Академический Документы

Профессиональный Документы

Культура Документы

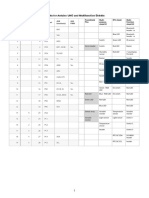

JSW Cement FZE Annex 11 List of Spare Parts

Загружено:

abdullah amanullahОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

JSW Cement FZE Annex 11 List of Spare Parts

Загружено:

abdullah amanullahАвторское право:

Доступные форматы

JSW CEMENT FZE

Annex 11 List of Spare parts for 2 Year Operation

Sl.No Description UOM Quantity

I RAW MILL (ROLLER PRESS CIRCUIT)

A Roller

1 Seal kit for rotary union Set 4

2 Rubber plate / packing for bearing housing No 4

3 Studs for Roller assembly No 20% of total quantity

B Bearing & bearing housing

1 Shaft lip seal complete set Set 4

2 V-seal complete set Set 4

3 Compensating gaskets complete set Set 6

4 Sealing material complete set Set 4

5 O-ring complete kit for bearing housing Set 4

6 Retaining ring Set 2

7 Catch / tyre for seal Set 4

8 Rtd & it's moounting No 2

C Bearings grease lubrication

1 Initiator No 1

2 Plug in connector No 1

3 Filter element No 6

4 Filter for water / strainer No 2

5 Water valve No 1

6 Breateher filter No 4

7 Pressure gauge with connector Set 1

8 Flow sensor with monitor Set 1

9 Progressive grease distributor (all types) No/ each 2

10 Pulse indicator No 1

11 Proximaty switches (all models) No/ each 2

12 Magnetic filter assembly No 1

D Temperature equipment

1 Resistant thermometer oil leak proof No 1

2 Proximity switch inductive No 1

3 Plug in connector No 1

4 Pulse indicator No 1

E Feeding device

1 Lateral wall tip Set 1

2 Bellows No 2

F Hydraulic, manifold and accumulators

1 Gasket & seal set Set 5

2 Transmittor pressure No 1

3 Pump for Hydraulic system No 1

4 Coupling with element Set 1

5 Filter element (all types) No/ each 5

6 Filter with element assembly Set 1

7 Pressure relief valve (all types) No/ each 1

8 Way-globe valve No 1

9 Direction control valve (all model) No/ each 1

10 Press.relief valve (all model) No/ each 1

11 Pressure valve No 1

12 Directional cartridge valve (all model) No/ each 1

13 Pressure valve No 2

Annex 11 List of Spare Parts for 2 Year Operation 1/16 Contract

JSW CEMENT FZE

Annex 11 List of Spare parts for 2 Year Operation

Sl.No Description UOM Quantity

14 Interface adopter No 1

15 Flow control valve (all model) No/ each 1

16 Catridge valve cover No 1

17 Clogging indicator No 1

18 Check valve (all sizes) No/ each 2

19 Pressure gauges with connector (all types) No/ each 1

20 Accumulator No 1

21 Bladder for accumulatror No 3

22 Seal kit for accumulator Set 4

23 Nitrogent filling unit No 1

24 Inl./exl valves No 1

25 Ventilating filter No 1

26 Rotary rheostat & position transmittor Set 1

27 Displacemt.pick-up transducer No 1

28 Water Strainer No 3

29 Hose (all types) No/ each 4

30 Solenoid Valve No

G Cylinder assembly

1 Flat cylinder No 1

2 Seal kit for flat cylinder Set 4

3 Retraction cylinder No 1

4 Seal kit for retraction cylinder Set 4

5 Bellow No 3

H Gear box

1 Seal kit for gear box Set 1

2 Cardon shaft assembly No 1

3 Repair kit for cardon shaft Set 1

4 Safe set coupling assembly for cardon shaft No 1

5 Seal kit for safe set coupling Set 2

6 Bearings for safe set coupling Set 1

7 Elastic coupling No 1

8 Rubber elements for coupling Set 1

9 Pressure monitor No 1

10 Vibration sensor No 1

11 Resistance thermometer with separated transmitter No 1

12 Pressure limiting valve gear box oil supply unit. No 1

13 Heat exchanger No 1

I Lubrication pump unit

1 Pump assembly No 1

2 Oil fiter element (all types) No/ each 4

3 Filter element for water No 4

4 Breather No 4

5 Hose (all types) Set 4

6 Set of seals gear box oil supply unit Nio 2

7 Strainer gear box oil supply unit No 1

J SKS separator

1 Impact ring segment No 1

2 Distribution ring segment No 1

K V separator

Annex 11 List of Spare Parts for 2 Year Operation 2/16 Contract

JSW CEMENT FZE

Annex 11 List of Spare parts for 2 Year Operation

Sl.No Description UOM Quantity

II Pyro system

A Preheater stage from top 1 to bottom 5

1 Flap casting for double flap box for stage-1 No 2

2 Flap casting for double flap box for stage 2 &3 No 2

3 Flap casting for double flap box for stage-4 No 2

4 Flap casting for double flap box for stage-5 No 2

5 Impact plate for inlet chute for raw mill piping (stage-1) No 2

6 Impact plate for inlet chute for raw mill piping stage-2 No 2

7 Impac plate for inlet chute for raw mill piping stage-3 & 4 No 2

8 Impact plate for inlet chute for fresh feed to preheater No 2

9 Flap castings for divertor No 2

10 Complete immerssion tube stage -3 Set 1

11 Complete immerssion tube stage -2 Set 1

12 Set of springs for flap assembly No 10

13 Set of packing rope & sealing kit for flap assembly Set 10

14 Air blaster (each one from all sizes) Set 1

15 Repair kit for air blaster (all size) Set /each 10

16 Timer panel for air blaster No 1

17 Solenoid valve for the air blaster No 5

18 Preheater mettallic expansion joints (all sizes) No/ each 1

B Kiln

1 Kiln outlet casting segment along with support arm & hardaware Set 1

2 Conical inlet ring with casting segments & hardware Set 1

3 Casting segments & hardware for brick retaining shell Set 1

4 Bearing bush for support roller No 1

5 Set of seals for thrust roller Set 2

6 Guide rail for thrust roller No 2

7 Pneumatic cylinder for inlet seal No 1

8 Kiln inlet wear ring segments with hardware Set 1

9 Kiln inlet seal packing rope Set 2

10 Pnuematic cylinder No 2

11 Seal kit for pnuematic cylinder Set 6

12 Kiln outlet set of inner lamella seal Set 1

13 Kiln outlet set of graphite blocks for seal Set 1

14 Oil scoops for support roller Set 1

15 Set of direction control valve for thrust roller hydraulic system Set 1

16 Filters for thrust roller hydraulic system (all sizes) No / each 3

17 Solenoid valve for thrust roller hydraulic system No 1

18 Pressure release valve for thrust roller hydraulic system No 2

19 Set of hose pipes for thrust roller hyd. System Set 2

20 Girth gear lubricant spray nozzle - complete No 5

21 Pump for girth gear lubricantion No 1

C Burner

1 Air / central nozzle assembly No 1

2 Expansion joints (all sizes) No / each 1

3 Hoses (all sizes) Set 2

D Hoisting damper

1 Roller chain length / screw with nut No 1

Annex 11 List of Spare Parts for 2 Year Operation 3/16 Contract

JSW CEMENT FZE

Annex 11 List of Spare parts for 2 Year Operation

Sl.No Description UOM Quantity

2 Hose for sealing fan No 1

3 Position indicator No 1

E Cooler (IKN) - 15% each spares of total quantity

1 Great Plates for KIDS No 4

2 Coanda wing ‐ box No 2

3 Coanda wing ‐ box, heat resistant No 1

4 First blade for grate plate No 20

5 Central blade for grate plate No 80

6 Final blade for grate plate No 15

7 Final blade for grate plate of movable rows No 5

8 Sliding block for grate plate No 12

9 Ridge for grate plate No 12

10 Sealing plate for grate plate No 12

11 Guillotine for grate plate No 12

12 Socket head cap screw M12x30 for grate plate No 50

13 Hexagon nut M12 for grate plate No 50

14 Hexagon screw M20for grate plate No 25

15 Disk spring No 12

16 Lock washer No 12

17 Socket head cap screw M12x40 No 2

18 Lock washer No 10

19 Feather key No 2

20 Wear spacer fixed, right side ‐ short No 1

21 Wear spacer fixed, left side ‐ short No 1

22 Wear spacer fixed, right side ‐ long No 1

23 Wear spacer fixed, left side ‐ long No 1

24 Wear spacer movable ‐ right and left side No 2

25 Wear board for fixed row No 2

26 Wear board for movable row No 2

27 Set of screw fittings for wear boards No 10

28 Clamping plate for outer boards No 8

29 Set of screw fittings for clamping plates No 16

30 Grate spacer, movable No 2

31 Distance plate No 10

32 Dust protector for pendulum stack No 1

33 Glass pane ‐ inspection port under grate No 1

34 Pane for inspection port upper grate housing No 1

35 1 m conveyor chain for TDE Set 3

36 Chain joint for TDE No 4

37 Control COANDA nozzles with 2 thermocouples No 1

38 Control blade with 2 thermocouples No 1

39 Halogen lamp No 1

40 Limit switch for TDE No 1

Proximity switch for pump valve, maintenance entries, TDE speed, crusher speed and chain

41 1

tension No

42 Encoder for DLD No 1

43 Cooler water spreay nozzle Set 2

44 Resistance thermometer ‐ bearing, for roller crusher No 1

F Hydraulic System

1 Seal kit for Hydraulic cylinder Set 4

Annex 11 List of Spare Parts for 2 Year Operation 4/16 Contract

JSW CEMENT FZE

Annex 11 List of Spare parts for 2 Year Operation

Sl.No Description UOM Quantity

2 Hydraulic pump No 1

3 Coupling for hydraulic pump No 1

4 Elements for Coupling of Hydraulic pump Set 1

5 Water strainer No 4

6 Breather complete No 1

7 Clogging Indicator No 1

8 Accumulator No 1

9 Blader for accumulator No 1

10 Accumulator seal kit Set 2

11 Heat exchanger No 1

12 Level Switch No 1

13 Directional Valve (All models) No / Each 1

14 Check Valve (All sizes) No / Each 1

15 Resistance Thermometer No 1

16 Ball valve No / Each 1

17 Inductive Proximity Switch No 1

18 Contamination Sensor No 1

19 Aqua Sensor No 1

20 Choke Valve No 3

21 Pressure Gauge No / Each 2

22 Analogue Amplifier No 1

23 Flexible Pipe Connection No / Each 2

24 Flow rate Transducer No 1

III Vertical Roller Mill (Coal Mill / Raw Mill)

A Grinding table

1 fastening bolts for table liners (all sizes) Set / Each 1

2 Spherical washer Set 1

3 Conical seat Set 1

B Grinding Roller:

1 0-Ring Kit (all sizes) Set / Each 3

2 Seal Kit (All sizes) Set / Each 3

3 Sealing air cover No 1

4 seal air sealing rings for grinding roller Set 1

5 Fastening bolts for Roller liners (all sizes) Set / Each 1

6 Set of Clamps for segments Set 1

C Roller Assemblies

1 Complete Seal Kit for roller assembly Set 3

D Tensioning System:

