок пока нет

- IEC60870-5-104 SLAVE Config. Guide For WorkbenchДокумент27 страницIEC60870-5-104 SLAVE Config. Guide For WorkbenchIlaiyaa RajaОценок пока нет

- IEC60870-5-104 SLAVE Config. Guide For WorkbenchДокумент27 страницIEC60870-5-104 SLAVE Config. Guide For WorkbenchIlaiyaa RajaОценок пока нет

- 994-0140 d20mx Instruction Manual v15x r0Документ218 страниц994-0140 d20mx Instruction Manual v15x r0Ilaiyaa RajaОценок пока нет

- Workbench IO Configuration ManualДокумент37 страницWorkbench IO Configuration ManualIlaiyaa RajaОценок пока нет

- Workbench User ManualДокумент89 страницWorkbench User ManualIlaiyaa RajaОценок пока нет

- 994 0146 d20mx v1.5x Product Documentation Set BinderДокумент4 073 страницы994 0146 d20mx v1.5x Product Documentation Set BinderIlaiyaa RajaОценок пока нет

- Data Display Panel ConfigurationДокумент1 страницаData Display Panel ConfigurationIlaiyaa RajaОценок пока нет

- Workbench IO Configuration ManualДокумент37 страницWorkbench IO Configuration ManualIlaiyaa RajaОценок пока нет

- D25 User's GuideДокумент191 страницаD25 User's GuideIlaiyaa RajaОценок пока нет

- 994-0140 d20mx Instruction Manual v15x r0Документ218 страниц994-0140 d20mx Instruction Manual v15x r0Ilaiyaa RajaОценок пока нет

- DNP3 Primer Rev AДокумент19 страницDNP3 Primer Rev ARick JordanОценок пока нет

- D25 User's GuideДокумент191 страницаD25 User's GuideIlaiyaa RajaОценок пока нет

- Check ListДокумент6 страницCheck ListosersОценок пока нет

- Foaming of Friction Stir Processed Al /mgco3 Precursor Via Ame HeatingДокумент27 страницFoaming of Friction Stir Processed Al /mgco3 Precursor Via Ame HeatingArshad SiddiqueeОценок пока нет

- Poloyagan Integrated School Monitoring Tool On Aip ImplementationДокумент3 страницыPoloyagan Integrated School Monitoring Tool On Aip ImplementationLALAINE BONILLAОценок пока нет

- Upload Photosimages Into Custom Table & Print in Adobe FormДокумент14 страницUpload Photosimages Into Custom Table & Print in Adobe FormEmilSОценок пока нет

- ORT ReportДокумент71 страницаORT ReportNaveen ChodagiriОценок пока нет

- Froth Flush ProcessДокумент33 страницыFroth Flush ProcessnivasssvОценок пока нет

- Water and Environmental Sanitation Strategic Plan BihacДокумент53 страницыWater and Environmental Sanitation Strategic Plan BihacEddiemtongaОценок пока нет

- Guide To Using In-Situ Tensile Pull-Off Tests To Evaluate Bond of Concrete Surface MaterialsДокумент12 страницGuide To Using In-Situ Tensile Pull-Off Tests To Evaluate Bond of Concrete Surface MaterialsMauricio Javier León TejadaОценок пока нет

- ESPRIT Milling Tutorial 02Документ11 страницESPRIT Milling Tutorial 02Sandaruwan සුජීවОценок пока нет

- Nust Entrance TestДокумент16 страницNust Entrance TestShawn Parker80% (30)

- Unit-1 - Spur Gears - Lecture - 6 - Problems Spur Gear - Mahesh GaikwadДокумент13 страницUnit-1 - Spur Gears - Lecture - 6 - Problems Spur Gear - Mahesh GaikwadNikhil JadhavОценок пока нет

- Steering Wheel Slip - Check: Pruebas y AjustesДокумент2 страницыSteering Wheel Slip - Check: Pruebas y AjustesLENIN JHAIR VALDERRAMA SEGURAОценок пока нет

- Symbolic TBДокумент512 страницSymbolic TBJanet LeongОценок пока нет

- Cost BreakdownДокумент241 страницаCost Breakdownbilisuma sebokaОценок пока нет

- Misumi s5m Pulley p1117Документ1 страницаMisumi s5m Pulley p1117tigor carakaОценок пока нет

- Gear Trains ProblemsДокумент9 страницGear Trains Problemsa c s Kumar100% (1)

- Spirent TestCenter Automation Obj RefДокумент3 210 страницSpirent TestCenter Automation Obj Refokie11Оценок пока нет

- Pt. Hans Jaya Utama: Lsagi FactoryДокумент46 страницPt. Hans Jaya Utama: Lsagi FactoryMatthew SiagianОценок пока нет

- 04 Rociador Tyco K11.2 SRДокумент6 страниц04 Rociador Tyco K11.2 SRRuben Saucedo JacomeОценок пока нет

- Microprocessors - Meppayil NarayananДокумент34 страницыMicroprocessors - Meppayil NarayananmeppayilnarayananОценок пока нет

- Technical Information Sheet: General Information: ISO 12944 TI - G 9 / UsaДокумент6 страницTechnical Information Sheet: General Information: ISO 12944 TI - G 9 / UsaBash MatОценок пока нет

- PCTDS 027 Fendolite MII Cold Wet Weather ApplicationДокумент2 страницыPCTDS 027 Fendolite MII Cold Wet Weather ApplicationMohammed AhteshamОценок пока нет

- Pedestrian Design Guidelines PDFДокумент50 страницPedestrian Design Guidelines PDFIvan AndradeОценок пока нет