1 Rinq for pull rod (Both sizes) No/ Each 1

2 Rod screw for joint head No 10

3 Rod screw for hydraulic cylinder No 10

4 Sealing air ring No 1

5 Joint head No 3

E Torque Rod

F Hydraulic Cylinder

1 Seal kit for hydraulic cylinder Set 3

2 Accumulator No 1

3 Bladder for accuulator No 1

4 Hydraulic hoses (All sizes) Set 1

G Hydrauiic Arrangement

Annex 11 List of Spare Parts for 2 Year Operation 5/16 Contract

JSW CEMENT FZE

Annex 11 List of Spare parts for 2 Year Operation

Sl.No Description UOM Quantity

1 Hiqh pressure banjo elbow No 1

2 Test point connector No 1

3 Needle valve No 1

4 Pressure gauge No 3

H Hydraulic Pump Station

1 Coupling with elements for all pumps Set 1

2 Oil Filter element (All sizes) No/ Each 5

3 Water strainer (All sizes) No/ Each 2

4 Oil diffuser No 2

5 Pressure gauge (All sizes) Set 1

6 Catridge Valve Insert (All models) No/ Each 2

7 Cover for valve insert No 1

8 Valve cover No 1

9 Insert kit Set 2

10 Pressure measurement No 1

11 Needle valve No 1

12 Pressure gauge connector No 2

13 Solenoid water valve No 1

14 Solenoid coil for DC valve No 1

15 Heat exchanger (All models) No/ Each 1

16 Heater No 1

17 D.C. valve (Pilot valve) No 2

I Roller Lubrication Pump unit

1 Water strainer No 1

2 Water line filter assembly No 1

3 Solenoid water valve No 1

4 Coil No 4

5 Air filter element No 3

6 Oil line filter assembly No 1

7 Feed pump No 1

8 Coupling with elements for all pumps Set 1

9 Proximity Sensor (Inductive) No 2

10 Seal kit (All sizes) Set / Each 1

11 Pressure gauge (All sizes) No/ Each 1

12 Pressure relief valve No 1

13 O ring set Set 2

14 Temperature sensor (All types) No/ Each 1

15 Vaccume gauge No 1

16 Flow meter No 1

17 Heater No 1

18 Level switch No 1

19 Magnetic cantamination switch No 1

20 Hose assembly (All sizes) No/ Each 1

21 Heat exchanger (All models) No/ Each 1

22 Vaccume transmittor No 1

J Seal Air System

1 Seal air pipe with articulation bearing for roller Set 1

2 Seal air bend with flange for roller No 1

3 Pressure transmitter No 1

4 Filterinq medium No 1

Annex 11 List of Spare Parts for 2 Year Operation 6/16 Contract

JSW CEMENT FZE

Annex 11 List of Spare parts for 2 Year Operation

Sl.No Description UOM Quantity

K Dynamic Seperator

1 Coupling pads for input shaft Set 1

2 Sealings kit (shaft sealing rings and O-rings) Set 1

3 Static vanes for the seperator Set 1

4 Parellel key No 1

5 Lip Seal No 1

6 RTD & it's mounting arrangement Set 2

L Mill Gear Box

1 Thrust Bearing pad Set 1

2 Oil Filter elements (All types) No/ Each 4

3 Oil line filter assembly No 1

4 Water strainer No 4

5 Water line filter assembly No 1

6 Pressure monitor No 1

7 Vibration sensor No 1

8 Seal kit for Input pinion Set 1

9 Resistance thermometer with separated transmitter No 1

10 Elastic Coupling No 1

11 Rubber elements for Coupling Set 1

12 Set of seals Gear box oil supply unit NIo 2

13 Strainer Gear box oil supply unit No 1

14 Seals for Strainer Gear box oil supply unit No 2

15 Coupling with elements for pumps Set 1

16 Pressure limiting valve Gear box oil supply unit. No 1

17 Heat exchanger No 1

IV Luffing Stacker for Limestone

1 Carrying Idler Rolls No 15

2 Return Idler Rolls No 10

3 Impact idler Rolls No 5

4 Flexible coupling seal kit & elements for Boom Conveyor & Travel Drive Set 1

5 Thruster brake & drum assembly No 1

6 Brake Shoe Liner for Travel Drive Pair 2

7 Belt Scrapers - Primary & Secondary Set 1

8 Pull cord Switch No 5

9 Belt Sway Switch No 5

10 Hydraulic Cylinder Seal Kit Set 2

11 Strainer No 2

12 Filter element No 4

13 Seal kit for Gear pump Set 2

V Bridge Reclaimer for Limestone

1 Input Pinion Shaft for Travel Drive No 1

2 Hydraulic Cylinder Seal Kit Set 2

3 Impact idler Rolls No 10

4 Thruster brake & drum assembly No 1

5 Brake Shoe Liner for Travel drive Pair 1

6 Scraper Chain Mtr 20

7 Scraper Blades N0 25

8 Spring No 2

9 Fluid coupling for Scrapper chain drive No 1

10 Fusible Plug & seal kit for Fluid Coupling Set 2

Annex 11 List of Spare Parts for 2 Year Operation 7/16 Contract

JSW CEMENT FZE

Annex 11 List of Spare parts for 2 Year Operation

Sl.No Description UOM Quantity

11 Snap Action Switch No 1

12 Chain Snap Proximity Sensor No 1

VI Luffing Stacker for Coal & Additive stacker

1 Carrying Idler Rolls No 25

2 Return Idler Rolls No 20

3 Impact idler Rolls No 10

4 Flexible coupling seal kit & elements for Boom Conveyor & Travel Drive Set 2

5 Brake Shoe Liner for Travel Drive Pair 2

6 Belt Scrapers - Primary & Secondary Set 2

7 Pull cord Switch No 5

8 Belt Sway Switch No 5

9 Hydraulic Cylinder Seal Kit Set 4

10 Strainer No 4

11 Filter element No 4

12 Seal kit for Gear pump Set 4

VII Side Scrapper Reclaimer for Coal

1 Scraper chain Mtr 10

2 Scrapper bucket / blades No 10

3 Spring No 2

4 Coarse strainer for lubricant filter No 2

5 Fine strainer for lubricant filter No 2

6 Douty seal for lubricant filter No 2

7 Fluid coupling for Scrapper chain drive No 1

8 Fluid coupling seal kit Set 2

VIII Side Scrapper Reclaimer Correctives

1 Scraper chain Mtr 10

2 Scrapper bucket/blades Set 10

3 Spring No 2

4 Coarse strainer for lubricant filter No 2

5 Fine strainer for lubricant filter No 2

6 Douty seal for lubricant filter No 2

7 Fluid coupling No 1

8 Fluid coupling seal kit Set 2

IX Crusher

1 Teeth Pcs 8

2 Set of V belts Set 2

X Coal Mill Bag house

1 Filter bags for Complete bag house Set 1

2 Cages with ventury No 40

3 Pulse valve No 10

4 Air header No 1

5 DP Transmittor No 1

6 Hopper level switch No 1

7 Rotary air lock seal plates Set 2

8 Air chamber door complete seal cord Set 1

9 Explosion vent sheet (All sizes) No 1

XI Raw Mill Bag house

1 Filter bags Set 500

2 Cages with ventury No 50

Annex 11 List of Spare Parts for 2 Year Operation 8/16 Contract

JSW CEMENT FZE

Annex 11 List of Spare parts for 2 Year Operation

Sl.No Description UOM Quantity

3 Pulse valve No 30

4 Air header No 4

5 DP Transmittor No 1

6 Hopper level switch No 2

7 Rotary air lock seal plates Set 4

8 Air chamber door complete seal cord Set 1

XII Cooler Mill Bag house

1 Filter bags Set 300

2 Cages with ventury No 30

3 Pulse valve No 20

4 Air header No 2

5 DP Transmittor No 1

6 Hopper level switch No 2

7 Rotary air lock seal plates Set 4

8 Air chamber door complete seal cord Set 1

XIII Noisance Bag filter

1 Filter bags No 500

2 Cages with ventury No 200

3 Pulse valve No 40

4 Air header No 2

5 Hopper level switch No 2

XIV Bucket Elevators- Kiln feed

1 Fluid couplings for Bucket elevator Set 1

2 Seal Kit & Fusible plug for fluid coupling Set 4

3 Friction lining & hardware for Bucket elevator Head drum Set 1

4 Buckets for Bucket elevator No 45

5 Profiled rubber S No 45

6 Complete Tension bearing block with bush & bearing Set 2

XV Bucket Elevators- Silo feed

1 Fluid couplings for Bucket elevator Set 1

2 Seal Kit & Fusible plug for fluid coupling Set 4

3 Friction lining & hardware for Bucket elevator Head drum Set 1

4 Buckets for Bucket elevator No 45

5 Profiled rubber S No 45

6 Complete Tension bearing block with bush & bearing Set 2

XVI Bucket Elevators- Raw mill recirculation (Chain)

1 Fluid couplings for Bucket elevator Set 1

2 Seal Kit & Fusible plug for fluid coupling Set 4

3 Sprocket segments for Bucket elevator Head drum Set 1

4 Sprocket segments for Bucket elevator Tail drum Set 1

5 Buckets for Bucket elevator No 45

6 Chain for bucket elevator Mtr 15% of total quantity

7 Complete Tension bearing block with bush & bearing Set 1

XVII Chain conveyors- Raw mill, Cooler bag house & Heat exchanger

1 Head sprocket No 1

2 Tail sprocket No 1

3 Chain Mtr 15% of total quantity

Annex 11 List of Spare Parts for 2 Year Operation 9/16 Contract

JSW CEMENT FZE

Annex 11 List of Spare parts for 2 Year Operation

Sl.No Description UOM Quantity

XVIII Deep Pan Conveyor for each Capacity

1 Conveyor section without roller brackets No 15% of total quantity

2 Conveyor section with roller brackets No 15% of total quantity

3 Roller Complete with stub axle and two bearings No 15% of total quantity

4 Chain left with fasteners Mtr 15% of total quantity

5 Chain right with fasteners Mtr 15% of total quantity

6 Loose tension bearing Set 2

7 Fixed tension bearing Set 2

8 Fluid coupling for the DPC No 1

9 Seal Kit for fluid coupling Set 4

10 Elements for Couplling Set 1

XIX Utility - Pump House

1 Coupling for the pumps (Each size) No/Each 1

2 Elements for coupling (Each size) Set / each 1

3 Valve (Each size) No/Each 2

4 Pump for RO System No 1

5 Coupling with elements for RO Pump Set/ each 1

6 Filters for RO system (Each type) No/Each 4

7 Solenoid valves (Each type) No/Each 1

8 Chemical doosing pump No 1

9 Submersible pumps (Each capacity) No/Each 2

XX Utility - Compressors

1 Air end No 1

2 Oil Cooler (Heat exchanger) No 1

3 After cooler (Heat exchanger) No 1

4 Hydraulic hoses (Each size) No / Each 2

5 MPCV No 1

6 Element thermostatic No 1

7 5SV Kit No 1

8 Blowdown valve No 1

9 Blowdown valve repair Kit No 3

10 Inlet valve No 1

11 Inlet valve repair kit No 3

12 Actuator thermal value No 1

13 Valve solenoid No 1

14 Spring gas No 1

15 Auto drain valves No 1

16 Pressure sensors No 1

17 Belt Set 1

18 Thermo stat valve No 1

19 Pnuematic cyclinder No 1

XXI Air Dryer for compressor

1 Liquid Seperator, No 1

2 Condensor, No 1

3 Filter dryer No 1

4 Pressure reulator Valve for water, No 1

5 Freon filling Valve, No 1

6 Complete Solenoid drain valve, No 1

Annex 11 List of Spare Parts for 2 Year Operation 10/16 Contract

JSW CEMENT FZE

Annex 11 List of Spare parts for 2 Year Operation

Sl.No Description UOM Quantity

7 Bypass hot gas valver, No 1

8 Tempreture sensors, No 1

9 Refrigerent Compressor No 1

10 Heat exchanger No 1

XXII Blowers

1 Set of seals for blowers Set / Each 1

2 Set of lobes for blowers Set / Each 1

3 Set of V- belts Set / Each 1

4 Set of drive & driven pulley with taper block Set / Each 1

5 Set of bearings for blowers Set / Each 1

XXIII Dust suppression system

1 Set of Coupling bush No 1

2 Gland packing No 1

3 Flow activation units No 5

4 Pressure regulating units No 5

5 Fog nozzles No 10

6 Spary bar assembly No 5

7 Pressure gauges No 2

8 Sensors No 2

9 Globe valve No 1

10 Non-return valve No 1

11 Filter No 4

12 Solenoid Coil No 2

XXIV EOT Crane

1 Brake Shoe with Liners (All capacity) Set /Each 1

2 Brake Springs (All capacity) Set /Each 1

3 Thruster (All capacity) Set /Each 1

4 Brake Coil (All capacity) Set /Each 1

5 Set of Fuse Links (All capacity) Set /Each 1

6 Set of Limit Switches (All capacity) Set /Each 1

7 Contractor Coils (All capacity) Set /Each 1

8 Control Transformer (All capacity) Set /Each 1

9 Over Load Relays (All capacity) Set /Each 1

XXV BRU / Surface feeder (All capacity)

1 Roller Complete No

2 Tail Toothed rim complete Set 1

3 Flange bearing complete Set 1

4 Loose tension bearing Set 1

5 Fixed tension bearing Set 1

6 Fluid coupling No 1

7 Seal Kit for fluid coupling Set 1

8 Elements for Couplling Set 1

XXVI Cooler Heat Exchanger

1 Set of wear sleeves No 50

XXVII Fine coal dosing system

1 Fine coal bin aeration pads No 10

Annex 11 List of Spare Parts for 2 Year Operation 11/16 Contract

JSW CEMENT FZE

Annex 11 List of Spare parts for 2 Year Operation

Sl.No Description UOM Quantity

2 Solenoid valve for aeration system No 5

3 Ventury for feeding shoe Set 1

XXVIII Mechanical Common Spares

1 Fabric for expansion joints complete length - All types / sizes No/ Each 1

2 Air slide fabric (All sizes) Mtr / Each 100

3 Air blower suction primary & secondary filters Set 20

4 Return Idlers (All sizes) No/ Each 50

5 Impact carring idlers ( All sizes) No/ Each 50

6 Endless belt for weigh feeder (All sizes) Set /Each 1

7 Belt conveyor drums/ pulleys (All sizes) Set 1

8 Set of Primary scrapper for all size belt conveyor Set 4

9 Complete clinker bulk loading spout No 1

10 Pin & Rubber bush/ Element for Couplings (All types) Set /Each 1

XXIX E & I Common spares

1 Motor of each capacity & frame up to 132 KW No 1

2 Load cells of different capacity No 1

XXX Control System

1 Colour Monitor No 1

2 Digital Input Modules With Connectors No 2

3 Digital Output Modules With connectors No 2

4 Analog input modules With Connectors No 2

5 Analog output modules With Connectors No 2

6 RTD input modules No 2

7 I/O interface modules No 2

8 Power supply for CPU Rack No 1

9 Power supply 230VAC to 24VDC, 5 Amps No 2

10 Power supply 230VAC to 24VDC, 10 Amps No 2

11 Processor of workstation PC No 1

12 Key boards No 1

13 Colour printer No 1

14 Ethernet switch No 1

15 Pressure transmitter (Each typel) No 2

16 Temperature transmitter (Each typel) No 2

17 Level switch probe (Each typel) No 1

18 RTDs (Each size) Lot 2

19 Thermocouples (Each typel) No 2

20 Resistance thermometer No 0

21 Relay Module No 1

XXXI Electrical

A 11kV MV SWITCHGEAR

1 Breaker

2 Trip coils suitable for each type of breaker No 2

3 Closing coils suitable for each type of breaker No 2

4 Spring charging motor for each type of breaker No 2

5 Undervoltage Coils for each type of breaker No 2

6 Breaker auxiliary contacts No 6

7 Breaker Tulip contacts (each type) No 2

Annex 11 List of Spare Parts for 2 Year Operation 12/16 Contract

JSW CEMENT FZE

Annex 11 List of Spare parts for 2 Year Operation

Sl.No Description UOM Quantity

8 Position signalling Switch No 2

9 VAJH 13 High Speed Relay No 3

10 64 Pin Socket No 2

B Battery & Battery Charger

1 Thyristor bridges of each rating No 1

2 Electronic cards of each type & rating No 2

3 Battery cells of each AH capacity No 4

4 MCBs & fuses of each type & rating No 4

C Motors

11kV MV Slip ring Motors

1 Oute Rubber seals (drive end & non-drive end) for each type & frame of motor No/ Each 1

2 Drive end bearing brush for each type & frame of motor No/ Each 1

3 Non-Drive end bearing brush for each type & frame of motor No/ Each 1

4 Sealing ring Drive end for each type & frame of motor No/ Each 1

5 Sealing ring Non-Drive end for each type & frame of motor No/ Each 1

6 Oil ring Drive End for each type & frame of motor No/ Each 1

7 Bearing RTDs for each type & frame of motor No/ Each 1

8 Space heater for each type & frame of motor No/ Each 1

9 Carbon brush Holders & brush for each type & frame of motor No/ Each 1

D Liquid Rotor Starters

1 Fixed Electrodes for each type No/ Each 1

2 Moving Electrodes for each type No/ Each 1

3 Support Insulators for each type No/ Each 1

4 Chain, reduction gear, operating shaft set for each type No/ Each 1

5 Phase barrier sheet for each type No/ Each 1

6 Declutching arrangement for each type No/ Each 1

7 Hand wheel & motor pulley for each type No/ Each 1

E 11kV MV Capacitor Banks

1 Capacitor of each rating No/ Each 1

2 Insulators No 1

3 Reactors of each rating No/ Each 1

4 Discharge resistors(if external) No 1

5 220 VAC coil No 1

6 Auxiliary contact No 1

7 4 Power Contactors No 1

F Transformers

1 HV bushing of each type No/ Each 2

2 LV bushing of each type No/ Each 2

3 Neutral bushing of each type No/ Each 2

4 Neutral Current Transformer No 2

5 Temperature scanner No 2

6 Loose Silica gel Kg 2

G LV Switchboards - Power Control Centre, Motor Control Centre & Auxiliary services

distribution boards

Breaker

1 Trip coils suitable for each type of breaker No/ Each 2

2 Closing coils suitable for each type of breaker No/ Each 2

3 Spring charging motor for each type of breaker No/ Each 2

4 Undervoltage Coils for each type of breaker No/ Each 2

5 Breaker auxiliary contacts (Each typel) No/ Each 2

Annex 11 List of Spare Parts for 2 Year Operation 13/16 Contract

JSW CEMENT FZE

Annex 11 List of Spare parts for 2 Year Operation

Sl.No Description UOM Quantity

6 Breaker contacts (each type) No/ Each 2

7 Mocroprocessor based release each type No/ Each 2

H Relays

1 Numerical relay No 2

2 Auxiliary multiplication relays No 2

3 Master trip relay No 2

4 Auxiliary protection relays No 2

5 Timer relays each type(as applicable) No 3

I Instruments & Meters

1 Ammeter of each type No/ Each 2

2 Voltameter of each type No/ Each 2

3 Multi function Meter No 2

4 Core balance current transformer of each type & size No/ Each 3

5 Current Transformer of each type No/ Each 2

6 Potential Transformer of each type No/ Each 2

7 Indicating lamps of each type No/ Each 6

J Miscillaneous

1 MCCBs(each rating) No/ Each 2

2 MPCBs(each rating) No/ Each 2

3 Fuses(each type) No/ Each 6

4 Surge Arrestor No 4

5 MCBs of each type No/ Each 6

6 Breaker control switch No 4

7 Selector switches No 4

8 Push buttons of each type No/ Each 4

9 Electronic hooter No 2

10 Busbar support insulators No 6

11 Vent flaps(if any) No 2

K LPBS

1 DOL No 4

2 RDOL No 3

L LV DRIVE

1 Control board No 1

2 Drive control unit No 1

3 Choke No 1

4 Thristor/module unit No 1

5 Power resistor No 1

6 Capacitor No 1

7 IGBT module No 1

8 IGBT module+ drive (each rating) No/ Each 1

9 Current transducer (each rating) No/ Each 1

10 Power supply board No 1

M MV DRIVE

1 Control boards (each type) No/ Each 1

2 Control panel interface No 1

3 Profibus adaptor No 1

4 RTD converter No 1

5 Power supply unit No 1

6 IGCT module (each rating) No/ Each 1

Annex 11 List of Spare Parts for 2 Year Operation 14/16 Contract

JSW CEMENT FZE

Annex 11 List of Spare parts for 2 Year Operation

Sl.No Description UOM Quantity

N Lighting System

Distribution Boards

1 Rotary drive kit No 10

2 Shunt Coil release No 15

3 Contactor (Each Type) No/ Each 5

4 MCB (Each Type) No/ Each 5

5 Contactor relay 2 no+2 nc (Each Type) No/ Each 10

6 Digital time switch No 10

7 Mf timer No 10

8 Indication lamp(each colour) No 10

9 Earth fault relay and time delay No 10

10 Different rating CT (Each type) No/ Each 1

11 Control TB (Each Type and Different Rating) No/ Each 50

O Electrical Spares LT Switchgear

1 Current measuring module for Intelligent controller (Simocode / UMC 100.3 or equivalent) for

differenet current ratings No/ Each 2

2 Current & Voltage measuring module for Intelligent controller (Simocode / UMC 100.3 or

equivalent) for differenet current ratings No/ Each 1

3 Digital Input/output Monostable Expansion module 4 binary inputs & 2 relay outputs,i/p

vol.110-240VAC/DC No 1

4 Indication Lamps No 30

5 Push Buttons No 15

6 Ammeter No 10

7 Voltmeter No 2

8 Multi Function Meter No 2

9 Auxiliary Contactor No 6

P Variable frequency Drive

1 Cell - 315A No 1

2 Cell - 260A No 1

3 Display Board No 1

4 Control Card - CU 320 No 5

5 Operator Panel No 1

Q RADIATION PYROMETER Lot 1

1 Air flow switch No 1

2 Lens shutter No 1

3 Isolation valve No 1

4 Filter regulator and gauge No 1

5 Power supply No 1

R GAS ANALYSER Lot 1

1 Probe filter No 44

2 Probe gasket No 4

3 Water pump kit No 1

4 Inline filter No 4

5 Condensate monitor cum diaphgram filter No 4

6 Water pump repair kit No 1

7 Solenoid valve No 4

S DUST MONITORING SYSTEM Lot 1

1 Filter cartridge No 2

2 gasket for shutter No 2

3 Power Supply unit No 1

Annex 11 List of Spare Parts for 2 Year Operation 15/16 Contract

JSW CEMENT FZE

Annex 11 List of Spare parts for 2 Year Operation

Sl.No Description UOM Quantity

T HIGH TEMPERATURE CCTV Lot 1

1 Air filter elements No 1

2 Fuses No 1

3 Replacement seal kit for cylinder No 1

4 Retraction limit switch. No 2

U UN-INTERRUPTED POWER SUPPLY Lot 1

1 Thyristor for charger No 1

2 Rectifier input fuse No 1

3 DC fuse No 1

4 Bypass fuse No 1

5 IGBT No 1

V FIRE ALARM SYSTEM

1 Loop card No 4

2 Power supply module No 2

3 Heat cum smoke detector No 5

4 Output module / Control module No 5

W GENERAL PURPOSE CCTV

1 Power supply for module camera No 2

2 Media convertor No 4

3 LIU No 2

4 Pigtail, patchcord & connectors No 2

X PA SYSTEM

1 Telephone handset No 2

2 Loudspeaker No 2

3 PTT switch for operator console No 1

4 Power supply for Main CPU unit No 1

Y EPBAX SYSTEM

1 Analog handset No 2

2 Telephone Field JB - 20 Terminals No 1

3 Krone Tool No 1

Z FIELD INSTRUMENTS

1 Hooters No 2

2 Pressure transmitter No 1

3 Temperature transmitter No 1

4 Radar type level transmitter (for 30 mtrs ) No 1

5 Level Switch - capacitance type No 0

6 Thermocouple No 2

AA Instruments Intelligent Motor Control relays

1 Intelligent Motor Control relay No 1

2 DI/DO Expansion modules No 1

3 Connecting Flat Ribbon Cables 0.3 Meters No 1

4 Connecting Flat Ribbon Cables 0.5Meters No 1

5 MCCB operating handle and trip coli No 1

Annex 11 List of Spare Parts for 2 Year Operation 16/16 Contract

Вам также может понравиться

- Example Recommended Spare Parts - DRAFTДокумент5 страницExample Recommended Spare Parts - DRAFTvoОценок пока нет

- Welcome: A Seminar Presention ONДокумент24 страницыWelcome: A Seminar Presention ONsushil kumarОценок пока нет

- NGДокумент10 страницNGbillОценок пока нет

- 650KW DOOSAN Diesel Generator PDFДокумент4 страницы650KW DOOSAN Diesel Generator PDFAhmad RifaiОценок пока нет

- SAM - G900 Electrical Part ListДокумент12 страницSAM - G900 Electrical Part ListDaniel CekulОценок пока нет

- Caterpillar XQ1000 Containerized Diesel Generator SetДокумент10 страницCaterpillar XQ1000 Containerized Diesel Generator SetMacAllister MachineryОценок пока нет

- Class - 8 Chapter - 3 Synthetic Fibres and PlasticsДокумент6 страницClass - 8 Chapter - 3 Synthetic Fibres and Plastics7A04Aditya MayankОценок пока нет

- Commissioning Electrical EquipmentДокумент3 страницыCommissioning Electrical EquipmentThomas RussellОценок пока нет

- Worksheet Rational NumbersДокумент2 страницыWorksheet Rational NumbersJoe KoОценок пока нет

- Conversion of CNG, Liter To KGДокумент1 страницаConversion of CNG, Liter To KGเสกสรรค์ จันทร์สุขปลูกОценок пока нет

- Livening Up NotesДокумент1 страницаLivening Up NotesAceel FitchОценок пока нет

- Operation and Maintenance Instructions Manual: Ju/Jw Model Engines FOR Fire Pump ApplicationsДокумент38 страницOperation and Maintenance Instructions Manual: Ju/Jw Model Engines FOR Fire Pump ApplicationsangelvhОценок пока нет

- Chloride FP 40r Ds en GL 0616 Rev6Документ2 страницыChloride FP 40r Ds en GL 0616 Rev6Tanveer Ahmed100% (1)

- Tender Document 1491902624Документ20 страницTender Document 1491902624Anshuman AgrawalОценок пока нет

- SF6 Circuit Breaker Nameplate Details ExplanationДокумент7 страницSF6 Circuit Breaker Nameplate Details Explanationlooyd alforqueОценок пока нет

- Process Design Basics for Station Facility Electrical System DesignДокумент4 страницыProcess Design Basics for Station Facility Electrical System DesignHenryOdohОценок пока нет

- EIT Course Diesel Power Plants CDG BrochureДокумент3 страницыEIT Course Diesel Power Plants CDG BrochureKatamba RogersОценок пока нет

- DC Charger (BTL 10)Документ16 страницDC Charger (BTL 10)chdi100% (1)

- Maint - Check List - Oil Filled TransforsДокумент2 страницыMaint - Check List - Oil Filled TransforsramОценок пока нет

- DCI JK5 Fire Protection Site Acceptance TestДокумент14 страницDCI JK5 Fire Protection Site Acceptance TestAwaludin Angga WОценок пока нет

- Inspection Test Plan (ITP) Procedure-DigabungkanДокумент9 страницInspection Test Plan (ITP) Procedure-Digabungkanpankrasius herbudiОценок пока нет

- Electrical Equipment in Hazardous AreasДокумент8 страницElectrical Equipment in Hazardous AreasMehulkumar PatelОценок пока нет

- ELE - Checklist For Sample DBДокумент2 страницыELE - Checklist For Sample DBibrahim680% (1)

- Lube Oil Pump 1: Commissioning Check List MДокумент4 страницыLube Oil Pump 1: Commissioning Check List Mamin100% (1)

- GIS 132 SubstationДокумент63 страницыGIS 132 SubstationNguyenBaCuongHungОценок пока нет

- متابعة صيانة التكييف المركزيДокумент52 страницыمتابعة صيانة التكييف المركزيRomou Alsaaq100% (1)

- Testing and Commissioning Procedure For MotorsДокумент7 страницTesting and Commissioning Procedure For MotorsDeepak Jha KashyapОценок пока нет

- Paint Certificate 80A45-1Документ1 страницаPaint Certificate 80A45-1Shyam_Nair_9667Оценок пока нет

- Mechanical Completion Certificate for Export PumpsДокумент1 страницаMechanical Completion Certificate for Export PumpsDeonОценок пока нет

- PLC Vs ControllerДокумент4 страницыPLC Vs ControllerththeeОценок пока нет

- LT Switchgear Technical SpecificationДокумент28 страницLT Switchgear Technical SpecificationUday Sankar YadavОценок пока нет

- Fin fan cooler cleaning scopeДокумент2 страницыFin fan cooler cleaning scopeShams TabrezОценок пока нет

- Testing and Commissioning of MetalClad SwitchgearДокумент4 страницыTesting and Commissioning of MetalClad Switchgearvijaydev75100% (1)

- Wadi El Neel General Hospital: Extension of StageДокумент8 страницWadi El Neel General Hospital: Extension of StagevirtechОценок пока нет

- Title: Job Description: Ups Technician 8-Skilled ElectricalДокумент4 страницыTitle: Job Description: Ups Technician 8-Skilled ElectricalSundar ThangapandianОценок пока нет

- Manual Instruciton NGRДокумент4 страницыManual Instruciton NGRAhmad Ikhsan KurniantoОценок пока нет

- Diesel GeneratorДокумент36 страницDiesel Generatorwintermae100% (1)

- Diesel Generator Inspection ChecklistДокумент1 страницаDiesel Generator Inspection ChecklistDedy Rifky SetyawanОценок пока нет

- 14 DG Set InspectionДокумент1 страница14 DG Set Inspectionabb hseОценок пока нет

- 26198-00 - REV1 - SLD, Schematics, Termination Diagrams - P8.31, 10kVA AC UPS - HAPCO JSC (AEG Ref 120004070)Документ9 страниц26198-00 - REV1 - SLD, Schematics, Termination Diagrams - P8.31, 10kVA AC UPS - HAPCO JSC (AEG Ref 120004070)khanh100% (1)

- Gu3311 Operation ManualДокумент94 страницыGu3311 Operation ManualShahzad Ali100% (1)

- Essential maintenance of power equipmentДокумент5 страницEssential maintenance of power equipmentSantoshkumar Gupta100% (1)

- Diesel Generator (DG) Inspection Checklist: AfconsДокумент1 страницаDiesel Generator (DG) Inspection Checklist: Afconsprabu lingamОценок пока нет

- APMRG1 Series: Packaged Air ConditionersДокумент32 страницыAPMRG1 Series: Packaged Air Conditionerszaid jamaluОценок пока нет

- Preventive Maintenance of Diesel Generator Sets Daily:: Specimen Check-List ForДокумент2 страницыPreventive Maintenance of Diesel Generator Sets Daily:: Specimen Check-List ForAndrewОценок пока нет

- Himel ACB Catalogue HDW9Документ72 страницыHimel ACB Catalogue HDW9Ronald H SantosОценок пока нет

- UPS commissioning manual proceduresДокумент19 страницUPS commissioning manual proceduresAldo Rodriguez MaturanaОценок пока нет

- HV SWITCHGEAR CONSTRUCTION AND DRAWING INDEXДокумент28 страницHV SWITCHGEAR CONSTRUCTION AND DRAWING INDEXmentong100% (2)

- Maintenance of Transformers (A Detailed Checklist) - Electrical4UДокумент11 страницMaintenance of Transformers (A Detailed Checklist) - Electrical4Umadantiwari2000% (1)

- Lightening Protection - AssignmentДокумент11 страницLightening Protection - AssignmentNalaka SiyanthaОценок пока нет

- 559 and 1042 Series Operator Interface User GuideДокумент306 страниц559 and 1042 Series Operator Interface User GuideAlcides ZorrillaОценок пока нет

- 16280x Eaton MV Autovar PFC Capacitor Bank Specifications Oct112013Документ16 страниц16280x Eaton MV Autovar PFC Capacitor Bank Specifications Oct112013Ahmed Said GhonimyОценок пока нет

- SECTION 16440 Switchboards, Panelboards & Control Centers Rev 0Документ32 страницыSECTION 16440 Switchboards, Panelboards & Control Centers Rev 0Ahmed HashimОценок пока нет

- ED6002 User ManualДокумент7 страницED6002 User ManualdocrafiОценок пока нет

- Minco Temperature SensorsДокумент164 страницыMinco Temperature Sensorsvenkin845074100% (1)

- Cummins 60 KVAДокумент4 страницыCummins 60 KVAMasri NurdinОценок пока нет

- Essential Transformer Spare PartsДокумент2 страницыEssential Transformer Spare PartsSristi MitraОценок пока нет

- Mandatory spare parts for dredgersДокумент3 страницыMandatory spare parts for dredgersBangladesh ToxisОценок пока нет

- Binnacle Gauges Kit Fitting Instructions for VY & VZ Commodore 6 and 8 CylindersДокумент12 страницBinnacle Gauges Kit Fitting Instructions for VY & VZ Commodore 6 and 8 CylindersAlcyoneSpiralОценок пока нет

- rc40 Spare PartsДокумент32 страницыrc40 Spare Partsburak cikirkanОценок пока нет

- Nonmetal Ducts - Guide Specification - Updated 6-2019Документ17 страницNonmetal Ducts - Guide Specification - Updated 6-2019abdullah amanullahОценок пока нет

- Mohamed Anas.S: Job ObjectiveДокумент3 страницыMohamed Anas.S: Job Objectiveabdullah amanullahОценок пока нет

- Sabb-Gray Water WsfuДокумент22 страницыSabb-Gray Water Wsfuabdullah amanullahОценок пока нет

- New Indian Model School, Sharjah: Islamic Holidays' Assignment Primary SectionДокумент1 страницаNew Indian Model School, Sharjah: Islamic Holidays' Assignment Primary Sectionabdullah amanullahОценок пока нет

- English Summer Break - Holiday Assignment 2019 - 20Документ2 страницыEnglish Summer Break - Holiday Assignment 2019 - 20abdullah amanullahОценок пока нет

- Aurora Fire PumpДокумент8 страницAurora Fire Pumpabdullah amanullahОценок пока нет

- CR Architecture + Design Kroger J717 Indianapolis, IN CR# 516361 May 4, 2016Документ5 страницCR Architecture + Design Kroger J717 Indianapolis, IN CR# 516361 May 4, 2016abdullah amanullahОценок пока нет

- Science Summer Break - Holiday Assignment 2019 - 20Документ2 страницыScience Summer Break - Holiday Assignment 2019 - 20abdullah amanullahОценок пока нет

- 15730-DX Cooling Units Rev 01Документ10 страниц15730-DX Cooling Units Rev 01abdullah amanullahОценок пока нет

- Learn Hindi Letters and NumbersДокумент3 страницыLearn Hindi Letters and Numbersabdullah amanullahОценок пока нет

- Uae Social Studies Summer Break - Holiday Assignment 2019 - 20Документ2 страницыUae Social Studies Summer Break - Holiday Assignment 2019 - 20abdullah amanullahОценок пока нет

- Uae Social Studies Summer Break - Holiday Assignment 2019 - 20Документ2 страницыUae Social Studies Summer Break - Holiday Assignment 2019 - 20abdullah amanullahОценок пока нет

- Tamil (Second Language) Summer Break - Holiday Assignment 2019 - 20Документ2 страницыTamil (Second Language) Summer Break - Holiday Assignment 2019 - 20abdullah amanullahОценок пока нет

- New Indian Model School, Sharjah: Islamic Holidays' Assignment Primary SectionДокумент1 страницаNew Indian Model School, Sharjah: Islamic Holidays' Assignment Primary Sectionabdullah amanullahОценок пока нет

- PT2 Revision Worksheet EnglishДокумент3 страницыPT2 Revision Worksheet Englishabdullah amanullahОценок пока нет

- Kairos ScheduleДокумент1 страницаKairos Scheduleabdullah amanullahОценок пока нет

- New Indian Model School, SharjahДокумент2 страницыNew Indian Model School, Sharjahabdullah amanullahОценок пока нет

- Infrastructure Charges Notice CalculatorДокумент1 страницаInfrastructure Charges Notice Calculatorabdullah amanullahОценок пока нет

- Our Body is a Wonderful MachineДокумент2 страницыOur Body is a Wonderful Machineabdullah amanullahОценок пока нет

- Worksheet - WaterДокумент2 страницыWorksheet - Waterabdullah amanullah100% (2)

- The King's Condition worksheet for Grade 3Документ2 страницыThe King's Condition worksheet for Grade 3abdullah amanullahОценок пока нет

- Ga Layout For Stem GeneratorДокумент1 страницаGa Layout For Stem Generatorabdullah amanullahОценок пока нет

- 0.list of Drawing - Lower LevelДокумент1 страница0.list of Drawing - Lower Levelabdullah amanullahОценок пока нет

- Revision SSTДокумент2 страницыRevision SSTabdullah amanullahОценок пока нет

- Indian Social Studies Class 3 EnvironmentДокумент2 страницыIndian Social Studies Class 3 Environmentabdullah amanullahОценок пока нет

- Compressed UCDM EnglishДокумент176 страницCompressed UCDM EnglishAnonymous zmYUcSPОценок пока нет

- Acoustic Performance Goals for Doha Oasis Theme ParkДокумент43 страницыAcoustic Performance Goals for Doha Oasis Theme Parkabdullah amanullahОценок пока нет

- Qatar Fire Safety Guidelines for Residential ApartmentsДокумент122 страницыQatar Fire Safety Guidelines for Residential ApartmentsAbdul Jamal100% (1)

- Automatedmeterreadingtechnology PDFДокумент5 страницAutomatedmeterreadingtechnology PDFabdullah amanullahОценок пока нет

- Infrastructure Charges Notice CalculatorДокумент1 страницаInfrastructure Charges Notice Calculatorabdullah amanullahОценок пока нет

- TransformerДокумент25 страницTransformerJerald SagusayОценок пока нет

- Stacker ManualДокумент60 страницStacker ManualAkhtar QuddusОценок пока нет

- Piezoelectricity:: Principle Knock SensorsДокумент1 страницаPiezoelectricity:: Principle Knock Sensorsdassi99Оценок пока нет

- Eco Line 60/245 - 260 W: Monocrystalline Module FamilyДокумент2 страницыEco Line 60/245 - 260 W: Monocrystalline Module FamilyNunoMoraisОценок пока нет

- AVA5-50FX Product SpecificationsДокумент5 страницAVA5-50FX Product SpecificationsPhi FeiОценок пока нет

- SERVO CONTROLLED VOLTAGE STABILIZERДокумент4 страницыSERVO CONTROLLED VOLTAGE STABILIZERYOUTH FUTUREОценок пока нет

- FA87Документ5 страницFA87IFLYОценок пока нет

- IC A200 BrochureДокумент2 страницыIC A200 BrochureelsaaddyОценок пока нет

- Digital B&W Copier (D159-NA) Parts CatalogДокумент128 страницDigital B&W Copier (D159-NA) Parts CatalogJ Enrique BlancoОценок пока нет

- Touareg 2003-07 Engine RepairsДокумент317 страницTouareg 2003-07 Engine RepairsZayd Majoka75% (4)

- NoteДокумент264 страницыNoteBelayneh TadesseОценок пока нет

- m10-3 Oil Purifier Operation Manual 3aДокумент76 страницm10-3 Oil Purifier Operation Manual 3aDavid BogdanОценок пока нет

- Pines Shield Multifuncion PDFДокумент3 страницыPines Shield Multifuncion PDFGustavo Portilla MartinezОценок пока нет

- ScionLife Check Engine Light CodesДокумент10 страницScionLife Check Engine Light CodesKiddОценок пока нет

- 100kN Stand Alone - 2009 Until 31-12-2009Документ1 страница100kN Stand Alone - 2009 Until 31-12-2009Adakole ObekaОценок пока нет

- R-Car Starterkit Hardware Manual: R-Car Starter Kit Premier R-Car Starter Kit ProДокумент37 страницR-Car Starterkit Hardware Manual: R-Car Starter Kit Premier R-Car Starter Kit ProbengaltigerОценок пока нет

- Aircraft Battery Testing Handbook V0.20Документ36 страницAircraft Battery Testing Handbook V0.20Rizky NugrahaОценок пока нет

- Steca TR 0603 Specification enДокумент2 страницыSteca TR 0603 Specification enForrester de Beer0% (1)

- 2010 Peugeot 508 508 SW Brochure NL NovemberДокумент12 страниц2010 Peugeot 508 508 SW Brochure NL NovemberFelipe FragosoОценок пока нет

- 6000 - EN - 02 - ACBB - Indd 404 06-10-02 14.21.53Документ64 страницы6000 - EN - 02 - ACBB - Indd 404 06-10-02 14.21.53Raja NarenderОценок пока нет

- Price List: Fourstar Electronic Technology Co., Ltd. Deyang ChinaДокумент30 страницPrice List: Fourstar Electronic Technology Co., Ltd. Deyang ChinaSanjeev JangraОценок пока нет

- Philips Bipap A40 High End Bipap Transport Ventilator PDFДокумент2 страницыPhilips Bipap A40 High End Bipap Transport Ventilator PDFgrrcОценок пока нет

- 022 - 01 - 03 - Fuel GaugeДокумент2 страницы022 - 01 - 03 - Fuel GaugeJaucafoОценок пока нет

- Transformer Protection Relay GRE160 Brochure 12027-1 0Документ22 страницыTransformer Protection Relay GRE160 Brochure 12027-1 0tanujaayerОценок пока нет

- Digi-Tool - PB-210D Calibration Unit For MCB-200 Digilon - Microwave BarrierДокумент2 страницыDigi-Tool - PB-210D Calibration Unit For MCB-200 Digilon - Microwave BarrierMario Gabriel MoralliОценок пока нет

- First Summative Test in CSS 1Документ3 страницыFirst Summative Test in CSS 1Ricky Rom MonteОценок пока нет

- Ateliers Bigata parts available for various aircraftДокумент4 страницыAteliers Bigata parts available for various aircraftparid ridwanОценок пока нет

- Precision Pliers 490-Bi... : Heavy Duty Side CutterДокумент1 страницаPrecision Pliers 490-Bi... : Heavy Duty Side CutterAkmalОценок пока нет

- Posidrive® Mds 5000: Operation ManualДокумент132 страницыPosidrive® Mds 5000: Operation ManualHarold Palma SuarezОценок пока нет

- To-5 Relays Established Reliability Military DPDT: Series 412Документ9 страницTo-5 Relays Established Reliability Military DPDT: Series 412Afzal ImamОценок пока нет